Real-Time Weld Quality Prediction in Automated Stud Welding:

A Data-Driven Approach

Beatriz Coutinho

1 a

, Bruno Santos

1 b

, Rita Gomes Mendes

2 c

, Gil Gonc¸alves

1 d

and V

´

ıtor H. Pinto

1 e

1

SYSTEC ARISE, Faculdade de Engenharia, Universidade do Porto,

Rua Dr. Roberto Frias, 4200-465 Porto, Portugal

2

ISQ&CTAG Automotive Technologies, Monc¸

˜

ao, Portugal

Keywords:

Stud Welding, Weld Quality Prediction, Sensorisation, Data Acquisition.

Abstract:

Drawn arc stud welding is extensively used in automotive assembly lines for attaching components to vehicle

bodies. In these automated processes, low-quality welds can compromise structural integrity and cause produc-

tion delays due to rework and maintenance. This paper describes the initial development stage of an artificial

intelligence (AI)-based system for real-time weld quality prediction in automated stud welding. The focus

of this first phase is on implementing sensorisation, developing a data acquisition system, and constructing a

dataset that captures the most relevant process variables characterizing the welding process. A Flask-based

application was developed to facilitate data collection, incorporating an automatic character recognition al-

gorithm to extract parameters directly from the control unit display. Initial welding experiments produced a

dataset of approximately 200 samples, with preliminary data analysis validating expected parameter trends.

The results confirm the system’s capability to effectively capture relevant data, forming the basis for future

development of a predictive model aimed at enhancing weld quality monitoring and minimizing assembly line

interruptions.

1 INTRODUCTION

Drawn arc stud welding (SW) is a process that uses

an electric arc to fuse a metal stud to a workpiece.

It is widely used across various manufacturing sec-

tors due to its fast cycle time, and the simplicity and

cost-effectiveness of the equipment involved (Klaric

et al., 2010). The SW process involves generating an

electric arc between the stud and the workpiece (Fig-

ure 1b), which melts both the surface of the workpiece

and the tip of the stud. Once the materials are molten,

the stud is pressed into the workpiece (Figure 1c), and

as the metal cools and solidifies, it forms a strong and

permanent bond (Figure 1d) (T. Lienert, 2011).

In the automotive industry, SW is commonly used

on assembly lines to attach different components to

the car body, with the process typically being fully au-

a

https://orcid.org/0009-0000-9769-6726

b

https://orcid.org/0009-0007-6038-6506

c

https://orcid.org/0009-0008-9899-6729

d

https://orcid.org/0000-0001-7757-7308

e

https://orcid.org/0000-0002-7840-0333

(a) Stud po-

sitioning.

(b) Lift. (c) Plunge. (d) Welded

stud.

Figure 1: Arc stud welding process.

tomated. Low-quality welds in these automated lines

can have a significant impact. If undetected, they may

compromise the structural integrity of the final prod-

uct, and even when detected, they lead to frequent in-

terruptions for maintenance and manual rework, re-

ducing overall efficiency and causing production de-

lays.

This work addresses this issue by proposing the

development of an artificial intelligence (AI) model

capable of predicting, in real-time, if a weld will be

defective. To achieve this, two main stages are re-

Coutinho, B., Santos, B., Mendes, R. G., Gonçalves, G. and Pinto, V. H.

Real-Time Weld Quality Prediction in Automated Stud Welding: A Data-Driven Approach.

DOI: 10.5220/0013714100003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 1, pages 251-258

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

251

quired: (1) the construction of a dataset containing

key process variables that reflect weld quality, and

(2) the selection, training, and testing of a super-

vised machine learning (ML) algorithm to predict the

weld quality outcomes. This project is part of the

GreenAuto Agenda, co-financed by the Portuguese

Recovery and Resilience Plan, that aims to posi-

tion the national automotive industry within the value

chain of low-emission vehicles (Agenda GreenAuto,

2021).

This paper primarily focuses on the first develop-

ment stage: the construction of the dataset . Section 2

presents a literature review supporting the selection

of relevant process parameters. Section 3 outlines

the methodology, including the welding environment

setup, welding experiments, and the key parameters

identified for assessing weld quality. Section 4 fo-

cuses on the implementation details of the sensorisa-

tion setup and the data acquisition system and meth-

ods. Section 5 presents the implementation results

along with a preliminary data analysis. Lastly, Sec-

tion 6 summarizes the main findings and future work

directions.

2 LITERATURE REVIEW

Accurately estimating and predicting the quality of

the stud weld requires identifying the most relevant

process parameters and selecting the appropriate anal-

ysis methods. This Section reviews studies on SW to

help determine the key parameters that best character-

ize the process.

In (Naddaf-Sh et al., 2023), an AI-based approach

was proposed to detect and classify defects in SW. An

experimental setup was created to intentionally pro-

duce defective welds while recording parameters such

as voltage, welding current, linear motor current, and

pin displacement. The study concluded that welding

voltage and pin lift distance were the most influential

factors in defect classification.

Similarly, (Samardzic et al., 2007) explored the ef-

fects of welding voltage and current on weld quality

by applying the process to surfaces with varying con-

tamination levels, such as dust and rust, while keeping

other variables constant. The findings reiterated that

welding voltage plays a critical role in identifying de-

fects, however changes in current alone were found to

be insufficient.

In (Klaric et al., 2010), several factors, such as

welding current, process duration, and stud plunge

and lift were evaluated to assess their impact on weld

penetration depth. The analysis revealed that welding

current and duration were the most significant factors.

Another author (Chambers, 2001) examined the

fundamental principles of SW to support better inter-

pretation of results. It emphasized the importance of

parameters like pin motion, process duration, and cur-

rent, as well as the condition of the welding equip-

ment and environment. Factors such as dust, humid-

ity, and high machine temperatures were found to de-

grade components, especially electrical cables, con-

sequently affecting weld quality. The study also high-

lighted more process specific parameters, including

the pin immersion depth, lift distance, weld duration,

current, and pin-to-plate alignment, as valuable for

characterizing the process.

Lastly, (Al-Sahib et al., 2009) emphasized the sig-

nificance of electrical parameters, particularly cur-

rent, in assessing weld quality. The analysed met-

rics included root mean square (RMS), average, time-

integrated, and peak current, identifying peak current

as the most indicative of weld quality. It also dis-

cussed how the welding duration, current range, plate

thickness, and pin diameter affect the process. Ad-

ditionally, the study highlighted challenges in using

external sensors due to heat, splatter, fumes, and elec-

tromagnetic noise generated during welding.

3 METHODOLOGY

The SW process being modelled involves the attach-

ment of metal studs to metal plates, as seen in Fig-

ure 2, as part of an automotive assembly line. The

process is carried out using an LM310 welding head,

which is powered by a DCE1500 control and energy

unit.

Figure 2: Stud welding process.

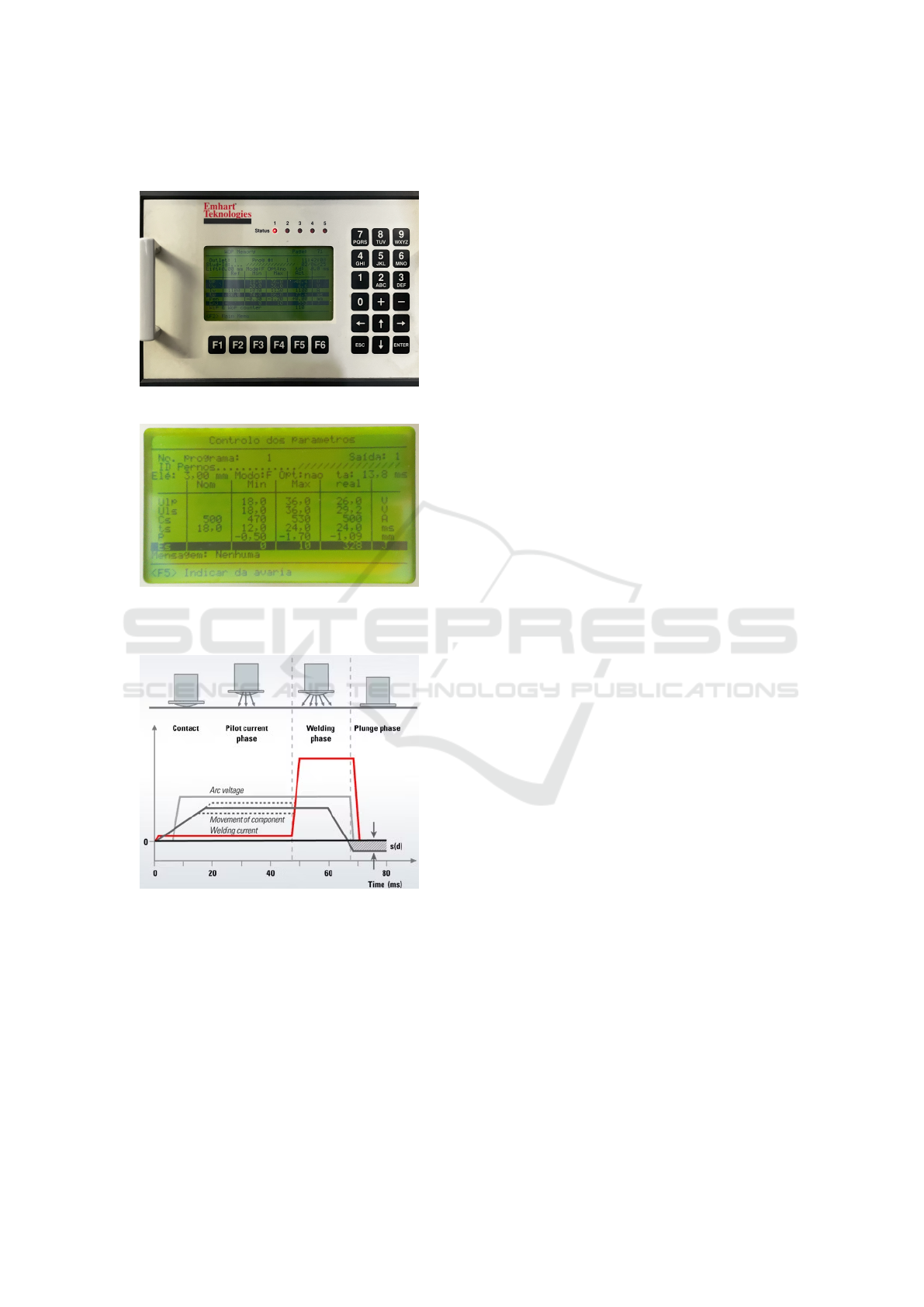

The DCE1500 unit features a small display that

shows some process parameters measured by the sys-

tem itself after each weld, such as the arc voltage in

the pilot current phase, arc voltage in weld current

phase, weld current, welding process duration, stud

drop time, lift distance and process energy, as illus-

trated in Figure 3. Figure 4 outlines the typical weld-

ing cycle under DCE1500 control, showing the tem-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

252

poral evolution of arc voltage, welding current, and

stud movement.

(a) DCE1500 control unit display.

(b) Displayed process parameters (close-up).

Figure 3: Welding system control and display panel.

Figure 4: Typical stud welding cycle under DCE1500 con-

trol (PT. Unggul Semesta, ).

Since the objective is to run the predictive model

in real-time during production, a Physical Twin of the

welding system was developed to enable model de-

velopment and testing in a non-disruptive way. This

Physical Twin will be used in the early project stages

to collect data and perform welding experiments, be-

fore the deployment on the assembly line.

The literature review presented in Section 2

guided the selection of the variables to be monitored

in this case study. These studies helped anticipate how

different welding parameters can affect the final weld

quality and revealed potential challenges in modelling

the SW process. As a result, the variables listed in

Table 1 were considered to be monitored for their po-

tential to accurately characterize the SW process, and

therefore support the successful development of the

weld quality prediction model.

4 IMPLEMENTATION

This Section details the implementation of the devel-

oped system.

4.1 Sensorisation

Among the parameters listed in Table 1, electrical

quantities such as voltage and current stand out as es-

sential for assessing the quality of the SW process.

The temperature reached by the plate during the weld-

ing is also a critical factor, as inadequate values can

result in excessive or insufficient fusion of the compo-

nents, jeopardising the final weld quality. Other im-

portant parameters include the distance between the

welding gun and the plate, as well as the inclination

of the plate during the process. Environmental condi-

tions, specifically the concentration of carbon monox-

ide (CO), ambient humidity, and temperature, were

also considered essential to monitor due to their po-

tential influence on process stability.

Considering this, the following sensors were se-

lected:

• LEM HTFS 800-P: a current sensor, capable of

measuring currents until 1200A with an accuracy

of 1%. Utilised to measure the welding process

current.

• MLX90614-DCI: an I2C non-contact in-

frared (IR) temperature sensor, suitable

for industrial applications due to its small

field of view (FOV) of 5º. It is capable of measur-

ing temperatures between -70ºC and 270ºC with

an accuracy of 0.5ºC. Utilised for measuring the

plate temperature.

• MQ-7: a CO sensor, capable of detecting

CO concentrations in the air from 20 to 2000

parts per million (ppm). Utilised to measure the

air quality during the welding process.

• BME688: an I2C environmental, utilised for

measuring the ambient temperature and humidity.

It is capable of measuring temperature between

0ºC and 65ºC with an accuracy of 0.5ºC and rel-

Real-Time Weld Quality Prediction in Automated Stud Welding: A Data-Driven Approach

253

Table 1: Relevant parameters to monitor during the welding process.

Category Variables

Electric Quantities Voltage, Current (peak, effective, and average), Power

Process Parameters Stud lift distance, Stud immersion length, Stud incidence angle, Process

time duration

Environmental Parameters Ambient temperature, Ambient humidity, Air purity

Other Factors Temperature of materials (stud and plate), Temperature of machinery

(head and feeder), Cleanliness of the equipment (head, stud, and plate),

Current/Speed of the linear actuator, Cooling rate of welding

Discarded Factors Factors dependent on the materials of the studs and plates (composition,

purity, dimensions, etc.)

ative humidity (RH) between 20% and 80% with

an accuracy of 3%.

• LM35: a temperature sensor, capable of measur-

ing temperatures between 0ºC and 100ºC. Utilised

to measure the ambient temperature during the

welding.

• VL53L0X: a time-of-flight (ToF) high-precision

distance sensor, capable of measuring distances

between 30mm and 2000mm with an accuracy of

3%. Utilised for measuring the plate distance.

• YDLIDAR GS2: a linear array solid Light Detec-

tion and Ranging (LiDAR) sensor with a FoV of

100º capable of measuring distance in a range be-

tween 25mm and 300mm with an accuracy of 8%

for distances superior than 200mm. Utilised to

measure the plate inclination angle, correspond-

ing to the stud incidence angle.

Figure 5: Welding system sensorisation.

Figure 5 illustrates the installation of sensors in

the Factory Twin. The CO sensor is mounted on the

top, the temperature sensor on the side, and the dis-

tance and plate inclination sensors are positioned at

the front. The sensors not visible in the image, such

as the humidity sensor and the current sensor attached

to the welding system’s ground cable, are installed on

the opposite side.

To acquire the data from the sensors, two Arduino

Nano boards were used: one exclusively dedicated to

capturing high-frequency data from the current sen-

sor, and the other for the remaining sensors.

4.2 Data Acquisition System

To store the collected data in an organized and struc-

tured manner, a data acquisition system was devel-

oped. The two previously mentioned Arduino Nano

boards were connected to a Raspberry Pi 5 (RPI5),

running a Flask-based data acquisition application de-

veloped using Python, HTML, JavaScript, and CSS.

Because the parameters measured and displayed by

the welding system itself could not be directly ac-

cessed, but were still considered relevant, the RPI5

was also connected to a camera to capture images of

the values shown on the DCE1500 display. Addition-

ally, a RPI touch display was used to provide a graph-

ical user interface (GUI).

The GUI, illustrated in Figure 6, allows users to

start and stop the sensor data recording at appropri-

ate moments during the welding tests, while track-

ing the weld identifiers (IDs) to maintain organized

records. During recording, real-time values from the

Arduino boards and the camera are displayed, allow-

ing users to confirm that the data is being captured

as expected. After recording, the user should capture

an image of the DCE1500 display using the system.

Once both sensor data and the image are collected,

they are automatically saved: the sensor data as a

comma-separated values (CSV) file and the image as

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

254

Figure 6: Data acquisition application GUI.

a separate file. Both files are named using the record-

ing date and the corresponding welding test ID (e.g.,

“20250512 4”), ensuring consistent organization and

easy identification. Finally, the system is integrated

with a cloud-based database, allowing remote access

to all the collected data.

4.3 Automatic Parameter Extraction

To extract the process parameters from the collected

images of the DCE1500 display, an automatic two-

stage procedure was developed.

In the first stage, image processing is performed

mainly by a YOLOv11 neural network trained to seg-

ment the display, isolating the relevant foreground

while filtering out the background. Morphologi-

cal operations, specifically a closing followed by an

opening, are applied to clean the segmentation mask.

This mask is then subjected to perspective correction

in order to standardise the output, and finally, the re-

gion of interest (ROI) is reduced to only the table con-

taining the process parameters.

In the second stage, optical character recogni-

tion (OCR) was necessary to extract the aforemen-

tioned parameters. Several OCR tools, including

pytesseract, EasyOCR, and Keras-OCR, were tested

but all proved ineffective. Consequently, a second

YOLOv11 model was trained to recognise and ex-

tract the characters from the ROI. This OCR model

was pre-trained using a publicly available dataset in

Roboflow (Phil, 2023). Once the characters were

identified, their values were extracted based on the

known positions of each parameter within the table.

5 RESULTS

The external system sensorisation behaved as ex-

pected, even under the demanding conditions of the

welding environment, which included sudden temper-

ature variations, sparks, smoke, and electromagnetic

noise. Despite such challenges, it was possible to cap-

ture data without interruptions or difficulties.

To explore the correlation between the monitored

parameters and final weld quality and to generate a

diverse dataset, several experiments were conducted

under varying conditions. Using the Factory Twin,

process variables such as weld current and duration

were adjusted. In total, 46 different combinations of

current and process duration were tested, resulting in

approximately 200 experimental welds. During each

experiment, both sensor data and process parameters

were recorded.

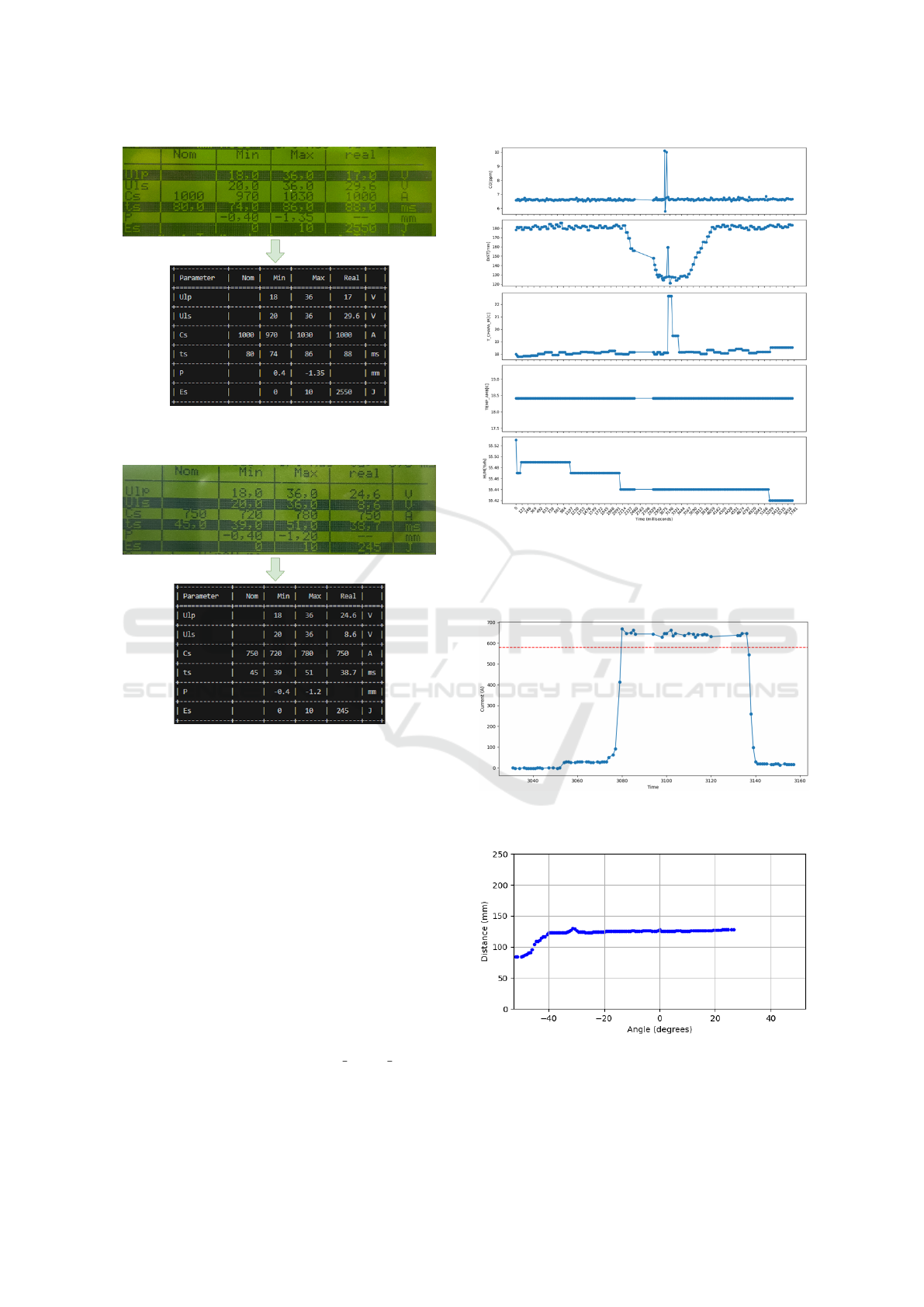

With the recording data available, the perfor-

mance of the automatic parameter extraction algo-

rithm was evaluated in two stages: (1) initial segmen-

tation of the display, and (2) character recognition.

Figure 7: Example of the display segmentation.

For the first stage, 15% of the dataset was reserved

as test data. The results were promising, with the

model achieving a mean Average Precision at Inter-

section over Union (IoU) 0.50 to 0.95 (mAP50-95) of

99.8%. Figure 7 illustrates this step with an example

showing both the input image and the resulting seg-

mented ROI.

For the second stage of the algorithm, 10% of the

dataset was used for evaluation, with each image con-

taining approximately 70 characters. The results were

less favourable, with a mAP50-95 of 67.7%. Never-

theless, the practical results were still acceptable, with

most errors being related to the recognition of the mi-

nus (“-”) character. Figures 8 and 9 show two exam-

ples of the character recognition algorithm’s output.

Having now both sensor data and process control

parameters available in a suitable format, a prelim-

inary data analysis was conducted. Since the final

weld quality classifications were not yet available, the

focus of this analysis was to verify whether the vari-

Real-Time Weld Quality Prediction in Automated Stud Welding: A Data-Driven Approach

255

Figure 8: Character recognition output from the OCR algo-

rithm - Example 1.

Figure 9: Character recognition output from the OCR algo-

rithm - Example 2.

ables showed the expected behaviours. To that end,

plots were generated using Python libraries such as

matplotlib.pyplot, pandas, and numpy, illustrat-

ing how sensor readings varied over time.

Figures 10, 11, and 12 illustrate the plots gener-

ated from the collected data for one test iteration. As

previously mentioned, the variables monitored during

this preliminary analysis were selected based on find-

ings from the literature (Table 1).

In Figure 10, it can be observed that during the lift

and plunge moments of the welding process (see Fig-

ure 1b and 1c), indicated by a drop in the DIST[mm]

value, which represents the distance between the

welding gun and the welding surface, there is a corre-

sponding spike in both CO concentration (CO[ppm])

and the welding plate temperature (T CHAPA IR[C]).

These variations are expected: the momentary in-

crease in CO concentration likely indicates gas emis-

sions caused by the welding arc, possibly due to the

Figure 10: Variation of CO concentration, welding surface

distance, welding surface temperature, ambient tempera-

ture, and ambient humidity, respectively, throughout the

welding cycle.

Figure 11: Approximation of the weld current near the peak

during the welding cycle.

Figure 12: Visualization of point cloud data captured during

the welding cycle.

combustion of surface materials. Similarly, the quick

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

256

rise and drop in the welding plate temperature reflects

the material’s heating during the arc, followed by a

quick cooling once the arc is extinguished.

The room ambient temperature (TEMP AMB[C])

stays constant during the welding process, confirm-

ing that the rise in the welding plate temperature is a

local effect and not due to a change in the overall en-

vironment. Humidity (HUM[%]) also shows very little

variation, specifically around 0.1 percentage points,

which is negligible considering the characteristics of

the sensor.

The peak current plot in Figure 11 shows the same

waveform shape as expected from the reference in

Figure 4. The red line represents the nominal current

value reported by the control unit during the weld.

The close match between the measured and expected

values shows that the sensor can accurately capture

the welding current.

Finally, the point cloud visualisation in Figure 12

shows the data collected by the LiDAR sensor. As

mentioned in Section 4, this sensor was mainly used

to measure the inclination of the plate, which corre-

sponds to the stud incidence angle. For most angles

measured, the distance values remain nearly constant,

which indicates that the welding plate is flat and par-

allel to the welding gun. From the conducted exper-

iments, it was observed that when the plate was not

parallel or not flat, the resulting welds were visibly of

poor quality or even broken. Therefore, this suggests

that plate inclination and surface flatness are relevant

parameters for detecting and predicting poor quality

welds.

Based on this example and the analysis of data

from additional test iterations, it can be concluded that

the collected sensor data exhibits the expected pat-

terns. This confirms that the selected variables are

suitable for characterizing the welding process. Fur-

thermore, these results validate the sensor setup and

establish a foundation for the development of future

models to predict weld quality.

6 CONCLUSIONS AND FUTURE

WORK

During automated SW processes, particularly in au-

tomotive assembly lines, low-quality welds can not

only compromise the quality of the final product but

also cause production delays due to the need for man-

ual rework. Real-time weld quality prediction sys-

tems can help identify potential defects early in the

assembly process, allowing operators to take correc-

tive actions immediately and mitigate these issues.

This paper presents the first development stage of

an AI-based system for real-time weld quality assess-

ment in an automated SW process. It focuses on the

study of the relevant variables that characterise the

welding process and their correlation with final weld

quality, as well as the welding setup sensorisation,

and the development of a data acquisition system to

build a dataset for future predictive model develop-

ment. A Flask-based application was developed as

part of the acquisition system to provide an interface

for data collection. Additionally, an automatic char-

acter recognition algorithm was developed to extract

welding parameters from images of the control unit

display, as this data could not be extracted directly.

Through a series of welding experiments, testing

with different variations of process parameters, an ini-

tial dataset of approximately 200 samples was gener-

ated. The implemented sensors performed well under

the challenging welding conditions, and the automatic

parameter extraction algorithm showed promising re-

sults. The preliminary data analysis confirmed the ex-

pected trends and variations in the recorded parame-

ters.

Overall, these initial results show that the system

was able to effectively capture data from the weld-

ing process, enabling the development of the predic-

tive model. Future work will focus on improving the

parameter extraction algorithm and performing weld

quality classifications on the experimental samples to

generate labelled data to train a supervised quality

prediction model.

ACKNOWLEDGEMENTS

This work was financially supported by PPS 14:

Quality control predictive system for soldering from

Agenda GreenAuto: Green Innovation for the Auto-

motive Industry, no. C644867037-00000013, invest-

ment project no. 54, from the Incentive System to

Mobilising Agendas for Business Innovation, funded

by the Recovery and Resilience Plan and by European

Funds NextGeneration EU.

REFERENCES

Agenda GreenAuto (2021). Agenda greenauto: Green in-

novation for the automotive industry. https://www.

agendagreenauto.pt/. Accessed: 2025-05-12.

Al-Sahib, N. K. A., Ameer, H. K. A., and Ibrahim, S. G. F.

(2009). Monitoring and quality control of stud weld-

ing. Al-Khwarizmi Engineering Journal, 5(1):53–70.

Chambers, H. A. (2001). Principles and practices of stud

welding. Pci, 46:46–59.

Real-Time Weld Quality Prediction in Automated Stud Welding: A Data-Driven Approach

257

Klaric, S., Kladari

´

c, I., and Kozak, D. (2010). The influ-

ence of the stud arc welding process parameters on

the weld penetration. BULETIN S¸TIINT¸IFIC, Seria C

/ SCIENTIFIC BULLETIN, Series C, XXIII(Fascicle:

Mechanics, Tribology, Machine Manufacturing Tech-

nology).

Naddaf-Sh, S., Naddaf-Sh, M.-M., Dalton, M., Ramezani,

S., Kashani, A. R., and Zargarzadeh, H. (2023).

Application of machine learning in automotive stud

weld defect classification. IEEE Sensors Journal,

23(20):25547–25556.

Phil (2023). Digits object detection dataset. https://universe.

roboflow.com/phils-workspace/digits-coi4f/dataset/3.

Accessed: 2025-07-25.

PT. Unggul Semesta. Dce control and energy source.

https://www.unggulsemesta.com/brand/tucker/

product/dce-control-and-energy-source/. Accessed:

2025-05-13.

Samardzic, I., Klaric, S., and Siewert, T. (2007). Analysis

of welding parameter distribution in stud arc welding.

Proceedings of the Conference: Welding and Materi-

als, Dubrovnik, Croatia, 1, YU.

T. Lienert, T. Siewert, S. B. V. A. (2011). Stud arc weld-

ing. In Welding Fundamentals and Processes. ASM

International.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

258