Design and Control of a New Wrist Rehabilitation Robot

Simona-Daiana Stiole

1a

, Pusca Alexandru

1b

, Paul Tucan

1c

, Iuliu Nadas

1d

,Vasile Bulbucan

1e

,

Andrei Cailean

1f

, Dragos Sebeni

1g

, Alexandru Banica

1h

, Daniela Jucan

1i

, Radu Morariu

1j

,

Calin Vaida

1k

, Petru Dobra

1l

, Jose Machado

1,2 m

and Doina Pisla

1,3 n

1

CESTER Research Center for Industrial Robots Simulation and Testing, Technical University of Cluj-Napoca,

Memorandumului 28, 400114 Cluj-Napoca, Romania

2

MEtRICs Research Center, Campus of Azurém, University of Minho, 4800-058, Guimarães, Portugal

3

Technical Sciences Academy of Romania, B-dul Dacia, 26, 030167, Bucharest, Romania

Keywords: Wrist Rehabilitation Robot, Robot Design, Kinematic, Dynamic Model, Cost-Effective Robotic,

Tracking Control.

Abstract: This paper presents the design and control of a cost-effective wrist rehabilitation robot with the aim of

providing an accessible and scalable solution for patients in need of upper-limb motor recovery. The primary

goal is to create a compact system that can support repetitive and controlled wrist movements, particularly for

individuals recovering from stroke. The robot’s mechanical structure, forward kinematic model and dynamic

model were defined to minimize cost without compromising essential therapeutic functionality. Three control

strategies were implemented and evaluated in simulation, including Independent Joint Control, Linear

Quadratic Regulator, and an observer-based version using a Luenberger estimator for situations where only

position sensors are available. These simulations serve to assess the feasibility of each control method in terms

of performance, complexity, and compatibility with low-cost components for future hardware development.

1 INTRODUCTION

The use of robotic systems in physical rehabilitation,

particularly for upper-limb therapy (Pollock, et al.,

2014), (Basteris, et al., 2014), (Tucan, et al., 2022),

(Tohanean, et al., 2023), has seen substantial growth

in recent years. Robotic devices (Guozheng, et al.,

2014) for wrist rehabilitation are increasingly being

incorporated into therapy programs (Wu Chuang, et

al., 2011) due to their ability to deliver consistent,

repetitive, and quantifiable movements - crucial

factors in the recovery of fine motor skills. Several

commercially available systems, such as MIT-Manus

a

https://orcid.org/0009-0002-5062-6936

b

https://orcid.org/0000-0002-5804-575X

c

https://orcid.org/0000-0001-5660-8259

d

https://orcid.org/0000-0002-6722-9972

e

https://orcid.org/0009-0005-3867-7687

f

https://orcid.org/0009-0004-4758-0468

g

https://orcid.org/0009-0009-7615-6240

(Krebs, et al., 1999), WristBot (Squeri, et al., 2014),

or Reharob (Toth, et al., 2005), have demonstrated the

feasibility of robotic-assisted therapy for post-stroke

(Parisi, et al., 2022) patients. These systems generally

employ complex mechanical structures and control

algorithms, such as impedance control, adaptive

control, or model predictive control, to guide patient

movement. However, many solutions come with

significant trade-offs in terms of cost, size, and

system complexity (Akdogan, 2016), which limit

their accessibility outside specialized clinical

environments. Moreover, a large part of the literature

focuses on multi-DOF exoskeletons (Vaida, et al.,

2018) or hybrid systems, which may be excessive for

h

https://orcid.org/0000-0001-7781-342X

i

https://orcid.org/0009-0004-0219-9858

j

https://orcid.org/0000-0003-4216-6132

k

https://orcid.org/0000-0003-2822-9790

l

https://orcid.org/0000-0001-6041-5820

m

https://orcid.org/0000-0002-4917-2474

n

https://orcid.org/0000-0001-7014-9431

Stiole, S.-D., Alexandru, P., Tucan, P., Nadas, I., Bulbucan, V., Cailean, A., Sebeni, D., Banica, A., Jucan, D., Morariu, R., Vaida, C., Dobra, P., Machado, J. and Pisla, D.

Design and Control of a New Wrist Rehabilitation Robot.

DOI: 10.5220/0013700400003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 219-226

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

219

specific rehabilitation needs such as isolated wrist

joint therapy. As noted in (Omarkulov, et al., 2016),

simpler, task-specific devices can often achieve

comparable outcomes if paired with efficient control

strategies, while also being more adaptable to home-

based therapy. The study in (Masiero, et al., 2011)

demonstrates that early robot-assisted therapy can

significantly improve upper-limb motor recovery in

stroke patients. The present work proposes a cost-

effective robotic solution dedicated to wrist

rehabilitation. Additionally, unlike the NeReBot

(Rosati, et al., 2007) trial which centers on clinical

protocol evaluation, this paper focuses on the

comparison of three control strategies 1) Independent

Joint Control (IJC), 2) Linear Quadratic Regulator

(LQR), and 3) Luenberger observer-based LQR

controller - highlighting how different control

methods impact performance, robustness, and the

feasibility of developing rehabilitation devices.

Therefore, this paper proposes a new wrist

rehabilitation robot, with a focus on simplicity,

compactness, and cost-efficiency, aiming to provide

accessible therapeutic support for patients in need of

upper-limb motor recovery. The device is developed

to allow repetitive and controlled wrist movements,

such as flexion and extension (Major, et al., 2021),

(Tarnita, et al., 2022), which are commonly required

in post-stroke.

To evaluate the feasibility of various control

solutions for such a system, three strategies were

implemented and tested in simulation. IJC was

considered as a baseline method, leveraging its

simplicity and ease of implementation. A more

advanced approach based on linearization followed

by LQR control was also explored, enabling better

tracking performance and disturbance rejection by

accounting for system nonlinearities. In addition, a

Luenberger observer was integrated to estimate the

full state vector in scenarios where only joint position

measurements are available - a common situation in

low-cost hardware implementations. Even if

additional sensors are introduced, they are likely to be

low-cost and less accurate, which would require

further filtering and increase system complexity.

To enable effective and affordable wrist

rehabilitation solutions, this study investigates three

control strategies implemented on a custom-designed

robotic platform. Each method offers distinct

advantages, making them suitable for different

application contexts. In particular, the LQR +

Observer demonstrates strong potential for

maintaining control performance while reducing

sensor requirements, addressing a challenge in the

development of low-cost rehabilitation devices. It

also investigates whether control performance can

still be maintained using lightweight design and

standard components - without sacrificing precision.

The findings will guide future development of

accessible robotic therapy platforms that balance

performance, cost, and usability.

This paper is organized as follows: Section 2

presents the mechanical design of the wrist

rehabilitation robot, outlining its purpose, intended

use, and functional relevance. This section also

includes the forward kinematic and dynamic model of

the system. Section 3 introduces three control

strategies - 1) IJC, 2) LQR, and 3) Luenberger

observer-based LQR controller - each discussed with

respect to its specific advantages and applicability. In

Section 4, the simulation results obtained using these

control methods are analysed. Finally, Section 5

summarizes the main conclusions of the study and

outlines directions for future development.

2 ROBOT DESIGN AND

DYNAMIC MODELING

The robot proposed within this paper (WRIST-X) is a

novel 3-DOF rehabilitation robot, able to perform

flexion, extension, adduction, abduction, pronation

and supination of the wrist (Mehrez, et al., 2025). The

main wrist rehabilitation movements targeted in this

study are flexion/extension, adduction/abduction, and

pronation/supination.

The virtual model of the rehabilitation robot is

presented in Figure 2. The final prototype can be seen

in Figure 3. The robot has 5 major components: the

forearm rest responsible for anchoring the arm of the

patient in such manner that the centre of the wrist joint

falls at the intersection point of the robot’s motion

axis (point O). The adduction/abduction mechanism

performs the revolute motion around the OZ axis, the

flexion/extension mechanism performs revolute

motion around the OY axis and the

pronation/supination mechanism performs the

revolute motion around the OX axis. During the

rehabilitation procedure the patient grabs the handle

of the robot and all the rehabilitation motions are

performed with the closed fist.

Basically, the robot consists of three revolute

joints performing the rehabilitation motions

individually and several adjustment passive/lockable

mechanisms to allow the configuration of the robot to

comply to different anthropometric characteristics of

the patient.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

220

Figure 1: Design and prototype of the robot.

The joint angles are denoted as:

𝑞

=𝜓 ,𝑞

=𝜃,𝑞

=𝜑 (1)

where q

1

, q

2

, q

3

represent the active joints of the

mechanism, ψ represents the adduction/abduction

angle, θ represents the flexion/extension angle and φ

represents the pronation/supination angle.

The explicit rotation matrix of the system is

obtained as:

𝑅=𝑅

(𝜑)𝑅

(𝜃)𝑅

(𝜓) (2)

where R

x

, R

y

, R

z

are standard rotation on 𝑥/𝑦/𝑧-axis,

(Spong, Hutchinson, & Vidyasagar, 2005) matrices.

The angular velocity expressed in the space frame

is computed using (4):

()Jq q

ω

=⋅

(3)

where 𝐽

(

𝑞

)

=

0 𝑐𝑜𝑠𝜓 𝑐𝑜𝑠 𝜓𝑐𝑜𝑠 𝜃

0 𝑠𝑖𝑛𝜓 𝑠𝑖𝑛𝜓𝑐𝑜𝑠 𝜃

10 −𝑠𝑖𝑛𝜃

denotes the

Jacobian. The accelerations are determined as:

() ()Jq q Jqq

α

=⋅+

(4)

where:

0 sin sin cos cos sin

() 0 cos cos cos sin sin

00 cos

Jq

ψψ ψ θψ ψ θθ

ψψ ψ θψ ψ θθ

θθ

−− −

=−

−

(5)

To implement and validate control strategies, a

dynamic model of the system is necessary. For this

robot, the wrist joint dynamics can be approximated

using the classical Euler-Lagrange modelling

approach (Spong, et al., 2005).

The dynamic modelling of the robot was

performed by excluding the detailed characteristics of

the motors. The torque and power requirements were

estimated independently of motor dynamics to

evaluate the suitability of different motor types for

achieving the desired performance. Additionally,

frictional effects were neglected at this stage to

simplify the model and focus on the core mechanical

dynamics. These assumptions serve as a preliminary

step in the design process, with the understanding that

motor behaviour and friction will be incorporated in

future developments for more accurate simulation

and control. The general equation of motion for an 𝑛-

degree of freedom (DOF) manipulator is given by:

𝐷

(

𝑞

)

𝑞+𝐶

(

𝑞,𝑞

)

𝑞+𝐺

(

𝑞

)

=𝜏 (6)

where 𝑞 𝜖 ℝ

is the vector of generalized joint

coordinates, 𝑞,𝑞 are the joint velocities and

accelerations, 𝐷

(

𝑞

)

𝜖 ℝ

is the inertia matrix,

𝐶(𝑞,𝑞) 𝜖 ℝ

is the Coriolis and centrifugal

matrix, 𝐺(𝑞)𝜖 ℝ

is the gravity vector and τ 𝜖 ℝ

is

the vector of applied joint torques.

For the wrist rehabilitation robot presented in this

paper, the configuration consists of three rotational

DOF (i.e. 𝑛=3). The parameters of the model, such

as link masses, lengths, and moments of inertia, were

defined based on the mechanical design using the 3D

virtual model designed using Siemens NX.

The matrices in (8) are:

𝐷=

𝑑

1

−𝑑

2

·(𝑠(2))

2

𝑑

3

·s

(

2

)

−𝑑

4

·s (2)

𝑑

3

·s(2) 𝑑

5

0

−𝑑

4

·s (2) 0 𝑑

4

where𝑑

= 0.088,𝑑

=0.006 ,𝑑

= 0.034, 𝑑

=

0.0027,𝑑

=0.0209, 𝑠

(

𝑖

)

=sin

(

𝑞

)

,𝑐

(

𝑖

)

=

cos

(

𝑞

)

,𝑖=1,3

.

𝐶=

−𝑞

2

(

2𝑐

1

s

(

2

)

𝑐(2)

)

00

0𝑐

2

·𝑞

1

·c

(

2

)

𝑐

3

·𝑞

1

·c

(

2

)

0𝑐

3

·𝑞

1

·c

(

2

)

0

where 𝑐

=0.0031,𝑐

=0.0339, 𝑐

=−0.00135

𝐺=

(

0,1.3029

·

c

(

2

)

,0

)

.

The dynamic model provides the base for the

control strategies in the following sections and allows

for torque estimation necessary for future motor

selection. In addition, a saturation limit of ±10 𝑁

·

𝑚

was applied to the control input to reflect the

limitations of the motors, for ensuring that the

simulated control efforts remain within realistic

actuator capabilities.

3 CONTROL STRATEGIES

Three control approaches (output feedback and state

feedback) for wrist rehabilitation robots, were

developed and tested in simulation. The control

strategies feed into a microprocessor. The

microprocessor communicates bidirectionally with a

user interface that allows a therapist to monitor,

evaluate, and adjust treatment parameters in real time.

Simultaneously, the microprocessor sends commands

to three DC motors that drive the robotic arm. The

robotic arm, in contact with the patient, performs

therapeutic movements. Feedback from the robot is

Design and Control of a New Wrist Rehabilitation Robot

221

captured by encoders and sensors. This feedback is

relayed back to the microprocessor to adjust control

outputs dynamically, ensuring tracking position.

All control strategies presented in this work were

initially designed and applied to the linearized model

of the system, and their performance was

subsequently validated by testing them on the full

nonlinear model. Starting from the dynamic model

(6) we want to achieve the linearized form:

𝑥=

𝑥

𝑥

=

𝑓

𝑓

;

𝑓

=𝑥

𝑓

=𝑞

=𝐷

(

𝑞

)

(𝜏− 𝐶

(

𝑞,𝑞

)

𝑞−𝐺

(

𝑞

)

)

(7)

where 𝑥

=

[

𝑞

,𝑞

,𝑞

]

represents the joint

positions and 𝑥

=

[

𝑞

,𝑞

,𝑞

]

the velocities.

Following the linearization of the nonlinear

dynamic model, the system was reduced to a linear,

controllable it is an double integrator for each joint

considering the state vector

𝑥=

[

𝑞

,𝑞

,𝑞

,𝑞

,𝑞

,𝑞

]

. The system was linearized

around the equilibrium point 𝑥

=

[

0,0,0,0,0,0

]

and 𝑢

=𝜏

=

[

0,1.3029,0

]

which represents the

wrist being at rest in the neutral (horizontal) position.

The resulting system is controllable and is

described below:

𝑥

=𝐴∙𝑥+𝐵∙⍙𝑢

𝑦=𝐶∙𝑥+𝐷∙⍙𝑢

(8)

𝐴=

𝑂

𝐼

𝑂

𝑂

;𝐶=

(

𝐼

𝑂

)

;𝐷=𝑂

(9)

𝐵=

⎝

⎜

⎜

⎛

000

000

000

11.41 0 0

0 47.84 0

0

0

3

7

0

.

3

7

⎠

⎟

⎟

⎞

(10)

where 𝑥is the state vector (joint positions and

velocities),

⍙𝑢=𝑢− 𝑢

0

is the control input vector

(joint torques). 𝑂

denotes the 3𝑥3 zero matrix, and

𝐼

represents the 3𝑥3 identity matrix.

The first method implemented was IJC (Spong, et

al., 2005), a straightforward strategy based on

classical PID, commonly used for systems with

minimal coupling and well-understood dynamics.

Subsequently, an optimal control strategy - the

LQR (Spong, et al., 2005) was implemented,

improving tracking performance and disturbance

rejection by explicitly accounting for the system's

state and optimizing control effort.

Finally, to address the practical limitation of not

having full state measurement in real-world

applications, a Luenberger observer (Levine, 2011)

was designed and implemented to estimate

unmeasured state variables (e.g., angular velocity)

based on available position feedback.

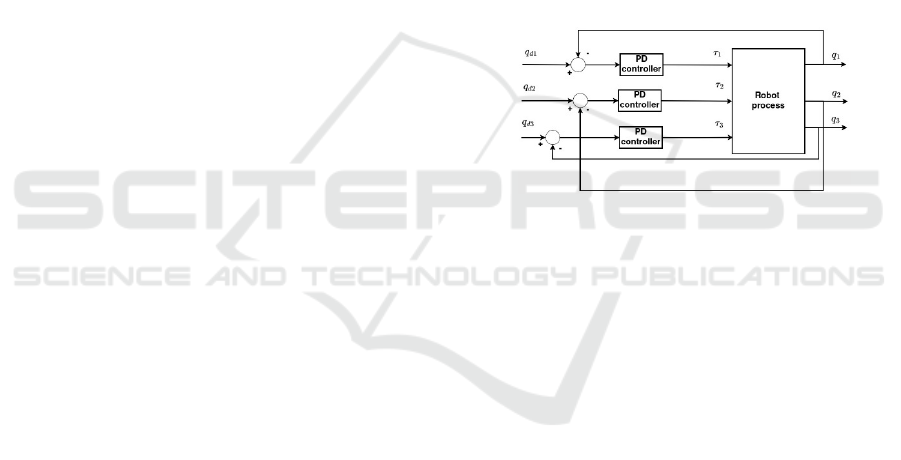

3.1 Independent Joint Control (IJC)

IJC is one of the most intuitive and widely used

control strategies in robotics, especially when dealing

with systems where dynamic coupling between joints

is minimal (Spong, et al., 2005) or deliberately

neglected. Given the nature of the rehabilitation

robot, the IJC approach is suitable and provides a

baseline for performance evaluation.

In this method, each joint 𝑞

is controlled

separately, typically using a Proportional-Derivative

(PD: 𝐾

+𝐾

∙𝑠) controller as it can be seen in

Figure 2 where 𝑞

is the desired reference value. The

simplified model assumes the robot behaves like a

second-order system with torque input and angular

position output.

Figure 2: Control structure for IJC.

This method is advantageous due to its ease of

implementation and minimal computational

requirements. However, it does not take into account

nonlinearities or external disturbances explicitly, and

performance may degrade in scenarios involving

interaction with a variable load (Prewett, at al., 2010)

(e.g., patient effort during therapy). The IJC strategy

(Spong, et al., 2005) starts from the idea of

simplifying the nonlinear, coupled dynamics of the

robot by reducing it to a set of three decoupled

second-order linear systems. This is achieved by

treating the dynamic interactions between joints and

other nonlinear effects as external disturbances. Once

the system is expressed in this simplified second

order (11) form for each joint, the control design

proceeds by imposing the denominator of the closed-

loop (13) performance specifications directly.

𝑠

+2ζ𝜔

𝑠+𝜔

(11)

Specifically for our robot, the desired damping

ratio 𝜁=1 and natural frequency 𝜔

=10 𝑟𝑎𝑑/𝑠𝑒𝑐

are selected to define the transient behavior, such as

small settling time and no overshoot.

The closed-loop transfer function results:

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

222

𝐻

(

𝑠

)

=

𝐾

⋅𝐾

⋅𝑠+𝐾

⋅𝐾

𝑠

+𝐾

⋅𝐾

𝑠+𝐾

⋅𝐾

(12)

The resulting control law is:

𝜏

(

𝑡

)

=𝐾

⋅𝑒

(

𝑡

)

+𝐾

⋅𝑒

(𝑡)

(13)

where 𝑒(𝑡) is the position tracking error, 𝐾

is the

proportional gain, 𝐾

is derivative gain of the

controller, 𝐾

=[11.4; 47.84; 370.37] is the

proportional constant of the individual transfer

function for each joint and 𝑖=1,3

corresponding to

the joint position.

By matching the characteristic equation of the

closed-loop system (12) to the standard second-order

form (11), the controller gains are computed

analytically. In practice, the choice of 𝜔

is limited

by the physical constraints of the system, particularly

actuator saturation. Therefore, the highest feasible 𝜔

is selected to balance performance and input

limitations. This allows the designer to systematically

tune the controller based on clear performance

objectives that can be easily implemented on each

joint 𝑞

(i.e. 𝑖=1,3

) independently.

3.2 LQR Control

To enhance control performance, particularly in terms

of precision and energy efficiency, a Linear Quadratic

Regulator (LQR) (Levine, 2011) is considered.

The LQR control law is given by:

𝑢

(

𝑡

)

=−𝐾𝑥

(

𝑡

)

+𝑢

(14)

where 𝑢(𝑡) is the input, 𝑥(𝑡) is the state vector of the

system and 𝐾 is the optimal gain matrix computed to

minimize the quadratic cost function:

𝐽

=

(

𝑥

𝑄𝑥+ 𝑢

𝑅𝑢

)

𝑑𝑡

(15)

where 𝑄 𝜖 ℝ

and 𝑅 𝜖 ℝ

are symmetric

positive semi-definite matrices that penalize

deviations, respectively the control effort.

The tracking problem in LQR is defined as the

requirement for the system output to follow a given

reference trajectory 𝑞

. Specifically, the position

tracking error, defined as 𝑞

−𝑞 must converge to

zero. The reference state vector 𝑥

is defined to

include the desired joint positions 𝑞

and

corresponding zero velocities, resulting in 𝑥

=

[

𝑞

,0

]

. The control law is then applied in the form:

𝑢

(

𝑡

)

=−𝐾(𝑥

(

𝑡

)

−𝑥

(𝑡)) +𝑢

(16)

where 𝑢

corresponds to the equilibrium condition

used during the linearization process.

3.3 State Estimation

In practical applications, it is often not feasible to

measure all state variables directly due to sensor

limitations or cost constraints. To enable the

implementation of state-feedback control, it is

therefore necessary to estimate the full state vector

from the available measurements. To this end, a

Luenberger observer was designed based on the

linearized model of the system, following the

methodology described in (Levine, 2011) and applied

on the nonlinear process. The observer reconstructs

the unmeasured states by using the system’s model

and correcting the estimation based on the error

between the measured and estimated outputs.

The linear observer has the following structure:

𝑥

(

𝑡

)

=

𝐴

·𝑥

+𝐵·𝑢+𝐿(𝑦

(

𝑡

)

−𝑦

(

𝑡

)

) (17)

After computing 𝐿, the nonlinear observer is:

𝑥

(

𝑡

)

=

𝑓

(𝑥

,𝑢)+𝐿(𝑦

(

𝑡

)

−𝑦

(

𝑡

)

) (18)

where 𝑥

(𝑡) is the estimated state vector, 𝑓

(

𝑥

,𝑢

)

represents the nonlinear system as presented in (7), 𝐿

is the observer gain matrix designed for the linear

model, 𝑦

(

𝑡

)

is the measured output (in this case, joint

position) and 𝑦

(

𝑡

)

=𝐶𝑥

(

𝑡

)

is the estimated output.

4 RESULTS

To evaluate the performance of the three

implemented control strategies - 1) IJC, 2) LQR, 3)

LQR and Luenberger observer - simulations were

conducted in Matlab/Simulink using the previously

defined dynamic model in (8). All the results are

presented for the nonlinear system, with white

measurement noise added to the joint position signals

to simulate realistic sensing conditions. The

evaluation focused on trajectory tracking

performance (𝑥

for adduction and abduction motion,

𝑥

for flexion and extension motion and 𝑥

for

pronation and supination motion), disturbance

rejection, and control effort.

The initial conditions were set to 𝑥

=

[

0.3, −0.3, 0.4, 0, 0, 0

]

and the reference

position is 𝑥

=

[

−0.2, −0.1, −0.2, 0, 0, 0

]

.

Following the tuning guidelines mentioned above,

the controller gains used for the joints in the IJC

approach are 𝐾

=

[

8.76,2.09,0.001

]

,𝐾

=

[

1.75,0.41,0.0001

]

.

These values were found to provide acceptable

tracking performance and stable response for the

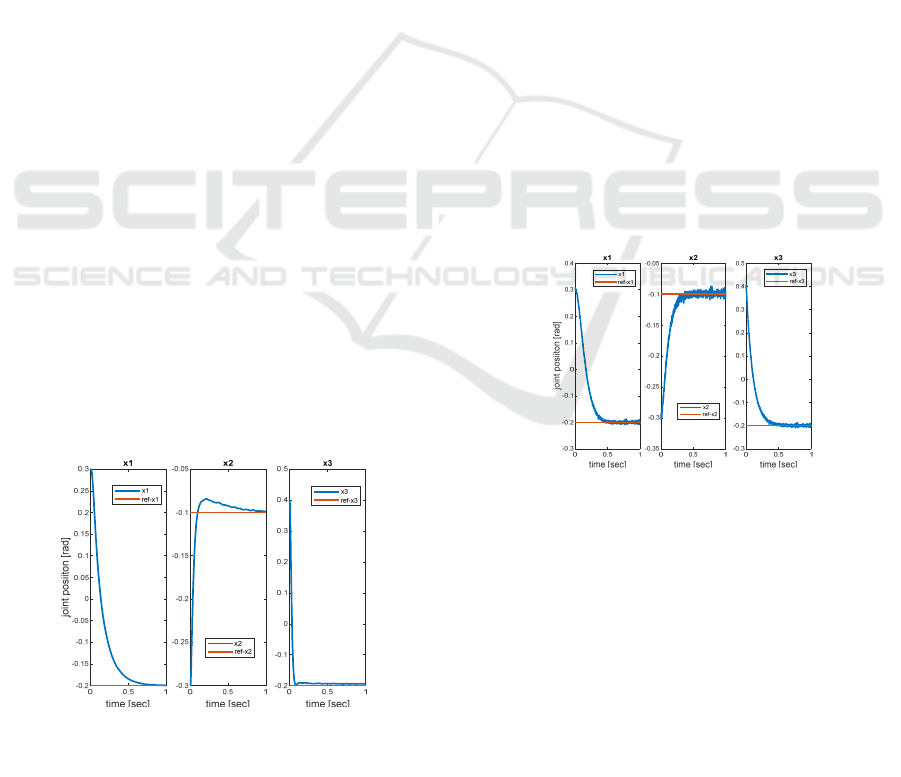

desired reference. Figure 3 illustrates the response of

Design and Control of a New Wrist Rehabilitation Robot

223

the system states under the IJC strategy, alongside the

reference signals (with red colour - the reference and

with blue - the joints positions). The measured

settling times are approximately 0.64 sec for joint 𝑥

,

0.7 sec for joint 𝑥

, and significantly lower at 0.3 sec

for joint 𝑥

. A small steady-state position error of

approximately is present for joint 𝑥

, indicating the

limitations of this decoupled control approach in fully

compensating for system nonlinearities and

interactions. Additionally, an overshoot was observed

for joint 𝑥

. Despite these limitations, the controller

maintains stable behaviour across all joints, making it

a viable solution for applications where cost and

simplicity are prioritized over high precision.

Moving to LQR simulations, multiple

combinations of 𝑄 and 𝑅 (Franklin, et al., 2014) were

tested through iterative tuning using the linearized

system to identify a configuration that provides a

balance between control effort, settling time,

overshoot, and tracking accuracy. Lower values in 𝑅

favor aggressive control with faster response, while

higher weights in 𝑄 emphasize precise state tracking.

Higher weights were assigned to the position states in

matrix 𝑄 to prioritize trajectory tracking, while lower

weights were set for the velocity states to reduce

sensitivity to noise and avoid aggressive control

actions. The final selected values achieved smooth

and accurate tracking with moderate control inputs,

making the controller viable for real-time

implementation. The chosen configuration is also

suitable for low-cost implementations, as it does not

require high-speed computation or complex hardware

resources. The final values for Q, R and K are:

𝑄=

300 ∙ 𝐼

𝑂

𝑂

3∙𝐼

; 𝑅 =2·𝐼

(19)

𝐾=

12.247 0 0 1.909 0 0

0 12.247 0 0 1.418 0

0 0 12.247 0 0 1.251

(20)

Figure 3: State and reference tracking under IJC.

This control strategy provided accurate tracking

for most of the states, with fast convergence and

minimal overshoot. Once the corresponding feedback

gain 𝐾 was obtained, the same controller was applied

to the original nonlinear model. The results confirm

that the control law remained effective, with the

system maintaining stability and accurate trajectory

tracking despite the presence of nonlinearities.

The state responses obtained using the LQR are

illustrated in Figure 4. The state trajectories are

plotted in blue, while the position reference signals

are in red. The IJC results show slower responses

compared to the LQR. All states converge to the

reference, with no overshoot and no steady state error,

confirming the effectiveness of the LQR design. The

settling times for each joint are about 0.47 sec for 𝑥

,

0.43 sec for 𝑥

, and 0.46 sec for 𝑥

.

After the LQR design, the next step was to

compute the observer gain 𝐿, based on the pole

placement. Specifically, the poles of the closed-loop

system with the state-feedback controller were

multiplied by a factor of 2 in magnitude. This pole

placement strategy ensures that the observer responds

relatively quickly to any deviations between the

measured and estimated outputs. Excessively fast

poles would increase estimation speed but also

demand high sampling rates and computational

power, which may not be feasible in a low-cost

implementation. The chosen configuration ensures

reliable state estimation while maintaining

compatibility with practical hardware constraints.

Figure 4: LQR-State trajectories and position reference.

As a result, the final poles of the observer are 𝑝 =

10

· [−9.07; −1.15; −0.20; −0.20; −0.21;0.09𝑖;

−0.21 + 0.09𝑖].

The gain observer matrix is:

𝐿=10

·

⎝

⎜

⎜

⎛

0.033 0.047 −0.651

0.086 0.098 0.574

0.068 0 0.975

0.111 0.886 −15.659

1.852 1.610 13.841

1.399 0.001 19.564

⎠

⎟

⎟

⎞

(21)

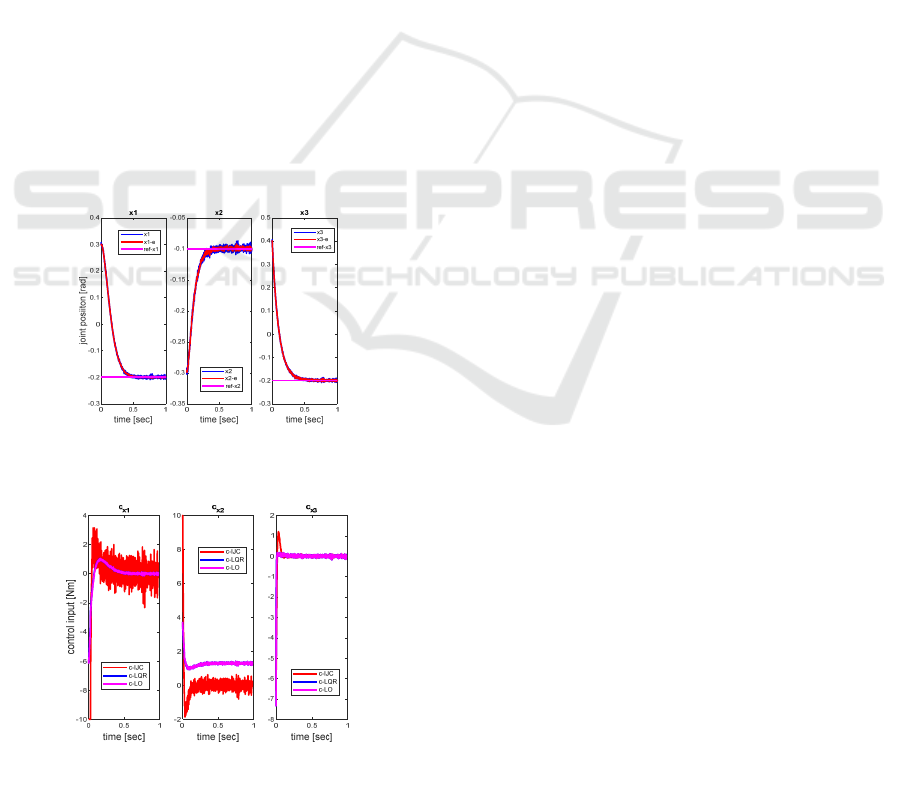

The results using the LQR controller together with

the Luenberger state observer are presented in Figure

6. The same feedback gain 𝐾, as a full state LQR, was

used with the same initial conditions.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

224

In Figure 5, the positions (𝑥

,𝑥

,𝑥

) are plotted in

blue, the corresponding estimated states are shown in

red (coincide with the estimated states), and the

reference signals are displayed in magenta. The

simulation results show that the positions

successfully converge to the reference values without

steady-state error, and that the estimated states match

the true states, confirming the effectiveness of the

overall controller-observer structure. The closed-loop

performance achieved using the LQR controller in

combination with the Luenberger observer

demonstrates accuracy across all controlled joints.

The settling times are approximately 0.46 sec for 𝑥

,

0.41 sec for 𝑥

, and 0.47 sec for 𝑥

. Throughout the

simulation, none of the joint responses exhibited

overshoot or steady-state error.

The estimation error (𝑥−𝑥

) generated by the

Luenberger observer is on the order of 10

. The

estimation error in all state components converges

toward zero. Figure 6 shows the control signals for

the three joints under each control strategy: the IJC

command is shown in red, the LQR command in blue,

and the LQR with observer in magenta (considered

best result in terms of noise reduction), with the last

two overlapping almost entirely. All signals remain

within the ±10 𝑁𝑚 range, which represents the

considered torque limit for the actuators.

Figure 5: System and estimated states and reference

trajectories for Luenberger observer.

Figure 6: Control signals for the system with the IJC, LQ

R

controller and LQR with Luenberger observer.

The IJC method stands out for its simplicity and

ease of implementation, providing fast response for

joint 𝑥

. However, it shows a significant overshoot

for 𝑥

and a small steady-state position error for 𝑥

,

highlighting the limitations of decoupled control.

The LQR achieves excellent overall performance,

with fast convergence, no overshoot, and zero steady-

state error, but it relies on full state feedback, which

may not be feasible in low-cost implementations.

In contrast, the LQR controller combined with a

Luenberger observer maintains similar performance

levels while using only joint position measurements.

This approach proves effective not only in reducing

sensor requirements but also in dealing with

modelling uncertainties and measurement noise,

making it highly suitable for practical, low-cost

rehabilitation systems.

5 CONCLUSIONS

This work presents the design, modeling, and control

simulation of a wrist rehabilitation robot developed

from scratch with emphasis on simplicity, low cost,

and compactness. The device is intended to support

repetitive wrist rehabilitation exercises, and to serve

as a practical solution for both clinical and home-

based rehabilitation.

Three control strategies were implemented in

simulation: IJC, LQR, and an observer-based LQR.

All proved feasible within the robot’s simplified

structure and intended use. IJC offers a

straightforward and accessible approach, while LQR

provides superior tracking accuracy and disturbance

rejection. The observer-enhanced LQR further

increases practicality by relying only on position

sensors, reducing hardware requirements while

maintaining performance.

These results establish a foundation for selecting

suitable control methods depending on application

priorities such as simplicity, precision, or sensor

economy. The findings will guide prototype

development, including the choice of motors, sensors,

and embedded hardware. They also highlight the

trade-offs between ease of implementation (IJC), high

control performance (LQR), and cost efficiency

(LQR + Observer). The next step is to build the

physical prototype and perform real-time testing,

initially with healthy users and later with patients

under clinical supervision.

Future work will expand the system’s capabilities

by including additional degrees of freedom and

modeling human–robot interaction forces to better

mimic realistic therapy. Integrating physiological

Design and Control of a New Wrist Rehabilitation Robot

225

feedback, such as electromyographic (EMG) signals,

could enable adaptive control strategies that adjust to

patient effort and fatigue. Long-term clinical studies

with healthcare professionals will also be pursued to

evaluate therapeutic outcomes and refine

rehabilitation protocols. Overall, the proposed system

demonstrates strong potential for becoming an

affordable and effective rehabilitation tool suitable

for deployment in hospitals and home-based recovery

programs.

ACKNOWLEDGEMENTS

This research was supported by the project New

frontiers in adaptive modular robotics for patient-

centered medical rehabilitation–ASKLEPIOS,

funded by European Union – NextGenerationEU and

Romanian Government, under National Recovery

and Resilience Plan for Romania, contract no.

760071/23.05.2023, code CF 121/15.11.2022, with

Romanian Ministry of Research, Innovation and

Digitalization, within Component 9, investment I8.

REFERENCES

Akdogan, E. (2016). Upper limb rehabilitation robot for

physical therapy: design, control, and testing. Turkish

Journal of Electrical Engineering and Computer

Sciences, 24(3), 911-934.

Basteris, A., et al (2014). Training modalities in robot-

mediated upper limb rehabilitation in stroke: a

framework for classification based on a systematic

review. J Neuroeng Rehabil, 11 111. doi:10.1186/1743-

0003-11-111

Franklin, G., Powell, J. D., & Emami-Naeini, A. (2014).

Feedback Control Of Dynamic Systems (7th ed.).

Prentice Hall Press.

Guozheng, X., et al (2014). Clinical experimental research

on adaptive robot-aided therapy control methods for

upper-limb rehabilitation. Robotica, 32(7), 1081–1100.

Krebs, H., et al (1999). Overview of clinical trials with

MIT-MANUS: a robot-aided neuro-rehabilitation

facility. Technology and Health Care, 419-423.

Levine, W. S. (2011). The Control Systems Handbook:

Control System Advanced Methods (2

nd

ed). CRC Press.

Major, Z. Z., et al (2021). Comparative Assessment of

Robotic versus Classical Physical Therapy Using

Muscle Strength and Ranges of Motion Testing in

Neurological Diseases. Journal of Personalized

Medicine, 11(10), 953.

Masiero, S., Armani, M., & Giulio, R. (2011). Upper-limb

robot-assisted therapy in rehabilitation of acute stroke

patients: Focused review and results of new randomized

controlled trial. Journal of Rehabilitation Research and

Development, 48(4), 355-366.

Mehrez, O., et al (2025). Development of an exoskeleton

for wrist-joint rehabilitation: modeling, identification,

and control. Multibody System Dynamics.

doi:10.1007/s11044-025-10066-0

Omarkulov, N., et al (2016). Preliminary mechanical

design of NU-Wrist: A 3-DOF self-aligning Wrist

rehabilitation robot. 2016 6th IEEE International

Conference on Biomedical Robotics and

Biomechatronics (BioRob), (pp. 962-967). Singapore.

Parisi, A., et al (2022). Efficacy of Multisensory

Technology in Post-Stroke Cognitive Rehabilitation: A

Systematic Review. Journal of Clinical Medicine,

11(21), 6324.

Pollock, A., et al (2014). Interventions for improving upper

limb function after stroke. Cochrane Database of

Systematic Reviews, 11(1).

Prewett, M. S., et al (2010). Managing workload in human–

robot interaction: A review of empirical studies.

Computers in Human Behavior, 26(5), 840-856.

Rosati, G., Gallina, P., & Masiero, S. (2007). Design,

Implementation and Clinical Tests of a Wire-Based

Robot for Neurorehabilitation. IEEE Trans. on Neural

Systems and Rehabilitation Eng., 15(4), 560-569.

Spong, M. W., Hutchinson, S., & Vidyasagar, M. (2005).

Robot Modeling and Control (First ed.). Wiley.

Squeri, V., et al (2014). Wrist rehabilitation in chronic

stroke patients by means of adaptive, progressive robot-

aided therapy. IEEE Transactions on Neural Systems

and Rehabilitation Engineering, 22(2), 312-325.

Tarnita, D., et al (2022). Analysis of Dynamic Behavior of

ParReEx Robot Used in Upper Limb Rehabilitation.

Applied Sciences, 12(15), 7907.

Tohanean, N., et al (2023). The Efficacity of the

NeuroAssist Robotic System for Motor Rehabilitation

of the Upper Limb—Promising Results from a Pilot

Study. Journal of Clinical Medicine, 12(2), 425.

Toth, A., et al (2005). Passive robotic movement therapy of

the spastic hemiparetic arm with REHAROB: report of

the first clinical test and the follow-up system

improvement. 9th International Conference on

Rehabilitation Robotics, 127-130. Chicago, IL, USA.

Tucan, P., et al (2022) Design and Experimental Setup of a

Robotic Medical Instrument for Brachytherapy in Non-

Resectable Liver Tumors. Cancers 2022, 14, 5841.

https://doi.org/10.3390/cancers14235841

Vaida C., et al (2018) Innovative development of a

spherical parallel robot for upper limb rehabilitation.

Int. J. Mech. Robot. Syst. 2018;4:256. doi:

10.1504/IJMRS.2018.096302.

Wu, C., et al (2011). Randomized Trial of Distributed

Constraint-Induced Therapy Versus Bilateral Arm

Training for the Rehabilitation of Upper-Limb Motor

Control and Function After Stroke. Neurorehabilitation

& Neural Repair, 25(2), 130-139.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

226