Development of a Control System for an Innovative Parallel Robot

Used in Laparoscopic Pancreatic Surgery

Doina Pisla

1,3 a

, Andra Ciocan

1,2 b

, Bogdan Gherman

1,* c

, Diana Schlanger

2d

,

Alexandru Pusca

1,* e

, Nadim Al Hajjar

2f

, Emil Mois

2g

, Andrei Cailean

1h

, Nicoleta Pop

1i

,

Paul Tucan

1j

, Ionut Zima

1k

and Calin Vaida

1l

1

CESTER, Technical University of Cluj-Napoca, 400114 Cluj-Napoca, Romania

2

Department of Surgery, “Iuliu Hatieganu” University of Medicine and Pharmacy, 400347 Cluj-Napoca, Romania

3

Technical Sciences Academy of Romania, B-dul Dacia, 26, 030167 Bucharest, Romania

Keywords: Parallel Robot, Master-Slave, Control System, Minimally Invasive Pancreatic Surgery, Robotic Assisted.

Abstract: This paper presents the development of the control architecture for an innovative parallel robot, designed to

assist surgeons during the minimally invasive pancreatic cancer surgery. Based on the defined medical

protocol and surgeon requirements. The robot was designed to serve as a surgical assistant and to manipulate

a third active instrument. The system features a 3-DOF parallel active module coupled to a passive spherical

module guiding the instrument through a Remote Center of Motion (RCM). The master-slave control

architecture enables surgeons to operate the robot using a 3D Space Mouse or haptic device (Omega.7). The

system automatically calculates RCM position using IMU sensors, validated through optical tracking.

1 INTRODUCTION

Pancreatic cancer ranks 7

th

globally in terms of

mortality rate and 14

th

in incidence. In Europe, it

ranks 2

nd

in terms of the number of new cases, with

countries such as Hungary, Slovakia, the Czech

Republic, and Serbia reporting the highest rates

(McGuigan, 2018) with a higher incidence in

developed countries (Wong MCS, 2017). Risk factors

include modifiable factors (obesity, diet, alcohol,

smoking) and non-modifiable factors (age, gender,

genetics) (McGuigan, 2018). The prognosis remains

challenging with a 5-year survival rate of only 5%,

increasing to 30% with early detection. However,

early detections increase the 5-year survival rate to

30%. Treatment involves surgery combined with

oncological therapy (Nortunen, 2023; Nießen, 2022).

Three main surgical procedures are used for

a

https://orcid.org/0000-0001-7014-9431

b

https://orcid.org/0000-0003-0126-6428

c

https://orcid.org/0000-0002-4427-6231

d

https://orcid.org/0000-0002-4427-6231

e

https://orcid.org/0000-0002-5804-575X

f

https://orcid.org/0000-0001-5986-1233

g

https://orcid.org/0000-0002-2972-3777

pancreatic cancer: Pancreaticoduodenectomy

(Whipple Procedure) (Cawich, 2023), Distal

Pancreatectomy (De Pastena, 2023), and Total

Pancreatectomy (Balzano, 2023).

The first robotic-assisted distal pancreatectomy

was performed using the da Vinci system in 2003

(Melvin, 2003), improving safety and feasibility

compared to manual laparoscopic surgery leading to

wider robotic surgery adoption (Damoli, 2015).

Robotic systems (da Vinci, Senhance, Versius) offer

advantages including the elimination of the

triangulation effect, enhanced precision, improved

dexterity, and increased patient safety, driving

adoption in surgical interventions. These surgical

robots reduce hand tremors, enable motion scaling

and multi-instrument manipulation, improve

ergonomics through master-slave control (Pisla,

2021), and support remote telesurgery interventions

h

https://orcid.org/0009-0004-4758-0468

i

https://orcid.org/0000-0001-5660-8259

j

https://orcid.org/0000-0001-5660-8259

k

https://orcid.org/0009-0007-0483-7691

l

https://orcid.org/0000-0003-2822-9790

*

Corresponding author

Pisla, D., Ciocan, A., Gherman, B., Schlanger, D., Pusca, A., Al Hajjar, N., Mois, E., Cailean, A., Pop, N., Vaida, C., Tucan, P. and Zima, I.

Development of a Control System for an Innovative Parallel Robot Used in Laparoscopic Pancreatic Surgery.

DOI: 10.5220/0013708700003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 243-250

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

243

(Li, 2023). Robotic-assisted surgery presents several

disadvantages, including the high cost of surgical

intervention, steep learning curves, potential arm

collisions, significant space, the lack of haptic

feedback, and the limited intraoperative space

(Haidegger, 2022).

Most robots for laparoscopic surgery use master-

slave architecture (Rus, 2023; Pisla, 2024 a). These

robots operate without autonomy in minimally

invasive surgery (Khachfe, 2022). These robotic

systems lack haptic feedback for surgeons

(Minamimura, 2024). Studies demonstrate haptic

device integration in the Senhance robotic system

(Kastelan, 2021). Force feedback sensors have been

placed near the robot flange, but the research in this

direction is in the early stages of development

(Bergholz, 2023). Alternative control approaches

using contactless interfaces have been explored.

Korayem demonstrated Leap Motion controller

integration for surgical robot control with Kalman

filtering (Korayem, 2021), hand tremor detection and

compensation techniques (Korayem, 2022 a), and

complete laparoscopic robot system development

(Korayem, 2022 b; Najafinejad, 2023).

Minimally invasive pancreatic procedures are

complex, requiring multiple instruments, extended

operative time, and involving high risks (Asbun,

2023), indicating significant research gaps in the

field. To address these challenges, a new parallel

robot was developed for minimally invasive

pancreatic surgery (Vaida, 2025). The proposed robot

acts as a surgical assistant during pancreatic

laparoscopy, performing tissue manipulation tasks

using an active surgical instrument.

The paper is structured as follows: Section 1

presents the introduction, section 2 outlines medical

protocol, robot design and integration, and

mathematical model implementation, section 3

illustrates the control architecture of the robot; section

4 illustrates the experimental testing and validation,

while section 5 presents conclusions and future

developments.

2 DESIGN OF THE INNOVATIVE

SURGICAL PARALLEL ROBOT

AND ACTIVE INSTRUMENT

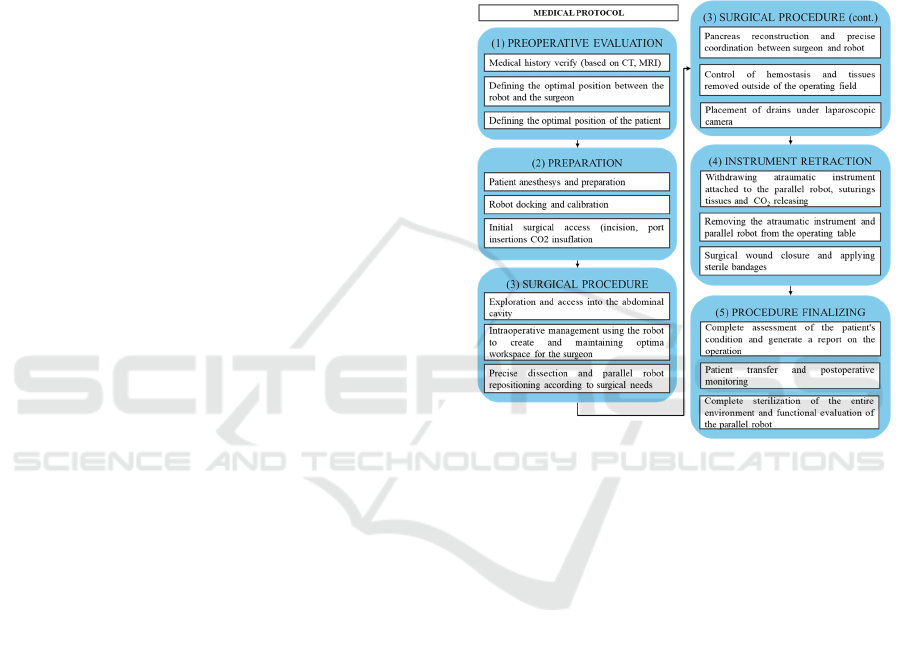

The Athena parallel robot was developed based on a

medical protocol (Figure 1) established in

collaboration with surgeons. This protocol outlines

the steps for laparoscopic pancreatic surgery targeting

the head of the pancreas (Whipple Procedure).

Based on the medical protocol and surgeon’s

requirements, the kinematic scheme of the robot

(Figure 2) was developed, together with an active

instrument, both subject to two patents (Pisla, 2025 b;

Vaida, 2025 a). The robot assists the main surgeon by

manipulating a third active atraumatic instrument to

create an intraoperative workspace and support

organs around the pancreas. A detail of the tasks that

the robot performs is extensively presented in (Vaida,

2025 b) and in (Tucan, 2025).

Figure 1: Medical protocol for laparoscopic pancreatic

surgery.

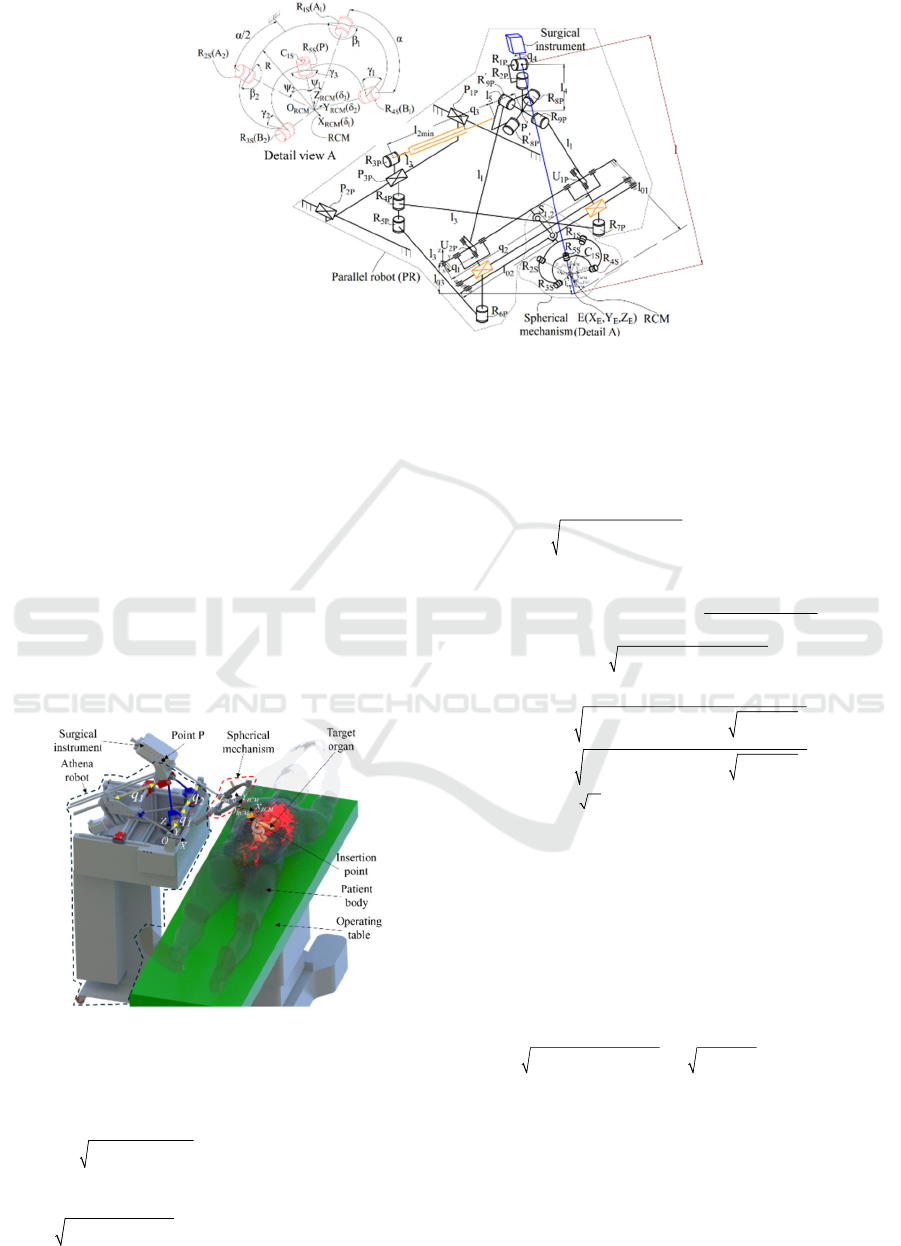

The ATHENA parallel robot mechanical

architecture (Figure 2) consists of two modules: an

active 3 degrees-of-freedom (DOF) parallel robot and

a passive parallel spherical mechanism. The spherical

mechanism fixes and holds the Remote Center of

Motion (Zhang, 2024), while the parallel robot

manipulates the active surgical instrument. The robot

consists of 9 passive revolute joints, three passive

prismatic joints, three active prismatic joints (qi,

i=1....3) and two passive universal joints. The global

coordinate system is placed on the robot base. The

spherical mechanism features five passive revolute

joints and one passive cylindrical joint that provide

rotation and insertion motion of the active instrument.

The spherical mechanism connects to the robot base

via a link and two spherical joints for RCM placement

and adjustment.

Detailed description of parameters is presented in

(Vaida, 2025), and integration of the robot into the

medical environment is illustrated in Figure 3.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

244

Figure 2: Kinematic scheme of the Athena robot.

Based on the kinematic scheme and parameters

presented in (Vaida, 2025), kinematic models

(forward and inverse) of the Athena robot were

developed and integrated into the control system

through input/output equations. Four mathematical

models are used to control the robot: forward (Eqs. 2-

5) and inverse (Eqs. 7-9) kinematic models without

RCM, used for robot positioning near the patient and

RCM before instrument attachment. Once the RCM

is defined, the instrument is positioned at the

abdominal insertion position and attached to the

robot. In this configuration, inverse (Eqs. 5-6) and

forward (Eqs. 7-9) kinematic models with RCM

control both the robot and the surgical instrument.

Figure 3: Athena robot integrated into the medical

environment.

The equations for these models are:

()()( )

02 1 2

2

222

2

41 2 03 0

1

21 1

:0

:/2) 0

((/2))

(

++ −

+−− −− − −

=

=

P

PP

fl q q Y

llqq Z Xlfl

(1)

() ()

(

()

)

()

()

2

32min5 014

2

2

2

2

321 4 03

3

:

/2) 0

cos

(sin

P

P

fql l Xll

lqq Zl l

λ

λ

++− −− +

−− − − =−

where:

()

ins ins

ins 03 01

() ()( ); () ()( )

()( ); , .

P

P

PP

P

cos sin l l sin sin l lXY

ataZcosll ZlXln

ψθ ψθ

θλ

−−

=− −−

==

=

(2)

() ()

44

;= ;

PPc PPcP Pc

XX lcos YYZZ lsin

ββ

+==+

(3)

and:

()

()

()

()

()

()

() ()

2

321 532min

21 32min

2

;

;

= / 2

/2; =

pc

pc pc

Xlqq lqlcos

Yqq Zqlsin lsin

α

αβ

+

−

−− −++

=− +

4

(4)

()

()

()

()

()

()

2222

1

32min

22 2

32min 3 1 21 2 5

21

2, ;

2

; 4 2 /2;

/2.

;

pc pc

ABlC

arctan Z X arccos

ql B

Aq l B l q qq q l

Cqq

βα

+−+

==

+

=+ = −+

=−

⋅

−+

()()

()()

()

()

22 22 22

114 4

22 22 22

214 4

3

.

2

+

;

2

/

;

2²

PPPPP

PPPPP

qY l l X Z l X Z

qY l l X Z l X Z

qND r

=− −− + + +

=−−+++

=

+

(5)

where:

( )() ()

66 24 5 32 4

1P P PP2 P5 5 5

22 2222

3345

5

222

2min 123456

2222 2 222

4

2

12 12 12

22

1

4

5

P

2

P

2;²

2

;;

²42

4;

4

T = 4Z + 4X + 1 X 4Z ; 8X 16 8 ;

4 ( )( );

XX

P

PP

PP

P

PP

P

PP

P

P

P

N

l

T

rl r X Z D T T T T T T

rX Z q q rqq XZ

l

lXZlXZl

TrXZll

T

qq

XZq

A

T

q

=− = + = + + + + +

−+ ++

+

−+=+

+

=+ +

=++

=

()

()

()

P

32 22 4 4

555

32

4

22 4 3 2

455

22 2 2 2

31

3

22 P

6

2

;

.

X

2

82

4

;

2;X

PP PP PP P

PPP

PP P P PP

P

XZ XZl XZ Z

Br X X Z l

Brl X Z Z X l X Z l

AlqqqqB Z

T

−

++ ++

+

−++++

=−

=

−=+

+

1

(6)

()

()

atan 2 sin , cos

atan 2 sin , cos

θθ

ψψ

θ

ψ

=

=

(7)

where:

Development of a Control System for an Innovative Parallel Robot Used in Laparoscopic Pancreatic Surgery

245

()()()

22 2

2

cos

sin 1 cos

RCM P RCM P RCM P

RCM P

XXYYZZ

ZZ

θ

θθ

−+ −+ −

=

−

=−

(8)

()()()

()

()()()

()

22 2

22 2

sin

1

sin

cos

1

sin

RCM P

RCM P RCM P RCM P

RCM P

RCM P RCM P RCM P

XX

XX YYZZ

YY

XX YYZZ

ψ

ψ

θ

θ

−

=⋅

−+ −+ −

−

=⋅

−+ −+ −

Finally, the end-effector coordinates are:

() ()

() ()

()

cos sin

sin sin

cos

EP

EP

EP

XL X

YL Y

ZL Z

ψθ

ψθ

θ

=⋅ +

=⋅ +

=⋅ +

(9)

An innovative active instrument (Pisla, 2024 b)

was developed and integrated with the robot.

The active instrument features a 10 mm diameter

shaft with an articulated distal head and four degrees

of freedom (DOF) to improve the workspace

compared to standard rigid laparoscopic instruments,

q

insi

, i=1…4.

The 3D design of the instrument and the

movements are illustrated in Figure 4.

Four actuators are used to control the instrument

movements (Figure 4): opening/closing of the distal

head (q

1

), rotation of the distal head (q

2

), flexible

element bending (q

3

) and the rotation of the entire rod

(q

4

).

The flexible segment (Figure 4) provides distal

head bending capability. The instrument is

manufactured using 3D printing (Stratasys J5 Prime

Med).

Figure 4: The 3D design of the active instrument and its

movements.

3 THE CONTROL SYSTEM

The control system converts surgeon hand motions

into robot commands using either a 3D Space Mouse

(3DConnexion, Munich, Germany, 2001) or

Omega.7 haptic device (Force Dimension,

Switzerland, 2001) as master console. The robot

reproduces the surgeon's movements following

established safety measures (Vaida, 2016).

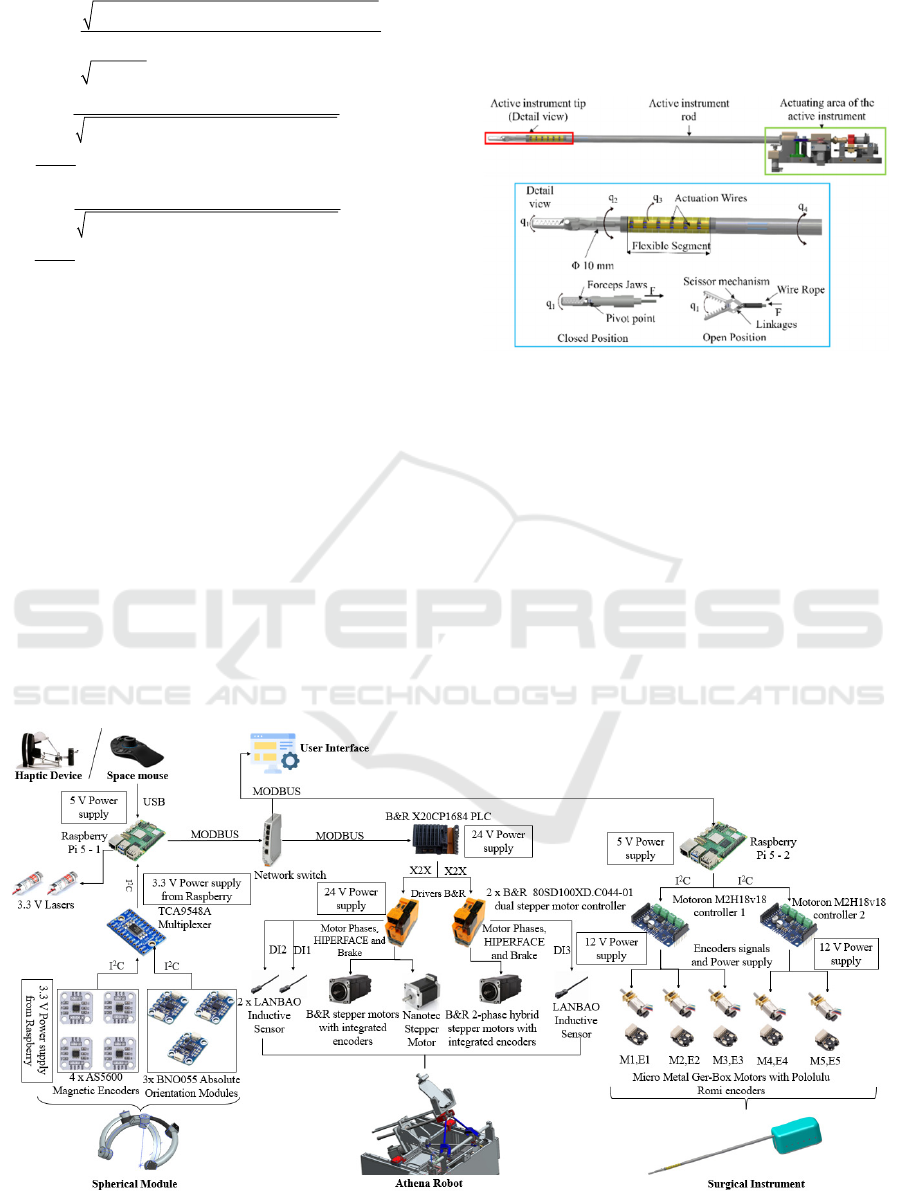

Figure 5: Hardware architecture of the Athena parallel robot.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

246

Figure 5 illustrates the hardware architecture of

the Athena parallel robot. The entire system can be

divided into three main modules, the surgical

instrument, the Athena robot and the spherical

module.

To control the surgical instrument, five Pololu

micro metal gear-box motors are used and to obtain

position feedback five Pololu Romi encoders are

used. To control the motors, two Motoron M2H18v18

controllers are used, with two different addresses. The

controllers are receiving data that is converted to

PWM signals from Raspberry Pi 5-2 via I²C BUS

communication protocol that allows the Raspberry Pi

to control multiple devices. The 12V supply powers

the Motoron controllers and Pololu motors, while the

5V supply operates the Raspberry Pi 5-2.

The Athena robot is controlled using a B&R PLC

system employing two B&R hybrid stepper motors

and one Nanotec stepper motor with integrated

encoders. Motor control is achieved using two B&R

stepper controllers. Three LANBAO inductive

sensors are used for the homing procedure.

To control both robot and the instrument, the

Raspberry pi 5 - 1 is receiving the data from a 3D

space mouse or from the haptic device via USB. The

PLC is receiving data from the rasp Raspberry pi 5 –

1 via Modbus, being connected to the LAN network

of the system though the Network Switch. The same

protocol and LAN network is used to send data from

the PLC to the second Raspberry Pi 5.

The spherical module represents the last element

of the system. To know the position and the

orientation of the module, three BNO055 Absolute

orientation modules and four AS5600 magnetic

encoders are used.

Three absolute orientation modules with 9-axis

IMUs determine the spherical module's position and

orientation.

Four magnetic encoders provide precise angle

feedback for each revolute joint of the spherical

mechanism. IMU sensors and encoders communicate

with Raspberry Pi 5 via I²C protocol through a

multiplexer powered by a 3.3 V supply. The

multiplexer manages multiple I²C devices and

prevents address conflicts, enabling simultaneous

data acquisition from all sensors and encoders.

Two lasers powered from a 3.3 V supply are used

to aid in the positioning of the RCM, with the RCM

located at the intersection of both laser beams.

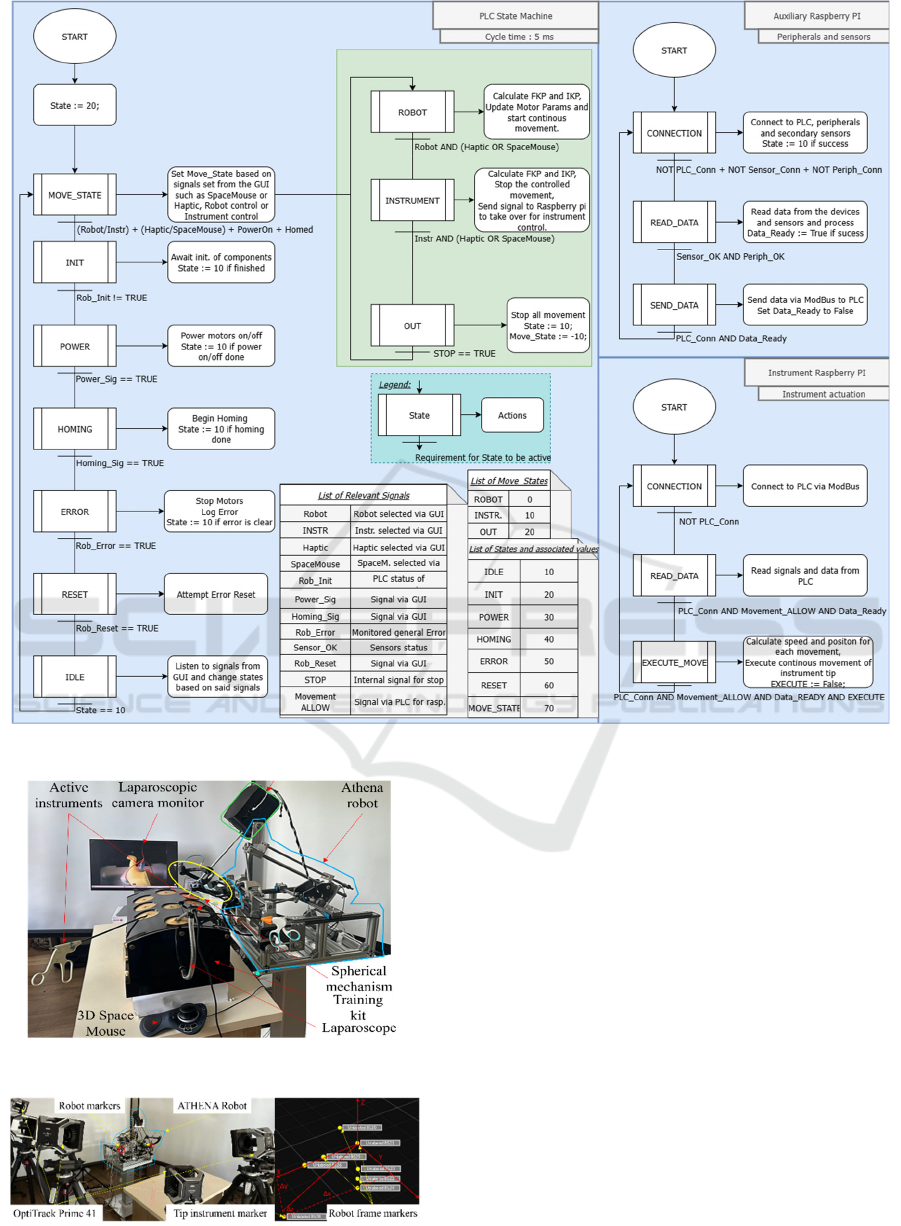

Figure 6 presents the state machines of the PLC

and two raspberry PI 5 boards. On the PLC side, the

initial state that is set on system power up is INIT,

which waits for every component of the system to be

powered up and ready for communication. If

successful, the system proceeds to the IDLE state in

which it awaits user inputs via the GUI such as:

Homing, Power, Reset etc. Once the user selects the

structure to control (Robot or active instrument) and

a method of controlling said structure (Haptic or

Space Mouse) the state machine switches to

MOVE_STATE. A secondary state machine allows

the smooth change between controlling the robot and

the active instrument and switching between control

peripherals. The Auxiliary Raspberry PI 5 that is used

for gathering data from the control peripherals and

secondary sensors (BNO-055 and AS5600) is

connected via MODBUS to the system’s LAN

network and presents a state machine of its own. A

simple one that connects, reads and sends the data

back to the PLC via Modbus. The instrument’s

Raspberry PI 5 also has a state machine that connects,

reads commands and data from the PLC and moves

the instrument’s tip according to the user’s input to

grasp, bend, twist and rotate.

4 EXPERIMENTAL TESTING

AND VALIDATION

Figure 7 illustrates the experimental setup that was

developed. Robot calibration is required before

testing (Pisla, 2009). The calibration consists of a

homing procedure for the active linear joints of the

robot (q

i

, i=1…3).

One IMU positioned on the robot frame represents

the reference, the second is positioned on the link

between the two spherical joints connecting the robot

frame with the spherical mechanism and one on the

spherical mechanism. The fixed one, positioned on

the robot frame, is aligned with the robot reference

system (OXYZ).

These sensors are only used once in the

determination of the RCM, specifically at system

power up, ensuring that angle drift has a minimal or

no impact on the Euler angles.

Development of a Control System for an Innovative Parallel Robot Used in Laparoscopic Pancreatic Surgery

247

Figure 6: Athena parallel robot state machines.

Figure 7: Experimental setup of the Athena robot.

Figure 8: Setup for RCM validation using Optitrack.

The RCM position within the robot coordinate

frame is automatically calculated using the IMU

sensors output, namely the yaw-pitch-roll angles

(following the z-y-x rotation convention). Thus, the

RCM position in the robot coordinates frame is:

12

01 2

1 001

T

Sph Sph SphMec T

RCM RCM RCM

Sph Sph

XYZ T T T R=⋅⋅ ⋅

(10)

where

1

0

Sph

T

is the transformation matrix from the

robot coordinate system to the first spherical joint,

2

1

Sph

Sph

T

the transformation matrix from the first to

second spherical joint,

2

SphMec

Sph

T

the transformation

matrix from the second spherical joint to the passive

spherical mechanism (the attaching point) and R is its

radius (Vaida, 2025). Knowing the coordinates of

point P (Eq. 3), the orientation of the instrument can

be determined using Eqs. 7-9.

The OptiTrack measurement system was used to

validate the detected RCM position obtained using

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

248

the IMU sensors and Eq 10. The setup for these

measurements is illustrated in Figure 8, which shows

the placement of the markers on the experimental

model to determine the coordinate system axes and

the actual position of the RCM (measured), as well as

their display in the virtual environment using the

Motive software program. The measurements were

performed after the IMU sensors calibration, which

reduces the drift) and the determined RMSE has been

of 0.58 mm, with a maximum positioning error of

1.56 mm within the experimental tests.

Experimental tests were performed using a

minimally invasive surgery kit (Figure 9) with 3D

printed pancreas and stomach. The soft-material

organs (Vaida, 2025) enable testing scenarios where

the instrument grasps and withdraws the stomach

from the pancreatic field, holding it outside the

intraoperative workspace required for pancreatic

procedures.

Figure 9: Stomach grasping and manipulation to generate

intraoperative field.

5 CONCLUSIONS

This paper presents the control architecture for the

Athena robot, a surgical assistant for laparoscopic

pancreatic surgery that manipulates an active

instrument. The master-slave control system uses

either a 3D Space Mouse or haptic device (Omega.7)

as the master console. The architecture integrates

hardware and software components to enable precise

surgical manipulation. Surgeons can define the RCM

position before insertion and modify it during surgery

as required. OptiTrack Motion Capture system

validation confirmed the approach's accuracy.

Experimental tests used a minimally invasive surgery

kit with 3D printed pancreas and stomach to

demonstrate the flexibility and dexterity for

pancreatic surgery. Future research will focus on

experimental tests to simulate resection and

reconstruction of the pancreas during the Whipple

procedure, using a pancreas realized at a scale of 1 to

1 based on 3D reconstruction using real CT scan data,

improvement of the GUI and integration of the robot

into a surgical simulator.

ACKNOWLEDGEMENTS

This research was funded by the project New smart

and adaptive robotics solutions for personalized

minimally invasive surgery in cancer treatment -

ATHENA, funded by European Union – Next

Generation EU and Romanian Government, under

National Recovery and Resilience Plan for Romania,

contract no. 760072/23.05.2023, code CF

116/15.11.2022, through the Romanian Ministry of

Research, Innovation and Digitalization, within

Component 9, investment I8.

REFERENCES

McGuigan, A., Kelly, P., Turkington, R. C., Jones, C.,

Coleman, H. G.,McCain, R. S. Pancreatic cancer: A

review of clinical diagnosis, epidemiology, treatment

and outcomes. W. J. of Gastroenterology, 24(43),4846–

4861, 2018. doi:10.3748/wjg.v24.i43.4846.

Asbun, D., Lluis, N., Jimenez, R.E., Asbun, H. J. A

narrative review of minimally invasive pancreatic

surgery: from pipedreams to pancreatoduodenectomies,

DMR 7(0), DMR9393, 2023.

Balzano, G., Zerbi, A., Aleotti, F., Capretti, G., Melzi, R.,

Pecorelli, N. et al. Total Pancreatectomy With Islet

Autotransplan-tation as an Alternative to High-risk

Pancreatojejunostomy After Pancreaticoduodenecto-

my: A Prospective Randomized Trial. Annals of

Surgery 277(6): p894-903, 2023. doi:

10.1097/SLA.0000000000005713.

Bergholz, M., Ferle, M. & Weber, B.M. The benefits of

haptic feedback in robot assisted surgery and their

moderators: a meta-analysis. Sci Rep 13, 19215, 2023.

doi: 10.1038/s41598-023-46641-8.

Cawich, S. O., Cabral, R., Douglas, J., Thomas, D. A.,

Mohammed, F. Z., Naraynsingh, V., & Pearce, N. W.

Whipple's procedure for pancreatic cancer: training and

the hospital environment are more important than

volume alone. Surgery in Practice and Science, 14,

100211, 2023. doi: 10.1016/j.sipas.2023.100211.

Damoli, I., Butturini, G., Ramera, M., Paiella, S.,

Marchegiani, G., Bassi, C. Minimally invasive

pancreatic surgery - a review. Wideochir Inne Tech

Maloinwazyjne; 10(2):141-149; 2015.

doi:10.5114/wiitm.2015.52705.

De Pastena, M., van Bodegraven, E. A., Mungroop, T. H.,

Vissers, F. L., Jones, L. R., Marchegiani, G. et al. Distal

pancreatectomy fistula risk score (D-FRS):

Development of a Control System for an Innovative Parallel Robot Used in Laparoscopic Pancreatic Surgery

249

development and international validation. Annals of

Surgery, 277(5), e1099-e1105, 2023. doi:

10.1097/SLA.0000000000005497.

Rus, G., Andras, I., Vaida, C., Crisan, N., Gherman, B., Radu,

C., Tucan, P., Iakab, S., Hajjar, N.A., & Pisla, D.

Artificial Intelligence-Based Hazard Detection in

Robotic-Assisted Single-Incision Oncologic Surgery.

Cancers, 15, 3387, 2023. doi: 10.3390/cancers15133387.

Haidegger, T., Speidel, S., Stoyanov, D., & Satava, R. M.

Robot-assisted minimally invasive surgery—Surgical

robotics in the data age. Proceedings of the IEEE, 110(7),

835-846, 2022. doi: 10.1109/JPROC.2022.3180350.

Kastelan, Z., Hudolin, T., Kulis, T., Knezevic, N., Penezic,

L., Maric, M., & Zekulic, T. Upper urinary tract surgery

and radical prostatectomy with Senhance® robotic

system: Single center experience—First 100 cases. The

International Journal of Medical Robotics and

Computer Assisted Surgery, 17(4), e2269, 2021. doi:

doi.org/10.1002/rcs.2269.

Khachfe, H.H., Habib, J.R., Harthi, S.A. et al. Robotic

pancreas surgery: an overview of history and update on

technique, outcomes, and financials. J Robotic Surg 16,

483–494, 2022. doi:10.1007/s11701-021-01289-2.

Korayem, M. H., & Vahidifar, V. (2022). Detecting hand's

tremor using leap motion controller in guiding surgical

robot arms and laparoscopic scissors. Measurement,

204, 112133. (a)

Korayem, M. H., Madihi, M. A., & Vahidifar, V. (2021).

Controlling surgical robot arm using leap motion

controller with Kalman filter. Measurement, 178,

109372.

Korayem, M. H., Vosoughi, R., & Vahidifar, V. (2022).

Design, manufacture, and control of a laparoscopic

robot via Leap Motion sensors. Measurement, 205,

112186. (b)

Li, J., et al (2023). Application of Improved Robot-assisted

Laparoscopic Telesurgery with 5G Technology in

Urology. European urology, 83(1), 41–44. doi:

10.1016/j.eururo.2022.06.018.

McGuigan, A., Kelly, P., Turkington, R. C., Jones, C.,

Coleman, H. G.,McCain, R. S. Pancreatic cancer: A

review of clinical diagnosis, epidemiology, treatment

and outcomes. W. J. of Gastroenterology, 24(43),4846–

4861, 2018. doi:10.3748/wjg.v24.i43.4846.

Melvin WS, Needleman BJ, Krause KR, Ellison EC.

Robotic resection of pancreatic neuroendocrine tumor.

J Laparoendosc Adv Surg Tech A.; 13:33–6, 2003. doi:

10.1089/109264203321235449.

Minamimura, K., Aoki, Y., Kaneya, Y., Matsumoto, S.,

Arai, H., Kakinuma, D., & Yoshida, H. Current status

of robotic hepatobiliary and pancreatic surgery. Journal

of Nippon Medical School, 91(1), 10-19, 2024.

Najafinejad, A., & Korayem, M. H. (2023). Detection and

minimizing the error caused by hand tremors using a

leap motion sensor in operating a surgeon robot.

Measurement, 221, 113544.

Nießen, A, Hackert, T. State-of-the-art surgery for pancreatic

cancer. Langenbecks Arch Surg.;407(2):443-450, 2022.

Nortunen, M., Meriläinen, S., Ylimartimo, A., Peroja, P.,

Karjula, H., Niemelä, J., Saarela, A., Huhta, H.

Evolution of pancreatic surgery over time and effects of

centralizationa single-center retrospective cohort study.

J Gastrointest Oncol. 2023;14(1):366-378.

doi:10.21037/jgo-22-649.

Pisla, D., Carami, D., Gherman, B., Soleti, G., Ulinici, I.,

Vaida, C. A novel control architecture for robotic-

assisted single incision laparoscopic surgery. The

Romanian Journal of Technical Sciences. Applied

Mechanics., 66(2), 141-162, 2021.

Pisla, D., Popa, C., Pusca, A., Ciocan, A., Gherman, B.,

Mois, E., Cailean, A.-D., Vaida, C., Radu, C., Chablat,

D., Al Hajjar, N. On the Control and Validation of the

PARA-SILSROB Surgical Parallel Robot. Appl. Sci.,

14, 7925, 2024. doi: 10.3390/app14177925. (a)

Pisla, D., Chablat, D., Birlescu, I., Vaida, C., Pusca, A.,

Tucan, P. Gherman, B. AUTOMATIC INSTRUMENT

FOR ROBOT-ASSISTED MINIMALLY INVASIVE

SURGERY. Romania, Patent number: RO138293A0.

2024, pp.15. (b)

Pisla, D., Plitea, N., Gherman, B., Pisla, A., Vaida, C.

Kinematical Analysis and Design of a New Surgical

Parallel Robot. In Computational Kinematics;

Kecskeméthy, A., Müller, A., Eds.; Springer:

Berlin/Heidelberg, Germany, 2009.

Tucan, P., Vaida, C., Horvath, D., Caprariu, A., Burz, A.,

Gherman, B., Iakab, S., Pisla, D. Design and

Experimental Setup of a Robotic Medica Instrument for

Brachytherapy in Non-Resectable Liver Tumors.

Cancers, 2022, 14, 5841.

Tucan, P.; Ciocan, A.; Gherman, B.; Radu, C.; Vaida, C.;

Hajjar, N.A.; Chablat, D.; Pisla, D. Design

Optimization of a Parallel Robot for Laparoscopic

Pancreatic Surgery Using a Genetic Algorithm. Appl.

Sci., 15, 4383., 2025. doi:10.3390/app15084383.

Vaida, C., Ciocan, A., Caprariu, A., Radu, C., Al Hajjar, N.,

Pisla, D. A 3D-printed anatomical pancreas model for

Robotic assisted Minimally Invasive Surgery. Journal

of Functional Biomaterials. J. Funct. Biomater. 2025,

16, 207. (a)

Vaida, C.; Birlescu, I.; Gherman, B.; Condurache, D.;

Chablat, D.; Pisla, D. An analysis of higher-order

kinematics formalisms for an innovative surgical

parallel robot. Mech. Mach. Theory, 2025, 209,

105986. (b)

Vaida, C.; Pisla, D.; Schadlbauer, J.; Husty, M.; Plitea, N.

Kinematic analysis of an innovative medical parallel

robot using study parameters. In New Trends in

Medical and Service Robots. Mechanisms and Machine

Science; Wenger, P., Chevallereau, C., Pisla, D.,

Bleuler, H., Rodić, A., Eds.; Springer: Cham,

Switzerland, 2016; Volume 39.

Wong MCS, Jiang JY, Liang M, Fang Y, Yeung MS, Sung

JJY. Global temporal patterns of pancreatic cancer and

association with socioeconomic development. Sci Rep.

2017;7(1):3165. Published 2017 Jun 9.

doi:10.1038/s41598-017-02997-2.

Zhang, W., Wang, Z., Ma, K. et al. State of the art in

movement around a remote point: a review of remote

center of motion in robotics. Front. Mech. Eng. 19, 14

2024. doi:10.1007/s11465-024-0785-3.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

250