Impact of Physiological Characteristics on Thermal Comfort of Cycling

Helmet

Zixiang Hu

a

, Xiaoyi Cai

b

and Peng Zhou

c

Department of Mechanical and Aerospace Engineering, The Hong Kong University of Science and Technology, Clear Water

Bay, Kowloon, Hong Kong SAR, China

Keywords:

Cycling Helmet, Thermal Comfort, Physiological Characteristics, Convective Heat Transfer.

Abstract:

Research on helmet thermal comfort is crucial for optimizing helmet design and enhancing cyclists’ acceptance

of helmets. However, existing studies often neglect the impact of cyclists’ physiological characteristics on

scalp heat dissipation details. To address this gap, a sweating thermal mannequin head was developed to

investigate the effects of physiological factors, including hair, sweating, and variations in head pitch angle,

on scalp heat dissipation at typical cycling speeds. The findings reveal that hair obstructs airflow within the

helmet, resulting in local thermal discomfort at the back of the scalp and potentially altering the optimal pitch

angle for helmet thermal performance. Moreover, sweating amplifies the temperature differences between

local ”hot spots” and ”cold spots” on the scalp, with the majority of heat loss attributed to sweat evaporation.

Additionally, adjusting the pitch angle can better align the ventilation holes with the airflow, thereby enhancing

thermal comfort at both the front and back of the scalp.

1 INTRODUCTION

Head injury is a leading cause of serious injuries in

cycling (Wood and Milne, 1988), and the use of cy-

cling helmets has been shown to significantly reduce

the risk of such injuries (Olivier and Creighton, 2017;

Cripton et al., 2014). However, the head is highly

sensitive to heat due to its critical role in regulat-

ing both brain and body temperature (Gerrett et al.,

2014). Prolonged cycling in elevated ambient tem-

peratures can result in overheating of the head, lead-

ing to thermal discomfort, which is a primary rea-

son cyclists may choose not to wear helmets (Bogerd

et al., 2015). Therefore, research on thermal comfort

in cycling helmets can help optimize the ventilation

design, thereby increasing cyclists’ acceptance of the

helmet.

The head is the most temperature-sensitive re-

gion of the human body (Kim et al., 2017). At

the same temperature, individuals tend to experience

greater discomfort from heat on the head compared to

other body parts (Mehrabyan et al., 2011). Fang et

al. (2018) conducted experiments with subjects and

found that sensitivity to temperature varies across dif-

ferent locations on the scalp, and the presence of hair

a

https://orcid.org/0009-0005-5227-9888

b

https://orcid.org/0009-0005-4430-8095

c

https://orcid.org/0000-0003-4936-9661

will suppress this sensitivity. During cycling, the in-

fluence of the helmet can lead to heat accumulation on

the scalp of the cyclist, resulting in thermal discom-

fort. In previous research, thermal comfort analysis

of helmets is primarily conducted using thermal man-

nequin heads with heating and temperature feedback

functions in wind tunnel experiments (Alam et al.,

2010).

Helmet thermal comfort evaluation typically em-

ploys convective heat transfer parameters for charac-

terization. Thermal resistance and heat transfer coef-

ficient (Zwoli

´

nska et al., 2014; Youssef et al., 2019)

are used to assess the cooling capacity of helmets in

non-sweating conditions, calculated based on scalp

area, temperature difference between the head and en-

vironment, and heat loss through the scalp. As cy-

clists inevitably encounter hot weather and perspire

during outdoor riding, evaporative resistance (Aljaste

et al., 2015; Pang et al., 2014) is used to evaluate hel-

met thermal performance in sweating conditions. The

aforementioned studies provided only global param-

eter values of helmets, typically obtained under low

wind speeds below 4 m/s. However, parameters such

as thermal resistance and evaporative resistance ex-

hibit significant sensitivity to wind speed. Mukun-

than et al. (2019) observed a 20% reduction in hel-

met global thermal resistance when wind speed in-

creased from 3 m/s to 6 m/s. Wind speed may exert

non-negligible influence on thermal comfort studies

178

Hu, Z., Cai, X. and Zhou, P.

Impact of Physiological Characteristics on Thermal Comfort of Cycling Helmet.

DOI: 10.5220/0013708600003988

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 13th International Conference on Sport Sciences Research and Technology Support (icSPORTS 2025), pages 178-185

ISBN: 978-989-758-771-9; ISSN: 2184-3201

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

of helmets.

Previous studies have investigated local thermal

comfort in different regions of the head. Bruhwiler et

al. (2003) utilized a commercially available thermal

manikin head to partition the head into two regions

(scalp and face) for comparing convective heat trans-

fer coefficients under varying wind speeds. Mart

´

ınez

et al. (2016) further subdivided the scalp into six

regions for similar investigations. The limited de-

ployment of only one temperature sensor per region

proves insufficient for detailed scalp thermal analysis,

consequently hindering precise correlation between

helmet ventilation configuration (vent holes and air

channels) and local thermal comfort.

Additionally, previous studies have also investi-

gated the influence of cyclists’ physiological char-

acteristics on helmet thermal comfort evaluation,

including hair (Abeysekera and Shahnavaz, 1990),

sweating (Mukunthan et al., 2019), and head pitch

angle (Alam et al., 2005). Aljaste et al. (2015) com-

pared the thermal resistance values of different hel-

mets with and without hair to assess the effect of hair

on thermal comfort. However, Bogerd and Bruhwiler

(2008) found that 40%-50% of the reduction in con-

vective heat transfer was caused by the hair-fixing

layer, meaning that hair thickness, material, and ther-

mal properties of the layer all influence experimen-

tal results. Br

¨

uhwiler et al. (2003) tested and com-

pared the convective heat loss of multiple helmets in

both sweating and non-sweating states, while Mus-

tary et al. (2014) compared scalp surface tempera-

ture differences among different helmets at three head

pitch angles. Nevertheless, these studies treated the

helmet as a whole and defined its thermal comfort

through a global parameter, neglecting the heat dis-

sipation details of the scalp, thus failing to reveal the

influence of these three physiological characteristics

on helmet thermal performance from the perspective

of local thermal comfort.

In this study, a sweating thermal mannequin head

was developed to investigate the influence of cy-

clists’ physiological characteristics on the assessment

of global and local thermal comfort in helmets. Wind

tunnel experiments were conducted on four commer-

cial helmets and one helmet prototype at a typical

cruising speed (9m/s) of cyclists. The details of scalp

heat dissipation were investigated, and the effects of

physiological characteristics such as hair, sweating,

and adjustments in head pitch angle on the assessment

of helmet thermal comfort were analyzed.

2 METHODOLOGY

2.1 Thermal Mannequin Head

To investigate the influence of physiological charac-

teristics on the heat dissipation details and local ther-

mal comfort of helmets, a thermal mannequin head

was developed to simulate hair, sweating, and varia-

tions in head pitch angle. The thickness of the ther-

mal head scalp is 10 mm, and the material is a pho-

tocurable resin with a thermal conductivity of 0.2

W/(m·K), similar to that of human scalp (Baldry et al.,

2018).

The upper section of the thermal head, function-

ing as the heating component, is equipped with a PID

temperature control system to precisely elevate scalp

surface temperature to predetermined levels. The

overall heat loss of the system is measured by a power

meter with an accuracy of 1%, and the temperature

variation on the scalp’s outer surface is maintained

within 2 °C under still air conditions, consistent with

actual human conditions (Kublanov et al., 2020). T-

type thermocouple is used for temperature measure-

ment, with a probe diameter of less than 0.5 mm and

a waterproof design, facilitating temperature collec-

tion under sweating conditions. Additionally, Sweat

simulation is achieved using a syringe pump, which

utilizes a high-precision step motor and gear reducer

to expel water from the syringe at a predetermined

rate.

The lower part of the thermal head functions as the

mechanical connection section, enabling head pitch

angle control via a step motor. An insulating pad is

placed between the upper and lower sections of the

head, as indicated by the black line in Figure 1b, to

ensure that all heat dissipates from the upper section.

The head pitch angle α is defined as the angle between

the insulating pad and the horizontal direction, with a

downward inclination being considered negative.

(a) (b)

Figure 1: Thermal mannequin head: (a) hair simulation (b)

pitch angle definition.

The thermal experiment is conducted using the de-

veloped sweating thermal head. The thermal head is

positioned in front of an open-jet wind tunnel, with a

Impact of Physiological Characteristics on Thermal Comfort of Cycling Helmet

179

Table 1: Thermal mannequin head specifications.

Item Values

Heat loss sampling frequency 1Hz

Heat loss sampling accuracy 1%

Temperature sampling frequency 1 Hz

Temperature sampling accuracy 0.5

◦

C

Temperature sampling resolution 0.01

◦

C

Syringe pump accuracy ≤ 0.5%

Figure 2: Experimental setup.

blockage ratio of 0.05. A wind speed of 32.4 km/h (9

m/s) was selected to represent the typical velocity of

a cyclist.

2.2 Helmet Samples

Four commercially available professional-grade road

cycling helmets were tested in this study. Due to

the complex configurations of ventilation holes and

air channels in these commercial helmets, which ex-

hibit strong interdependencies, it is necessary to re-

duce the number of ventilation holes and air channels

to investigate the influence of physiological charac-

teristics on helmet thermal performance under a sim-

pler vent configuration. Therefore, a helmet proto-

type with adjustable ventilation hole positions and air

channel depths, created through 3D printing, was also

used for wind tunnel experiments.

The helmet prototype consists of an outer shell, an

inner shell, ventilation hole walls, and insulation fill-

ing material, which effectively suppresses the conduc-

tive heat transfer between the thermal head and the air.

As shown in Figure 4b, under stable natural convec-

tion conditions, the outer surface temperature of the

helmet prototype is generally consistent with the air

temperature. Both the inner and outer shells, as well

as the walls of the ventilation holes, are produced us-

ing 3D printing and undergo surface treatment, which

includes polishing and applying matte paint, to simu-

late the material properties of actual helmet surfaces.

The helmet can simulate different depths of air chan-

nels by replacing the inner shell with different de-

signs.

(a) (b)

(c) (d)

Figure 3: Tested road cycling helmets: (a) helmet 1 (b) hel-

met 2 (c) helmet 3 (d) helmet 4.

(a) (b)

(c) (d)

Figure 4: 3D printed helmet prototype: (a) model structure

(b) thermal insulation performance (c) 0 mm air channel

depth (d) 20 mm air channel depth.

2.3 Experimental Procedures

The experimental procedure comprised the following

key steps: First, the heating device was turned on

to elevate the scalp surface temperature to 35°C to

simulate human thermal physiology, while the am-

bient temperature is 20.5°C. Data acquisition equip-

ment was initiated to record the scalp surface tem-

perature, heat loss dissipated from the head, and am-

bient temperature and humidity, establishing a base-

line with the stabilized scalp surface temperature. The

test helmet was placed on the head, allowing the scalp

surface temperature to stabilize again. The wind tun-

nel was then turned on with wind speed adjusted to 9

icSPORTS 2025 - 13th International Conference on Sport Sciences Research and Technology Support

180

m/s. After stabilization, the scalp surface temperature

was compared to the baseline to evaluate temperature

drops at various scalp locations. The final tempera-

ture drop results were mapped onto a plane to visual-

ize local heat dissipation details. Finally, the global

thermal resistance, global evaporative resistance, and

convective heat transfer coefficient were calculated.

(a)

(b)

Figure 5: Visualization of scalp surface temperature: (a)

projection method (b) projection result.

The convective heat transfer coefficient h and

global thermal resistance R

ct

of helmets are calculated

using the following formula:

h =

1

R

ct

=

H

dry

− H

rad

A

scalp

· (T

scalp

− T

air

)

, (1)

where H

dry

and H

rad

denote the power supplied to the

head and the heat dissipation from the scalp through

thermal radiation, respectively. A

scalp

represents the

scalp surface area, and T

scalp

and T

air

are temperatures

of the scalp surface and the ambient environment, re-

spectively.

The global evaporative resistance is calculated us-

ing the following formula:

R

et

=

A

scalp

· (p

scalp

− p

air

)

H

wet

− H

conv

− H

rad

− H

correct

, (2)

where p

scalp

and p

air

represent the saturated water va-

por pressures at the scalp surface temperature and the

air’s water vapor pressure, respectively. H

conv

and

H

rad

are the dry heat loss consisting of convective heat

and radiative heat loss, and H

correct

is the inevitable

heat loss owing to sweating conditions, caused by the

temperature difference between the sweat in the sy-

ringe pump and on the scalp.

3 RESULTS AND DISCUSSION

In this section, the effects of physiological charac-

teristics such as hair, sweating, and changes in head

pitch angle on the helmet thermal comfort were ana-

lyzed using the four commercial helmets mentioned

above. Additionally, experiments were conducted us-

ing the helmet prototype with air channel depths of

0 mm and 20 mm under the same testing conditions,

with the results serving to validate and complement

the previous conclusions.

The upper part of the thermal head was made from

suitable materials and thickness to simulate the ther-

mal conductivity and thickness between the outer sur-

face of the human scalp and the skull. The inner sur-

face of the upper part is heated by a heating layer to

optimally simulate the temperature regulation mech-

anism of the human scalp surface. In different com-

parative experiments, the temperature of the heating

layer inside the thermal head was maintained at a con-

stant level.

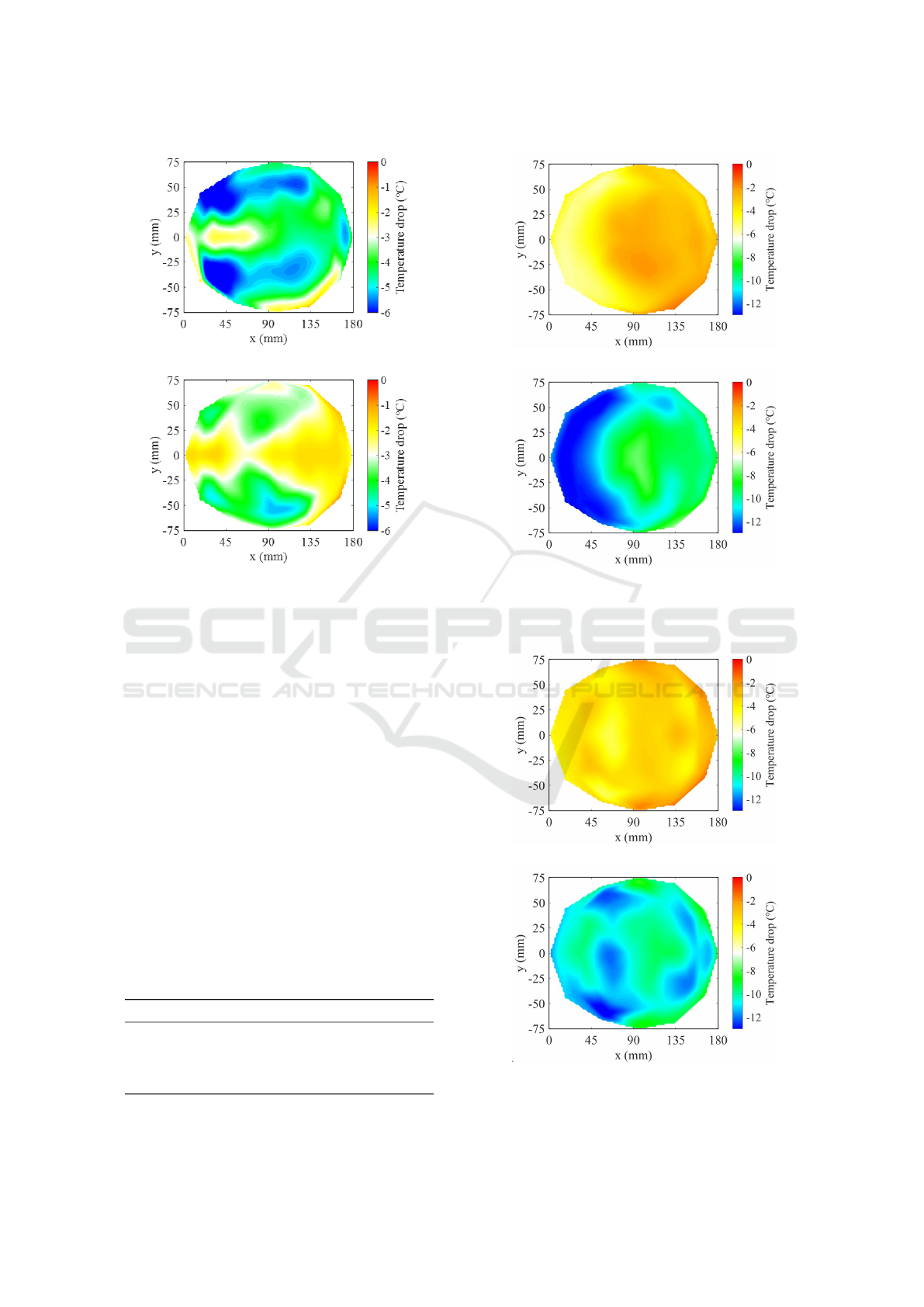

3.1 Effect of Hair

The helmet 1 was tested under both conditions of hav-

ing hair and being hairless, revealing scalp heat dis-

sipation details in both scenarios, as shown in Fig-

ure 6. First, when the helmet’s ventilation holes are

connected to the air channels, air can more easily pass

over the scalp, thereby removing heat and promoting

local thermal comfort. This trend is observed regard-

less of whether hair is present or not.

In the hairless condition, air can more easily circu-

late in the gap between the scalp and the helmet, even

if the air channel depth is relatively small. As shown

in Figure 6a, the rear part of the scalp exhibits a local

low-temperature area, with a temperature difference

of only 1°C compared to the scalp surface tempera-

ture near the ventilation holes, indicating that airflow

can reach this region within the helmet. However,

when hair is present, this phenomenon disappears, re-

placed by a large high-temperature area at the back

of the scalp, which is 3.5°C higher than the tempera-

ture near the ventilation holes, as shown in Figure 6b.

This suggests that the presence of hair obstructs air-

flow within the helmet, resulting in local thermal dis-

comfort at the rear.

Impact of Physiological Characteristics on Thermal Comfort of Cycling Helmet

181

(a)

(b)

Figure 6: Heat dissipation details of helmet 1 under: (a)

hairless condition (b) hair condition.

3.2 Effect of Sweating

The internal heating temperature of the thermal head

is maintained at the same level in both the sweat-

ing and non-sweating experiments using a PID con-

trol method. The helmet 2 and helmet 3 were tested

under both conditions, revealing scalp heat dissipa-

tion details in both scenarios, as shown in Figure 7

and Figure 8. The results indicate that while the heat

dissipation patterns are similar in both sweating and

non-sweating conditions, there is a significant temper-

ature difference, reaching up to 7 °C. This highlights

the substantial impact of sweating on heat dissipation.

Additionally, although the patterns of heat dissipation

are similar, the temperature differences between local

”hot spots” and ”cold spots” are amplified during the

sweating condition.

Table 2: Heat loss of helmet 2 under non-sweating and

sweating conditions

Item Values

Total heat loss (non-sweating condition) 11.33 W

Total heat loss (sweating condition) 17.20 W

Sensible heat loss (sweating condition) 3.16 W

Latent heat loss (sweating condition) 14.04 W

Under sweating conditions, the total heat loss of

(a)

(b)

Figure 7: Heat dissipation details of helmet 2 under: (a)

non-sweating condition (b) sweating condition.

(a)

(b)

Figure 8: Heat dissipation details of helmet 3 under: (a)

non-sweating condition (b) sweating condition.

icSPORTS 2025 - 13th International Conference on Sport Sciences Research and Technology Support

182

helmet 2 reached 17.20 W, representing an increase of

51.7% compared to the non-sweating condition, with

the latent heat loss reaching 14.04 W. This indicates

that over 80% of the heat is dissipated through the

evaporation of sweat, which corresponds to convec-

tive mass transfer.

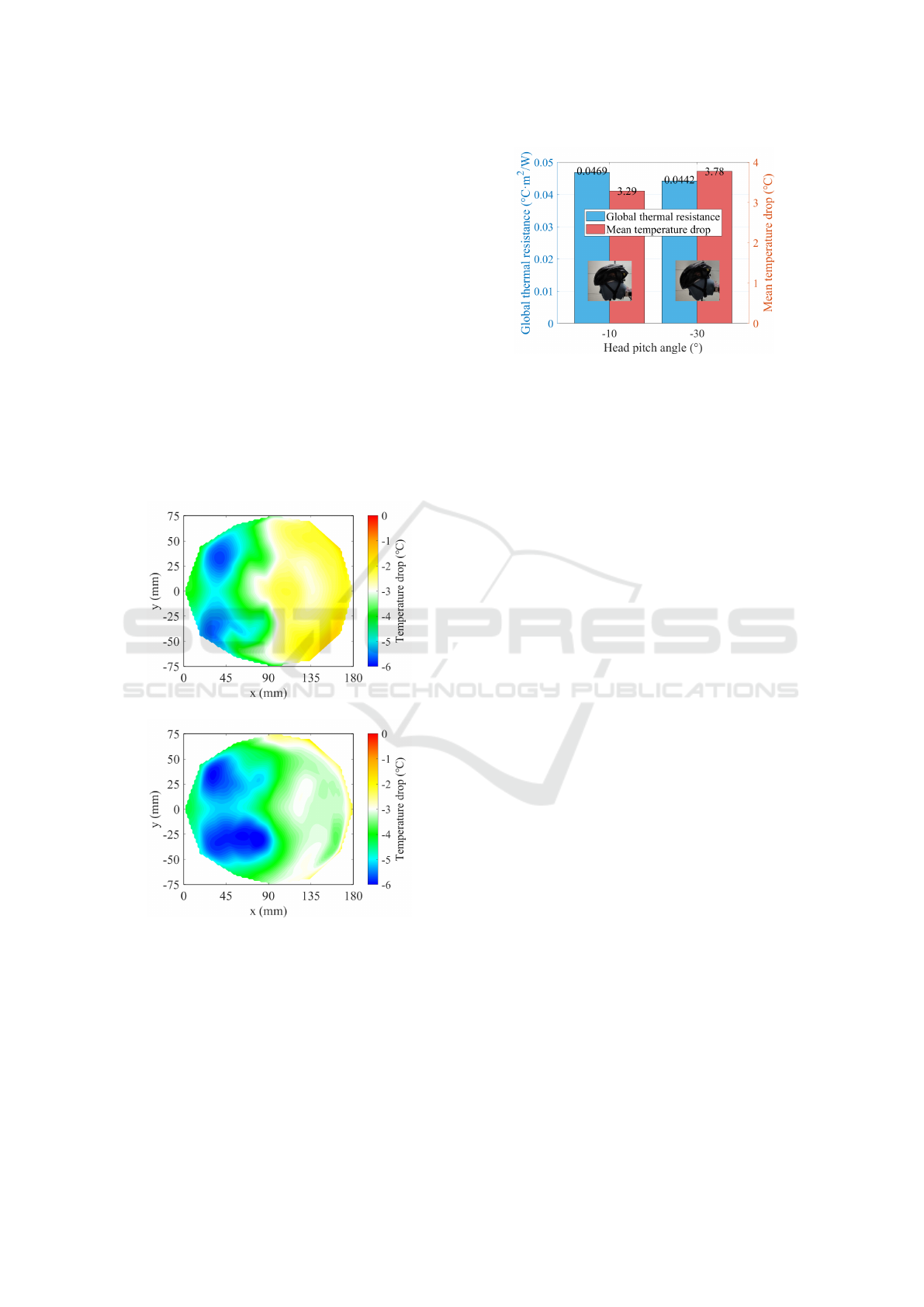

3.3 Effect of Head Pitch Angle

Helmet 4 was tested at two common head pitch angles

used by cyclists: a normal angle (-10°) and a more ag-

gressive angle (-30°), under non-sweating conditions.

The heat dissipation details reveal the differences, as

shown in Figure 9. When the pitch angle is smaller,

the orientation of the ventilation hole is more directly

aligned with the incoming airflow, resulting in a larger

low-temperature area at the front of the scalp. Ad-

ditionally, air can more easily reach the back of the

scalp, lowering the temperature in that area.

(a)

(b)

Figure 9: Heat dissipation details of helmet 4 in: (a) -10

°pitch angle (b) -30 °pitch angle.

The change in pitch angle results in a 10.2% re-

duction in the global thermal resistance of the helmet.

Based on previous test results of different helmets at

the same pitch angle, it can be observed that the differ-

ence in global thermal resistance values of the same

helmet at different pitch angles can be greater than

the differences in global thermal resistance values be-

Figure 10: Comparison of global thermal resistance and

mean temperature drop in different pitch angles.

tween different helmets. This demonstrates the sig-

nificant impact of pitch angle on the global thermal

comfort of helmets.

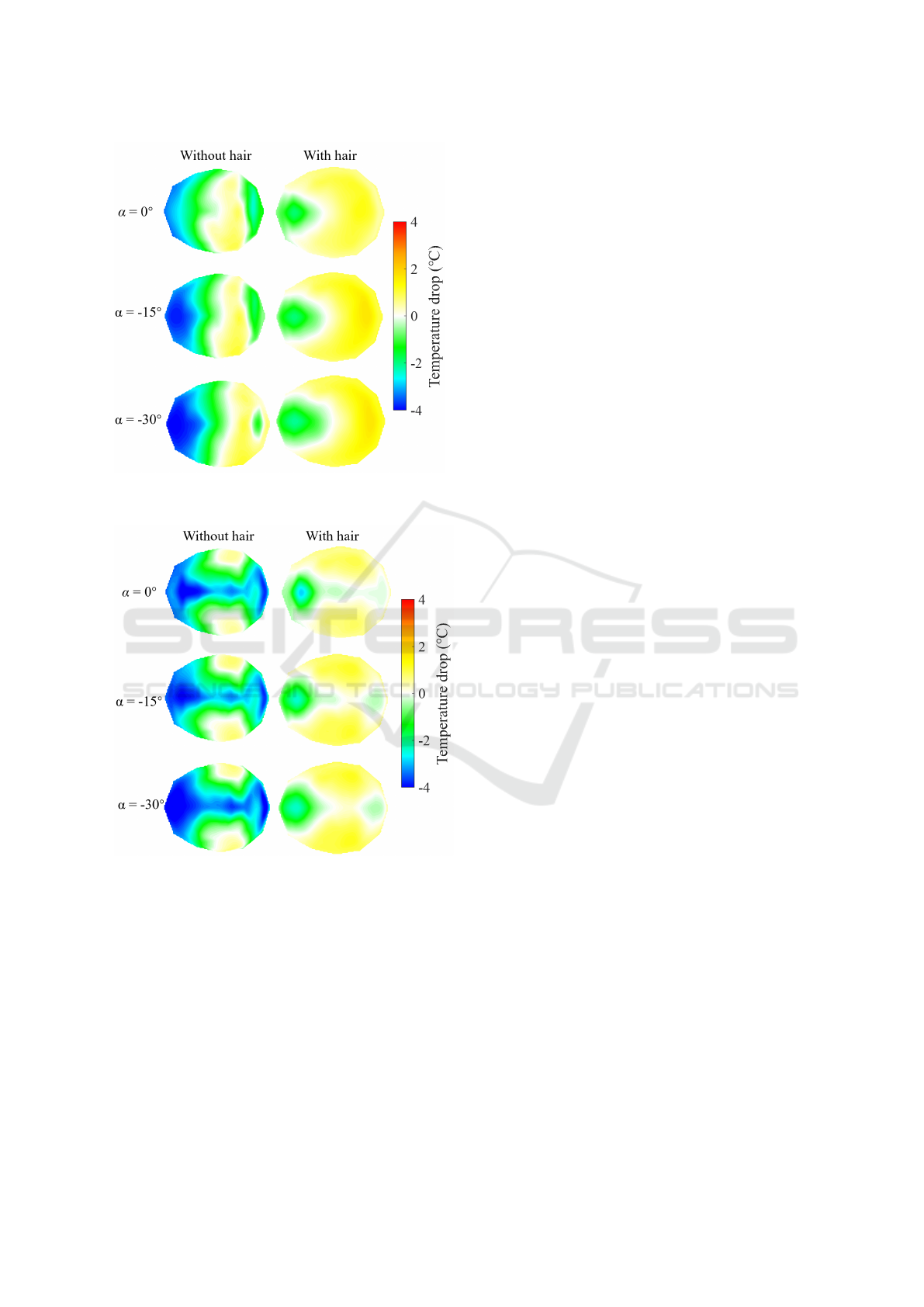

3.4 Helmet Prototype Experiment

The experimental setup for the helmet prototype is

identical to that of the four commercial helmets. The

wind tunnel experiment results clearly demonstrate

the significant influence of hair on the internal airflow

within helmets. For helmets with 0 mm air channel

depth, air can still pass through the narrow gap be-

tween the scalp and helmet inner surface in hairless

conditions. However, the presence of hair substan-

tially impedes internal airflow circulation. This re-

striction limits heat transfer primarily to impingement

cooling from the frontal ventilation hole, while caus-

ing significant heat accumulation in the rear region.

Such uneven thermal distribution ultimately leads to

pronounced thermal discomfort for the cyclist.

In the case of 20 mm air channel depth, when there

is no hair, air can smoothly flow along the air channel

to the back of the scalp, thereby enhancing the con-

vective heat transfer at the rear. However, when hair

is present, the difficulty of airflow along the air chan-

nel significantly increases, and in certain pitch angles,

the air channel’s contribution to convective heat trans-

fer is not very pronounced.

Pitch angle also has a substantial impact on the

thermal performance of the helmet. For 0 mm air

channel depth, in the absence of hair, a decrease in

pitch angle results in a noticeable increase in the ”cool

region” at the front of the scalp and a corresponding

increase in the ”hot region” at the back of the scalp.

Similarly, the same conclusion can be drawn when

hair is present.

In the case of 20 mm air channel depth, the situ-

ation is slightly different. In the absence of hair, as

the pitch angle decreases, convective heat transfer in-

creases, and the enhancing effect of the air channel

Impact of Physiological Characteristics on Thermal Comfort of Cycling Helmet

183

Figure 11: Experimental results of 0 mm depth air channel

helmet prototype.

Figure 12: Experimental results of 20 mm depth air channel

helmet prototype.

on heat dissipation can be clearly observed. However,

when hair is present, the pattern is quite the opposite.

As the pitch angle decreases, the effectiveness of the

air channel diminishes, and the temperature remains

low only at the front and rear areas close to the ven-

tilation holes, indicating that the heat dissipation per-

formance of the helmet at different pitch angles also

depends on the presence of hair. The optimal pitch an-

gle for a helmet differs between conditions with and

without hair.

4 CONCLUSIONS

In this study, a sweating thermal mannequin head was

developed, and four commercial helmets along with

one prototype were used to investigate the effects of

physiological characteristics, including hair, sweat-

ing, and variations in head pitch angle, on scalp heat

dissipation. The conclusions can be effectively ap-

plied to the thermal comfort optimization of helmet

design, thereby enhancing cyclists’ acceptance and

wearing compliance. The main conclusions are as fol-

lows:

The hair filling the gap between the scalp and hel-

met inner surface significantly alters the internal air-

flow patterns compared to hairless conditions, often

inducing local thermal discomfort at the rear region.

Furthermore, the presence or absence of hair modi-

fies the optimal pitch angle for helmet thermal perfor-

mance.

Sweating enhances the helmet’s overall thermal

comfort while simultaneously amplifying tempera-

ture differentials between localized ”hot spots” and

”cold spots” on the scalp. It also suppresses sensible

heat transfer, resulting in the majority of heat dissipa-

tion being attributable to sweat evaporation.

Adjusting the pitch angle alters the ease of airflow

entry through ventilation holes into the helmet inte-

rior, significantly affecting local thermal comfort of

the scalp, particularly in the rear region.

ACKNOWLEDGEMENTS

This work is partially supported by the Hong

Kong Innovation and Technology Commission (No.

ITS/101/23FP). The study was conducted in the Aero-

dynamics Acoustics & Noise Control Technology

Centre (aantc.ust.hk).

REFERENCES

Abeysekera, J. D. and Shahnavaz, H. (1990). Adaptation to

discomfort in personal protective devices: an example

with safety helmets. Ergonomics, 33(2):137–145.

Alam, F., Chowdhury, H., Elmir, Z., Sayogo, A., Love,

J., and Subic, A. (2010). An experimental study of

thermal comfort and aerodynamic efficiency of recre-

ational and racing bicycle helmets. Procedia Engi-

neering, 2(2):2413–2418.

Alam, F., Watkins, S., and Subic, A. (2005). Aerodynamic

efficiency and thermal comfort of bicycle helmets. In

Proc. of the 6th International Conference on Mechan-

ical Engineering (ICME2005), pages 28–30. ICME.

TH-32 (1–6).

icSPORTS 2025 - 13th International Conference on Sport Sciences Research and Technology Support

184

Aljaste, H., Kuklane, K., and Heidmets, S. S. (2015). The

effects of air channel construction and design ele-

ments on heat transfer characteristics of bicycle hel-

mets for commuters. In 4th International Cycling

Safety Conference, Medizinische Hochschule Han-

nover, Germany. ICSC.

Baldry, M., Timchenko, V., and Menictas, C. (2018). Ther-

mal modelling of controlled scalp hypothermia using

a thermoelectric cooling cap. Journal of Thermal Bi-

ology, 76:8–20.

Bogerd, C. P., Aerts, J. M., Annaheim, S., Br

¨

ode, P., De

Bruyne, G., Flouris, A. D., and Rossi, R. M. (2015).

A review on ergonomics of headgear: Thermal effects.

International Journal of Industrial Ergonomics, 45:1–

12.

Cripton, P. A., Dressler, D. M., Stuart, C. A., Dennison,

C. R., and Richards, D. (2014). Bicycle helmets are

highly effective at preventing head injury during head

impact: Head-form accelerations and injury criteria

for helmeted and unhelmeted impacts. Accident Anal-

ysis & Prevention, 70:1–7.

Gerrett, N., Ouzzahra, Y., Coleby, S., Hobbs, S., Redortier,

B., Voelcker, T., and Havenith, G. (2014). Thermal

sensitivity to warmth during rest and exercise: a sex

comparison. European Journal of Applied Physiology,

114:1451–1462.

Kim, Y. B., Jung, D., Park, J., and Lee, J. Y. (2017). Sensi-

tivity to cutaneous warm stimuli varies greatly in the

human head. Journal of Thermal Biology, 69:132–

138.

Kublanov, V. S., Borisov, V. I., and Babich, M. V. (2020).

Simulation the distribution of thermodynamic temper-

atures and microwave radiation of the human head.

Computer Methods and Programs in Biomedicine,

190:105377.

Mehrabyan, A., Guest, S., Essick, G., and McGlone, F.

(2011). Tactile and thermal detection thresholds of the

scalp skin. Somatosensory & Motor Research, 28(3–

4):31–47.

Mukunthan, S., Vleugels, J., Huysmans, T., Kuklane, K.,

Mayor, T. S., and De Bruyne, G. (2019). Thermal-

performance evaluation of bicycle helmets for convec-

tive and evaporative heat loss at low and moderate cy-

cling speeds. Applied Sciences, 9(18):3672.

Olivier, J. and Creighton, P. (2017). Bicycle injuries and

helmet use: a systematic review and meta-analysis. In-

ternational Journal of Epidemiology, 46(1):278–292.

Pang, T. Y., Subic, A., and Takla, M. (2014). Evaluation

of thermal and evaporative resistances in cricket hel-

mets using a sweating manikin. Applied Ergonomics,

45(2):300–307.

Wood, T. and Milne, P. (1988). Head injuries to pedal cy-

clists and the promotion of helmet use in victoria, aus-

tralia. Accident Analysis & Prevention, 20(3):177–

185.

Youssef, A., Colon, J., Mantzios, K., Gkiata, P., Mayor,

T. S., Flouris, A. D., and Aerts, J. M. (2019). Towards

model-based online monitoring of cyclist’s head ther-

mal comfort: smart helmet concept and prototype. Ap-

plied Sciences, 9(15):3170.

Zwoli

´

nska, M., Bogdan, A., and Fejdy

´

s, M. (2014). Influ-

ence of different types of the internal system of the

ballistic helmet shell on the thermal insulation mea-

sured by a manikin headform. International Journal

of Industrial Ergonomics, 44(3):421–427.

Impact of Physiological Characteristics on Thermal Comfort of Cycling Helmet

185