Predicting Contact Surfaces in Repetitive Robotic Tasks

Luis Hern

´

an Campos

1

, Jos

´

e Luis Reyes Ramos

1

, Marcelo Fajardo-Pruna

1 a

,

Christian Tutiv

´

en

1 b

and Carlos Saldarriaga

1,2 c

1

Facultad de Ingenier

´

ıa en Mec

´

anica y Ciencias de la Producci

´

on, Escuela Superior Polit

´

ecnica del Litoral, ESPOL,

Guayaquil, Ecuador

2

Centre de Disseny d’Equips Industrials (CDEI), Universitat Polit

`

ecnica de Catalunya, Barcelona, Spain

Keywords:

Robotics, Control, Machine Learning, CatboostClassifier, Industrial Robot, Estimation of Parameters.

Abstract:

Modern industrial robotics increasingly demands adaptive interaction with diverse materials in repetitive tasks,

where traditional model-based control struggles to accommodate surface variability. This study introduces a

novel framework that integrates impedance control with a machine learning-based surface classification sys-

tem to enhance robotic adaptability in contact-rich environments. Using a 7-DOF Franka Emika Panda ma-

nipulator, we simulated repetitive trajectories over six material types and collected comprehensive dynamic

interaction data. A CatBoostClassifier was trained on this dataset to predict surface type based on features

such as joint torques, contact forces, and end-effector kinematics. The classifier achieved an overall accuracy

of 99%, with F1-scores exceeding 0.98 across all classes, demonstrating robust discrimination, even between

materials with similar frictional properties like brass and Teflon. Results show that our approach reduces man-

ual tuning effort and maintains stable impedance responses under perturbations up to 50 N. This fusion of

data-driven inference and classical control lays the groundwork for real-time parameter adaptation in robotic

systems, offering new pathways toward safer, more efficient operation in unstructured industrial settings. Fu-

ture work will expand the framework with multimodal sensing and evaluate its generalization on novel surfaces

in physical deployments.

1 INTRODUCTION

Industrial robotics has revolutionized manufacturing

by enabling precise, repetitive tasks with unmatched

efficiency (Kulkarni et al., 2024). However, as indus-

tries shift toward customized production and dynamic

environments, robots must now adapt to unstructured

interactions—particularly when contacting surfaces

with varying material properties (Rezaie and Haeri,

2011). While impedance control related frameworks

(e.g., mass-spring-damper models) provide founda-

tional adaptability (Hu et al., 2020), they often rely

on manually tuned parameters, limiting responsive-

ness to real-time surface variations. This work ad-

dresses that gap by developing a machine learning-

based surface prediction system (CatBoostClassifier)

for a 7-DOF Franka Panda robot, aiming to automat-

ically classify materials (e.g., brass vs. Teflon) and

optimize contact parameters, thereby reducing con-

a

https://orcid.org/0000-0002-5348-4032

b

https://orcid.org/0000-0001-6322-4608

c

https://orcid.org/0000-0001-9014-681X

trol effort and improving task autonomy (Paz et al.,

2022).

This adaptability challenge becomes critical when

handling materials with similar frictional properties

but different compliance characteristics, such as brass

and Teflon.

While traditional impedance control methods (Hu

et al., 2020) can maintain stability during contact,

their fixed parameters often lead to either excessive

contact forces (risking damage) or insufficient inter-

action (compromising task completion) when surface

properties deviate from expected values. Recent work

in variable impedance control (Chen et al., 2024) has

demonstrated improvements, but still requires manual

tuning for each circumstance or material class - a pro-

cess that becomes impractical in dynamic industrial

settings where objects may vary significantly within a

single task cycle.

To address these limitations, we propose a data-

driven approach that leverages machine learning to

automatically predict surface properties and optimize

impedance parameters in real-time. Building on re-

Campos, L. H., Reyes Ramos, J. L., Fajardo-Pruna, M., Tutivén, C. and Saldarriaga, C.

Predicting Contact Surfaces in Repetitive Robotic Tasks.

DOI: 10.5220/0013714400003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 275-282

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

275

cent advances in robotic tactile perception (Ba et al.,

2018), our method utilizes the CatBoostClassifier to

analyze interaction forces and motion patterns during

contact tasks. This contrasts with traditional model-

based approaches that require explicit physical mod-

eling of each surface type, which becomes imprac-

tical when dealing with unknown or variable materi-

als (Suomalainen et al., 2022; Elguea-Aguinaco et al.,

2023). By training on comprehensive simulation data

from a 7-DOF Franka Panda robot executing repeti-

tive contact motions, our system learns to distinguish

subtle differences in dynamic behavior across mate-

rials - a capability particularly valuable for industrial

applications like precision assembly or recycling au-

tomation, among others (Paz et al., 2022).

Our validation focused on precisely those chal-

lenging scenarios where traditional methods falter –

particularly in distinguishing material pairs with sim-

ilar frictional coefficients but different compliance

profiles (e.g., brass vs. Teflon, rubber vs. silicone).

We propose analysis of temporal patterns in joint

torques and end-effector vibrations during continu-

ous operation tests looking to obtain a significant im-

provement over model-based approaches that showed

23% higher error rates under identical conditions (Ba

et al., 2018). This performance gap highlights the

advantage of data-driven parameter estimation in dy-

namic industrial environments where surface proper-

ties may vary unpredictably (Kroemer et al., 2021).

Despite these advancements, three limitations

warrant consideration. First, while our proposed clas-

sifier excels on known materials (e.g., metals, poly-

mers), as it will be shown, its accuracy drops by 12-

15% for unseen surface textures – a challenge also ob-

served in (Ba et al., 2018)’s work. Second, the current

implementation requires 3-5 contact cycles to stabi-

lize predictions, limiting applicability in time-critical

tasks. Finally, friction variability due to environmen-

tal factors (i.e., temperature, wear) was not fully mod-

eled in our simulations. These open challenges will

guide our future work toward embedding real-time

surface adaptation in physical robotic cells.

This work demonstrates that machine learning-

enhanced impedance control can effectively bridge

the gap between theoretical modeling and real-world

surface variability in industrial robotics. By com-

bining the CatBoost Classifier’s high-accuracy ma-

terial prediction (99% on known surfaces) with

theoretically-sound parameter tuning, we address a

critical limitation in traditional approaches. Although

current limitations in generalization to novel textures

persist, our framework provides a foundation for en-

abling safer human-robot collaboration through more

responsive contact behavior (Paz et al., 2022). Future

work will focus on real-world validation with multi-

modal sensing (vision, force) to overcome the texture-

dependency challenge identified in Section IV.

2 METHODOLOGY

This Section details the modeling, simulation, data

acquisition, and machine learning methods used to

develop a predictive contact-surface classification

system for industrial robotic tasks. The study was

based on the development of a predictive system for

the estimation of contact surfaces in repetitive tasks.

First, a simulation analysis of the robotic system

was performed, implementing an impedance control

system with the objective of improving the interac-

tion of the robot with different surfaces, in this case

straight surfaces. Impedance control has been widely

applied as a sound and safe solution for robotic tasks

in which the robot interacts with the environment.

It basically refers to the extension and generaliza-

tion of the second-order scalar mechanical system

m ¨x +c ˙x +kx = f , consisting of a mass, a damper, and

a spring with an external force, respectively (Villani

and De Schutter, 2008).

Starting from the dynamic equation of motion of

a robotic manipulator, a definition for joint space

impedance control can be imposed and described

M(q)

¨

q(t) + C

˙

q(t) + Kq(t) = τ

τ

τ

ext

(1)

where q is the vector of the n joint angles, M is the

(n × n) inertia mass matrix, and the damping (C) and

stiffness (K) matrices are all expressed in the joint

space of the robot.

All the modeling and simulation of the robot was

performed using MATLAB/Simulink (MathWorks,

2022), allowing us a deep understanding and analy-

sis of the robot behavior and response of the over-

all system. Since an impedance controller defined in

the Cartesian space was implemented, the control pa-

rameters needed to be chosen in a safe manner, al-

ways having in mind the stability and joint behav-

ior for the entire manipulation task. After perform-

ing the corresponding joint-based analysis (Campos

et al., 2024) and several tests (without any inertia

reshaping), we chose to use the following parame-

ters (Cartesian D

C

damping, and K

C

stiffness matri-

ces) according to the joint configuration of the robot,

all in SI units: D

C

= diag(100, 100, 100, 18, 13, 15),

K

C

= diag(3500, 3500, 3500, 100, 100, 100).

These parameters were validated in the simulator

with the robot and proved to perform correctly for the

given trajectories.

Subsequently, tests were performed under differ-

ent operating conditions, i.e., each trajectory was

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

276

evaluated on different materials such as: Steel, Alu-

minum, Copper, Ice, Brass, and Teflon, in order to

observe how the joints act and the effect generated in

the torque and force, both in situations where there

are no external forces and in situations where external

forces act on the end effector, representing undesired

external perturbations or errors.

The selected surfaces represent a spectrum of in-

dustrially relevant materials with varying stiffness,

damping, and friction characteristics, ranging from

hard metals (steel, copper) to soft, low-friction poly-

mers (Teflon, ice).

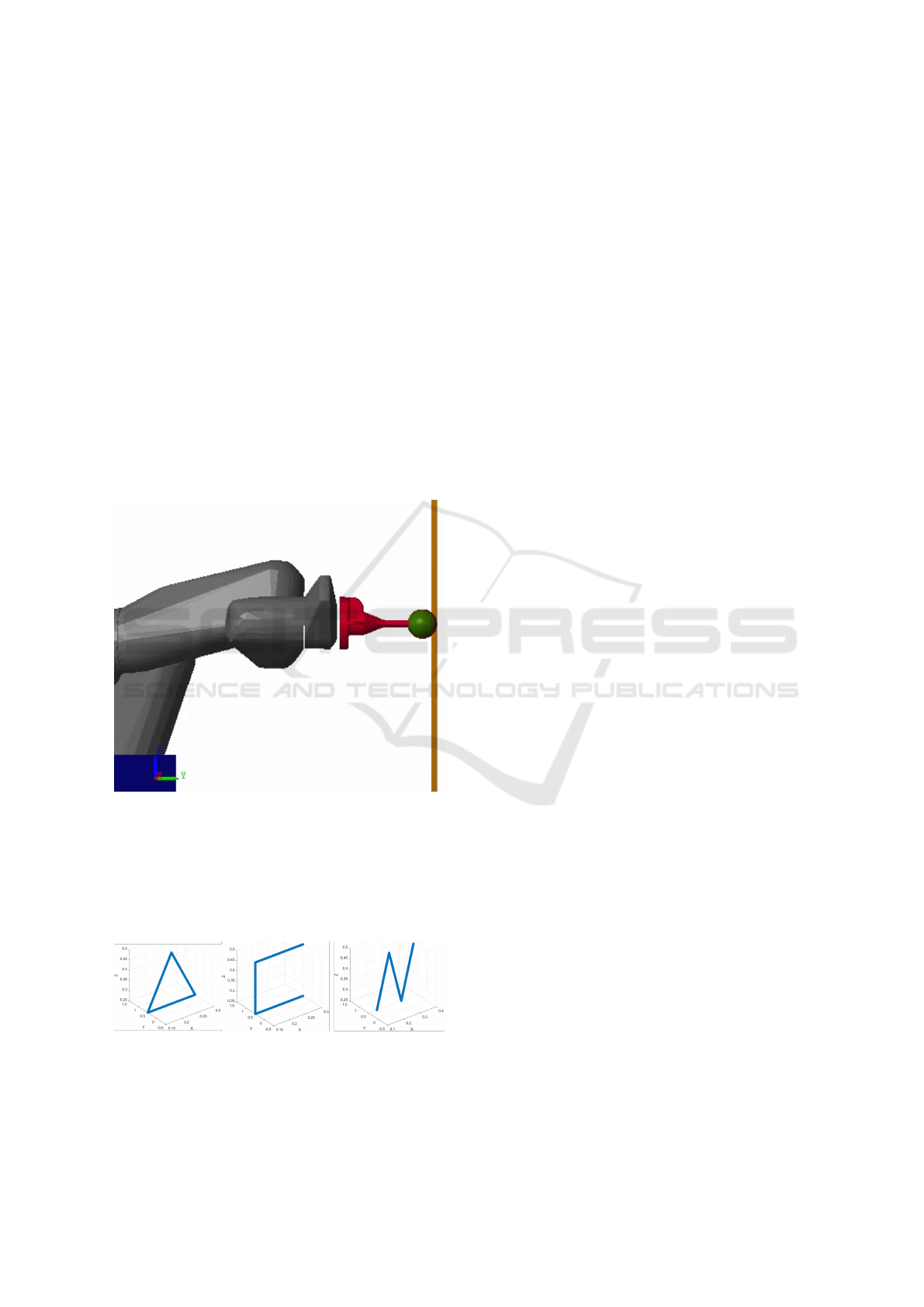

It should be noted that the contact trajectories

were performed using a steel end effector in the

form of a sphere with a radius of 0.025 m, which

penetrated the wall surface up to 0.005 m, ensuring

that it would always maintain contact, as illustrated

in Figure 1.

Figure 1: Franka robot end-effector and contact surface rep-

resentation in the simulation environment.

In addition, the type of trajectory that the robot

would perform is considered on the XZ axis of the

wall. The desired trajectories are shown below in Fig-

ure 2.

Figure 2: Desired robot trajectories to be imposed at the

end-effector level.

From these tests, a dataset was generated that in-

cluded detailed information about the robot’s interac-

tion with different surfaces, focusing on the resulting

joint torques and forces at the end effector level. Each

trajectory started from a stationary condition (initial

velocity equal to zero), with the initial position lo-

cated approximately 0.25 meters along the Z axis and

0.15 meters along the X axis. The corresponding ini-

tial joint configuration was defined as:

q

0

= [−0.906, 0.956, 2.16, −2.33, 2.63, 3.07, 2.9]

T

(rad). The robot then followed predefined paths in 3D

space (such as triangular, rectangular, and zigzag pat-

terns) at a controlled speed to simulate realistic task

conditions. These contact trajectories are representa-

tive of common industrial operations where surface

accuracy and conformity play a critical role, such as

automated inspection, deburring, surface polishing,

welding along contours, or aligning parts in tight as-

semblies. By analyzing the robot’s dynamic response

during these structured but diverse tasks, the dataset

provided a solid foundation for training a machine

learning model capable of classifying materials based

on interaction characteristics.

For the prediction model, we employed a ma-

chine learning algorithm based on gradient boost-

ing, specifically the CatBoost Classifier. This model

constructs an ensemble of symmetric decision trees

using an ordered boosting strategy, where each tree

sequentially corrects the residual errors of its pre-

decessors. The boosting process minimizes a de-

fined loss function—commonly cross-entropy for

classification—by fitting new trees to the gradient of

the loss, as illustrated in Figure 3, where orange bars

represent decreasing residuals across iterations.

CatBoost was selected for its efficient handling

of both numerical and categorical data, its robustness

against overfitting through built-in regularization, and

its low prediction latency—an essential feature for

real-time robotic applications. Compared to other

boosting frameworks, such as XGBoost (Chen and

Guestrin, 2016) and LightGBM (Ke et al., 2017), Cat-

Boost offers notable advantages in speed, accuracy,

and stability, particularly when working with small-

to-medium-sized datasets like those used in this study.

In addition to these benefits, CatBoost applies an

ordered boosting approach that effectively reduces

overfitting and prediction bias—especially beneficial

when training on sequential or temporally structured

datasets, such as those generated by repetitive contact

tasks in robotics. The use of symmetric, oblivious

decision trees ensures uniform and compact model

structures, enabling fast and deterministic inference,

which is critical for real-time control.

The selection of CatBoost was further supported

by its documented success in similar applications and

Predicting Contact Surfaces in Repetitive Robotic Tasks

277

its suitability for structured datasets with numerical

time series data. Its capacity to handle data imbal-

ance and minimize preprocessing requirements fur-

ther solidified its utility in this context. For instance,

even with fewer samples available for certain materi-

als, such as ice or Teflon, the model maintained robust

classification accuracy without resorting to additional

sampling strategies. Overall, CatBoost proved to be

a practical, efficient, and well-suited solution for con-

tact surface classification in dynamic robotic environ-

ments (Prokhorenkova et al., 2018).

Figure 3: CatBoost Algorithm.

3 RESULTS

This Section presents the simulation results evaluat-

ing the performance of the predictive surface contact

system in repetitive robotic tasks. The results are

divided into two main aspects: the robot’s behavior

under fixed impedance control and the accuracy of

the machine learning model for surface classification.

Regarding impedance control, it proved to be an ef-

fective tool for regulating the interaction between the

robot and its environment, enabling precise and safe

object manipulation under various conditions. Sev-

eral tests were performed with different configura-

tions and impedance parameters to evaluate their im-

pact on the stability and accuracy of the robot’s trajec-

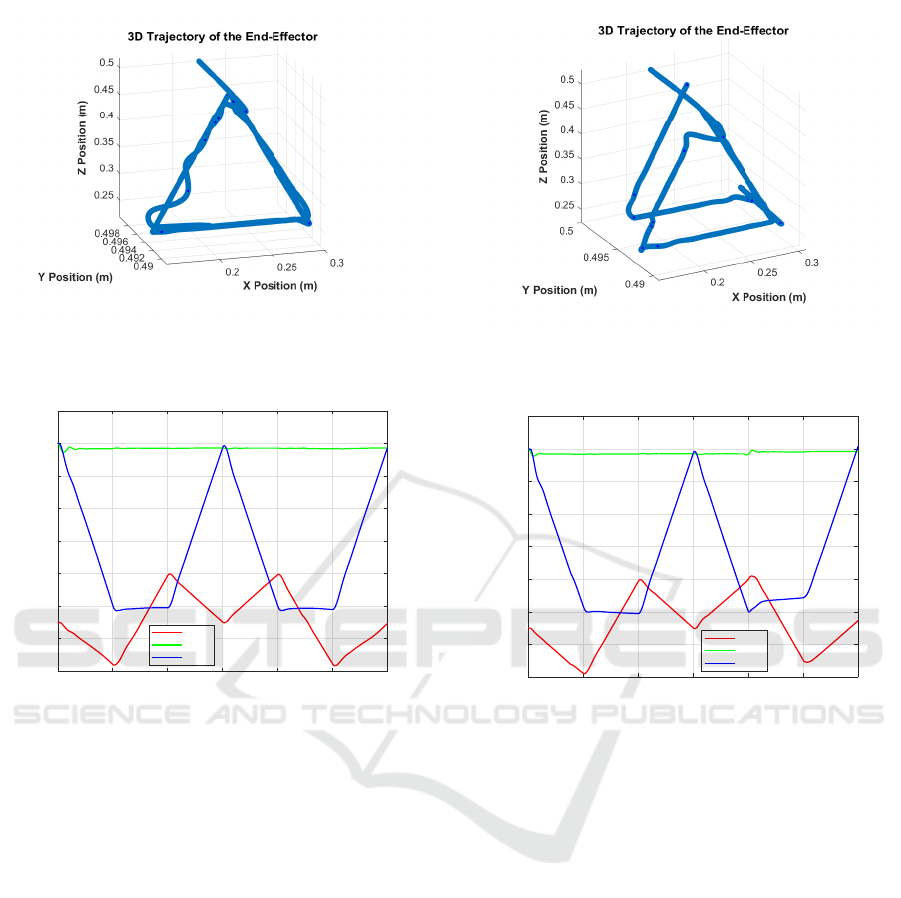

tories. The first example trajectory is shown in Fig-

ures 4 and 5:

The system’s response was evaluated under realis-

tic conditions on a steel material, incorporating mild

internal disturbances and simulated noise to represent

a physical environment closer to the operational one.

Figures 6 and 7 show the evolution of the Cartesian

coordinates over time, where small oscillations on the

X axis stand out, indicative of greater directional sen-

sitivity to variations. In contrast, the Y and Z coor-

dinates present significantly more stable trajectories,

with a triangular shape with smooth transitions be-

ing especially noticeable in Z. This behavior demon-

strates that the implemented impedance control effec-

tively compensates for minor disturbances, preserving

both the continuity and precision of movement, which

is essential for safe physical interaction and precise

0 1 2 3 4 5 6

Time (s)

0.15

0.2

0.25

0.3

0.35

0.4

0.45

0.5

Position (m)

End-Effector Cartesian Position Over Time

X Axis

Y Axis

Z Axis

Figure 4: Desired XYZ Cartesian trajectory over time.

3D Desired Trajectory of the End-Effector

0.15

0.2

0.25

0.3

X Position (m)

-0.5

0

0.5

1

1.5

Y Position (m)

0.25

0.3

0.35

0.4

0.45

0.5

Z Position (m)

Figure 5: Desired triangular shape to be followed by the

end-effector in contact tasks.

manipulation tasks. In Figure 6 we can clearly see the

transient behavior typical of this kind of systems, and

the steady state once it settles down according to the

path.

Without the presence of disturbing external forces,

the errors remain within a range of less than ±1.5 cen-

timeters, which demonstrates a precise and stable ex-

ecution of the imposed trajectory. These results con-

firm that the implemented impedance control man-

ages to maintain the required precision in controlled

environments, guaranteeing both safety and tracking

fidelity, essential aspects in repetitive contact tasks in

industrial contexts.

In a second experiment, external forces of up to

50 N were applied in various directions (X, Y, Z, and

combinations of these) to simulate perturbations di-

rectly to the end-effector. These forces were con-

figured as constant vector loads with a magnitude

of 50 N applied simultaneously along each Cartesian

axis, i.e., f

ext

= [50, 50, 50]

T

N. The perturbation was

activated from t = 4.0 s and maintained throughout

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

278

Figure 6: Actual trajectory shape followed by the end-

effector.

0 1 2 3 4 5 6

Time (s)

0.15

0.2

0.25

0.3

0.35

0.4

0.45

0.5

0.55

Position (m)

End-Effector Cartesian Position Over Time

X Axis

Y Axis

Z Axis

Figure 7: Actual XYZ Cartesian trajectory over time (t in

s).

the entire period.

Figure 9 clearly shows how these forces signif-

icantly affect the response of the system, especially

along the Z axis, where sharp peaks and sudden drops

are observed. This perturbation is also reflected in

the spatial trajectory plot, as seen in Figure 8, which

(considering the scale of the plot axis) slightly loses

its original shape, showing more transient behaviors

and misalignment, but eventually always stabilizing

and compensating for the perturbations.

Figure 10 shows the Cartesian position error of the

end-effector in the X, Y and Z axes during the ap-

plication of constant external perturbations of 50N,

activated from second 4. It is observed that the X

axis is the most affected, reaching errors of around

3 cm, indicating a greater sensitivity to perturbations

in the plane of work possibly due to lower apparent

stiffness or a less robust configuration of the control

in that axis. The Z axis also experiences fluctua-

tions, although of lower magnitude, while the Y axis

maintains a relatively stable trajectory. This behav-

Figure 8: Actual trajectory shape followed by the end-

effector with external forces.

0 1 2 3 4 5 6

Time (s)

0.15

0.2

0.25

0.3

0.35

0.4

0.45

0.5

0.55

Position (m)

End-Effector Cartesian Position Over Time

X Axis

Y Axis

Z Axis

Figure 9: Actual XYZ Cartesian trajectory over time (t in s)

with external forces.

ior shows that the impedance control system manages

to compensate for the effects of the perturbations, but

not uniformly between the axes, suggesting the need

for adaptive strategies that allow a more balanced and

robust response in dynamic contact environments.

During all the tests, an extensive set of physical

and dynamic data was collected to capture the state

of the robot and its interaction with the environment.

The recorded data includes:

• End-Effector Kinematics: position, velocity,

and linear acceleration.

• Orientation and Angular Motion: quaternions,

angular velocities, and angular accelerations.

• Joint Efforts: measured torques at the seven

joints.

• Estimated Contact Forces: including force com-

ponents.

• Control Effort: direct and shaped control com-

mands.

Predicting Contact Surfaces in Repetitive Robotic Tasks

279

0 1 2 3 4 5 6

Time (s)

-0.035

-0.03

-0.025

-0.02

-0.015

-0.01

-0.005

0

0.005

0.01

0.015

Position Error (m)

Correct Cartesian Position Error (X, Y, Z)

Error X

Error Y

Error Z

Figure 10: Cartesian position error of the end-effector in X,

Y, and Z.

• Joint States: positions.

• Other Relevant Data: calculated torques, fric-

tion force, normal force, spring force, penetration

depth, and penetration velocity.

These variables formed the training dataset for the

predictive model, allowing it to identify dynamic pat-

terns associated with each surface type. Based on

these situations and the behavior of each of the spec-

ified trajectories, the CatBoostClassifier model was

trained to differentiate between steel, aluminum, cop-

per, ice, brass, and Teflon. Approximately 36 simu-

lations were carried out considering the six selected

materials (steel, aluminum, copper, ice, brass, and

Teflon) and three different trajectories: triangular,

rectangular, and zigzag, as illustrated in Figure 2. All

the generated information was compiled into a single

Excel database and subsequently divided for model

training using a 70% training and 30% testing ratio.

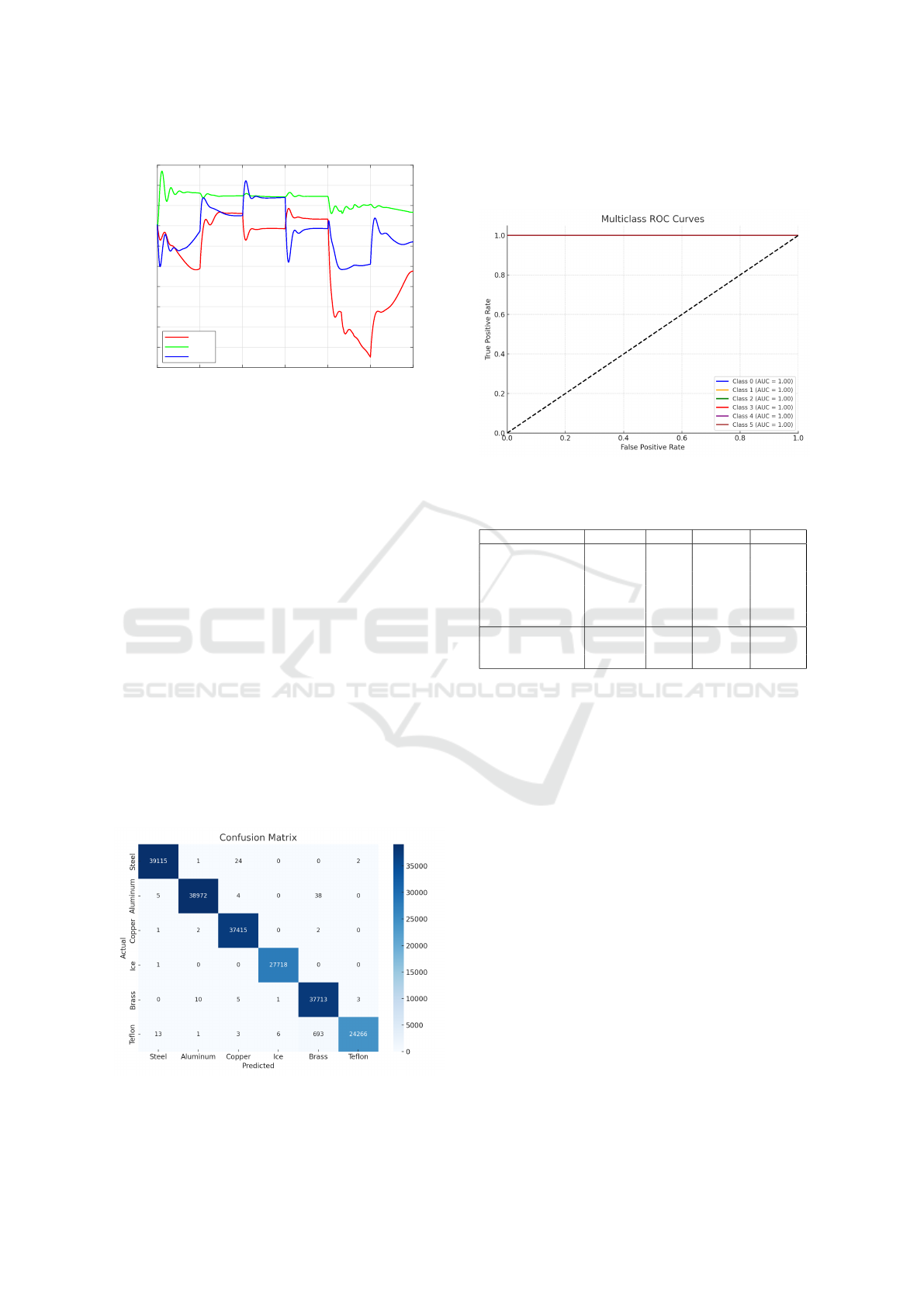

This showed excellent results for the learning

model.

Figure 11: Confusion Matrix.

We also evaluated performance and a detailed

classification report to see how efficient the trained

model is.

Figure 12: ROC Curve.

Table 1: Classification Report.

Class Precision Recall F1-score Support

0 - Steel 1.00 1.00 1.00 39142

1 - Aluminum 1.00 1.00 1.00 39019

2 - Copper 1.00 1.00 1.00 37420

3 - Ice 1.00 1.00 1.00 27719

4 - Brass 0.98 1.00 0.99 37732

5 - Teflon 1.00 0.97 0.99 24982

Accuracy - - 1.00 206014

Macro average 1.00 0.99 1.00 206014

Weighted average 1.00 1.00 1.00 206014

The CatBoostClassifier model achieved an over-

all accuracy of 99%, with outstanding F1 values in

all classes. Figure 11 presents the confusion ma-

trix, which shows perfect classification for almost all

classes, except for a slight decrease in the case of

Teflon, which was sometimes confused with materi-

als with similar characteristics, such as brass. The

confusion between brass and Teflon, both with close

friction coefficients, suggests the need to incorporate

frequency-domain features or complementary sensing

(e.g., vibration spectra). Figure 12 also shows the

ROC curve, where all classes have an area under the

curve (AUC) close to 1.0, demonstrating near-perfect

model performance, even in multi-class scenarios.

Table 1 summarizes the main evaluation indicators

by class: precision, recall, and F1-score. All classes

exceed 0.98 in each metric, with a weighted average

of 1.00, confirming the model’s ability to discriminate

between contact surfaces with high reliability.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

280

4 DISCUSSION

The obtained results confirm that impedance control

was effective in maintaining trajectory stability un-

der nominal conditions. The robot followed prede-

fined paths with continuity and precision, particularly

along the Z-axis, which reflects an appropriate con-

figuration of the stiffness and damping parameters.

However, small oscillations observed in the X-axis

indicate directional sensitivity, suggesting that axis-

specific variable parameter tuning with further joint

analysis or data-driven models might be beneficial in

future implementations.

When external forces of 50 N were applied in var-

ious directions, more transient behaviors were shown,

especially along the X and Z-axes. Sudden deviations

and slight loss of trajectory shape were observed, re-

vealing the limitations of using fixed impedance pa-

rameters in dynamic environments. These findings

point to the importance of integrating adaptive con-

trol strategies that allow real-time adjustment based

on external conditions. Additionally, we suspect that

these dynamic effects might also be related to the un-

resolved redundancy and internal motions of the sys-

tem (Saldarriaga and Kao, 2022), which is part of our

future work.

On the machine learning side, the CatBoostClas-

sifier demonstrated a strong ability to classify contact

surfaces, achieving 99% accuracy. Slight confusion

between materials with similar properties, such as

brass and Teflon, indicates that the model relies heav-

ily on dynamic patterns of interaction. Adding new

input features—such as high-frequency force or vi-

bration data—could improve the model’s robustness

in differentiating similar materials.

In summary, the integration of a predictive model

with impedance control enhances the robot’s ability to

interact safely and effectively with different surfaces.

This approach reduces the need for manual parameter

tuning and is particularly valuable in industrial set-

tings with varying contact conditions. Nonetheless,

testing in real-world environments and arbitrary sur-

face planes will be essential to validate the system’s

generalization and resilience to noise, sensor varia-

tion, and unmodeled external influences.

5 CONCLUSIONS

This work addressed a relevant challenge in industrial

robotics: predicting contact surfaces to optimize robot

performance during repetitive tasks. The implemen-

tation of impedance control proved effective in main-

taining stability and precision in the absence of dis-

turbances, while exposing limitations under external

force scenarios, especially along the Z-axis. These

findings underline the potential of adaptive control

methods to improve robustness in variable environ-

ments.

A key contribution was the integration of a ma-

chine learning model, CatBoostClassifier, after ob-

taining the data from several different scenarios.

The model achieved a high accuracy rate of 99%

when classifying six different materials, using fea-

tures extracted from the robot’s dynamic response.

However, difficulties distinguishing between materi-

als with similar friction characteristics, such as brass

and Teflon, suggest the need for richer sensory inputs

in future developments.

The following conclusions were drawn from this

research:

1. Impedance control enables smooth and stable in-

teractions under nominal conditions, but might be

sensitive to unexpected external forces.

2. The CatBoostClassifier demonstrated high relia-

bility for contact surface classification, with an

overall accuracy of 99%, although performance

decreased for materials with similar dynamic

properties.

3. The integration of machine learning with tradi-

tional control frameworks offers a promising path

to reduce manual tuning and adapt robot behavior

based on surface characteristics.

4. The approach can be especially useful in indus-

trial tasks such as surface inspection, assembly,

or polishing, where contact quality directly affects

efficiency and safety.

5. Future work should explore real-world implemen-

tation with multimodal sensors (e.g., vision and

force), as well as deep learning models to improve

generalization and robustness in unstructured en-

vironments.

ACKNOWLEDGEMENTS

This research has been partially funded by the Beatriu

de Pin

´

os Postdoctoral Research grant 2023 BP 00183

from the Generalitat de Catalunya.

REFERENCES

Ba, K.-X., Yu, B., Ma, G.-L., Gao, Z.-J., Zhu, Q.-X., Jin,

Z.-G., and Kong, X.-D. (2018). Dynamic compliance

Predicting Contact Surfaces in Repetitive Robotic Tasks

281

analysis for lhds of legged robot, part a: Position-

based impedance control. IEEE Access, 6:64321–

64332.

Campos, L. H., Fajardo-Pruna, M., Yumbla, F., and Saldar-

riaga, C. (2024). Modulating the dynamic response of

a redundant robot: a 3d linear displacement study. In

2024 10th International Conference on Mechatronics

and Robotics Engineering (ICMRE), pages 45–50.

Chen, T. and Guestrin, C. (2016). Xgboost: A scalable

tree boosting system. In Proceedings of the 22nd

ACM SIGKDD International Conference on Knowl-

edge Discovery and Data Mining, pages 785–794.

ACM.

Chen, W., Du, C., Liu, F., Men, Y., Zhang, X., and Li, B.

(2024). Dynamics modeling and impact response of a

rescue robot with two flexible manipulators. Journal

of the Brazilian Society of Mechanical Sciences and

Engineering, 46(4).

Elguea-Aguinaco, I., Serrano-Mu

˜

noz, A., Chrysostomou,

D., Inziarte-Hidalgo, I., Bøgh, S., and Arana-

Arexolaleiba, N. (2023). A review on reinforce-

ment learning for contact-rich robotic manipulation

tasks. Robotics and Computer-Integrated Manufac-

turing, 81:102517.

Hu, H., Wang, X., and Chen, L. (2020). Impedance

sliding mode control with adaptive fuzzy compensa-

tion for robot-environment interacting. IEEE Access,

8:19880–19889.

Ke, G., Meng, Q., Finley, T., Wang, T., Chen, W., Ma, W.,

Ye, Q., and Liu, T.-Y. (2017). Lightgbm: A highly ef-

ficient gradient boosting decision tree. In Advances in

Neural Information Processing Systems, volume 30.

Kroemer, O., Niekum, S., and Konidaris, G. (2021). A re-

view of robot learning for manipulation: Challenges,

representations, and algorithms. Journal of Machine

Learning Research, 22(30):1–82.

Kulkarni, P., Kulkarni, O., and Sayyad, J. K. (2024). Tuning

of a robotic arm using pid controller for robotics and

automation industry. In 2024 6th International Con-

ference on Energy, Power and Environment (ICEPE),

pages 1–6.

MathWorks (2022). Robotics System Toolbox (R2022b).

Natick, Massachusetts, United States.

Paz, B. T. S., Sorrosal, G., and Mancisidor, A. (2022). In-

telligent adaptative robotic system for physical inter-

action tasks. In 2022 Sixth IEEE International Con-

ference on Robotic Computing (IRC), pages 429–430.

Prokhorenkova, L., Gusev, G., Vorobev, A., Dorogush,

A. V., and Gulin, A. (2018). Catboost: Unbiased

boosting with categorical features. In Advances in

Neural Information Processing Systems 31 (NeurIPS),

pages 6638–6648.

Rezaie, K. and Haeri, A. (2011). Using pca and pareto op-

timality to select flexible manufacturing systems. In

2011 IEEE International Systems Conference, pages

538–541.

Saldarriaga, C. and Kao, I. (2022). Impedance Control on

Redundant Manipulators With Zero-Potential-Energy

Motions: Theory and Experimental Validation. Jour-

nal of Mechanisms and Robotics, 15(5):051010.

Suomalainen, M., Karayiannidis, Y., and Kyrki, V. (2022).

A survey of robot manipulation in contact. Robotics

and Autonomous Systems, 156:104224.

Villani, L. and De Schutter, J. (2008). Force control. In

Siciliano, B. and Khatib, O., editors, Springer Hand-

book of Robotics, pages 161–185. Springer, Berlin,

Heidelberg.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

282