Comparative Analysis of Robotic Topologies for Transmission Line

Inspection

Davi Riiti Goto Valle, Ronnier Frates Rohrich and Andr

´

e Schneider de Oliveira

Graduate Program in Electrical and Computer Engineering, Universidade Tecnol

´

ogica Federal do Paran

´

a (UTFPR),

Curitiba, Brazil

Keywords:

Robotic Systems, Transmission Line Inspection, Simulation, Inspection Robots, Robot Topologies.

Abstract:

Power transmission line inspection plays a crucial role in maintaining the integrity and reliability of electrical

infrastructure. With the increasing complexity of transmission line systems, robotic systems have emerged as

a viable solution to automate the inspection process. This paper presents an analysis of three distinct robotic

platforms designed for transmission line inspection. Each robot employs different topologies and mechanisms

to perform the task, which are simulated environment. The paper compares the design, functionality, and sim-

ulation results of each robot, highlighting their strengths, weaknesses, and potential for real-world application.

1 INTRODUCTION

Power transmission lines are critical in ensuring the

continuous delivery of electricity from generation

sites to distribution networks and, ultimately, to con-

sumers. Due to the vast geographical coverage and

the often challenging terrains in which these lines are

installed, including remote, mountainous, or forested

regions, regular inspections are essential to maintain

the integrity and reliability of the electrical infrastruc-

ture. However, human operators traditionally carry

out these inspections, which involve significant safety

risks, high operational costs, and logistical complexi-

ties.

In recent years, robotic systems have emerged as

a promising and increasingly viable alternative to au-

tomating the inspection of high-voltage transmission

lines. The deployment of robots in this context of-

fers several advantages, most notably enhancing oper-

ator safety by reducing the need for physical presence

in hazardous environments. In addition, robotic in-

spections can increase the efficiency, precision, and

frequency of monitoring tasks, thus enabling more

effective predictive maintenance strategies and early

anomaly detection, which is essential to minimize ser-

vice interruptions and costly repairs.

The trend towards automation in the field of trans-

mission line inspection has been well documented

in the literature. For example, as discussed by

(A. B. Costa, 2023), significant advances have been

made in robotic technologies tailored for the power

sector, particularly in systems capable of navigat-

ing and analyzing transmission infrastructure. These

robots often integrate sophisticated sensor arrays - in-

cluding high-resolution cameras, LIDAR (Light De-

tection and Ranging), and infrared sensors — allow-

ing them to perform detailed structural assessments,

detect corrosion, measure component displacement,

and accurately identify potential failure points.

Furthermore, incorporating artificial intelligence

and machine learning into robotic platforms has im-

proved the autonomy and decision-making capabili-

ties of inspection systems. As noted in (Y. Zhang,

2021), AI-based navigation and data analysis tech-

niques have significantly improved the precision and

reliability of automated inspections, allowing robots

to adapt to dynamic environments and complex struc-

tural configurations. These intelligent systems can

also process the collected data in real-time, facilitat-

ing the generation of actionable insights and mainte-

nance recommendations.

An additional innovation in robotic inspection is

presented in the work of (R. P. Almeida, 2022), who

proposes a robotic platform that combines pulleys,

clamping, and gripping mechanisms. These mechan-

ical solutions ensure the robot’s stability and adher-

ence to the transmission line, even in adverse con-

ditions such as strong winds or irregular geometries.

Such mechanisms are essential to maintain contact

and operational continuity during inspection tasks, es-

pecially in suspended or elevated settings.

This study evaluates three different robotic sys-

Valle, D. R. G., Rohrich, R. F. and de Oliveira, A. S.

Comparative Analysis of Robotic Topologies for Transmission Line Inspection.

DOI: 10.5220/0013710500003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 259-266

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

259

tems explicitly developed for inspecting transmission

lines. Each system features a unique structural topol-

ogy and specialized mechanical and sensory compo-

nents to facilitate movement along the conductors and

allow thorough inspection routines. The three robots

were modeled and simulated using CoppeliaSim to

assess their capabilities. This versatile and widely

adopted simulation platform allows for the detailed

testing of robotic designs and their interactions with

physical environments.

The primary objective of this research is to per-

form a comparative analysis of these robotic systems,

focusing on key criteria such as structural design,

mobility strategies, sensor integration, and overall

performance in simulated inspection scenarios. The

study also aims to identify common challenges each

system faces, such as maneuverability around obsta-

cles, adaptability to different line geometries, and data

acquisition quality. Insights gained from this compar-

ison will contribute to developing and refining robotic

solutions for safer, more efficient, and cost-effective

inspection of power transmission infrastructure.

2 RELATED WORK

Previous studies have focused on the development

of robotic systems for transmission line inspection,

highlighting the importance of mechanical design,

sensor integration, and control strategies. It is widely

recognized that these advanced systems are crucial

for reducing maintenance costs and improving safety.

Similarly, (T. A. Silva, 2020) discussed the challenges

faced by robots in high-voltage environments and pro-

posed solutions to improve the reliability of these sys-

tems. In this context, the robots developed in this

study build on these existing works, paying particular

attention to their ability to maneuver in challenging

environments and perform detailed inspections.

Topology, in the context of robotics, refers to a

robot’s physical, structural, and functional configura-

tion, including the arrangement of its modules, joints,

locomotion systems, and sensors. For transmission

line inspection robots, defining the topology is a crit-

ical aspect of research and development, as it directly

influences the robot’s ability to adapt to different line

segments, overcome obstacles, and perform inspec-

tions with precision. This field of study continuously

seeks to improve inspections’ efficiency, safety, and

reliability in high-voltage environments, where oper-

ational challenges are amplified by adverse conditions

such as height, weather, and electromagnetic interfer-

ence (Jiang et al., 2018).

These robots are specifically designed to navigate

transmission lines, detecting and reporting faults or

anomalies in real-time. To perform this function ef-

fectively, they must be positioned as close as pos-

sible—or even in direct contact—with the energized

line. This requirement poses significant technical

challenges in arranging electronic components, sen-

sors, and mechanical systems, which must be inte-

grated safely and efficiently. Furthermore, the appro-

priate selection of materials used in construction is

crucial, as these robots operate in extreme environ-

ments exposed to high levels of electrical voltage and

severe weather variations (Wang and Wang, 2016).

From a functional perspective, transmission line in-

spection robots can be classified into three main cat-

egories: climbing robots, which move directly on ca-

bles or structures; flying robots (UAVs), which offer

greater agility and access to remote areas; and hybrid

robots, which combine climbing and flying capabil-

ities to optimize inspection coverage and efficiency

(Chai et al., 2024).

The mechanical topology of these robots plays

a decisive role in their mobility and performance.

The arrangement of joints—including their number,

sequence, type, and axis—defines the robot’s kine-

matic structure, directly impacting its rigidity, reach,

and maneuverability (Alhassan et al., 2020). Addi-

tionally, topology optimization techniques have been

applied to reduce robotic systems’ structural weight

and energy consumption. Studies show that this ap-

proach can reduce the weight of mobile robots by up

to 20% without compromising their strength, result-

ing in greater energy efficiency and more robust field

performance (Zhu et al., 2020).

In collaborative inspection contexts, such as dis-

tributed robotic networks, maintaining a regular and

predictable topology facilitates the implementation of

communication protocols. It enables dynamic forma-

tions, such as lines, rings, and meshes. This con-

tributes to improved robot coordination, increased in-

spection coverage, and greater system redundancy

and reliability (Bayındır, 2016).

3 SIMULATION ENVIRONMENT

To simulate the three robots in dynamic environ-

ments, we used the educational version of Cop-

peliaSim. In addition to being an effective tool for

robotic systems simulation, the platform offers ef-

ficient integration with ROS (Robot Operating Sys-

tem), which is used to control each robot. The envi-

ronment was configured to replicate real-world con-

ditions, such as variations in cable length and com-

mon obstacles found on transmission lines. The per-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

260

formance of the robots was evaluated based on their

ability to traverse the lines, avoid obstacles, and per-

form inspection tasks such as visual monitoring of in-

sulators and cables.

The simulation environment was inspired by the

region of Curitiba, in the state of Paran

´

a, Brazil.

Specifically, a section between two transmission tow-

ers located in a suburban area of the city was mod-

eled, where the cable crosses various geographical

and structural elements. In real scenarios, it is com-

mon to find busy avenues with heavy traffic of cars

and trucks beneath the cables. Near the towers, there

is medium-density vegetation, including trees that,

over time, can grow close to the lines, posing contact

risks.

Along the cable, there are also various struc-

tural components of the transmission system that act

as potential obstacles for the robots, such as vibra-

tion dampers, suspension clamps, marker balls, and

EPDM or glass insulators, as shown in Figure 1.

These devices, essential to the integrity of the electri-

cal system, pose mechanical challenges that require

the robot to be capable of maneuvering, suspension,

and obstacle avoidance. Additionally, due to the prox-

imity to industrial areas and logistics hubs, the pas-

sage of large vehicles such as buses and trucks be-

neath the line can generate electromagnetic fields and

air currents that affect the stability of the robots dur-

ing inspection. Furthermore, four distinct obstacles

were measured to serve as a benchmark for the ma-

neuvering clearance achieved by each robot during

the simulations.The key parameters are described in

Table 1.

Figure 1: Objects found on transmission lines. (a) Glass

insulators, (b) Vibration dampers, (c) EPDM insulators, (d)

Suspension clamps, (e) Marker ball.

Table 1: Dimensions of the Simulated Obstacles.

Obstacle Length (cm) Height (cm) Diameter (cm) Notes

Vibration Damper 35.0 - 5.0 Cylindrical shape

EPDM Insulator - 150.0 15.0 20 sheds

Glass Insulator - 24.0 25.4 A single glass disc

Marker Ball - - 60.0 Spherical shape

To optimize simulation performance, a represen-

tative section was selected: the area closest to the

high-voltage tower, where a vibration damper is in-

stalled and dense vegetation exists on one side, cre-

ating a semi-urban environment ideal for testing lo-

comotion, gripping, and obstacle-avoidance capabili-

ties, as shown in Figure 2.

Figure 2: Simulated environment and objects in Cop-

peliaSim. (a) Simulated section, (b) Vibration dampers, (c)

EPDM insulators.

The use of CoppeliaSim, as highlighted by Frates

et al. (2023), has been essential for validating robots

in simulated scenarios before practical deployment,

particularly for robotic platforms used in transmis-

sion line inspection, similar to those evaluated in this

study.

4 OVERVIEW OF ROBOTIC

SYSTEMS

This section overviews the three robotic platforms

used for transmission line inspection. Each platform

has been designed with specific features and method-

ological approaches tailored to address the unique

challenges of transmission line environments. The

methodologies proposed in this work focus on key

aspects such as the ability to traverse complex trans-

mission line structures, offering high flexibility and

adaptability to accommodate different types and mod-

els of equipment commonly found in the field. Fur-

thermore, these platforms are developed with a mod-

ular and scalable architecture, allowing for the in-

tegration of additional tools, sensors, and functional

modules as needed. This modularity ensures that the

robotic systems can be expanded or reconfigured to

meet the varying operational requirements and tech-

nical characteristics of different transmission lines

and their components. Each methodology empha-

sizes a particular aspect of the inspection process,

whether mobility, versatility, or expandability, provid-

Comparative Analysis of Robotic Topologies for Transmission Line Inspection

261

ing a comprehensive solution for reliable and efficient

transmission line maintenance.

4.1 LineWalker: Simple Grasping

Mechanism

LineWalker is designed with a strong emphasis on

balance and safe traversal along transmission lines.

Its mechanical architecture relies on a simple yet ef-

fective system composed of three pulleys, one of

which functions as a gripper that securely attaches

the robot to the conductor. The robot’s body inte-

grates two motors: one dedicated to driving the pul-

leys for forward movement along the line, and another

connected to a crank-slider mechanism responsible

for operating the gripper, enabling precise attachment

and detachment from the cable. This configuration

ensures that the robot maintains stability and reliable

adherence to the line during operation, prioritizing

safety during movement.

Among the robotic platforms presented in this

work, LineWalker stands out for having the simplest

and lightest mechanical arrangement. Its reduced

structural complexity not only facilitates easier de-

ployment and handling but also directly contributes

to achieving the highest traversal speed compared to

the other topologies analyzed. This makes it partic-

ularly advantageous for inspection tasks where effi-

ciency and agility are critical, provided that the line

is free of complex obstacles. While the system offers

robust performance in line traversal, it may present

limitations when navigating around obstacles. The

overall design is similar to the topology presented by

(Rohrich et al., 2023), as illustrated in Figure 3.

Figure 3: LineWalker attached to the high-voltage cable

(CoppeliaSim).

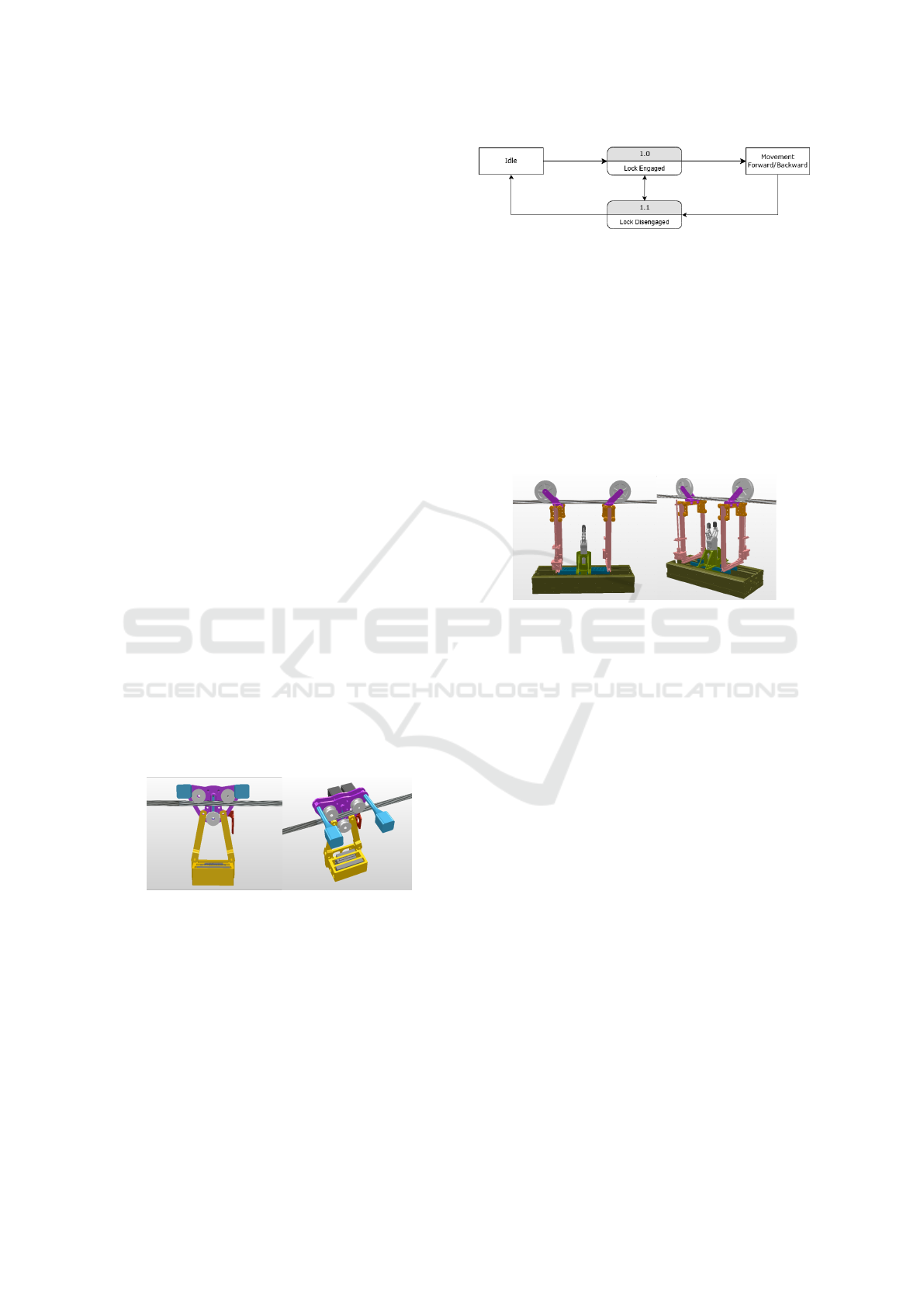

The flowchart of the movement sequences that

LineWalker is capable of performing during its op-

eration is illustrated in Figure 4.

4.2 FlexRover: Dual-Arm System with

High Maneuverability Gripper

FlexRover is the most complex of the three robots,

featuring a dual-arm system with articulated arms ca-

Figure 4: Flowchart illustrating LineWalker’s movement se-

quence.

pable of extending and retracting to navigate obstacles

on the transmission line. The robot also includes a

central gripper mechanism that serves as an additional

contact point with the cable, providing increased sta-

bility. This third point of support reduces the risk of

the robot twisting or falling when one of the pulleys

opens. The robot’s ability to navigate obstacles be-

neath the cable adds another layer of complexity to

its design, ensuring it can operate in more challeng-

ing environments. It is presented in Figure 5.

Figure 5: FlexRover, attached to the high-voltage cable

(CoppeliaSim).

Due to its higher mechanical complexity and,

consequently, greater flexibility in movement, the

FlexRover features a larger and more sophisticated

set of motion capabilities compared to simpler plat-

forms. This advanced mobility allows the robot to

overcome a wider variety of obstacles typically found

on transmission lines, making it highly versatile for

more challenging inspection scenarios. The complete

sequence of movements and operational transitions is

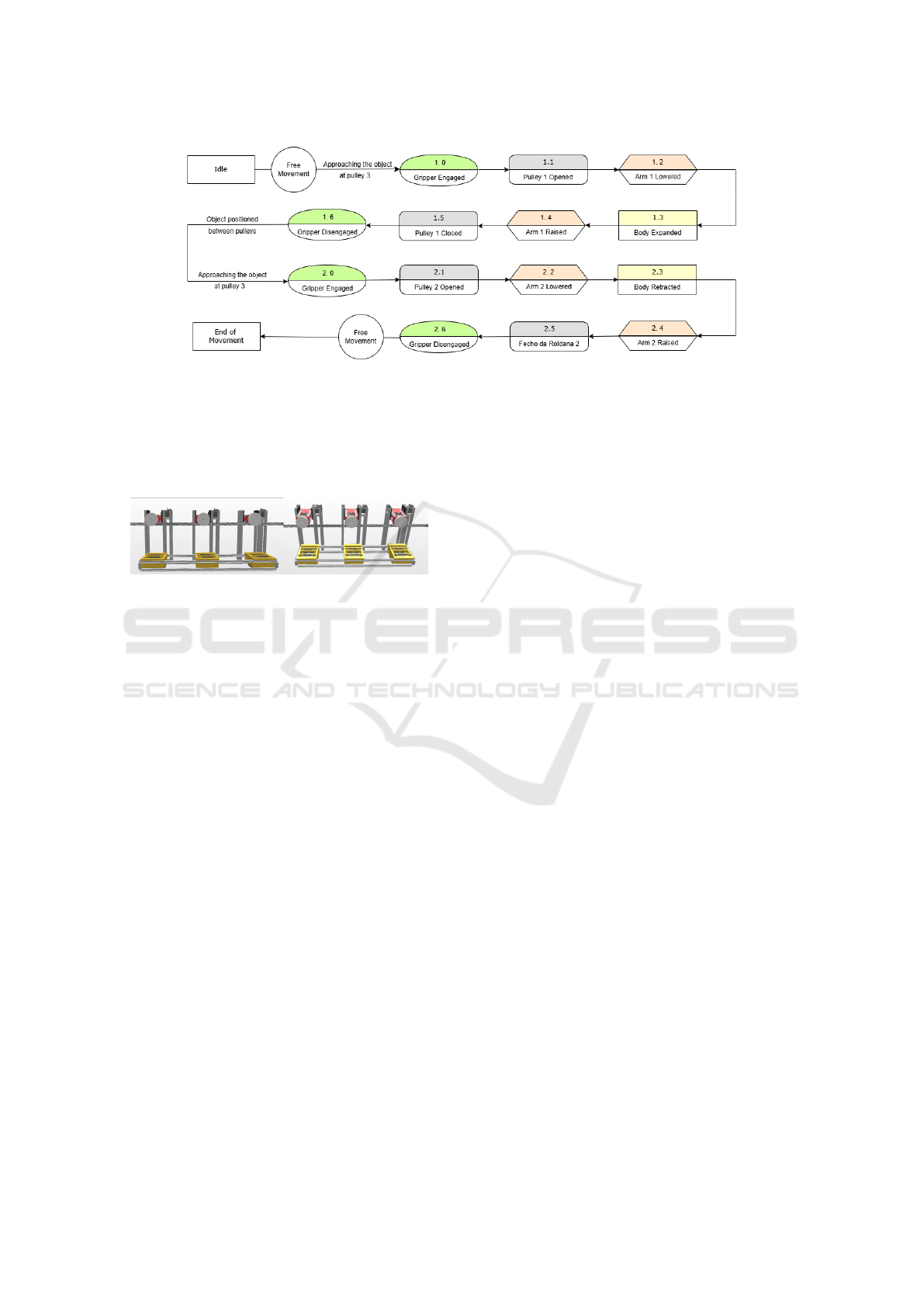

presented in the flowchart shown in Figure 6.

4.3 ModuClimber: Advanced Arm and

Pulley System

ModuClimber is distinguished by its modular archi-

tecture, which allows it to adapt to different obstacle

sizes commonly found on transmission lines. One of

its most notable features is the ability to easily ad-

just its size and configuration, providing a high degree

of versatility for various inspection scenarios. The

robot employs a more sophisticated design, consist-

ing of three pulleys, motors, and articulated arms that

can be raised or lowered to navigate obstacles such as

dampers. Each arm is equipped with a pulley system

that ensures proper balance and movement along the

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

262

Figure 6: Flowchart illustrating FlexRover’s movement sequence.

high-voltage cable. This modular approach enables

the robot to be reconfigured quickly and efficiently,

making it a highly adaptable solution for inspecting

different transmission line segments. Figure 7 illus-

trates the overall structure and functionality.

Figure 7: ModuClimber attached to the high-voltage cable

(CoppeliaSim).

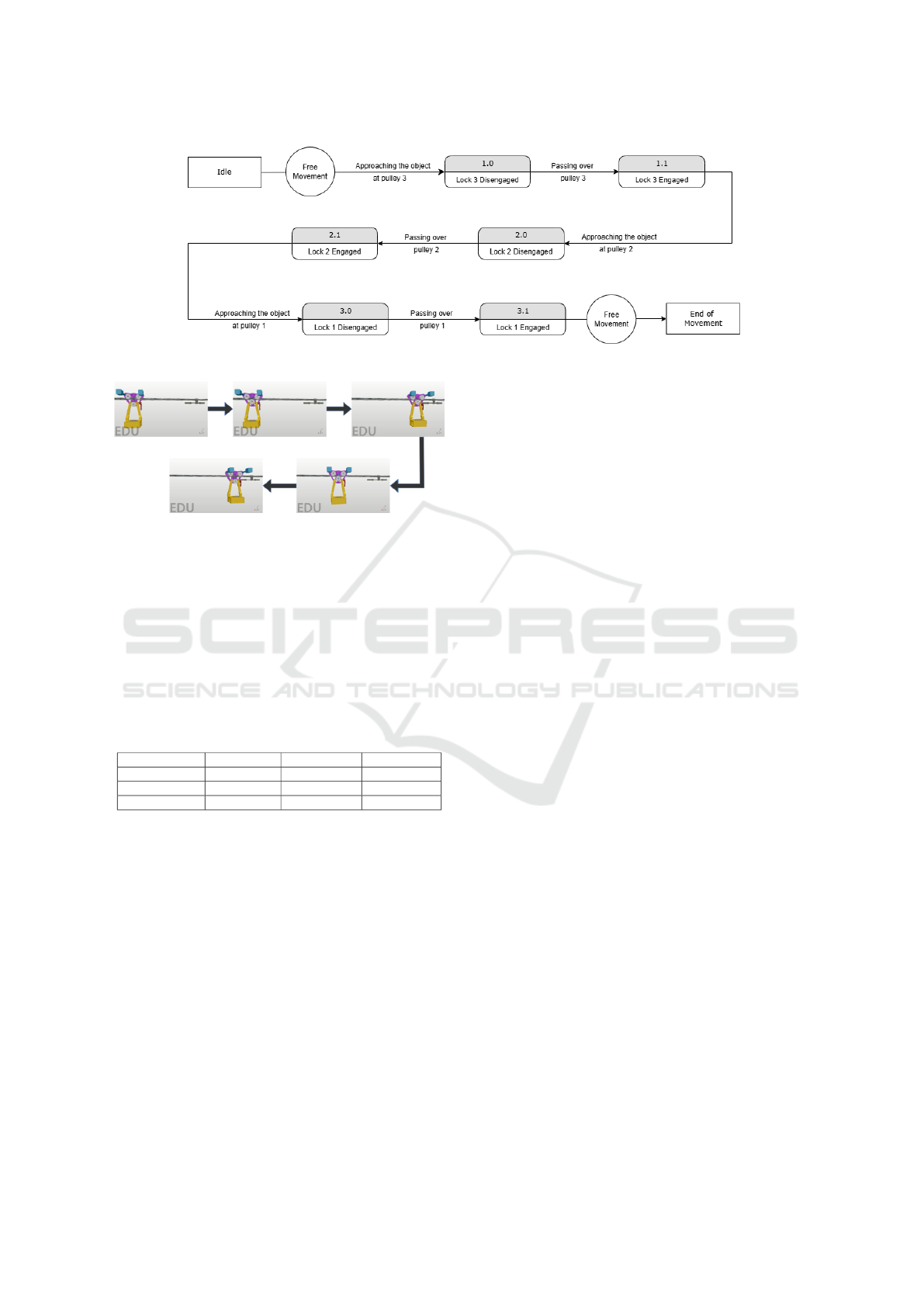

The set of movement sequences that Mod-

uClimber can perform is presented in Figure 8. This

flowchart illustrates how the robot manages its modu-

lar configuration and articulates its arms to adapt to

different obstacle sizes, ensuring safe and efficient

traversal along the transmission line.

5 SIMULATION RESULTS

5.1 LineWalker Simulation Results

In CoppeliaSim, the LineWalker maintained a stable

trajectory along the transmission line, securely attach-

ing to the cable and avoiding slippage. However, its

performance declined when encountering obstacles,

as the robot lacked the ability to dynamically adjust

its position or height, resulting in zero maneuvering

clearance. Despite these limitations, the LineWalker

performed well in simple scenarios, as its gripper

mechanism provided the strongest grasp on the cable

among the three models.

Below, as shown in Figure 9, its movement within

the simulation environment can be observed.

5.2 FlexRover Simulation Results

The FlexRover exhibited an exceptional performance

in CoppeliaSim, demonstrating the highest level of

maneuverability among the three robots. The dual-

arm system provided excellent stability, and the cen-

tral gripper mechanism ensured the robot could main-

tain balance even under challenging conditions. Ad-

ditionally, its extended reach allowed it to avoid larger

obstacles, achieving a span of 90 cm, with a maneu-

vering length of 35 cm provided by the central grip-

per. The FlexRover successfully navigated obstacles

both above and below the cable, showcasing its capa-

bility to handle more complex inspection tasks. The

movement sequences performed by FlexRover in the

CoppeliaSim simulation are illustrated in Figure 10.

5.3 ModuClimber Simulation Results

n CoppeliaSim, the ModuClimber demonstrated su-

perior performance compared to LineWalker, with its

articulated arms enabling more dynamic navigation.

The robot successfully avoided simple obstacles, such

as dampers and EPDM insulators, by raising and low-

ering its arms, although this was limited by an arm

length of only 25 cm. The additional motors and pul-

ley system allowed ModuClimber to adjust its height,

ensuring better stability and preventing potential falls,

as shown in Figure 11. However, the complexity of

the arm system required more careful control, and

some imbalances were observed in the simulation due

to its weight distribution.

All topologies struggled to longitudinally traverse

larger obstacles such as marker balls and insulators.

While ModuClimber encountered no issues with ob-

stacles located below the cable, it was unable to over-

come glass insulators; their larger diameter exceeded

the reach of its arms. FlexRover, in turn, faced chal-

lenges with obstacles positioned far below the cable.

These results clearly illustrate the inherent advantages

Comparative Analysis of Robotic Topologies for Transmission Line Inspection

263

Figure 8: Flowchart illustrating ModuClimber’s movement sequence.

Figure 9: (Illustration of LineWalker’s movement within the

CoppeliaSim simulation environment.

and disadvantages of each model.

To provide a quantitative comparison of their

obstacle-handling capabilities, the key maneuvering

dimensions for each robot are detailed in Table 2.

This table specifies the maximum clearance achieved

lengthwise, as well as above and below the cable, dur-

ing the simulations.

Table 2: Comparison of the maneuvering clearance (in cm)

for each robotic platform.

Topologie Lengthwise Above-Cable Below-Cable

LineWalker - - -

FlexRover 35.0 ∞ 20.0

ModuClimber 25.0 ∞ ∞

6 DISCUSSION AND

COMPARISON

The comparative analysis of the three simulated

robotic platforms highlights distinct design ap-

proaches, each with specific characteristics that stand

out depending on the complexity of the inspection en-

vironment.

LineWalker, with its simple grasping mechanism,

demonstrated excellent performance in stable and un-

obstructed scenarios, showing the highest structural

stability among the three models. Its simplified de-

sign favors low implementation costs, reduced main-

tenance, and reliability in linear trajectories. How-

ever, its lack of dynamic adaptability compromises

its efficiency when facing obstacles. Structural mod-

ifications, such as adapting a secondary body using

LineWalker as a support base, may enable future ap-

plications in more complex environments, such as the

traversal of transmission towers.

FlexRover presented the highest degree of ma-

neuverability. Its system of dual articulated arms,

combined with a third point of contact via a central

gripper, provided excellent stability and the ability

to overcome obstacles located both above and below

the cable. Nevertheless, its more complex mechan-

ical structure demands sophisticated control systems

and more frequent maintenance. The strategy of over-

coming obstacles through pulley opening proved to

be ingenious but raises concerns about grip safety, es-

pecially due to the robot’s weight. Therefore, it is

recommended to develop a new cable coupling mech-

anism that does not rely on pulley opening.

ModuClimber represents an intermediate solution,

combining flexibility and robustness. Equipped with

articulated arms and a modular pulley system, it

showed good performance when dealing with mod-

erate obstacles and flexibility in height adjustment

during inspection. Although its maneuverability is

inferior to that of FlexRover, its modularity makes

it a highly scalable platform for different scenarios.

However, its mechanical complexity and weight dis-

tribution require additional attention during calibra-

tion and dynamic control. Improvements in weight

distribution, as well as the implementation of a front

anti-torsion mechanism, are strongly recommended.

Minor adjustments to arm length and pulley spacing

can significantly increase its ability to overcome vari-

ous types of obstacles.

In summary, the results indicate that LineWalker

is most suitable for inspections along continuous and

interference-free lines, offering robustness through

simplicity. FlexRover is best suited for challeng-

ing environments with frequent obstacles and a need

for high precision, although its complexity demands

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

264

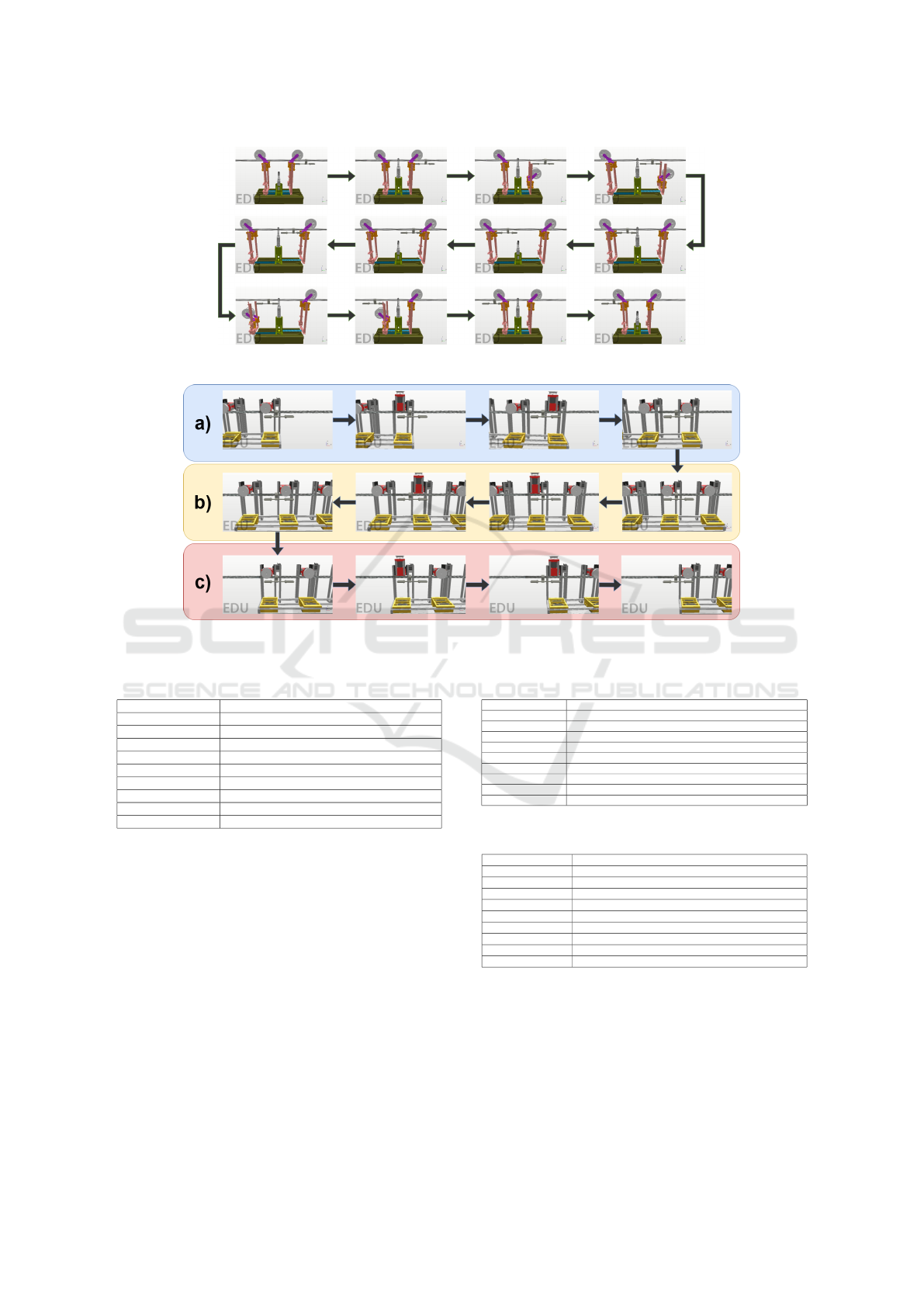

Figure 10: Illustration of FlexRover’s movement within the CoppeliaSim simulation environment.

Figure 11: Illustration of ModuClimber’s movement within the CoppeliaSim simulation environment.(a) Overcoming the

obstacle with pulley 1 (b) Overcoming the obstacle with pulley 2 (c) Overcoming the obstacle with pulley 3.

Table 3: Advantages and Disadvantages of LineWalker.

Aspect LineWalker

Design Simple, easy to control

Stability Good in simple scenarios

Maneuverability Limited, does not dynamically adjust position

Inspection Suitable for simple environments

Implementation Low operational cost

Maintenance Low maintenance due to simple design

Advantages Stability on simple lines, low cost

Disadvantages Limited maneuverability, cannot avoid obstacles

Obstacle Overcome None

greater attention to control and maintenance. Mod-

uClimber, meanwhile, combines elements of both

previous models, offering a good balance between

adaptability, scalability, and stability, making it ideal

for versatile applications in scenarios with moderate

obstacles. These aspects are summarized in the Table

3, Table 4, and Table 5.

7 CONCLUSIONS AND FUTURE

WORK

This study compared three robotic systems for trans-

mission line inspection, each employing different

Table 4: Advantages and Disadvantages of FlexRover.

Aspect FlexRover

Design Complex, with dual arms and central gripper

Stability Excellent stability, even with dynamic obstacles

Maneuverability High, can navigate complex areas and adjust position

Inspection Excellent for complex environments and challenging inspections

Implementation High, due to advanced design and control systems

Maintenance Higher likelihood of failures due to complexity

Advantages Greater stability, adaptability to dynamic environments

Disadvantages High costs, increased likelihood of mechanical failures

Obstacle Overcome Vibration Damper, EPDM and Glass Insulator

Table 5: Advantages and Disadvantages of ModuClimber.

Aspect ModuClimber

Design Complex, with articulated arms

Stability High stability with adaptable pulley system

Maneuverability Good, can raise and lower arms to avoid obstacles

Inspection Suitable for more detailed inspections, including insulators

Implementation Moderate, due to complexity of motors and systems

Maintenance Higher complexity, may require frequent maintenance

Advantages Greater versatility, good adaptability

Disadvantages Complex control system, potential glitches

Obstacle Overcome Vibration Damper and EPDM Insulator

topologies and mechanisms to address the challenges

of operating in hazardous environments. Simulation

results demonstrated that ModuClimber offers the

highest level of performance and stability, making it

the most suitable for complex inspection tasks. How-

ever, LineWalker and FlexRover also provide valu-

able solutions depending on the complexity of the

inspection environment. Future work will focus on

Comparative Analysis of Robotic Topologies for Transmission Line Inspection

265

refining the control systems of FlexRover and Mod-

uClimber to enhance their reliability in real-world ap-

plications.

The automation of transmission line inspections

is continuously evolving. Although current systems

have achieved significant advancements, challenges

remain in improving efficiency and reliability. It is an-

ticipated that robots will become more autonomous,

reducing dependence on human operators and en-

hancing inspection accuracy. Artificial intelligence

will also enable robots to make real-time decisions,

such as obstacle avoidance and route optimization.

Another significant advancement will be the im-

plementation of autonomous power systems, replac-

ing fixed power supplies with rechargeable batteries,

such as Li-ion or Li-po. This will provide greater au-

tonomy, reducing maintenance needs and increasing

inspection efficiency. Optimizing energy consump-

tion and in-field battery recharging are promising ar-

eas for future research.

Next-generation sensors and wireless communica-

tion technologies will play a fundamental role in im-

proving inspections. The use of high-definition cam-

eras, thermal sensors, and LIDAR will allow for more

precise fault detection. The integration of intercon-

nected sensor networks will enable real-time commu-

nication with control centers, facilitating analysis and

decision-making.

In terms of control architecture, the integration

of multi-robot systems will be crucial. Coordination

among robots will allow for greater coverage of trans-

mission lines and increased task efficiency. Collabo-

rative navigation systems, where robots share infor-

mation about position and environmental conditions,

can result in more efficient and safer operations.

Future research should focus on improving the au-

tonomy, maneuverability, and adaptability of robots,

especially in dynamic environments. The integration

of artificial intelligence to optimize control and navi-

gation is also a promising area. The work of (de Al-

buquerque et al., 2024), which utilized a simulation

environment similar to CoppeliaSim for transmission

line inspections, exemplifies how these technologies

can be applied in real-world scenarios.

ACKNOWLEDGEMENTS

The project is supported by the National Council for

Scientific and Technological Development (CNPq)

under grant number 407984/2022-4; the Fund for

Scientific and Technological Development (FNDCT);

the Ministry of Science, Technology and Innovations

(MCTI) of Brazil; Brazilian Federal Agency for Sup-

port and Evaluation of Graduate Education (CAPES);

the Araucaria Foundation; the General Superinten-

dence of Science, Technology and Higher Education

(SETI); and NAPI Robotics.

REFERENCES

A. B. Costa, J. M. P. (2023). Tend

ˆ

encias em rob

´

otica para

inspec¸

˜

ao de sistemas el

´

etricos de pot

ˆ

encia. Encontro

Nacional de Engenharia, 12(1):58–65.

Alhassan, A. B., Zhang, X., Shen, H., and Xu, H. (2020).

Power transmission line inspection robots: A review,

trends and challenges for future research. Interna-

tional Journal of Electrical Power & Energy Systems,

118:105862.

Bayındır, L. (2016). A review of swarm robotics tasks. Neu-

rocomputing, 172:292–321.

Chai, R., Guo, Y., Zuo, Z., Chen, K., Shin, H.-S., and Tsour-

dos, A. (2024). Cooperative motion planning and

control for aerial-ground autonomous systems: Meth-

ods and applications. Progress in Aerospace Sciences,

146:101005.

de Albuquerque, J. M. N., Neto, O. R., Arm

ˆ

enio, G. F.,

Corr

ˆ

ea, V. M., do Valle, D. R. G., Domingues, A.,

Rohrich, R. F., and de Oliveira, A. S. (2024). A

novel method for multi-modal predictive inspection of

power lines. IEEE Access, 12:184680–184691.

Jiang, W., Liu, R., Yang, Y., Wan, S., Guo, X., Jiao, Z., and

Yu, H. (2018). Design and implementation of a new

climbing robot for high voltage transmission tower.

IOP Conference Series: Materials Science and Engi-

neering, 428(1):012071.

R. P. Almeida, L. F. Souza, M. J. C. (2022). T

´

ecnicas

avanc¸adas de inspec¸

˜

ao automatizada em linhas de

transmiss

˜

ao. Revista Brasileira de Engenharia

El

´

etrica, 17(3):215–229.

Rohrich, R. F., Valle, D. G. D., Albuquerque, J. M. N. D.,

Neto, O. R., Oliveira, A. S., and Oliveira, A. S. D.

(2023). A robotic cable-gripper for reliable inspection

of transmission lines. In Proceedings of the IEEE In-

ternational Symposium on Robotics and Automation.

T. A. Silva, R. F. Gomes, P. V. L. (2020). Rob

ˆ

os

para inspec¸

˜

ao em ambientes energizados: desafios e

soluc¸

˜

oes. Revista de Automac¸

˜

ao e Controle, 14(2):89–

97.

Wang, L. and Wang, H. (2016). A survey on insulator in-

spection robots for power transmission lines. pages

1–6.

Y. Zhang, L. Chen, H. W. (2021). Ai-based navigation for

power line inspection robots. IEEE Transactions on

Industrial Informatics, 17(5):3420–3430.

Zhu, B., Zhang, X., Zhang, H., Liang, J., Zang, H., Li, H.,

and Wang, R. (2020). Design of compliant mecha-

nisms using continuum topology optimization: A re-

view. Mechanism and Machine Theory, 143:103622.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

266