A Model-Based Approach to the Definition of Collaborative Processes in

Supply Chain Environments

Mohsen Khorram Dastjerdi

a

, J. A. Garc

´

ıa-Garc

´

ıa

b

, J. G. Enr

´

ıquez

c

and

M. J. Escalona Cuaresma

d

Computer Languages and Systems Department, University of Seville, Avd. Reina Mercedes s/n, 41012, Sevilla, Spain

Keywords:

Supply Chain Management, Business Process, Metamodel, Diamond Industry, Traceability.

Abstract:

Global supply chains involve multiple actors and complex interactions, often spanning multiple organizations

and geographic regions. However, issues such as limited process automation, coordination gaps, and concerns

about data security and integrity continue to hinder collaboration in these networks. This paper addresses these

challenges by presenting a metamodel to support secure and seamless collaboration in the diamond jewelry

supply chain in Spain. Based on business process management standards, the metamodel improves trace-

ability, coordination, and automation across organizational boundaries. The metamodel includes mechanisms

for hash-based certification, certificate of origin, and shared traceability rules that facilitate the exchange of

transparent information while maintaining data integrity. A case study focused on diamond certification from

Lesotho to Spain demonstrates the feasibility and benefits of this approach. The results show improvements in

process efficiency, fraud reduction, and stakeholder trust, especially in high-value and highly regulated supply

chains.

1 INTRODUCTION

Global supply chains are complex, fragmented

ecosystems that involve diverse actors across geo-

graphic and organizational boundaries. The growing

demands of international trade have exposed signifi-

cant challenges in the management of these networks,

including limited integration, coordination gaps, lack

of cross-organizational automation, and the reluc-

tance to share sensitive information (Garcia-Garcia

et al., 2020; Shen, 2007).

These issues are especially critical in collabora-

tive supply chain (CSC) environments, where coordi-

nation and information exchange are vital (Han and

Fang, 2024). Although business process management

(BPM) has matured within organizations, its applica-

tion in inter-organizational contexts remains scarce,

constrained by the absence of frameworks and tools

to support collaboration (Szelkagowski and Berniak-

Wo

´

zny, 2024).

Concerns over data privacy and manipulation fur-

a

https://orcid.org/0009-0006-9740-0546

b

https://orcid.org/0000-0003-2680-1327

c

https://orcid.org/0000-0002-2631-5890

d

https://orcid.org/0000-0002-6435-1497

ther hinder the adoption of BPM in supply chains,

limiting the realization of its full potential bene-

fits—such as transparency, efficiency, and account-

ability—in collaborative scenarios (Akinsola and

Akinde, 2024).

In response to the identified limitations in current

supply chain systems, this study proposes a meta-

model designed to facilitate secure and integrated col-

laboration among stakeholders in the diamond jew-

elry supply chain in Spain. The metamodel is de-

veloped with the goal of improving process trace-

ability, coordination, and automation by using es-

tablished BPM standards. By leveraging this inte-

grated supply chain, all stakeholders within the sup-

ply chain and logistics network can benefit from unre-

stricted information sharing facilitated by secure data

exchange mechanisms that eliminate data tampering

concerns. This enhanced transparency contributes to

improved production efficiency, faster customer ser-

vice, greater process synchronization, cost reduction,

higher product quality, and a significant decrease in

fraudulent activities (Esan et al., 2024; Kalla et al.,

2025). These capabilities are particularly critical in

high-value, high-regulation sectors, such as the dia-

mond industry, where authenticity and origin issues

pose significant challenges (Dasaklis et al., 2019). For

Dastjerdi, M. K., García-García, J. A., Enríquez, J. G. and Cuaresma, M. J. E.

A Model-Based Approach to the Definition of Collaborative Processes in Supply Chain Environments.

DOI: 10.5220/0013713300003985

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 21st International Conference on Web Information Systems and Technologies (WEBIST 2025), pages 181-188

ISBN: 978-989-758-772-6; ISSN: 2184-3252

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

181

example, a diamond claimed to have been manufac-

tured in Lesotho (South Africa) may, in reality, orig-

inate from a less expensive source, undermining both

consumer trust and market transparency. Therefore,

ensuring product integrity requires the ability to trace

the journey of a diamond from the mine to the end

customer.

To address this issue, in addition to proposing an

integrated supply chain with traceability of goods,

payments, and all processes, we proposed a Certifi-

cate of Origin

1

capable of verifying the provenance

of diamonds extracted from mines and transported to

Spain. This approach is reinforced by the growing

economic importance of the diamond market, which

was valued at 80 billion USD in 2017 and is projected

to exceed 123 billion by 2030 (Thakker et al., 2020).

The effectiveness of the proposed metamodel

is demonstrated through a case study incorporating

hash-based certification, shared Objectives and Key

Results (OKRs)

2

and traceability rules to ensure se-

cure verification and transparent collaboration. The

meta-model also supports auxiliary components, such

as insurance integration, payment gateways, and spe-

cialized monitoring mechanisms tailored for handling

high-value goods in regulated markets.

The rest of this paper is structured as follows. Sec-

tion 2 reviews the most relevant literature. Section 3

details our proposed metamodel and its implementa-

tion, focusing on how it enhances supply chain mod-

eling. Section 4 presents a case study to validate the

model in the international diamond industry. Finally,

Section 5 summarizes our findings and outlines future

research directions.

2 RELATED WORK

Recently, blockchain and model-based approaches in

BPM and supply chains have been explored. How-

ever, most studies focus on technological implemen-

tation rather than on modeling collaborative business

processes.

For example, (Dasaklis et al., 2019) highlights

the challenge of limited monitoring and tracking of

goods, proposing a blockchain-based framework to

improve transparency and auditing. Similarly, (Li

1

A Certificate of Origin or Declaration of Origin (of-

ten abbreviated to C/O, CO, or DOO) is a document widely

used in international trade transactions that attests that the

product listed therein has met certain criteria to be consid-

ered as originating in a particular country.

2

Objectives and Key Results (OKRs) is a goal-setting

framework used by individuals, teams, and organizations to

define measurable goals and track their outcomes.

et al., 2022) emphasizes the role of end-to-end visibil-

ity in enhancing supply chain resilience (SCR), show-

ing that blockchain-supported business model designs

(BMDs) significantly improve SCR and firm perfor-

mance. Trust issues in data sharing are addressed

in (Kamble et al., 2020), which proposes blockchain

to enhance traceability, data integrity, and auditabil-

ity. Additionally, (Shi et al., 2022) introduces a

Blockchain-Based Service Modeling (BOSM) ap-

proach to improve quality management through busi-

ness and technical domain alignment, as demon-

strated in the dairy industry.

Despite these advances, current literature presents

several limitations. First, insurance visibility and

management are rarely integrated into supply chain

models. Second, many approaches lack a unified,

end-to-end view, focusing instead on isolated compo-

nents. Third, the use of OKRs with measurable indi-

cators for service provider evaluation and risk man-

agement is underexplored. Fourth, decision-making

processes are often absent in existing metamodels.

Fifth, while tracking is widely discussed, it is sel-

dom implemented via a dynamic, integrated platform.

Sixth, contracts are typically treated as secondary el-

ements rather than central entities. Lastly, mecha-

nisms ensuring goods authenticity and compatibility

with blockchain technologies are largely overlooked.

These gaps underscore the need for a compre-

hensive metamodel that addresses these shortcom-

ings through a more integrated and functional ap-

proach. To address these gaps, our study proposes a

technology-independent metamodel for collaborative

supply chains, supported by a BPMN-based model-

ing approach. This framework integrates traceability,

risk management, contract handling, and evaluation

mechanisms based on OKRs. It also supports trans-

parency, service quality validation, and secure collab-

oration among stakeholders—without dependence on

specific platforms or technologies.

3 PROPOSAL FOR SUPPLY

CHAIN PROCESS MODELLING

This section presents the technical details of the pro-

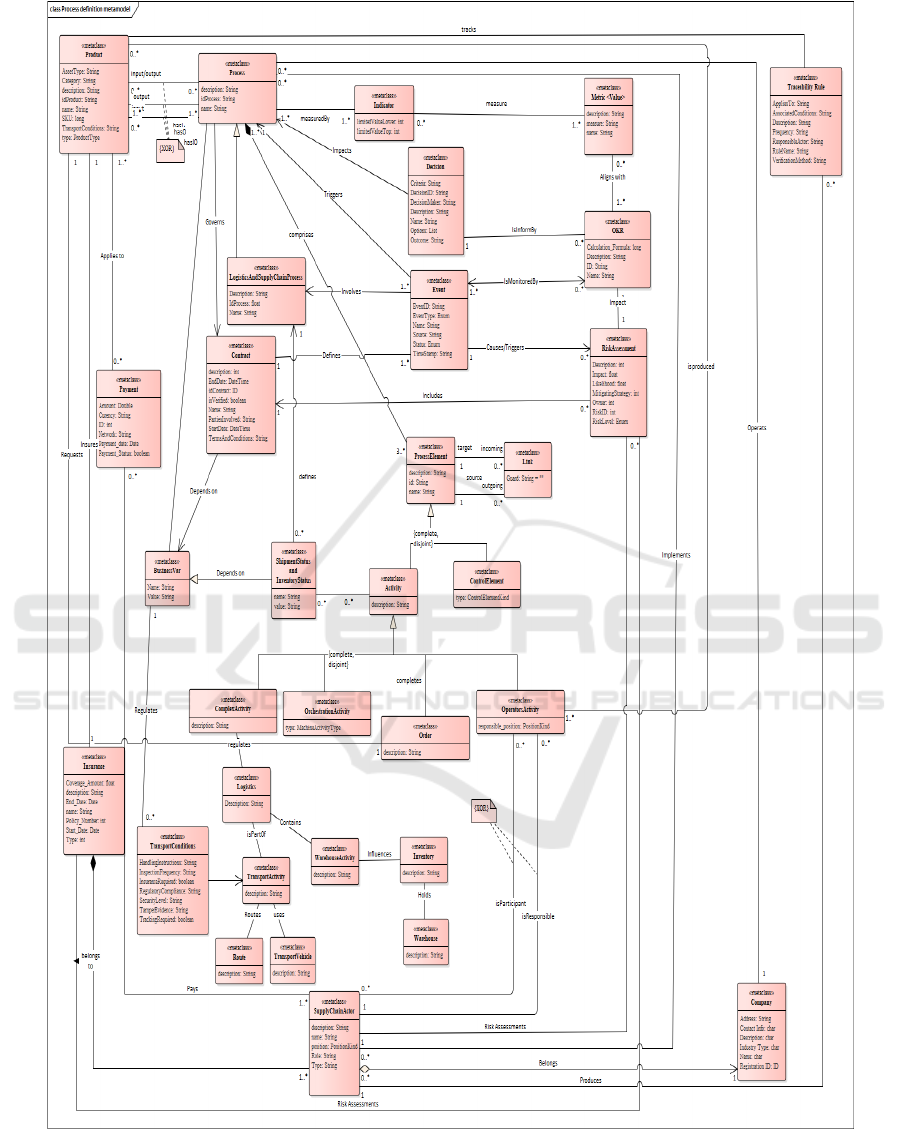

posed metamodel (cf. Figure 1) and its defining char-

acteristics. As previously mentioned, the primary ob-

jective of our metamodel is to offer an integrated ap-

proach to a CSC to facilitate efficient information ex-

change, data sharing, and synchronization among par-

ticipants. Our approach provides a realistic yet sim-

plified metamodel that can be valuable for both indus-

trial and academic applications.

The Process metaclass is the core metaclass in

WEBIST 2025 - 21st International Conference on Web Information Systems and Technologies

182

Figure 1: Integrated Collaborative Supply Chain Process Meta-Model.

our metamodel. In fact, it has been connected to

some metaclasses to produce result, product, and up-

date the measurments for the metamodel. Contract

is the most important metaclass connected to the Pro-

cess metaclass. It serves as a pivotal control layer that

guarantees and verifies workflow execution defined

A Model-Based Approach to the Definition of Collaborative Processes in Supply Chain Environments

183

within the Process metaclass. In supply chain con-

texts, actors and organizations establish formal agree-

ments, which are represented and validated by this

metaclass.

The Contract metaclass is immutable; once final-

ized and loaded, it prohibits any modifications, ensur-

ing a unidirectional execution flow that preserves the

integrity of contractual agreements. It acts as a ledger,

managing, guiding, and enforcing all contract clauses

to ensure compliance throughout the supply chain.

This addresses a key challenge in reliably executing

complex supply chain processes. This metaclass is in-

fluenced by the BusinessVar and Event metaclasses,

enabling it to dynamically reflect business conditions

and respond to specific triggers. As such, contracts

can adapt to real-time events while maintaining en-

forcement of business rules.

Additionally, it is linked to the RiskAssessment

metaclass, which provides metrics for evaluating ac-

tors and processes. These assessments are supported

by historical data from OKR metaclasses, aligning

risk evaluation with strategic objectives and perfor-

mance metrics. This integration allows the Contract

metaclass to contribute to proactive risk management

and greater consistency with business goals.

Furthermore, the Contract metaclass is directly

linked to both SupplychainActor and Company

metaclasses, enabling the formalization and enforce-

ment of agreements at the individual and organiza-

tional levels. This ensures that obligations and com-

pliance are clearly defined and governed across the

supply chain. Additionally, OKR data support the

evaluation and selection of reliable partners, reinforc-

ing trust within the network.

The Product metaclass represents either inputs or

outputs of a Process, or both. Its role is defined by an

XOR constraint among hasI, hasO, and hasIO, ensur-

ing it assumes only one type within a process. Every

Process must involve at least one Product, as enforced

by cardinality rules, aligning with the core principles

of process-product relationships defined in (Garcia-

Garcia et al., 2020).

The Decision metaclass plays a strategic role by

guiding the Process based on OKRs, which are linked

to Metrics and Indicators. Indicators provide real-

time data that influence process execution, whereas

Metrics measure progress toward objectives. The De-

cision metaclass ensures that the actions taken dur-

ing the process align with organizational goals, creat-

ing a feedback loop that fosters data-driven and goal-

oriented execution.

The LogisticsAndSupplyChainProcess meta-

class plays a crucial role in managing and oversee-

ing supply chain operations, relying on ShipmentSta-

tusAndInventoryStatus for real-time tracking of ship-

ments and stock. The Event metaclass, which is

closely linked to this process and other key meta-

classes like RiskAssessment, OKR, and Contract,

drives dynamic responses to triggers, enabling proac-

tive risk management, contract enforcement, and

alignment with strategic goals within the supply

chain.

The Event metaclass plays a crucial role in col-

laborative business and supply chain contexts by

serving as a trigger for processes, workflows, and

decision-making. It is directly linked to Logistic-

sAndSupplyChainProcess, Process, RiskAssessment,

OKR, and Contract metaclasses. Events represent

both external conditions (e.g., supplier delivery de-

lays) and internal changes (e.g., stock reaching criti-

cal levels), initiating actions such as order reception

or risk detection, defining process preconditions, and

influencing performance goals and contractual terms.

Also, the BusinessVar is another metaclass that

has a direct association with the Process metaclass. In

fact, the BusinessVar metaclass defines dynamic vari-

ables associated with a single process, enabling adapt-

ability and decision-making. Linked to the Process

metaclass through aggregation, these variables drive

conditional logic, helping determine the next activity

based on their values. Acting as building blocks for

business rules, they ensure processes are flexible and

context-aware.

The ProcessElement metaclass, directly associ-

ated with the Process metaclass, forms the funda-

mental building block of workflows. It encapsulates

all elements within a process, serving as the back-

bone for constructing interconnected and dynamic

sequences. This metaclass branches into two spe-

cialized types: ControlElement and Activity, each

shaping the workflow’s structure and intent. The

Link metaclass connects ProcessElements, establish-

ing logical pathways that ensure seamless transitions

and coherent process flow.

The Activity metaclass defines the executable

tasks within a process, bridging intent and action. As

a specialization of ProcessElement, it not only per-

forms work but also updates business variables upon

completion. It includes four specialized subtypes:

(i) Order, representing commands that trigger activ-

ities; (ii) OrchestrationActivity, for automated sys-

tem tasks; (iii) ComplexActivity, enabling subpro-

cess integration for hierarchical process design; and

(iv) OperatorsActivity or HumanActivity, involving

tasks performed by individuals, highlighting human

roles in workflows. ComplexActivity is key in supply

chain and logistics, encapsulating logistics, transport

conditions, and inventory management subprocesses.

WEBIST 2025 - 21st International Conference on Web Information Systems and Technologies

184

This allows hierarchical workflow modeling and en-

sures efficient coordination of transportation, ware-

housing, and resource allocation, thus improving the

effectiveness of the supply chain process.

In addition, the SupplyChainActors would for-

mulate the Insurance and Payment metaclasses, with

a tangible association to the Company metaclasses,

reflecting their roles in managing financial and risk-

related aspects of the supply chain process. Specif-

ically, the Insurance metaclass would be associated

with SupplyChainActors that manage risk, while the

Payment metaclass would be linked to financial trans-

actions between SupplyChainActors and Companies,

ensuring that the contractual and financial obligations

within the supply chain are met efficiently.

4 VALIDATION

This section presents a use-case model based on the

previously described metamodel. It assumes an ideal

scenario without constraints to demonstrate the meta-

model’s flexibility and effectiveness. To highlight

traceability, origin assurance, and fraud prevention,

diamonds—a highly valuable commodity—are used

as the focus. The model follows the BPMN 2.0 stan-

dard, enabling comprehensive representation of the

main process and its subprocesses.

4.1 General Overview

This case study describes a jewelry store in Spain

working with a hub in South Africa to procure di-

amonds directly from a mine in Lesotho. It illus-

trates a complex supply chain involving multiple ac-

tors: buyer, shippers (land and sea), customs, mining

company, South African partner, insurers, and pay-

ment systems.

Through a secure and integrated platform, or

cross-platform communication system, these actors

exchange data in a manner that ensures data integrity

and security at every step of the process. Real-time

OKR updates keep all actors informed of the goods’

status, promoting transparency and efficiency. This

coordinated communication enhances the reliability

and security of the diamond procurement process,

aligning all stakeholders across the transaction.

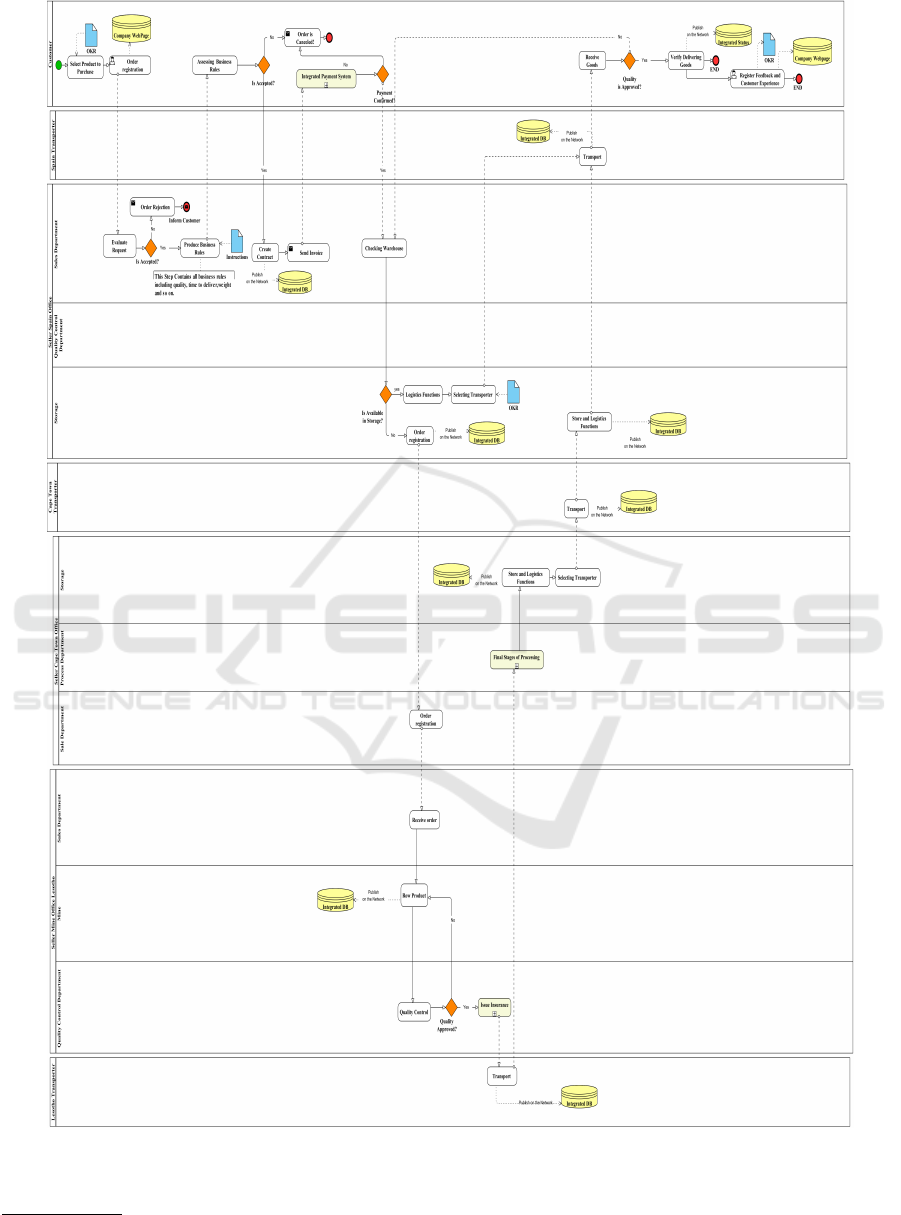

The process model (cf. Figure 2) depicts the life-

cycle of order processing, logistics coordination, and

product delivery within a supply chain. Its goal is to

improve operational efficiency, reduce delays, and en-

sure stakeholder integration. The model emphasizes

automation, data-driven decisions, and inter-system

communication, reflecting modern BPM practices.

Activities are segmented by roles such as customers,

payment systems, logistics managers, and storage fa-

cilities, ensuring clear accountability and highlighting

cross-department collaboration.

4.2 Mapping Metamodel Elements to

BPMN Constructs

The BPMN model (cf. Figure 2) reflects key con-

cepts from our metamodel. Each BPMN element

maps to one or more metaclasses, ensuring alignment

between process representation and model structure.

For example, the BPMN Pool for “Logistics and Sup-

ply Chain Coordinator” corresponds to the Process

metaclass. Tasks like “Send Invoice” and “Transport”

align with the Activity metaclass, while Events such

as “Payment Received” map to the Event metaclass,

which triggers actions and transitions. Data Objects

and Messages (e.g., “Order Approval,” “Purchase

Contract”) correspond to Order, Contract, and Pay-

ment metaclasses. Decision Gateways like “Is avail-

able in stock?” relate to Decision and RiskAssessment

metaclasses. Data Stores such as “Warehouse” match

InventoryData and Warehouse metaclasses. Strate-

gic goals and performance metrics represented as Ar-

tifacts or Annotations correspond to OKR and Met-

ric metaclasses, linking performance targets with risk

management. This alignment allows the BPMN

model to serve as an executable representation of the

metamodel’s structured concepts.

4.3 Process Phases

This section models the complete diamond purchas-

ing process involving a jeweler in Spain and part-

ners in South Africa and Lesotho. The approach fol-

lows the previously described metamodel and uses the

BPMN 2.0 standard for process representation.

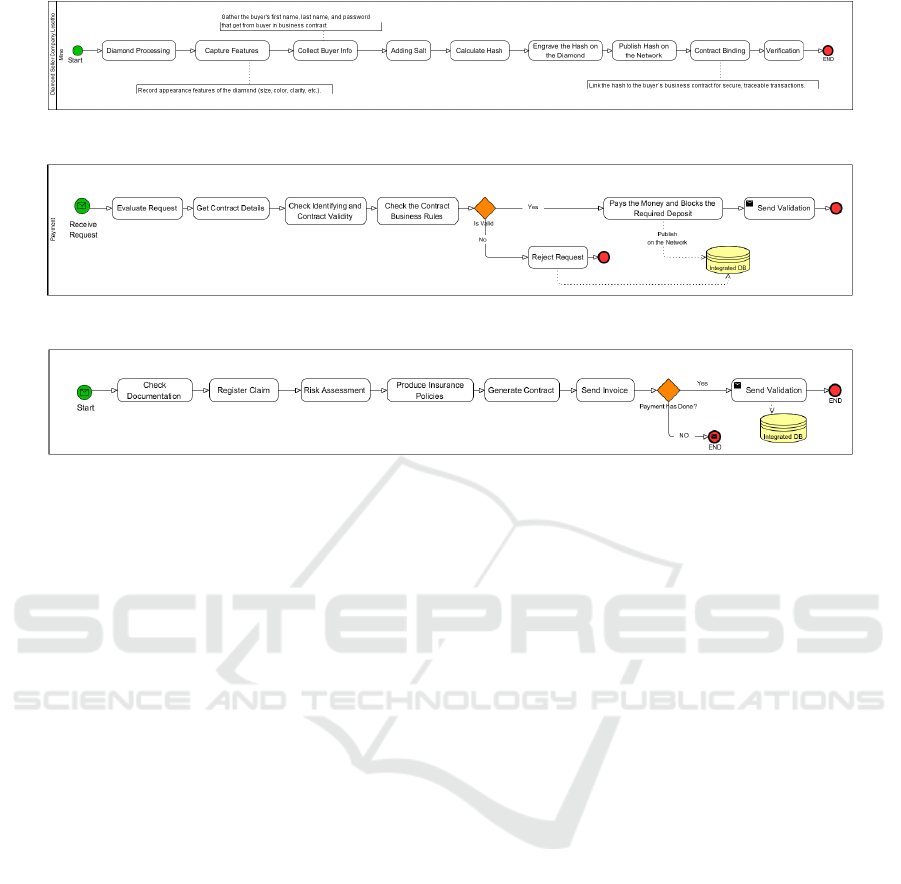

Figure 2 shows the main diamond purchasing

workflow. Figure 4 details the integrated payment

process, enabling transparent and secure transactions

among stakeholders. Figure 5 illustrates the insurance

process, protecting goods during transit and enforc-

ing liabilities through contracts. These subprocesses

ensure trust, automation, and compliance across le-

gal and logistical boundaries. Figure 3 depicts the

generation and engraving of a cryptographic hash on

the diamond to guarantee authenticity and contrac-

tual integrity. Buyer-specific data (name, confiden-

tial password) is combined with diamond attributes

(size, weight, color, clarity) and salted to enhance se-

curity. This data is salted

3

and used to calculate a

3

In cryptography, a salt is random data added before

A Model-Based Approach to the Definition of Collaborative Processes in Supply Chain Environments

185

Figure 2: Diamond Purchasing Main Process.

unique hash, which is engraved onto the diamond and

hashing to increase resistance against precomputed attacks

such as rainbow tables (Mustafa, 2024).

published on a secure network. The resulting hash

is cryptographically linked to the contract, enabling a

verifiable connection between the physical asset and

WEBIST 2025 - 21st International Conference on Web Information Systems and Technologies

186

Figure 3: Diamond Hash Processing.

Figure 4: Integrated Payment System.

Figure 5: Integrated Issue Insurance Process.

its digital record.

This approach enables the original buyer, possess-

ing the correct input data, to regenerate and verify

the hash, confirming ownership. Future buyers and

sellers can similarly validate the diamond’s authentic-

ity and transaction history on a tamper-resistant plat-

form. Due to space limitations, technical details like

hashing algorithms, encryption, and system integra-

tion will be covered in a separate article focused on

implementation.

• Order Registration: The process starts with the

customer submitting the product order, followed

by validation of order details to ensure compli-

ance with business rules. This step integrates with

the Integrated Payment System shown in Figure 4

for invoicing.

• Logistics Coordination: After successful pay-

ment, warehouse availability is checked and trans-

port resources are allocated. Decision gateways

manage process flow based on inventory sta-

tus and transport options. Advanced transport

scheduling algorithms are implied to reduce lead

times and optimize resource use.

• Product Processing: As illustrated in Figure 3,

once produced at the mine, the diamond is trans-

ported to the South African partner for final pro-

cessing. This critical stage ensures quality stan-

dards and verifies the diamond’s authenticity and

origin.

• Insurance and Payment: The supply chain sup-

ports autonomous, comprehensive payment exe-

cution without external approval, exemplified in

the subprocess of Figure 4. Additionally, insur-

ance issuance is integrated, enabling risk assess-

ment reviews for each actor and stage throughout

the product lifecycle.

• Quality Control and Storage: Products undergo

inspection before storage or dispatch. Data feed-

back loops update the inventory system in real-

time for accurate stock management.

• Final Transport and Delivery: Products are

loaded and shipped according to predefined

schedules, with monitoring mechanisms ensuring

secure and timely delivery.

• Traceability and Integrated Database:

Throughout the process, actors update and

record progress in a comprehensive database, ac-

cessible to all stakeholders for real-time tracking

of both the process and the product status.

5 CONCLUSIONS AND FUTURE

WORKS

This study presented a technology-independent meta-

model and a BPMN-based modeling approach that

enhances transparency, traceability, and coordination

in collaborative supply chains. The emphasis has

been placed on conceptual clarity, process integrity,

and stakeholder alignment, without dependence on a

specific technological platform.

The proposed model is designed to facilitate

A Model-Based Approach to the Definition of Collaborative Processes in Supply Chain Environments

187

seamless and reliable data exchange across organiza-

tional boundaries, addressing common concerns re-

lated to data manipulation or misuse. One of its

core strengths lies in improving traceability, allow-

ing buyers to verify the authenticity and origin of

goods at each step of the chain. A key differen-

tiator of the model is the integration of risk man-

agement as a continuous process, enabling structured

and objective evaluation of each actor and service

provider involved. The use of Objectives and Key

Results (OKRs) as a decision-making framework em-

powers participants to assess and select trusted busi-

ness partners based on transparent and measurable

performance indicators.

As future work, we plan to implement the pro-

posed model and its underlying metamodel on a

blockchain-based platform to evaluate its practical

viability and performance —focusing especially on

synchronization, security, and decentralized trust

mechanisms. We plan to integrate these technologi-

cal aspects into our methodological framework to en-

hance its practical applicability. We also intend to de-

velop the concept of a certificate of origin based on

the proposed “Engraving Hash on Diamond” mecha-

nism in a practical and detailed manner. Additionally,

a comparative and quantitative evaluation will be de-

signed to assess the impact of our approach against

existing methods, providing stronger empirical sup-

port. These extensions aim to validate and refine the

proposed concepts in real-world collaborative envi-

ronments and further strengthen both their theoretical

and operational contributions.

ACKNOWLEDGEMENTS

This research was supported by the EQUAVEL

project PID2022-137646OB-C31, funded by MI-

CIU/AEI/10.13039/501100011033 and by ERDF,

EU.

REFERENCES

Akinsola, A. and Akinde, A. (2024). Enhancing software

supply chain resilience: Strategy for mitigating soft-

ware supply chain security risks and ensuring security

continuity in development lifecycle. arXiv preprint

arXiv:2407.13785.

Dasaklis, T. K., Casino, F., Patsakis, C., and Douligeris,

C. (2019). A framework for supply chain traceabil-

ity based on blockchain tokens. In Business Process

Management Workshops: BPM 2019 International

Workshops, Vienna, Austria, September 1–6, 2019,

Revised Selected Papers 17, pages 704–716. Springer.

Esan, O., Ajayi, F. A., and Olawale, O. (2024). Supply

chain integrating sustainability and ethics: Strategies

for modern supply chain management. World Jour-

nal of Advanced Research and Reviews, 22(1):1930–

1953.

Garcia-Garcia, J. A., S

´

anchez-G

´

omez, N., Lizcano, D.,

Escalona, M. J., and Wojdy

´

nski, T. (2020). Using

blockchain to improve collaborative business process

management: Systematic literature review. IEEE Ac-

cess, 8:142312–142336.

Han, Y. and Fang, X. (2024). Systematic review of adopting

blockchain in supply chain management: bibliometric

analysis and theme discussion. International Journal

of Production Research, 62(3):991–1016.

Kalla, C., Scavarda, L. F., and Hellingrath, B. (2025). In-

tegrating supply chain risk management activities into

sales and operations planning. Review of Managerial

Science, 19(2):467–497.

Kamble, S. S., Gunasekaran, A., and Sharma, R. (2020).

Modeling the blockchain enabled traceability in agri-

culture supply chain. International Journal of Infor-

mation Management, 52:101967.

Li, G., Xue, J., Li, N., and Ivanov, D. (2022). Blockchain-

supported business model design, supply chain re-

silience, and firm performance. Transportation Re-

search Part E: Logistics and Transportation Review,

163:102773.

Mustafa, N. A. A. (2024). Analysis attackers’ methods with

hashing secure password using csprng and pbkdf2.

Wasit Journal of Engineering Sciences, 12(2):60–70.

Shen, Z. (2007). Integrated supply chain design models:

a survey and future research directions. Journal of

industrial and management optimization, 3(1):1.

Shi, Y., Ying, J., Shi, D., and Yan, J. (2022). Service-

oriented modeling for blockchain-enabled supply

chain quality information systems. Security and Com-

munication Networks, 2022(1):1987933.

Szelkagowski, M. and Berniak-Wo

´

zny, J. (2024). Bpm

challenges, limitations and future development

directions–a systematic literature review. Business

Process Management Journal, 30(2):505–557.

Thakker, U., Patel, R., Tanwar, S., Kumar, N., and Song, H.

(2020). Blockchain for diamond industry: opportuni-

ties and challenges. IEEE Internet of Things Journal,

8(11):8747–8773.

WEBIST 2025 - 21st International Conference on Web Information Systems and Technologies

188