Video-Based Vibration Analysis for Predictive Maintenance: A Motion

Magnification and Random Forest Approach

Walid Gomaa

1,2 a

, Abdelrahman Wael Ammar

1 b

, Ismael Abbo

1 c

, Mohamed Galal Nassef

1 d

,

Tetsuji Ogawa

3 e

and Mohab Hossam

1 f

1

Faculty of Engineering, Egypt-Japan University of Science and Technology, Alexandria, Egypt

2

Faculty of Engineering, Alexandria University, Alexandria, Egypt

3

Graduate School of Fundamental Science and Engineering, Waseda University, Tokyo, Japan

Keywords:

Condition Monitoring, Machinery, Video Motion Magnification, Machine Learning, Non-Contact Approach.

Abstract:

Condition monitoring of high-speed machinery is critical to prevent unexpected breakdowns that could lead to

injuries and cost billions. Traditional contact-based vibration sensors face limitations including measurement

perturbations, point-specific data coverage, and installation constraints. This paper presents a novel non-

contact machinery fault detection framework combining Eulerian video motion magnification with machine

learning classification. The methodology comprises two integrated components. Primarily, a video-based

vibration analysis pipeline utilizing Eulerian motion magnification with dense optical flow, which accomplish

comprehensive signal processing for feature extraction using Fast Fourier transform. Then, a Random Forest

classifier trained on video-derived temporal and frequency domain features. The system was validated based

on ground-truth data from the Gunt PT500 machinery diagnosis and the Gunt TM170 balancing apparatus

under four operational conditions: normal operation, outer ring bearing fault, and two imbalance severities

(10g and 37g). Hence, experimental results demonstrate exceptional performance with 96.7% overall accuracy

and a macro-averaged F1-score of 0.965 in discriminating fault conditions using solely video-derived features.

The video processing allowed to identify distinct vibration signatures, from imbalance conditions showing

amplitude variations to proportional fault severity ultimately offering a cost-effective solution for industrial

condition monitoring applications.

1 INTRODUCTION

Modern manufacturing depends heavily on complex

machinery, making reliable condition monitoring a

cornerstone of operational efficiency. Unplanned

equipment failures can halt production, incur safety

risks, and generate substantial costs—estimated at

$28.6 billion per year in Australia alone (Li et al.,

2025; de Koning et al., 2024). Early detection of

issues such as overheating, fluid leaks, or drive-belt

slippage is therefore critical to avert these disruptions.

A range of diagnostic techniques has emerged,

including particle debris analysis, acoustic emission

a

https://orcid.org/0000-0002-8518-8908

b

https://orcid.org/0009-0005-8695-9144

c

https://orcid.org/0009-0003-4834-8962

d

https://orcid.org/0000-0002-3192-7154

e

https://orcid.org/0000-0002-7316-2073

f

https://orcid.org/0000-0003-2075-2050

monitoring, and vibration signal inspection (Zhong

et al., 2025; Xu and Lu, 2025). Among these, vi-

bration and acoustic methods are especially attractive

because they permit online health assessment without

machine disassembly. However, these contact sensors

suffer from alignment errors and environmental noise,

which can degrade accuracy by up to 15% (Kalaiselvi

et al., 2018; Kiranyaz et al., 2024). These limitations

have spurred interest in non-contact alternatives.

Video Motion Magnification (VMM) acts like a

“motion microscope,” amplifying minute movements

in video sequences to reveal hidden dynamics (Lima

et al., 2025). Its applications span medical diag-

nostics (Nieto, 2025), structural health and condition

monitoring (Lado-Roig

´

e and P

´

erez, 2023; Yang and

Jiang, 2024; Zhang et al., 2025). Initial VMM im-

plementations relied on Lagrangian tracking which

are computationally heavy with optical-flow methods

sensitive to occlusion and complex motion (

´

Smieja

et al., 2021). Eulerian techniques then emerged, de-

Gomaa, W., Ammar, A. W., Abbo, I., Nassef, M. G., Ogawa, T. and Hossam, M.

Video-Based Vibration Analysis for Predictive Maintenance: A Motion Magnification and Random Forest Approach.

DOI: 10.5220/0013715900003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 1, pages 445-452

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

445

tecting pixel-level intensity changes for faster pro-

cessing, though prone to blurring and noise artifacts

that could reduce magnification fidelity by roughly

20% (Wu et al., 2012;

´

Smieja et al., 2021). More re-

cently, data-driven models using Convolutional Neu-

ral Networks (CNNs) or Swin Transformers have

learned optimized filters, delivering sharper results

and up to 30% better noise suppression, yet often de-

pend on synthetic training sets that may not capture

real-world variability (Lado-Roig

´

e et al., 2023; Lado-

Roig

´

e and P

´

erez, 2023; Oh et al., 2018).

In this work, we build upon Eulerian VMM by

integrating enhanced optical-flow estimation and tai-

lored feature extraction to strengthen motion amplifi-

cation. Coupling these video-derived features with a

Random Forest classifier trained on ground-truth vi-

bration measurements from a rotating-machinery test

rig, we introduce a machine learning–driven, non-

contact vibration analysis framework. Our approach

aims to overcome the drawbacks of traditional contact

sensors and synthetic-data bias, offering a robust solu-

tion for continuous condition monitoring in industrial

environments.

The remaining sections are organized as follows.

We present related works in section 2, followed by

a detailed scaffold of our methodology in section 3.

Then we present, illustrate and discuss our results in

section 4. Finally, we acknowledge perspectives in

section 5.

2 RELATED WORKS

According to the review (

´

Smieja et al., 2021), VMM

techniques are commonly divided into two main cat-

egories: Eulerian and Lagrangian approaches. Par-

allel in fluid dynamics, Eulerian methods observe

changes within a stationary volume here, by decom-

posing video sequences into motion-related represen-

tations, which are then mathematically enhanced and

reconstructed into magnified output frames. On the

other hand, Lagrangian methods trace elements as

they move here, focus on tracking individual pixel or

feature trajectories across time. Hence, Eulerian ap-

proaches are particularly effective for detecting subtle

motions but can introduce blur when applied to larger

movements.

Eulerian VMM involves three stages: spatial de-

composition, motion extraction and amplification,

and noise suppression. The VMM problem can be

formulated following (Oh et al., 2018; Lado-Roig

´

e

et al., 2023): given an image signal I(x;t), where x

denotes spatial location and t time, and a displace-

ment function δ(t) representing temporal motion, the

original signal function derived from the original im-

age f (x) is expressed in Equation 1.

I(x;t) = f (x + δ(t)) I(x;0) = f (x) (1)

The goal is to synthesize a magnified version of

the signal expressed in Equation 2.

ˆ

I(x;t) = f (x + (1 + α) ·δ(t)) (2)

Here, α denotes the amplification factor. In prac-

tice, only motions within certain frequency ranges are

meaningful, and thus a temporal band-pass filter T (·),

is applied to isolate those components of δ(t).

Before learning-based advances, most VMM

methods relied on multi-frame temporal filtering to

extract and enhance relevant motion signals (Wu

et al., 2012; Wadhwa et al., 2013; Wadhwa et al.,

2014). Notably, (Wadhwa et al., 2013) proposed an

Eulerian magnification approach using local phase

variations which extracts motion through a complex

steerable pyramid and multi-scale orientation filters.

Oh et al. shifted to a CNN-driven pipeline that

learns motion features end-to-end, removing the need

for explicit temporal filtering (Oh et al., 2018). Due to

scarce real videos, they trained on synthetically gen-

erated sequences with controlled sub-pixel displace-

ments, enabling adaptive, data-driven magnification.

These allowed the application of VMM techniques

in areas such as Structural Health Monitoring (SHM)

and machinery fault diagnosis.

Hence, Yang et al. augmented phase-based

VMM (PVMM) with a gradient-domain filter

(GDGIF) (Yang and Jiang, 2024). In SHM experi-

ments against the original PVMM method (Wadhwa

et al., 2013), their approach raised the SSIM to 0.9222

and the PSNR to 35.2236dB. However, these fil-

ters require manual tuning for the relevant frequency

band, making the process laborious. To address this

drawback, the work of (Lado-Roig

´

e et al., 2023)

followed the LB-VMM framework targeting micro-

displacement bands with minimal prior information.

Under an 20% damage condition, frequency estimates

deviated only by 0.01% from accelerometer readings.

Likewise, machinery fault diagnosis has embraced

VMM. (Zhao et al., 2023) proposed a luminance-

based magnification framework to detect rotor unbal-

ance, loose bearings, and misalignment by amplifying

one to two times rotational frequencies. A rotor un-

balance appeared as axial shaking, loosened bolts as

vertical displacement, and misalignment as axial mo-

tion. Separately, a Swin Transformer–based method

used Residual Swin Transformer Blocks to enhance

magnification (Lado-Roig

´

e and P

´

erez, 2023). Though

fine-tuned on real videos and yielding a 9.63% boost

in MUSIQ (Ke et al., 2021) scores, its initial train-

ing relied on synthetic datasets like PASCAL VOC

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

446

and MS COCO (Lin et al., 2014; Everingham et al.,

2010). Similar caveats apply to LB-VMM and the

band-passed acceleration methods (Oh et al., 2018;

Lado-Roig

´

e et al., 2023; Zang et al., 2025). While

synthetic data simplifies controlled testing, it cannot

fully replicate real-world lighting, texture, and motion

artifacts.

3 METHODOLOGY

This study proposes a video-based approach for ma-

chinery fault detection and condition monitoring, con-

sisting of two main components: (1) a non-contact

video motion magnification pipeline for extracting vi-

bration signals, and (2) a Random Forest classifier us-

ing features derived from the magnified video data.

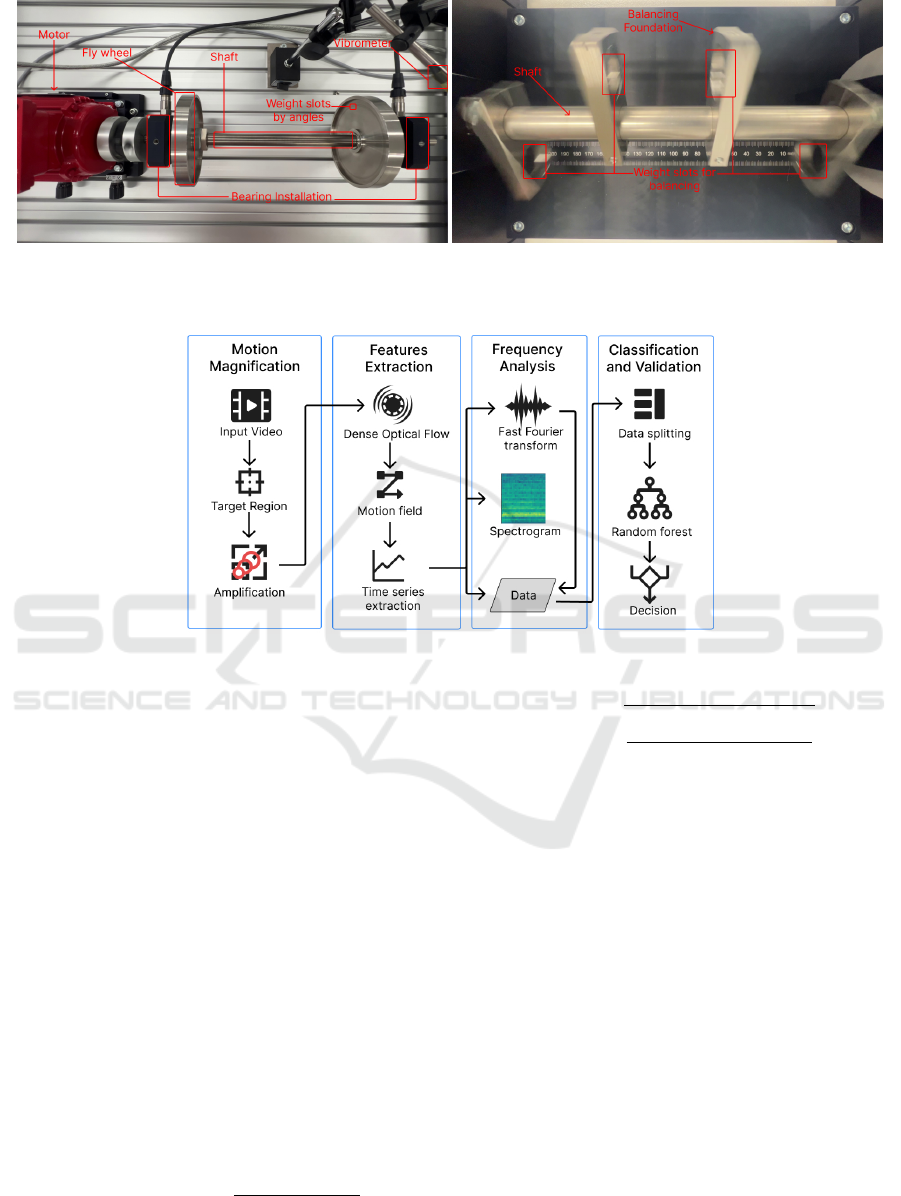

3.1 Dataset Collection

All extracted features are derived from the working

conditions of two rotating machines. The first is the

Machinery Diagnosis System, Gunt PT500, which

supports vibration measurement and field balancing

tasks (Song et al., 2025; Gunt, 2025a). Three oper-

ating conditions were tested: a normal condition with

healthy components and no added mass, a faulty con-

dition with outer ring bearing damage, and a weighted

condition where a 10g mass was added at a 90

◦

angle

on the flywheel, as shown in Figure 1a.

The second setup is the Balancing Apparatus Gunt

TM170, used to illustrate imbalance scenarios (Gunt,

2025b). It includes weighted condition where 37g is

placed across different slots on the balancing founda-

tion (Figure 1b). These configurations serve as the

basis for video collection and subsequent feature ex-

traction through motion magnification.

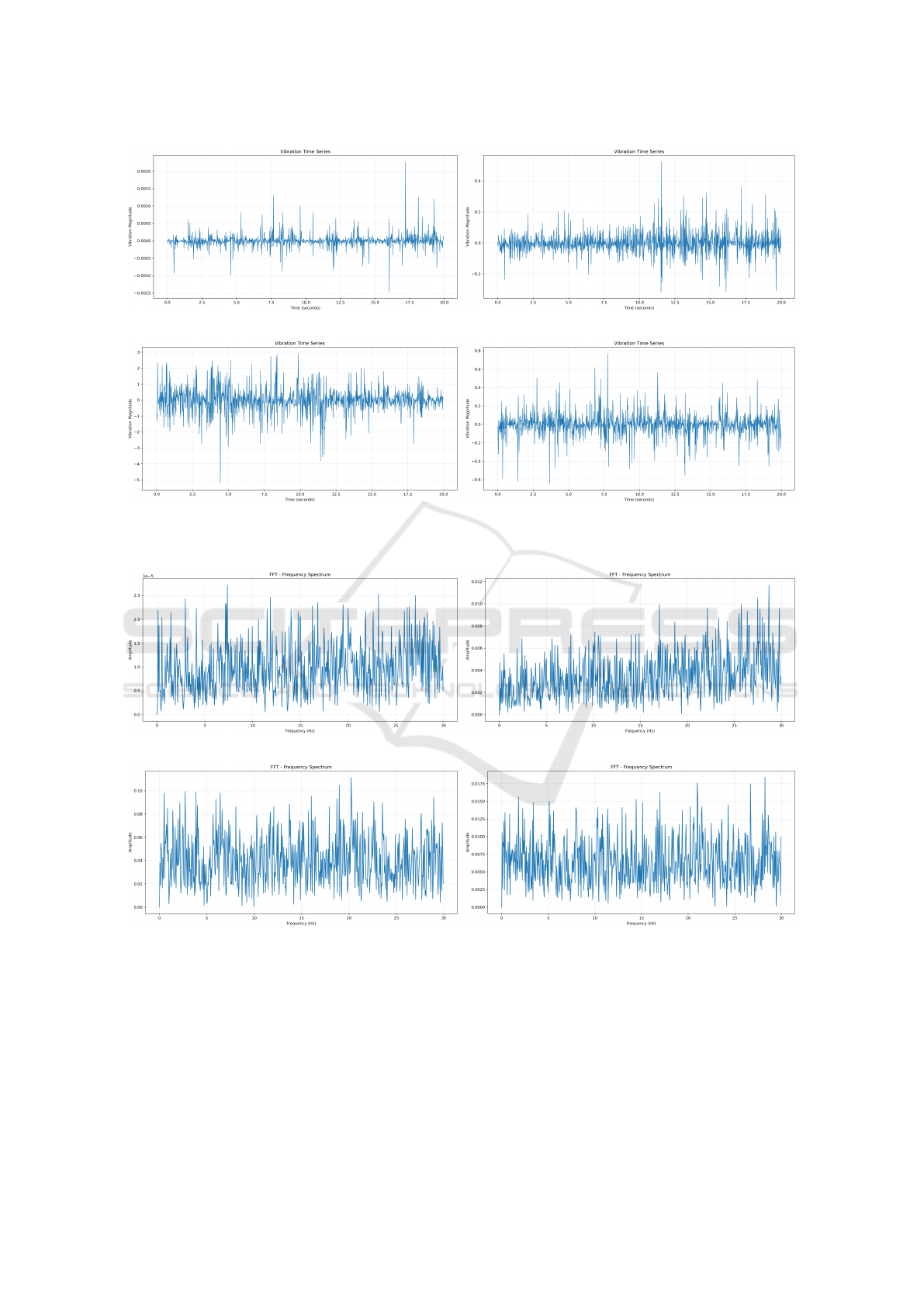

3.2 Our Proposed Framework

The overall methodology, as depicted in Figure 2 is

structured as an integrated pipeline comprising se-

quential processing stages that work in tandem.

3.2.1 Motion Magnification

The primary component of our methodology intro-

duces an approach to vibration monitoring that elim-

inates the need for physical sensor contact with ma-

chinery. Here, the computer vision-based system

leverages Eulerian Motion Magnification as the cor-

nerstone step, combined with dense optical flow ex-

traction to capture vibration signatures directly from

video recordings.

The process begins with an interactive region of

interest (ROI) selection corresponding to the vibrating

machine parts. The mathematical representation of

ROI is defined in Equation 3.

I

ROI

(x,y,t) = I(x

0

+ x,y

0

+ y,t) (3)

Where (x

0

,y

0

) represents the top-left corner of the

selected ROI, and (x, y) are the relative coordinates

within the cropped region of the initial frames from

Equation 1.

Given an input video sequence I(x,t) as presented

in Equation 1, the Eulerian magnification process is

applied on a region of interest (ROI) of the frames

to obtain an output similar to Equation 2. Then, the

dense optical flow computation quantifies pixel-wise

motion vectors between consecutive frames within

the ROI as temporal displacement fields vibration pat-

terns. The motion magnitude is computed as the Eu-

clidean norm of the flow vectors, and the spatial aver-

aging across the ROI produces the final motion time-

series as presented in Equation 4.

S(t) =

1

|ROI|

∑

(x,y)∈ROI

q

u(x,y,t)

2

+ v(x,y,t)

2

(4)

Where u, v are the optical flow vectors, and x, y

are the relative spatial coordinates.

3.2.2 Feature Extraction

The extracted motion timeseries undergoes process-

ing to generate discriminative features for fault clas-

sification. The preprocessing pipeline includes DC

component removal by subtracting the signal mean to

eliminate any constant offset as developed in Equa-

tion 5.

x

i

= S(t

i

) −

1

N

N

∑

j=1

S(t

j

) (5)

With S(t

i

) representing the raw motion timeseries

samples from Equation 4, x

i

are the DC-removed sig-

nal samples, N is the total number of samples. Sta-

tistical measures are computed from the DC-removed

motion signal to capture the temporal characteristics

of each working condition. Particularly, the key time

domain features include the mean, variance, skewness

and zero-crossing rate.

As each operating condition is characterized by

distinct vibrational signatures, this pipeline aims to

generate comprehensive datasets for each working

condition of the captured scene.

3.2.3 Frequency Analysis

Comprehensive frequency domain analysis is per-

formed using Fast Fourier Transform (FFT) to iden-

tify dominant vibrational frequencies and extract

Video-Based Vibration Analysis for Predictive Maintenance: A Motion Magnification and Random Forest Approach

447

(a) Machinery diagnosis Gunt PT500 setup. (b) Balancing apparatus Gunt TM170 setup.

Figure 1: Setups for machinery diagnosis and balancing apparatus.

Figure 2: Video-based vibration analysis framework.

spectral characteristics relevant to the condition mon-

itored. The FFT computation transforms the dis-

crete time-domain signal to frequency domain, with

an implementation of the Discrete Fourier Transform

(DFT).

From the frequency spectrum, multiple discrim-

inative features are extracted for analysis. These

include the total spectral energy (Equation 6), the

maximum amplitude and its corresponding frequency

(Equations 7 and 8), the spectral centroid (Equa-

tion 9), spectral bandwidth (Equation 10), and the

spectral entropy (Equation 11).

Total Energy =

N/2−1

∑

k=0

A(k)

2

(6)

Max Amplitude = max

k

A(k) (7)

HF = f

k

, where k = argmax

j

A( j) (8)

Spectral Centroid =

∑

N/2−1

k=0

f

k

· A(k)

∑

N/2−1

k=0

A(k)

(9)

SB =

v

u

u

t

∑

N/2−1

k=0

( f

k

− f

c

)

2

· A(k)

∑

N/2−1

k=0

A(k)

(10)

Spectral Entropy = −

N/2−1

∑

k=0

P

k

log

2

(P

k

) (11)

Here, A(k) represents the normalized amplitude at

frequency bin k, f

k

is the corresponding frequency, f

c

is the spectral centroid, and P

k

= A(k)/

∑

N/2−1

j=0

A( j)

is the normalized probability density for entropy cal-

culation.

3.2.4 Classification and Validation

The final component of our framework applies Ran-

dom Forest-based machine learning classification to

the comprehensive features extracted from the video-

based vibration analysis. Here, an important step in-

volves a preprocessing pipeline to ensure data quality

through systematic process such as: data structuring

and, 80-20 train-test split using stratified sampling.

Furthermore, the performance evaluation encom-

passes multiple metrics for comprehensive assess-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

448

ment including the accuracy, and the F1-score com-

puted based on obtained true positives, true negatives,

false positives, and false negatives predictions.

In the following section, we will present the re-

sults of our framework in ground truth test rigs.

4 RESULTS AND DISCUSSION

In this section, we present the configuration in which

we captured the machinery scene and the empirical

results we obtained from our proposed framework de-

picted in Figure 2.

4.1 Experimental Setup

The baseline established in subsection 3.1, we

recorded a set of 1 minute videos of both the Gunt

PT500 and Gunt TM170 (Figure 1) at 4K@60FPS

resolution for each of their operating conditions run-

ning at 250RPM. More precisely, for the Gunt PT500,

the camera has been installed from above at 50cm

height of the base plate supporting the machine; and

from the front at 91.5cm away and elevated at 120cm

height. Regarding the Gunt TM170, we recorded

from the front view at 11cm away with 12cm height

then 16cm away with 20cm height.

Furthermore, we fed the captured scenes into our

proposed framework which runs on a Linux distribu-

tion in a DELL Intel Core i5-2410M 2.3GHz 8GB

RAM to extract and process the features relevant for

frequency analysis.

4.2 Dataset Description

The dataset extraction of our proposed framework

maximizes data utilization and create sufficient train-

ing samples using a sliding window approach imple-

mented for temporal segmentation. More particularly,

each video is systematically divided into overlapping

clips of 20s with a 5s overlap interval. Thus, this

segmentation strategy produces nine clips per initial

video, where the first clip encompasses the range 0

to 20s, the second one covers 5s to 25s, and so on.

We obtained a set of 272 compiled clips for each of

the operational condition. Hence, this overlapping

segmentation approach served multiple purposes: it

increased the available training data from the limited

original recordings, with temporal continuity between

adjacent clips, and ensured that transient vibrational

events were captured in multiple segments.

4.3 Vibration Signal Analysis

The video processing pipeline successfully extracted

meaningful vibration signatures for each of the four

monitored test conditions: normal operation, 10g im-

balance, 37g imbalance, and outer ring bearing fault.

The extracted time-domain signals reveal clear,

condition-dependent signatures. In the healthy

state (Fig. 3a), oscillation amplitudes remain within

±0.002, reflecting a stable baseline with only spo-

radic spikes. Introducing a 10g imbalance (Fig. 3b)

elevates peak excursions to nearly ±0.4, indicating

emergent impulsive events and increased variabil-

ity. Under 37g loading (Fig. 3c), the system ex-

hibits the most severe response, with swings up to

±5 and sustained high-magnitude bursts, underscor-

ing the method’s sensitivity to imbalance severity.

The outer-ring fault (Fig. 3d) produces moderate am-

plitudes (≈ ±0.7) but with pronounced periodic im-

pacts characteristic of bearing defects, distinguishing

it from pure imbalance cases. Together, these patterns

confirm that our pipeline reliably captures both subtle

and extreme vibration behaviors directly from video

data.

The FFT results further validate condition sep-

arability. The normal spectrum (Fig. 4a) shows

low-level peaks near 8Hz, 23.5Hz, and 27Hz (am-

plitudes ≈ 2.5 × 10

−5

), representing nominal rota-

tional harmonics. With a 10g mass (Fig. 4b), energy

concentrates between 20–30Hz, peaking at 28–29Hz

(≈ 0.012), signaling elevated high-frequency con-

tent due to imbalance. The 37g case (Fig. 4c) dis-

plays a broader spectral footprint, with significant

components at 3Hz, 19Hz, and 20Hz (0.1–0.12),

reflecting combined low- and high-frequency exci-

tation. Faulted bearing (Fig. 4d) presents distinct

peaks at 21Hz, 27Hz, and 28.5Hz (0.017–0.018),

yielding a spectral profile that diverges from both

healthy and imbalance conditions. The four-order-

of-magnitude span in amplitude (2.5 × 10

−5

–0.12)

demonstrates that video-derived spectra quantita-

tively capture condition-specific dynamics suitable

for reliable classification.

Spectrograms analysis add temporal resolution to

these findings. Healthy state (Fig. 5) maintain uni-

form energy across the band at –40 to –20dB. The 10g

imbalance (Fig. 6) shows band-limited energy surges

of ≈ –60dB at rotational harmonics, while the 37g

condition (Fig. 7) exhibits stronger bursts between

10–20Hz, particularly at 7–15s approaching –20dB.

The bearing fault (Fig. 8) is marked by a high-energy

event at 6–8s spanning 15–25Hz greater than –60dB,

a different signature from imbalance cases.

Collectively, analysis of 272 video clips yielded

Video-Based Vibration Analysis for Predictive Maintenance: A Motion Magnification and Random Forest Approach

449

(a) Normal operation. (b) 10g imbalance.

(c) 37g imbalance. (d) Faulty bearing.

Figure 3: Time-domain vibration signals extracted from video recordings under different conditions.

(a) Normal operation. (b) 10g imbalance.

(c) 37g imbalance. (d) Outer ring fault.

Figure 4: Frequency spectra from FFT analysis of vibration signals under different conditions.

14 discriminative frequency features. Their consis-

tency across time, frequency, and time–frequency do-

mains underpins the subsequent Random Forest clas-

sifier’s strong performance.

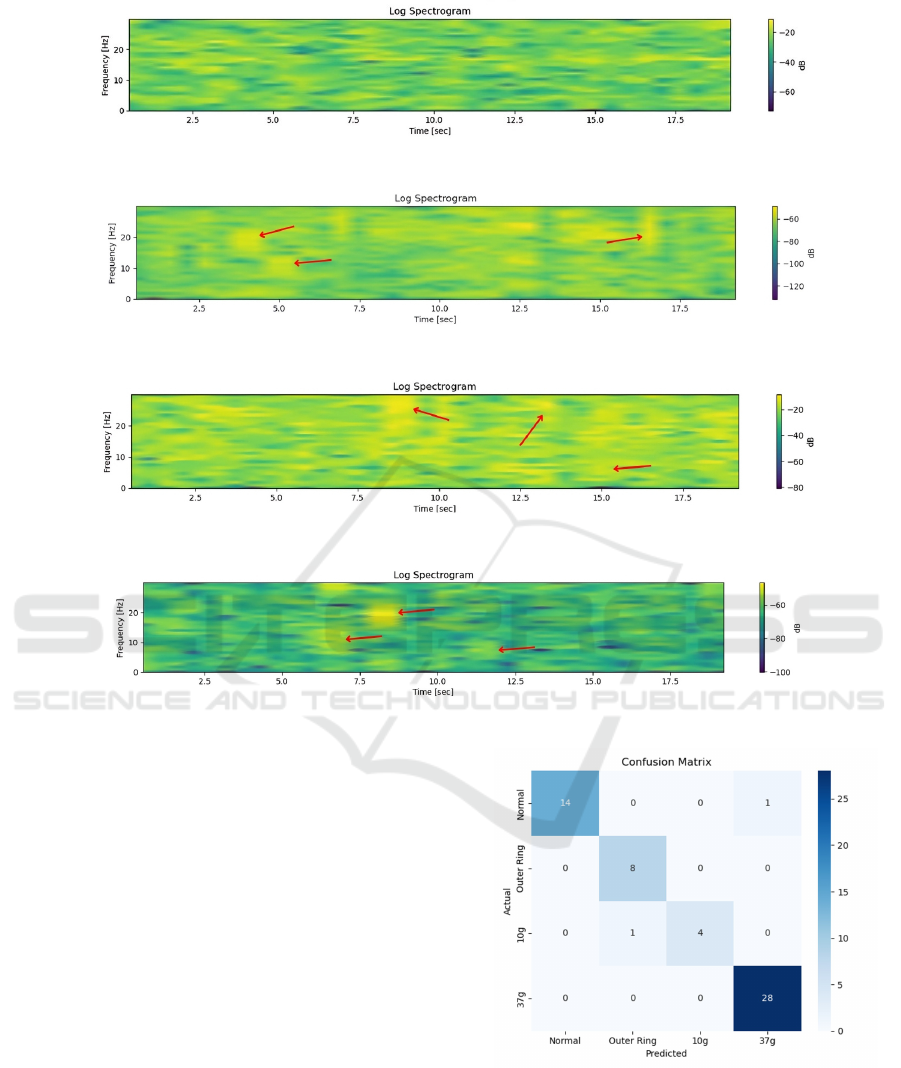

4.4 Classification Performance

The Random Forest classifier demonstrated excellent

performance in distinguishing between the four ma-

chinery conditions using the video-derived features.

We configured its parameters with 200 estimators at a

maximum depth of 10. To ensure robust model eval-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

450

Figure 5: Spectrogram analysis under normal operating condition.

Figure 6: Spectrogram analysis for 10g imbalance showing time-varying frequency patterns.

Figure 7: Spectrogram analysis for 37g imbalance with time-varying frequency patterns.

Figure 8: Spectrogram analysis for faulty condition showing time-varying frequency patterns.

uation, the dataset was partitioned using an 80 − 20

split, allocating 80% of the clips (218 clips) for train-

ing purposes and reserving the remaining 20% (54

clips) for testing. Hence, the model achieved an over-

all accuracy of 96.7% on the test set, demonstrating

robust fault detection capabilities using solely video-

derived vibration features.

Moreover, the macro-averaged F1-score of 0.965

indicates balanced performance across all fault cate-

gories. Figure 9 presents the resulting confusion ma-

trix, where each cell represents the number of classi-

fied video clips from the 54 clips test set, revealing

detailed classification patterns and potential areas for

improvement.

5 CONCLUSIONS

This work confirms that video-based motion mag-

nification can serve as a reliable, non-contact ap-

proach for machinery fault diagnosis. We introduced

Figure 9: Classification performance of all conditions.

a feature extraction pipeline capturing both tempo-

ral and frequency characteristics of vibrations di-

rectly from video frames, and validated it, based on

ground-truth measurements of rotating equipment un-

like prior synthetic-data studies.

Experimental tests on the Gunt PT500 and TM170

Video-Based Vibration Analysis for Predictive Maintenance: A Motion Magnification and Random Forest Approach

451

under four operating conditions demonstrated that

the extracted features effectively discriminate normal,

faulty, and imbalance states. A Random Forest clas-

sifier trained on these features achieved 96.7% accu-

racy and a macro-averaged F1-score of 0.965, under-

scoring the method’s robustness. Nevertheless, future

work will extend this framework to diverse machin-

ery types and fault scenarios, and explore real-time

processing for continuous industrial monitoring.

ACKNOWLEDGEMENTS

This work is funded by the Japan International Coop-

eration Agency (JICA) Program, Egypt – Grant Num-

ber (TB1-25-4: ”Contactless Predictive Maintenance

for Rotating Equipment: An AI and Vision-Based

Approach”).

REFERENCES

de Koning, M., Machado, T., Ahonen, A., Strokina, N., Di-

anatfar, M., De Rosa, F., Minav, T., and Ghabcheloo,

R. (2024). A comprehensive approach to safety for

highly automated off-road machinery under regulation

2023/1230. Safety Science, 175:106517.

Everingham, M., Van Gool, L., Williams, C. K., Winn, J.,

and Zisserman, A. (2010). The pascal visual object

classes (voc) challenge. International journal of com-

puter vision, 88:303–338.

Gunt (2025a). Pt 500 machinery diagnostic system, base

unit.

Gunt (2025b). Tm 170 balancing apparatus.

Kalaiselvi, S., Sujatha, L., and Sundar, R. (2018). Fabri-

cation of mems accelerometer for vibration sensing in

gas turbine. In 2018 IEEE SENSORS, pages 1–4.

Ke, J., Wang, Q., Wang, Y., Milanfar, P., and Yang, F.

(2021). Musiq: Multi-scale image quality transformer.

In Proceedings of the IEEE/CVF international confer-

ence on computer vision, pages 5148–5157.

Kiranyaz, S., Devecioglu, O. C., Alhams, A., Sassi, S.,

Ince, T., Avci, O., and Gabbouj, M. (2024). Exploring

sound vs vibration for robust fault detection on rotat-

ing machinery. IEEE Sensors Journal.

Lado-Roig

´

e, R., Font-Mor

´

e, J., and P

´

erez, M. A. (2023).

Learning-based video motion magnification approach

for vibration-based damage detection. Measurement:

Journal of the International Measurement Confedera-

tion, 206.

Lado-Roig

´

e, R. and P

´

erez, M. A. (2023). Stb-vmm:

Swin transformer based video motion magnification.

Knowledge-Based Systems, 269:110493.

Li, H., Sun, Y., Adumene, S., Goleiji, E., and Yazdi,

M. (2025). Machinery safety improvement in

manufacturing-oriented facilities: a strategic frame-

work. The International Journal of Advanced Man-

ufacturing Technology, pages 1–30.

Lima, J. A., Miosso, C. J., and Farias, M. C. (2025). Syn-

flowmap: A synchronized optical flow remapping for

video motion magnification. Signal Processing: Im-

age Communication, 130:117203.

Lin, T.-Y., Maire, M., Belongie, S., Hays, J., Perona, P.,

Ramanan, D., Doll

´

ar, P., and Zitnick, C. L. (2014).

Microsoft coco: Common objects in context. In Com-

puter vision–ECCV 2014: 13th European conference,

zurich, Switzerland, September 6-12, 2014, proceed-

ings, part v 13, pages 740–755. Springer.

Nieto, J. J. (2025). Digital twins, history, metrics and future

directions. Mechatronics Technology, 2(1).

Oh, T.-H., Jaroensri, R., Kim, C., Elgharib, M., Durand, F.,

Freeman, W. T., and Matusik, W. (2018). Learning-

based video motion magnification. In Proceedings of

the European conference on computer vision (ECCV),

pages 633–648.

Song, Y., Zhuang, Y., Wang, D., Li, Y., and Zhang, Y.

(2025). Fault diagnosis in rolling bearings using

multi-gaussian attention and covariance loss for single

domain generalization. IEEE Transactions on Instru-

mentation and Measurement.

Wadhwa, N., Rubinstein, M., Durand, F., and Freeman,

W. T. (2013). Phase-based video motion processing.

ACM Transactions on Graphics (ToG), 32(4):1–10.

Wadhwa, N., Rubinstein, M., Durand, F., and Freeman,

W. T. (2014). Riesz pyramids for fast phase-based

video magnification. In 2014 IEEE International

Conference on Computational Photography (ICCP),

pages 1–10. IEEE.

Wu, H.-Y., Rubinstein, M., Shih, E., Guttag, J., Durand, F.,

and Freeman, W. (2012). Eulerian video magnifica-

tion for revealing subtle changes in the world. ACM

transactions on graphics (TOG), 31(4):1–8.

Xu, X. and Lu, Y. (2025). Acoustic modal analysis method

for helicopter acoustic scattering. AIAA Journal,

pages 1–21.

Yang, Y. and Jiang, Q. (2024). A novel phase-based video

motion magnification method for non-contact mea-

surement of micro-amplitude vibration. Mechanical

Systems and Signal Processing, 215.

Zang, Z., Yang, X., Zhang, G., Li, S., and Chen, J. (2025).

Video-based subtle vibration measurement in the pres-

ence of large motions. Measurement, 240:115559.

Zhang, G., Hou, J., Wan, C., Li, J., Xie, L., and Xue,

S. (2025). Non-contact vision-based response recon-

struction and reinforcement learning guided evolu-

tionary algorithm for substructural condition assess-

ment. Mechanical Systems and Signal Processing,

224:112017.

Zhao, H., Zhang, X., Jiang, D., and Gu, J. (2023). Research

on rotating machinery fault diagnosis based on an im-

proved eulerian video motion magnification. Sensors

2023, Vol. 23, Page 9582, 23:9582.

Zhong, S., Jin, G., Chen, Y., Ye, T., and Zhou, T. (2025).

Review of vibration analysis and structural optimiza-

tion research for rotating blades. Journal of Marine

Science and Application, 24(1):120–136.

´

Smieja, M., Mamala, J., Pra

˙

znowski, K., Ciepli

´

nski, T.,

and Łukasz Szumilas (2021). Motion magnification

of vibration image in estimation of technical object

condition-review. Sensors, 21.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

452