Towards Industry 5.0: AAS/MLOps-Driven Model Maintenance for

Data-Centric Production

∗

Kiavash Fathi

1,2

, Marcin Sadurski

2

, Stefan Waskow

3

,

Tobias Kleinert

1

and Hans Wernher van de Venn

2

1

Chair of Information and Automation Systems for Process and Material Technology, RWTH Aachen University,

52064 Aachen, Germany

2

Institute of Mechatronic Systems, Zurich University of Applied Sciences, 8400 Winterthur, Switzerland

3

OEE Improvement team, ABB, 8200 Schaffhausen, Switzerland

Keywords:

Model and Data Life-Cycle, Machine Learning Operations (MLOps), Asset Administration Shell (AAS),

Human-in-the-Loop Design, Industry 5.0.

Abstract:

Despite the advancements brought by digitalization across industries, only a few state-of-the-art data-driven

methods successfully transition to production and remain viable. The sheer volume of physical assets in pro-

duction lines, combined with constantly evolving requirements, makes model deployment and maintenance

highly complex. This paper presents a production-ready architecture developed for data-driven digital assets

at ABB Schaffhausen AG. The solution integrates MLOps best practices orchestrated via MLRun with the

industry-standard metadata modeling system, Asset Administration Shell (AAS). We demonstrate how con-

trolled artifact generation from MLRun facilitates experiment tracking and knowledge sharing while AAS

ensures standardization and long-term maintenance. By combining MLOps and AAS, we effectively manage

the ever-growing artifacts of data-driven solutions. Additionally, we explore how controlled artifact genera-

tion enables role-based MLOps by restricting access to relevant information based on industrial roles. This

architecture supports a smooth transition to Industry 5.0.

1 INTRODUCTION

One of the main focuses of production lines compliant

with Industry 4.0 standards is flexibility in produc-

tion which is normally implemented and deployed

as modular automation. Due to the short lifespan

of products and manufacturing technologies, modu-

lar automation helps ensure that final products meet

constantly evolving customer requirements with min-

imal engineering effort. (Xia et al., 2023). Addition-

ally, it makes sure that the production line is capa-

ble of coping with unforeseen situations in a safe and

secure manner (Huang et al., 2021). This flexibility

and adaptability will not only ensure fully personal-

ized product for the market but also helps to achieve

a more sustainable production (Ghobakhloo, 2020;

Brettel et al., 2016).

*

This project is part of the research conducted at Com-

petence Centre for Automation and Digitalisation entitled

Pre-Prime (Pre-Process Refinement for Improved Manufac-

turing Efficiency) in collaboration with ABB Schaffhausen

AG.

The demand for production flexibility has driven

extensive research into the management and orches-

tration of physical and digital assets (DAs) in smart

factories. In fact, deploying modular automation re-

quires not only the integration of different assets,

such as robots and automation systems (M

¨

uller et al.,

2021c; M

¨

uller et al., 2021b), but also reconfigurable

assets and processes (M

¨

uller et al., 2021a; Kozma

et al., 2019).

All the changes induced in the physical assets is

reflected in the data readings from them, ultimately

impacting the related DAs. In that regard, given the

fact that majority of the DAs implemented in Industry

4.0 settings for production monitoring and optimiza-

tion are data-driven, there have been numerous re-

search on data handling and data-driven model adap-

tation given changes in the production and processes.

(Further details can be found in (Polke et al., 2023;

Yue and Wang, 2022; Morgan et al., 2021)).

In all the above-mentioned research, one of the

main concerns during the solution development is

changes in the data exposed during data-driven model

Fathi, K., Sadurski, M., Waskow, S., Kleinert, T. and van de Venn, H. W.

Towards Industry 5.0: AAS/MLOps-Driven Model Maintenance for Data-Centric Production.

DOI: 10.5220/0013716300003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 495-502

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

495

training compared to model deployment and testing

data. This discrepancy between the two data distribu-

tions, and also changes in the data in general, is an

active research area in the field of Machine Learning

Operations (MLOps).

As the matter of fact, MLOps aims to facilitate the

efficient deployment and serving of machine learning

(ML) models in production which consequently also

constantly improves the business activities (Haviv and

Gift, 2023). In that regard, for tracking changes in the

production line and adapting the DAs, it is crucial to

version the data, models and also the code. Doing

so makes the entire pipeline repeatable and traceable

for performance evaluation and comparison (Faubel

et al., 2023). To this regards, we aim to answer the

following research question (RQ) concerning model

serving:

RQ1: How can an orchestration tool like MLRun

efficiently

1

track experiments, data, and models in

artifact form for knowledge sharing in data-centric

production?

In what follows, we use predictive maintenance

(PdM) as an example to explain the deployment re-

lated problems in industry. Nonetheless, the pro-

posed architecture can be generalized to any other

data-driven solution such as zero defect manufactur-

ing (ZDM), C O

2

emission tracking (CO2-T), etc.

In the field of PdM, as an important concept in

Industry 4.0, research dealing with MLOps tries to

ensure the performance of deployed solution despite

the changes in the production line. Such solutions

suggest to have triggers for retraining the data-driven

model either given a drop in the accuracy, or other

performance indicators (Raj et al., 2021; Fathi et al.,

2024b), or instead doing it periodically (Oluyisola

et al., 2020; Shakhovska and Campos, 2024).

There are several issues for model maintenance

using the aforementioned approaches. Firstly, the

lack of annotated data in PdM is a well-known but still

unresolved issue. Thus, accuracy-based triggers are

inefficient, as model adaptation occurs too late—only

after downtime has already occurred. Secondly, these

approaches neglect the operator’s domain knowledge

for maintaining a physical asset which is counter pro-

ductive. Numerous successful production lines have

operators which have years of experience working

with different production assets. Therefore, it is of

utmost importance to integrate their knowledge into

the MLOps design and deployment cycle. Lastly and

most importantly, high model accuracy does not au-

1

Efficient in terms of reducing excessive overhead gen-

eration and preventing bursts of excessive information.

tomatically translate into more profit, increased sus-

tainability, etc., for the company and rather the im-

pact of the deployed model should be monitored and

evaluated by the plant or asset operator (Haviv and

Gift, 2023).

Unfortunately, MLOps studies trying to include

the business side’s opinion and/or expertise into the

design and deployment, when at all, merely con-

sider their expertise only in the initial concept devel-

opment (Faubel et al., 2023; Colombi et al., 2024;

Kreuzberger et al., 2023; Salama et al., 2021). How-

ever, we believe a more effective solution would be

to integrate the asset operator in the maintenance of

the PdM models as well. This will allow the op-

erator to make requests to the ML engineer directly

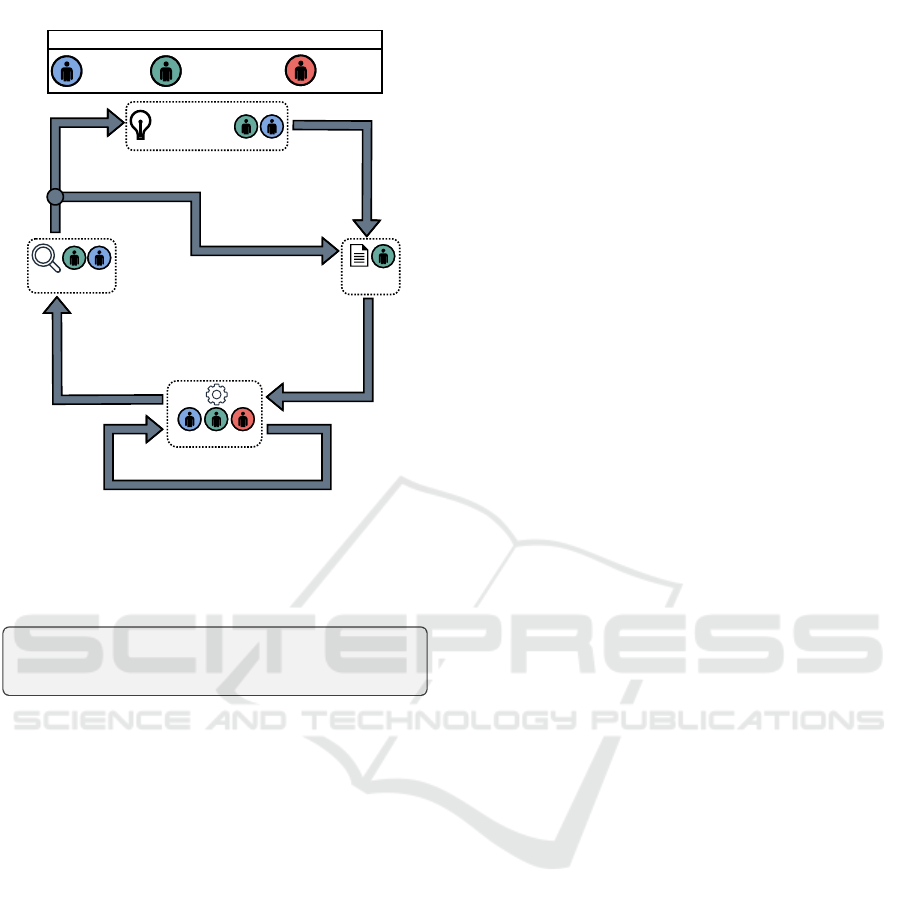

(Fathi et al., 2024a). Fig. 1 shows our proposal for

this integration which is heavily based on the work

from Faubel et al. (Faubel et al., 2023). The arrows

in this figure, indicate the actions performed by the

roles within the dashed rectangles to reach the next

step. Furthermore, each dashed rectangle describes

the contributions of these roles in the corresponding

MLOps step. With this solution we aim to answer the

following RQ:

RQ2: How can domain knowledge from the shop

floor be effectively

2

integrated with artifacts gener-

ated in data-driven architectures?

In that regard, another important improvement

in our proposed solution for maintaining data-driven

models is the integration of different required roles.

As a generic and high-level solution, instead of break-

ing down the roles needed for developing and deploy-

ing a data-driven solution given MLOps requirements

(Colombi et al., 2024; Kreuzberger et al., 2023),

namely data scientist, data engineer, etc., we divide

them in the following ones (refer to Section 3 for more

details):

1. Operator

2. ML engineer

3. Ecosystem manager

The main reason for defining the roles as suggested

above is effective information sharing between dif-

ferent actors working in a company on a specific prod-

uct or a production asset (Milicic et al., 2016).

After integrating domain knowledge in the pro-

posed solution and also defining roles the last and

most important step would be to choose a represen-

2

Effective in terms of providing added value and se-

mantic meaning (Zhou et al., 2023) to different parts of a

pipeline.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

496

Business idea

(problem)

High level

architecure

Monitoring

Business value to

machine learning

problem conversion

Machine learning

solution preparation,

training, testing and

deployment

Integrating the

machine learning

model in the

existing process

Feedback

Deployed model

Updating the model given

operator needs/domain knowledge

Machine learning

Engineer

Ecosystem

Manager

Operator

Roles

Figure 1: Overview of the DA maintenance cycle (refer to

Section 3 for detailed role descriptions).

tation for sharing information between different ac-

tors. This leads to the following RQ:

RQ3: How can information from data-driven solu-

tions be structured in an industry-approved format?

For addressing this issue, we utilize the Asset Ad-

ministration Shell (AAS) (Wei et al., 2019) as a stan-

dardized digital representation of digital and physical

assets in industry.

These steps will enable successful product life cy-

cle management in industrial use cases, where prod-

uct is the deployed DA in smart factories.

Lastly, as a closing statement of this section, by

highlighting the roles in the proposed ecosystem, we

aim to shift the current model-driven design towards

a product-oriented one as suggested by Kreuzberger

et al. (Kreuzberger et al., 2023). Only then it is pos-

sible to implement the concepts required by Industry

5.0 for bringing human in model maintenance loop

and increasing the acceptance of models in the mod-

ern and complex industrial plants. As the final goal

of this paper we hope to pave the way for a balance

between automatization and collaboration as intro-

duced by (Ruppert et al., 2022; Sabuncu and Bilge-

han, 2025).

As a short summary, our main contributions are

thus 3-fold. We:

1. pinpoint the importance of efficient artifact gener-

ation,

2. provide a systematic way for coupling informa-

tion from shopfloor to the developed and deployed

DAs (and their artifacts),

3. propose an industry approved system to handle ar-

tifacts from MLRun.

2 PROBLEM SETTING AND

FOCUS AREA

During the development of this solution, we focused

heavily on two distinctive aspects of production lines.

Namely, the lack of (annotated) historical data and

therefore the importance of human feedback and also

the overwhelming number of physical assets to be

monitored. The former results in excessive number

of (experimental) implementations with their corre-

sponding artifacts containing data, metadata, models,

etc., which need to be versioned for improved trace-

ability. The later further exacerbates the problem by

extending this issue across multiple physical assets,

whose performance is decisive in the productivity of

the production line.

On top of that, various aspects of the production

potentially require dedicated models for monitoring

for enhancing their performance. These aspects in-

clude but are not limited to PdM, ZDM, CO2-T, etc.,

which we collectively refer to as tasks in this paper.

As a result, these monitoring systems will also lead

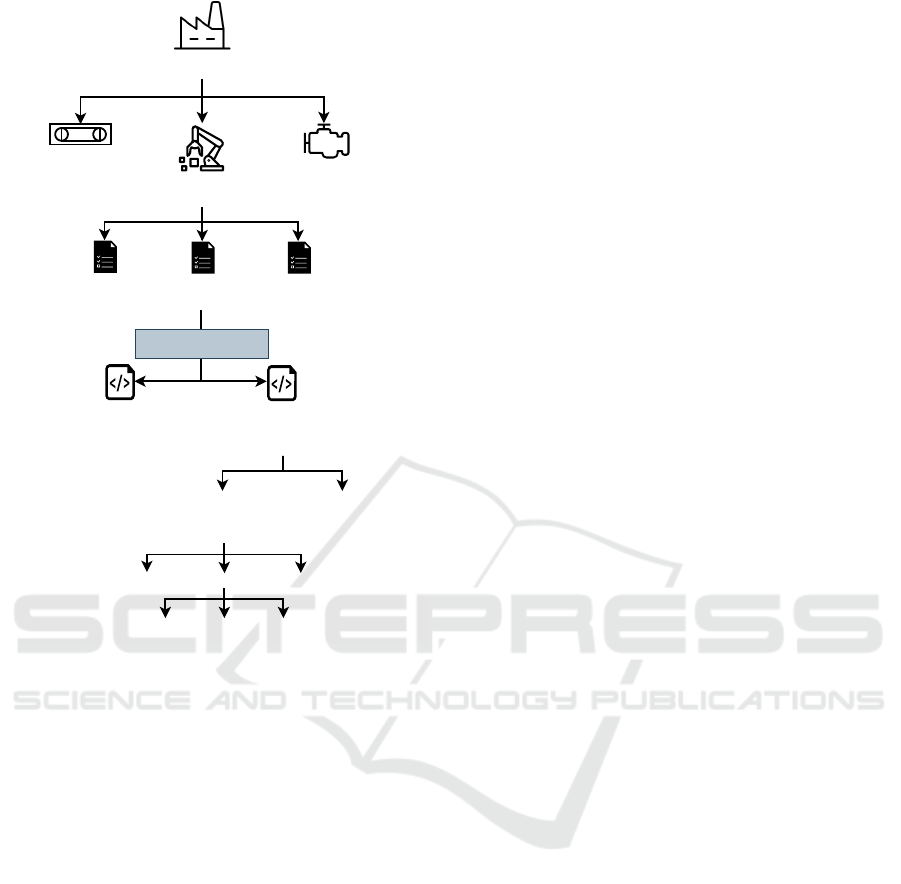

to more artifact generation from the solution. Fig. 2,

from a machine and not component point of view,

shows how the number of artifacts can exponentially

grow given the scale of the production line.

We aim to highlight the pivotal role of managing

data and metadata generated by DAs. In fact, in In-

dustry 4.0/5.0, physical assets are not the only type of

assets that firstly produce data and secondly require

maintenance in response to changes occurring in the

production line.

In addition, given the current digitalization state

of different industries, our observations are mostly in

Switzerland, it is rarely the case that the available data

is annotated for solving the optimization problem at

hand. Therefore, the heavily focused automation in

MLOps for model training and serving, e.g., using

AutoML, becomes obsolete. Please refer to (Salama

et al., 2021; Colombi et al., 2024; Cerquitelli et al.,

2021). This characteristic highlights the importance

of implementation and artifact tracking and also hu-

man feedback for ensuring the performance of the

system. After defining the boundaries for the prob-

lem at hand, in what follows, the architecture of the

proposed method is introduced.

Towards Industry 5.0: AAS/MLOps-Driven Model Maintenance for Data-Centric Production

497

Data-centric

production line

Production asset 2

(physical asset)

Production asset 1

(physical asset)

Production asset 3

(physical asset)

Task 1:

ZDM

Task 2:

PdM

Task 3:

CO2-T

Digital asset 1:

PdM for production

procedure A

Digital asset 2:

PdM for production

procedure B

Implementation 1:

physical asset running at

90% capacity

(e.g., day shift)

Implementation 2:

physical asset running at

60% capacity

(e.g., night shift)

Scripts Artifacts

Metadata

Report Data Pipeline

models

ML engineer translates

tasks into digital assets

Figure 2: Exponential growth in artifact generation in data-

centric production.

3 SYSTEM ARCHITECTURE

In industrial settings, model verification and deploy-

ment are inherently experimental due to the scarcity

of annotated data. High model accuracy does not nec-

essarily correlate with improved productivity or sus-

tainability, making human involvement critical.

To address these challenges, our proposed system

provides a foundation for generating and archiving

DA implementations, along with corresponding infor-

mation from human operators. This information pro-

vides sentiment for the generated DA. This in the long

run facilitates DA tracking and matching developed

for different physical assets or tasks. Our proposed

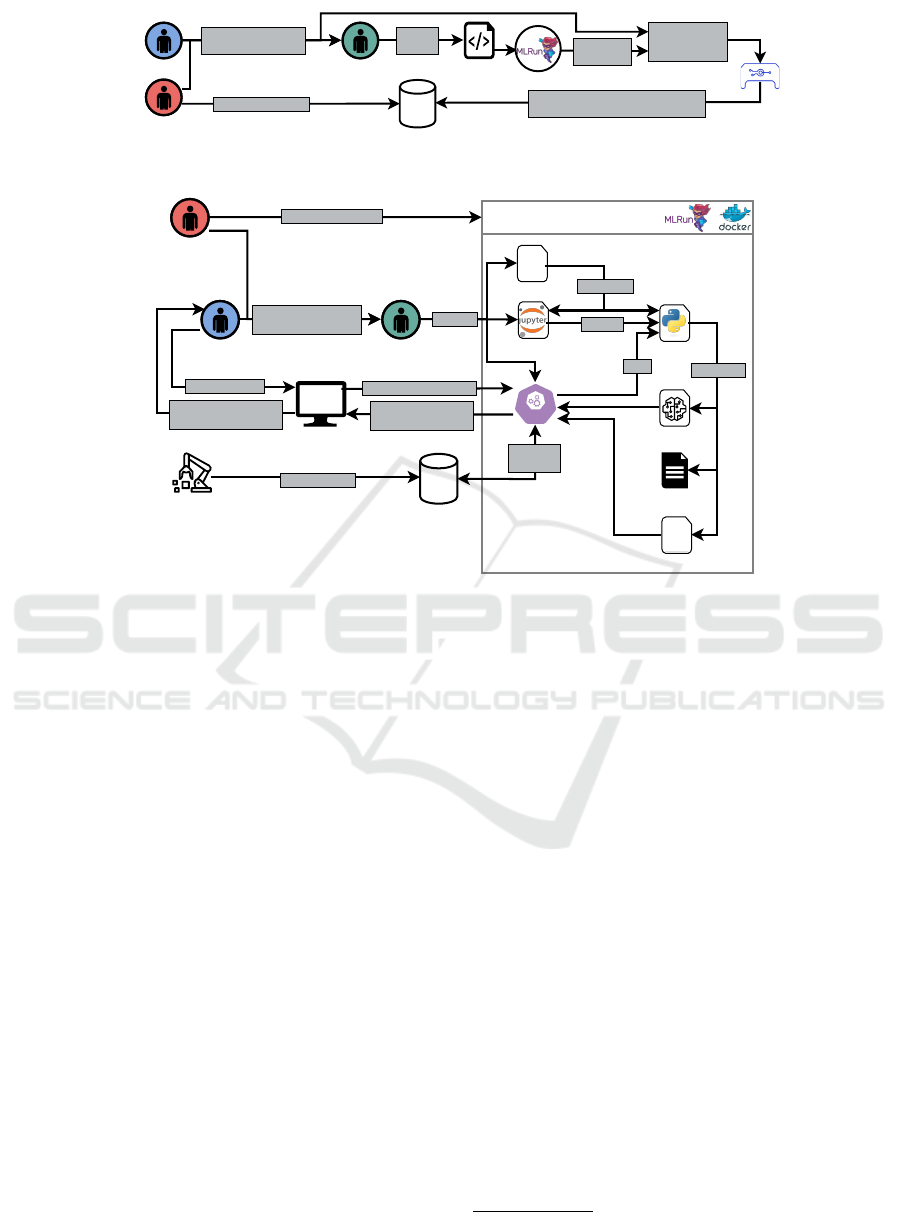

architecture (Fig. 3) integrates three key roles:

1. Operator: Defines tasks and provides feedback.

2. ML Engineer: Develops and maintains DAs.

3. Ecosystem Manager: Oversees data aggregation

and solution inspection.

The system workflow is as follows. Operators define

tasks requiring DA development. Afterwards, ML en-

gineers develop solutions and generate artifacts using

MLRun.

Thereafter, the generated artifacts (data, metadata,

models and their hyperparameters, etc.) are encap-

sulated within AAS submodel instances along with

the task description. These artifacts contain the min-

imum information required to recreate the entire

pipeline for the solution. In fact, despite the con-

venience of tools like MLRun and MLFlow, exces-

sive artifact generation can make it difficult to orga-

nize and use this information effectively for decision-

making. Lastly, the ecosystem manager inspects and

manages DAs across production lines. Ultimately,

this structure ensures traceability, effective feedback

integration, and reduced model development costs.

For adapting and/or improving the deployed DA,

the operator and the ecosystem manager can actively

provide feedback to the ML engineer for further ad-

justment of the DA leading to new instances from

these DAs in the database. Human agency is a key

design choice in the proposed system. It is therefore

assumed that provided feedback is deliberate, accu-

rate and aligns with production requirements.

In what follows, our proposed structure for gen-

erating DA implementations in ABB Schaffhausen is

provided. Please note that this structure is referred to

as Pre-Prime Ecosystem.

4 INDUSTRIAL USE CASE: ABB

PLANT

The Pre-Prime ecosystem developed for ABB

Schaffhausen AG is shown in Fig. 4. Once the op-

erator defines a new task for the ML engineer, they

can use the provided Jupyter notebooks to work on

different parts of the ML project. Given the require-

ments from ABB, we divided these Jupyter notebooks

into the following:

1. Data preparation and preprocessing: contains

all the operations needed for making the data vec-

tor ready for different algorithms.

2. Model training and validation: contains all the

steps to go from an idea for solving the task to a

verified and functional model(s).

3. Model serving: contains the logic for running the

model and integrating it into the existing IT in-

frastructure of the target company.

However, these can change given the needs and/or

limitations.

In addition, the parameters, hyperparameters, etc.,

impacting the behavior of the implementation are also

stored separately as a metadata file. Once the solution

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

498

ML Engineer

Ecosystem Manager

Defines a new task /

Provides feedback

Generating

AAS submodel

instance

Digital asset

Creates/

Updates

Storing encapsulated information

(context pairs of task and artifacts)

Database

Inspects instances

Operator

Generating

artifacts

Figure 3: System overview.

Pre-Prime Ecosystem instance

powered by:

Jupyter notebook(s)

Operator

ML Engineer

Ecosystem Manager

Defines a new task /

Provides feedback

Script(s)

metadata

01

Influences

Exports

Pipeline Model(s)

Reports

Generates

Sends output from

digital asset

api

Updates

Calls

Connects

and reads

Data

01

Database(s)

Sends signals

Physical asset(s)

User interface

Provides input

Sends operator input

Provides insights

into physical assests

Inspects instances

Figure 4: Overview of Pre-Prime ecosystem. Based on feedback from the ecosystem manager or operator, the ML engineer

designs a new DA in Jupyter notebooks, generating updated scripts, models, reports, and data. These newly created artifacts

are then integrated into the API during model serving to meet shopfloor requirements.

has reached the maturity level to be tested in the pro-

duction line, scripts, models, reports and data (specifi-

cally used for model training, testing and verification)

are extracted as a form of artifact. For the sake of

traceability, the data before and after being vectorized

are stored separately, so that in case of erroneous pre-

dictions, the pipeline can be debugged easier. This

separation is also in accordance with the demands of

the EU AI Act for safety critical systems (ISACA,

2024; Dorigo et al., 2025).

Later on, the designated API uses these artifacts to

serve the operator and the rest of the implementation

is frozen. The API basically contains all the endpoints

for its different functionalities. Thereafter, in case the

performance of the DA implementation is not accept-

able, given the feedback from the operator and/or the

ecosystem manager, the ML engineer can go thorough

the development cycle and update the solution.

5 INTEGRATION WITH AAS

For having the most efficient and easily standardiz-

able solution for industry, in this section we demon-

strates how a data-centric production lines can lever-

age various official AAS submodels to optimize its

operations.

As the main motivation, we aim to use the avail-

able AAS submodels for different physical and DAs

to ease communication between them. As an ex-

ample, an OEM provides submodels for their assets,

which as a result help different customers access in-

formation from the assets in a unified way.

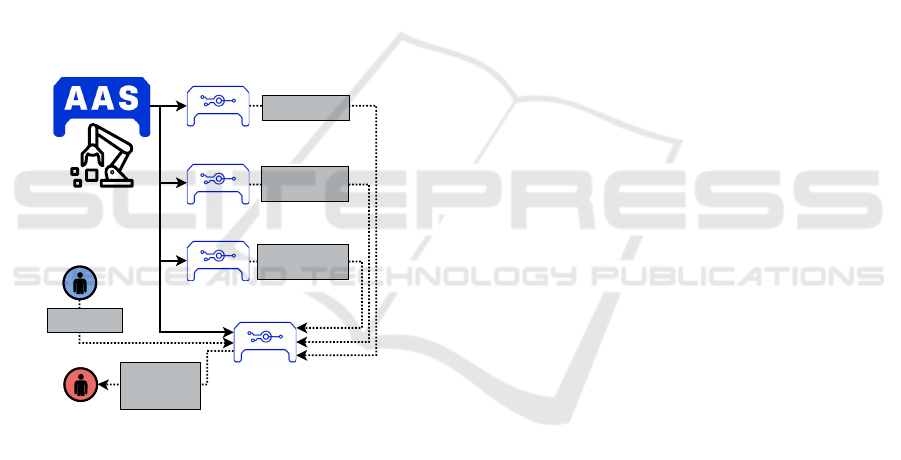

As shown in Fig. 5, the information about the

physical asset is contained within the digital name-

plate. This information is useful when the operator is

defining a new task for which a DA is to be imple-

mented.

Furthermore, for ensuring structural and

schematic consistency of the data, we propose

to use the time series data submodel. In fact, this

submodel can also be used to detect potential data

shifts impacting DA which are developed later.

In addition, the (data-driven) DAs are in accor-

dance with the AI submodel

3

to ensure all the re-

quired information for model development, deploy-

ment and serving are contained.

3

As of the writing this paper, this submodel is not yet

published.

Towards Industry 5.0: AAS/MLOps-Driven Model Maintenance for Data-Centric Production

499

As a side note, the data-driven DAs can potentially

benefit from other submodels as well. As of the writ-

ing this paper, these submodels include but are not

limited to Carbon footprint, Predictive maintenance,

etc. In fact, these submodels help the ML engineer

incorporate the required domain knowledge, enhanc-

ing traceability and making troubleshooting easier for

the solution.

Lastly, all these submodel instances along with

their artifacts are encapsulated into the data-driven

model maintenance submodel instance. In addition,

the task description from the operator is also included

in this submodel to provide the required sentiment to

the implementation. The ecosystem manager then by

looking at different instances of our proposed sub-

model can have all the required information for so-

lution inspection, model and data aggregation, etc.

Moreover, information from this submodel then can

be filtered according to different access permissions

of different roles, adding even more value to this sub-

model.

Physical asset

Provides physical

asset information

Submodel:

Digital nameplate

Provides physical

asset signal

readings

Submodel:

Timeseries

Provides digital

assets for different

tasks

Submodel:

AI model

Provides insight

about tasks,

digital and

physical assets

Submodel:

Data-driven model

maintenance

Operator

Provides

task description

Ecosystem

Manager

Figure 5: Physical and DA management via human-in-the-

loop AAS.

6 DISCUSSION

In this paper, the foundation required for DA life-

cycle management was presented. Such a solution

can later be adapted for creating digital product pass

(Psarommatis and May, 2024) for DAs in an Indus-

try 4.0/5.0 setting. Furthermore, with the increasing

use of advanced models, such as large language mod-

els (LLMs), traceability becomes a vital characteris-

tic of AI-powered solutions. In fact, by generating

controlled artifacts, it is possible to pave the way for

trustworthy AI in industry. This is facilitated by the

availability of information and logs for model behav-

ior inspection in case of a system failure. As an addi-

tional benefit of this architecture, it is also possible to

track the CO

2

emissions of a given DA, which is very

relevant for resource intensive solutions employing

LLMs. As an example, it can be inspected whether

an LLM-based sustainability model emits more CO

2

than it can optimize or not. Nonetheless, since all de-

cisions regarding different DA implementations rely

on information from the proposed architecture, au-

tomating instance-specific verification remains a chal-

lenge for future work. Furthermore, for future work

will need to explore LLM-assisted DA creation, inte-

grating operator-defined tasks into an AutoML work-

flow for task-specific model generation.

7 CONCLUSION

In this paper an architecture for encapsulating in-

formation from different DA implementations along

with their designated tasks was introduced. We aimed

to point out the fact that, the MLOps cycle is a small

part of the entire solution development given the over-

whelming number of assets and experimental solu-

tions developed for them. Furthermore, we discussed

how important it is to prune the artifact generation

from different parts of the DA to keep it traceable

for debugging as well as data and model aggrega-

tion. In addition, we introduced a human-in-the-loop

design for AAS creation of a physical asset, aiming

for maximized operator involvement in the designing

process of different DAs. For future work, we aim

to feed prompts containing operator generated tasks

with corresponding solutions from the model mainte-

nance submodel to train a LLM for creating new DAs

for new tasks. The ultimate goal is to incorporate task

descriptions into the AutoML solution development

process, making it more relevant to real-world indus-

try use cases.

ACKNOWLEDGMENT

The authors of this paper would like to express their

deep sense of gratitude to SMC Schweiz AG, espe-

cially Mr. Alessandro Grizzetti, for their unceasing

assistance in promoting Competence Centre for Au-

tomation and Digitalisation among different industrial

partners in Europe. Additionally, we extend our grat-

itude to the amazing team at ABB OEE team (Marko

Barutcu and Patrick Henzi) for their invaluable sup-

port in ensuring the success of this project.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

500

REFERENCES

Brettel, M., Klein, M., and Friederichsen, N. (2016). The

relevance of manufacturing flexibility in the context of

industrie 4.0. Procedia Cirp, 41:105–110.

Cerquitelli, T., Nikolakis, N., Morra, L., Bellagarda, A.,

Orlando, M., Salokangas, R., Saarela, O., Hietala, J.,

Kaarmila, P., and Macii, E. (2021). Data-driven pre-

dictive maintenance: A methodology primer. Predic-

tive Maintenance in Smart Factories: Architectures,

Methodologies, and Use-cases, pages 39–73.

Colombi, L., Gilli, A., Dahdal, S., Boleac, I., Tortonesi,

M., Stefanelli, C., and Vignoli, M. (2024). A ma-

chine learning operations platform for streamlined

model serving in industry 5.0. In NOMS 2024-2024

IEEE Network Operations and Management Sympo-

sium, pages 1–6. IEEE.

Dorigo, T., Brown, G. D., Casonato, C., Cerd

`

a, A., Cia-

rrochi, J., Da Lio, M., D’souza, N., Gauger, N. R.,

Hayes, S. C., Hofmann, S. G., et al. (2025). Artifi-

cial intelligence in science and society: The vision of

usern. IEEe Access.

Fathi, K., Kleinert, T., and van de Venn, H. W. (2024a).

Trustworthy machine learning operations for predic-

tive maintenance solutions. In PHM Society European

Conference, volume 8, pages 4–4.

Fathi, K., Ristin, M., Sadurski, M., Kleinert, T., and van de

Venn, H. W. (2024b). Detection of novel asset failures

in predictive maintenance using classifier certainty. In

2024 32nd Mediterranean Conference on Control and

Automation (MED), pages 50–56. IEEE.

Faubel, L., Schmid, K., and Eichelberger, H. (2023). Mlops

challenges in industry 4.0. SN Computer Science,

4(6):828.

Ghobakhloo, M. (2020). Industry 4.0, digitization, and op-

portunities for sustainability. Journal of cleaner pro-

duction, 252:119869.

Haviv, Y. and Gift, N. (2023). Implementing MLOps in the

Enterprise. ” O’Reilly Media, Inc.”.

Huang, Y., Dhouib, S., and Malenfant, J. (2021). Aas

capability-based operation and engineering of flexible

production lines. In 2021 26th IEEE International

Conference on Emerging Technologies and Factory

Automation (ETFA), pages 01–04. IEEE.

ISACA (2024). Understanding the eu ai act: Requirements

and next steps. Accessed: 2025-02-06.

Kozma, D., Varga, P., and Larrinaga, F. (2019). Data-

driven workflow management by utilising bpmn and

cpn in iiot systems with the arrowhead framework. In

2019 24th IEEE International Conference on Emerg-

ing Technologies and Factory Automation (ETFA),

pages 385–392. IEEE.

Kreuzberger, D., K

¨

uhl, N., and Hirschl, S. (2023). Ma-

chine learning operations (mlops): Overview, defini-

tion, and architecture. IEEE access, 11:31866–31879.

Milicic, A., Kiritsis, D., and Efendioglu, N. (2016). From

english to rdf-a meta-modelling approach for predic-

tive maintenance knowledge base design. In Advances

in Production Management Systems. Initiatives for a

Sustainable World: IFIP WG 5.7 International Con-

ference, APMS 2016, Iguassu Falls, Brazil, September

3-7, 2016, Revised Selected Papers, pages 214–224.

Springer.

Morgan, J., Halton, M., Qiao, Y., and Breslin, J. G. (2021).

Industry 4.0 smart reconfigurable manufacturing ma-

chines. Journal of Manufacturing Systems, 59:481–

506.

M

¨

uller, M., M

¨

uller, T., Ashtari Talkhestani, B., Marks,

P., Jazdi, N., and Weyrich, M. (2021a). Industrial

autonomous systems: a survey on definitions, char-

acteristics and abilities. at-Automatisierungstechnik,

69(1):3–13.

M

¨

uller, T., Jazdi, N., Schmidt, J.-P., and Weyrich, M.

(2021b). Cyber-physical production systems: en-

hancement with a self-organized reconfiguration man-

agement. Procedia CIRP, 99:549–554.

M

¨

uller, T., Lindemann, B., Jung, T., Jazdi, N., and Weyrich,

M. (2021c). Enhancing an intelligent digital twin

with a self-organized reconfiguration management

based on adaptive process models. Procedia CIRP,

104:786–791.

Oluyisola, O. E., Sgarbossa, F., and Strandhagen, J. O.

(2020). Smart production planning and control: Con-

cept, use-cases and sustainability implications. Sus-

tainability, 12(9):3791.

Polke, D., Surjana, A., Diepers, F., Ahle, E., and S

¨

offker,

D. (2023). Development of a modular automation

framework for data-driven modeling and optimization

of coating formulations. In 2023 IEEE 28th Interna-

tional Conference on Emerging Technologies and Fac-

tory Automation (ETFA), pages 1–8. IEEE.

Psarommatis, F. and May, G. (2024). Digital product pass-

port: A pathway to circularity and sustainability in

modern manufacturing. Sustainability, 16(1):396.

Raj, E., Buffoni, D., Westerlund, M., and Ahola, K. (2021).

Edge mlops: An automation framework for aiot ap-

plications. In 2021 IEEE International Conference on

Cloud Engineering (IC2E), pages 191–200. IEEE.

Ruppert, T., L

¨

ocklin, A., Romero, D., and Abonyi, J.

(2022). Intelligent collaborative manufacturing space

for augmenting human workers in semi-automated

manufacturing systems. In 2022 IEEE 27th Interna-

tional Conference on Emerging Technologies and Fac-

tory Automation (ETFA), pages 1–7. IEEE.

Sabuncu,

¨

O. and Bilgehan, B. (2025). Human-centric iot-

driven digital twins in predictive maintenance for op-

timizing industry 5.0. Journal of Metaverse, 5(1):64–

72.

Salama, K., Kazmierczak, J., and Schut, D. (2021). Prac-

titioners guide to mlops: A framework for continuous

delivery and automation of machine learning. Google

Could White paper.

Shakhovska, N. and Campos, J. (2024). Predictive mainte-

nance for wind turbine bearings: An mlops approach

with the diafs machine learning model.

Wei, K., Sun, J. Z., and Liu, R. J. (2019). A review of as-

set administration shell. In 2019 IEEE International

Conference on Industrial Engineering and Engineer-

ing Management (IEEM), pages 1460–1465.

Towards Industry 5.0: AAS/MLOps-Driven Model Maintenance for Data-Centric Production

501

Xia, Y., Shenoy, M., Jazdi, N., and Weyrich, M. (2023).

Towards autonomous system: flexible modular pro-

duction system enhanced with large language model

agents. In 2023 IEEE 28th International Conference

on Emerging Technologies and Factory Automation

(ETFA), pages 1–8. IEEE.

Yue, F. and Wang, Y. (2022). Cross-domain fault diagno-

sis via meta-learning-based domain generalization. In

2022 IEEE 18th International Conference on Automa-

tion Science and Engineering (CASE), pages 1826–

1832. IEEE.

Zhou, B., Nikolov, N., Zheng, Z., Luo, X., Savkovic, O.,

Roman, D., Soylu, A., and Kharlamov, E. (2023).

Scaling data science solutions with semantics and ma-

chine learning: Bosch case. In International Semantic

Web Conference, pages 380–399. Springer.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

502