Health-Aware Charging of Li-Ion Batteries Using MPC and Bayesian

Degradation Models

Taranjitsingh Singh

a

, Jeroen Willems

b

, Bruno Depraetere

c

and Erik Hostens

d

MotionS, Flanders Make, Lommel, Belgium

fi fl

Keywords:

Model Predictive Control (MPC), Health-Aware Charging, Lithium-Ion Batteries, Bayesian Networks.

Abstract:

We propose a Model Predictive Control (MPC) approach for health-aware optimal charging of Lithium-ion

Nickel Manganese Cobalt (Li-NMC) batteries. Our method integrates electrical, thermal, and degradation

models using Bayesian Networks (BNs) to estimate the battery’s State of Health (SOH). These models are

embedded into an MPC framework to generate charging profiles that reduce long-term degradation while

ensuring fast charging performance. Validation is performed through high-fidelity simulations using the

PyBaMM battery modeling environment. Results show improved SOH retention compared to conventional

Constant Current-Constant Voltage (CC-CV) strategy.

1 INTRODUCTION

The electric vehicle (EV) market, particularly the

part using Lithium-ion Nickel Manganese Cobalt (Li-

NMC) batteries, is experiencing significant growth,

with forecasts indicating continued expansion in the

coming decades. In 2023, nearly 14 million electric

cars were sold globally, making up 18% of all EV

sales worldwide, indicating a growing trend in sales.

This upward trend is expected to continue, with key

markets like China, Europe, and the United States at

the forefront. As the market expands, the demand for

charging infrastructure is also anticipated to rise sub-

stantially. To support the increase in electric vehicles,

the number of public charging stations will need to

grow sixfold by 2035 (Agency, 2024).

Despite advancements, range anxiety and battery

aging continue to be significant obstacles to broader

EV adoption. Enhancing charging infrastructure is

essential, but reducing charging times is equally criti-

cal. A smart and fast charging strategy aims to reduce

charging time while preserving lithium-ion battery

lifespan. This requires precise regulation of charg-

ing currents within physical limits to avoid conditions

that could cause rapid, unwanted degradation of batter-

ies or, in extreme cases, thermal runaway. Developing

a

https://orcid.org/0000-0003-3255-3796

b

https://orcid.org/0000-0002-2727-6096

c

https://orcid.org/0000-0003-2011-3857

d

https://orcid.org/0000-0003-2482-7523

such a fast charging strategy for EVs with Li-NMC bat-

teries is a complex and resource-intensive task (Was-

siliadis et al., 2023).

The standard fast charging protocols used in

EVs have long been the classical Constant-Current

Constant-Voltage (CC-CV) method (Abdollahi et al.,

2016). To mitigate the risk of degradation, these proto-

cols have been extended to include multiple CC phases

along with a CV phase (MCC) (Li et al., 2020). Ad-

ditionally, researchers have explored methods that de-

liver high C-rate pulses to further preserve battery

health (Qin et al., 2022). However, while these meth-

ods perform well for slow charging, they are inherently

static and fail to provide a charging profile that ac-

counts for the preservation of battery health (Lu et al.,

2024).

As previously mentioned, smart fast charging

presents the challenge of balancing charging times

with battery degradation, which can affect the long-

term State-of-Health (SOH) of EV batteries (Agency,

2024). Extensive reviews on fast charging meth-

ods, particularly for EVs, have been conducted by

researchers, as noted in (Tomaszewska et al., 2019).

Their discussions highlight the impact of overcharging

on battery degradation. Most fast charging algorithms

prioritize avoiding thermal runaways, which leads to

a focus on the design part of thermal management

rather than the algorithms themselves (Tomaszewska

et al., 2019). In the realm of charging algorithm in-

vestigations, the research predominantly depends on

degradation models, which are empirical-based meth-

Singh, T., Willems, J., Depraetere, B. and Hostens, E.

Health-Aware Charging of Li-Ion Batteries Using MPC and Bayesian Degradation Models.

DOI: 10.5220/0013691400003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 1, pages 37-46

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

37

ods and so their performance can only be tested for

a limited range of chemistries (Tomaszewska et al.,

2019; Erdinc et al., 2009).

Despite these difficulties in modeling, incorporat-

ing battery degradation into fast charging algorithms

is essential. Battery degradation is a complex pro-

cess resulting from multiple mechanisms within the

battery chemistry. Some of the key mechanisms in-

clude the formation of a solid electrolyte interphase

(SEI) layer on the anode surface, lithium plating

−

where lithium ions from the electrolyte are deposited

as metallic lithium on the anode

−

and the loss of

active materials (Birkl et al., 2017). Fast charging

and high currents lead to elevated temperatures, which

accelerate these degradation processes, subsequently

increasing the anode potential which must be avoided

when designing charging profiles.

Advanced health-aware fast charging algorithms

exist, where researchers have dived into the use of

Model Predictive control (MPC) techniques by includ-

ing these degradation models in the optimization. One

of the first MPC techniques considered for optimal

charging dates back to 2011, where the researchers uti-

lized advanced degradation models (Wassiliadis et al.,

2023; Klein et al., 2011). Although these models are

derived from accurate electrochemical models, they

are inherently complex involving multiple states. Con-

sequently, identifying model parameters, or estimating

the intermediate states presents a significant compu-

tational challenge. Therefore, the studies conducted

in (Xavier and Trimboli, 2015; Xavier et al., 2020)

employ a reduced-order model of the battery, which is

derived from a complex electrochemical model.

In this paper, we use a Bayesian Network (BN)

model that relies on the degradation drivers rather than

using the electrochemical model states, along with a

model for battery and electro-thermal dynamics. This

method stands in contrast to the one presented in (Lu

et al., 2024) which employs a deterministic parametric

state-space model for degradation. The key advantage

of our approach is its ability to account for stochastic

variations. This method can also be applied in closed-

loop simulations to achieve more accurate degradation

estimates. Our novelty is in framing the optimal health-

aware charging problem as a Nonlinear MPC problem

using the BN predicted distributions and conducting

realistic high-fidelity simulations for validation.

The article is organized as follows. Section 2 de-

tails the proposed models and estimators. Section 3

outlines the formulation of the MPC problem for

health-aware charging control. Section 4 presents the

validated results, and finally, Section 5 draws the con-

clusions of this article and provides insights on future

research directions.

2 MODELING APPROACH

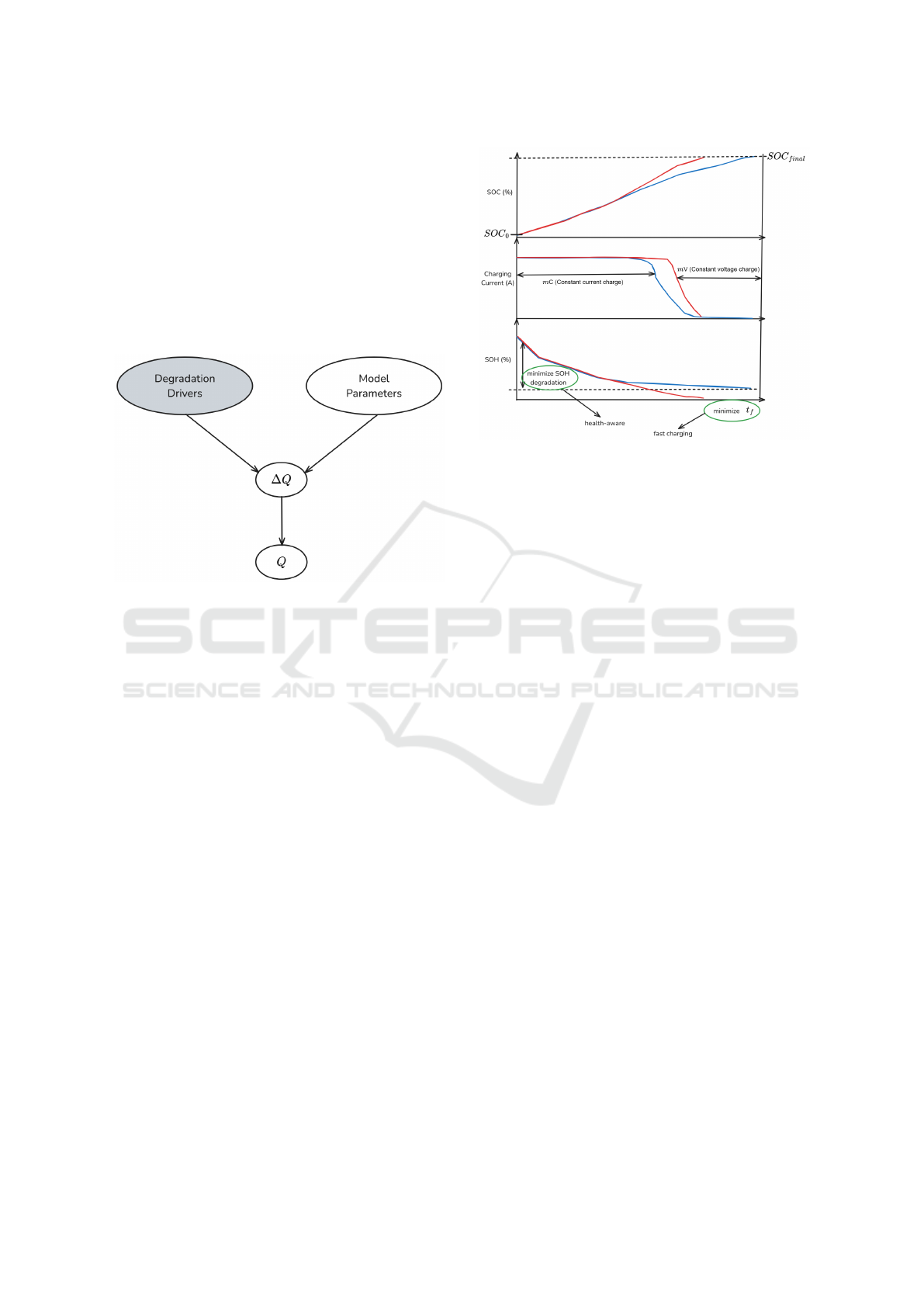

Figure 1 explains the interconnected modeling frame-

work necessary for health-aware charging optimiza-

tion. It highlights three necessary models: the Battery

Model, the Electro-Thermal Model, and the State of

Health Model, which collectively govern the behavior

and performance of a battery (Wassiliadis et al., 2023).

The Battery Model simulates the relationship between

the State of Charge (SOC) and the battery’s voltage.

The Electro-Thermal Model models the temperature

variations, and interactions of temperature with SOC

and the SOH. Lastly, the SOH model includes the long-

term degradation of the battery, taking into account the

operating conditions and impact of various charging

strategies.

Figure 1: Coupling and interconnected framework required

for health-aware charging (Wassiliadis et al., 2023).

This section provides the detailed descriptions of

these three models.

2.1 Battery Model

The battery dynamics are modeled using a first-

order Resistance-Capacitance (RC) Equivalent Circuit

Model (ECM). This describes the relationship between

the overpotential

o

k

and the terminal voltage

y

k

, as a

function of the current

u

k

. This influence is a function

of resistances and capacitances that vary with parame-

ters such as the SOC

s

k

and temperature

T

k

. Therefore,

the dynamic behavior of

T

k

and

s

k

will be modeled

as well: for

T

k

this will be done in the thermal model

in the next section, but the evolution of

s

k

is added

here to the ECM model. This yields an overall battery

model with states x

ECM

= [s

k

,o

k

]

T

given by:

ECM

s

k+1

o

k+1

=

1 0

0 θ

1

s

k

o

k

+

∆t

Q

k

θ

2

u

k

y

k

= o

k

+V

OCV

(s

k

,T

k

) + θ

3

u

k

(1)

Herein,

Q

k

expresses the battery’s total capacity,

V

OCV

(

s

k

,T

k

) expresses the open-circuit-voltage (OCV)

as a function of current, and

θ

1

,

θ

2

and

θ

3

express

gains depending on resistances and capacitances that

vary over time as a function of

s

k

and

T

k

. As a result,

this becomes a Linear Parameter Varying – Input Out-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

38

put (LPV-IO) model. We have used experimental logs

of voltages, current, temperature, and SOC, to identify

these model parameters in multiple conditions using

the methodology as given in (Hoekstra et al., 2023).

2.2 Electro-Thermal Model

Now we will describe the thermal behavior of the

battery. As seen in the previous section, the parameters

of the ECM are influenced by the battery temperature.

Likewise, how much the battery heats up, is affected

by electrical parameters like the current, the terminal

voltage and the OCV. Consequently, there is a mutual

coupling and interaction between the ECM and the

thermal model (Cai et al., 2021).

The electro-thermal model expresses the heat

˙q

th

generated at the core of the battery, how this affects

the core temperature

T

c

and the surface temperature

T

s

, as well as how much cooling is obtained at the

battery’s surface which is in contact with the envi-

ronment at ambient temperature

T

f

. This yields the

electro-thermal battery models (ETBM) with states

x

ET BM

= [q

th

k

,T

c

k

,T

s

k

]

T

as given by:

ET BM

˙q

th

k

= u

k

V

OCV

(s

k

,T

k

) − y

k

T

c

k+1

= T

c

k

+

∆t

C

c

q

th

k

+

T

s

k

− T

c

k

R

c

T

s

k+1

= T

s

k

+

∆t

C

s

T

f

k

− T

s

k

R

u

+

T

c

k

− T

s

k

R

c

(2)

Here, the first equation expresses the heat generation

due to the charging, as the product of the current

u

,

and the voltage which is a function of electrical param-

eters as mentioned. The second and third equations

express the evolution of core and surface temperatures,

with

C

c

and

C

s

the centralized heat capacity of the bat-

tery core and the battery surface respectively. These

evolutions are a function of the generated heat and the

cooling, as well as of the heat transfer between the two.

This transfer is affected by

R

c

, denoting the equivalent

conduction heat resistance used to simulate the heat

exchange between the core and the surface, and

R

u

,

denoting the equivalent convective resistance used to

simulate the convective cooling on the battery surface.

Remark 1. Note that for simplicity, the temperature

T

used in the ECM model is taken as the average

between T

c

and T

s

.

2.3 State-of-Health Model

For health-aware control, we need a reliable model

for degradation of batteries. Indeed, if we know how

degradation evolves as a function of charging and dis-

charging profiles, then (i) it can be included as a cost

function for optimal control, and (ii) it can be used to

improve the SOH estimation and therefore the SOC

estimation, since the latter relies on an accurate knowl-

edge of the actual value of Q

k

in (1).

SOH

k

which represents the current state of health,

is related to the loss of capacity due to degradation is

expressed as follows:

SOHM

SOH

k+1

=

1

Q

nom

(Q

k

− ∆Q

k

)

or

SOH

k+1

= SOH

k

−

∆Q

k

Q

nom

(3)

where,

Q

k

is the current cell’s capacity,

Q

nom

in the

nominal cell capacity, and ∆

Q

k

represents the capacity

degradation.

While this is a simple model, it is in practice very

hard to estimate these quantities correctly. The degra-

dation model therefore needs to include the uncer-

tainty. An accurate quantification of the uncertainty

distribution is important as we know that the SOC level

has a strong influence on degradation, especially in

case of under- and overcharging, for which the tails

of the SOC distribution matter. This information is

then fused with other sources of information such as

sensor inputs (current, voltage, temperatures, etc) or

other models such as the SOC to open-circuit voltage

relation, to then form a total posterior distribution for

the SOC. However, detailed models of degradation,

such as (Sulzer et al., 2021) for Li-ion batteries, are

too complicated to use in an online optimal control

calculation. Furthermore, although these models rely

on a profound understanding of the physics of degra-

dation, it is a process that relies on many influences,

many of which are unmeasured or even unknown, as

such rendering it highly stochastic. This stochastic

behavior can be derived from real measurement data

only. A useful tool for training stochastic models are

Bayesian Networks (BN), as they provide a compre-

hensible graphical description of all involved variables

and their stochastic relations. Especially for SOH

and/or remaining useful life (RUL) predictions, where

data is censored and models and measurements with

their uncertainties have to be fused in a nontrivial way

to support maintenance decisions, BNs have proven

their usefulness (Hostens et al., 2024).

In this paper, we adopt a simplified use of BNs,

and we assume availability of periodic capacity mea-

surements

Q

in the data. This is motivated by the exis-

tence of explicit procedures for capacity measurement,

such as (Christophersen, 2015, p14). We then model

the change in capacity as a function of the degrada-

tion drivers, such as temperature, depth-of-discharge

(DoD) and C-rate. Full formulations are provided in

Section 4.

Health-Aware Charging of Li-Ion Batteries Using MPC and Bayesian Degradation Models

39

In absence of prior knowledge of the nature of

these relations, it is recommended to use data-based

regression techniques and suggest specific functions

and distributions with a low number of parameters. In

many cases, generalized linear regression is a good

starting point. Training of the BN returns the poste-

rior distribution of the model parameters, as shown in

Fig. 2. An ill-chosen model will result in bad conver-

gence, yielding for instance multi-modal posteriors,

which can be used to trigger a refinement of the model,

or to collect more data (in case of too wide posteriors).

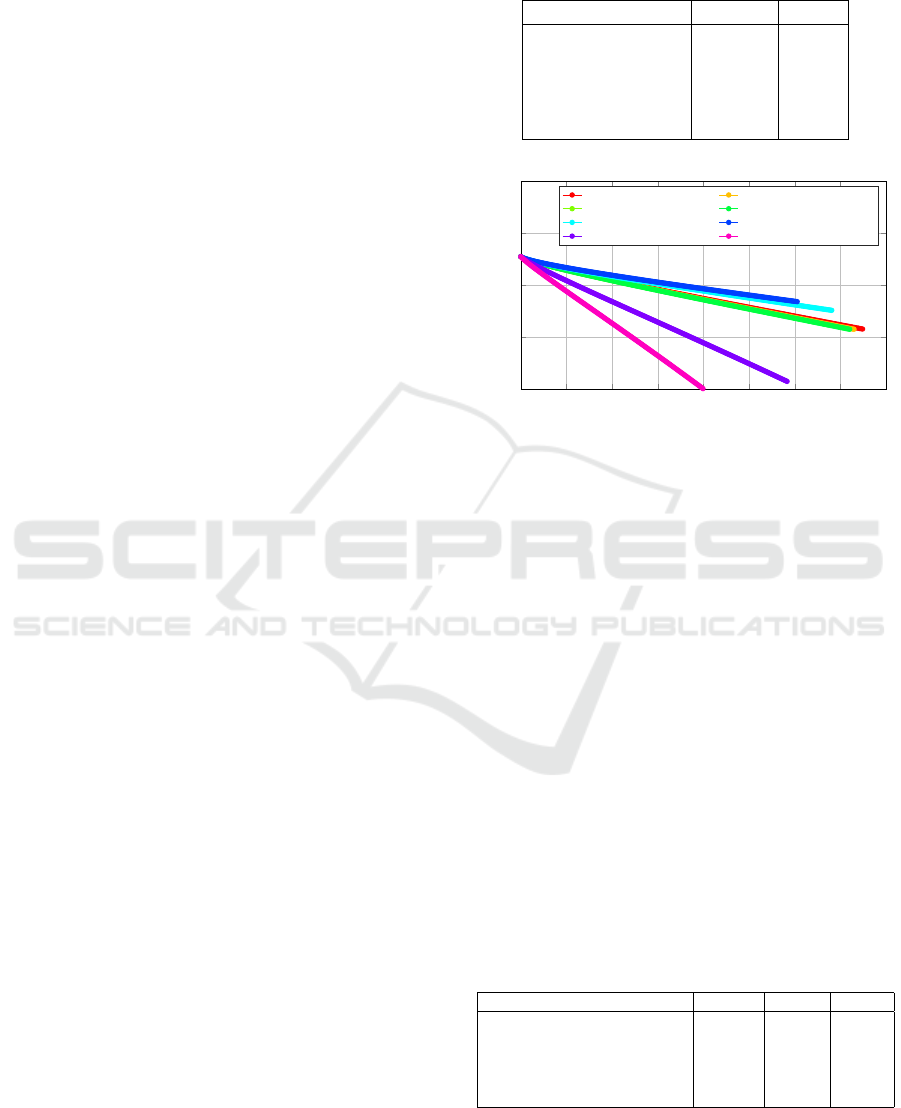

Figure 2: Generic BN representation of battery degradation.

The gray-colored variables are observed during training.

3 HEALTH-AWARE PROBLEM

FORMULATION

In this section we introduce our problem formula-

tion for the health-aware charging for the lithium ion-

batteries.

The trade-off between fast charging and health

degradation, is illustrated in Figure 3. It shows the

battery’s SOC, charging current, and SOH over time,

for two different current profiles. The bottom graph

illustrates the SOH over time, with the red curve in-

dicating a faster decline in SOH due to aggressive

charging, and the blue curve showing less degradation

with conservative charging. The overall goal of health-

aware charging is to minimize the total charging time,

which is to reach the desired SOC as fast as possible,

while also minimizing SOH degradation, yielding a

trade-off between fast charging and preserving battery

health.

Now, to define the Health-aware optimal charging

problem formulation, we first gather all needed mod-

els. We couple the discretized ECM model (1) with the

discretized ETBM model (2) and couple it to the dis-

cretized SOH model (3). This results in the collective

states,

x

= [

x

ECM

,x

EBT M

,x

SOH

], with

n

x

= 6, and input

Figure 3: Illustration of the health-aware optimal charging.

u

as the current. With that model, the MPC formula-

tion for Health-aware charging can now be formulated

as follows.

Formulation 3.1. Given a battery model with the

ECM model (1) from section 2.1, the discretized

ETBM (2) from section 2.2 and the discretized SOH

model mapped from the capacity degradation model

from section 2.3, the optimal charging current protocol

sequence input sequence

u

=

{u

0;x

k

,u

1;x

k

,...,u

N

h

−1;x

k

}

is the one that from an initial SOC, brings the system

to the final desired SOC as quickly as possible while

preserving SOH:

minimize

x

k

,u

k

J (x

k

,u

k

)

subject to (1),(2),(3)

s

min

≤ s

k

≤ s

max

−I

max

≤ u

k

≤ I

max

V

min

≤ y

k

≤ V

max

T

min

≤ T

k

≤ T

max

x

0

= X

0

(4)

Remark 2. Note: In our MPC formulation, the ex-

pected value of the SOH distribution from the Bayesian

Network model is used in the optimization cost.

Formulation 3.2. The objective term

J

(

x

k

,u

k

) is a

sum consisting of the following three terms:

1.

Fast charging term:

J

1

=

Q

s

∑

N

h

k=0

||s

k

− s

final

||

2

.

This first objective term penalizes deviations of the

SOC from

s

f inal

, encouraging the SOC to get close

to this value.

2.

Degradation preserving term:

J

2

=

Q

soh

∑

N

h

k=0

||SOH

k

− SOH

0

||

2

. This term penalizes

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

40

changes in the SOH, promoting preservation in

the battery’s health.

3.

Input regularization:

J

3

=

Q

u

∑

N

h

k=0

∥u

k+1

− u

k

∥

2

2

.

This term penalizes the rate of change of the charg-

ing current, promoting smoother current profiles.

The combination of objectives

J

1

,

J

2

and

J

3

ensures

a smooth, health-aware charging current

u

is obtained,

which also ensures the battery is charged sufficiently

quickly.

4 VALIDATION RESULTS

4.1 NMC Battery Data Collection

The Oxford Mathematical modeling Battery

Group’s Python Battery Mathematical Model

(PyBaMM) (Sulzer et al., 2021), built on top of

CasADi (Andersson et al., 2019), was used to collect

efficient battery simulations data. The specific

Doyle-Fuller-Newmann (DFN) model for Lithium-ion

NMC batteries with electrochemistry as depicted

in (O’Kane et al., 2020) for 5Ah was used.

This model is configured with several options that

captures various degradation mechanisms and physical

phenomena occurring within the battery. For instance,

the “SEI” (Solid Electrolyte Interphase) formation is

set to be “solvent-diffusion limited”, and changes in

SEI porosity are enabled. The model also includes

options for lithium plating porosity change, particle

mechanics (both swelling and cracking), SEI forma-

tion on cracks, and stress-driven loss of active mate-

rial (O’Kane et al., 2022).

The models use a discretization of the different re-

gions of the battery. These regions include the negative

electrode (

x

n

), separator (

x

s

), positive electrode (

x

p

),

and the particles within the negative (

r

n

) and positive

(

r

p

) electrodes. The number of regions determines

the resolution of the numerical solution in each region,

with higher values providing more detailed simulations

at the cost of increased computational effort. The used

values of the discretization parameters are listed in

Table 1.

We performed a series of experiments with sev-

eral charging protocols and voltage limits. We also

included noise to introduce stochasticity in the experi-

ments. A subset of the resulting capacity degradation

curves is shown in figure 4.

4.2 Model Parameters

The parameters of the ECM model, i.e.,

θ

1

,

θ

2

, and

θ

3

are chosen as polynomial functions. For this spe-

Table 1: Overview of the used discretization parame-

ters for PyBaMM simulations for the cell stoichiometry

from (O’Kane et al., 2020).

Parameter Name Symbol Value

negative electrode x

n

5

positive electrode x

p

5

negative particle r

n

30

positive particle r

p

30

separator x

s

5

0 100 200 300 400 500 600 700 800

4.6

4.8

5

5.2

5.4

Time (days)

Capacity (Ah)

Capacity vs. Time

1C, [2.5, 4.2] V, Conc.: 500 1C, [2.5, 4.2] V, Conc: 1000

1C, [2.5, 4.2] V, Conc: 1250 1C, [2.5, 4.2] V, Conc: 1500

1C, [3.0, 4.0] V, Conc: 500 1C, [3.2, 3.9] V, Conc: 1000

2C, [2.5, 4.2] V, Conc: 1000 3C, [2.5, 4.2] V, Conc: 1000

Figure 4: Capacity degradation curves resulting from differ-

ent degradation mechanisms, with charging protocols varied

from 1C-rate, 2C-rate and 3C-rate, along with several values

of Depth of Discharge (DoD) and initial concentration in

electrolyte [mol.m-3].

cific model, a seventh-order polynomial function of

the SOC is selected. The values of their coefficients

were estimated from the data using the LPVCore tool-

box (den Boef et al., 2021).

Remark 3. On establishing the curves

V

OCV

(

s

k

,T

k

)

for the considered cell, it was observed thatthe sensi-

tivity to temperature was found to be negligible, and

so for the results shown in the next subsection, the

dependency of

T

k

was dropped from the

V

OCV

curve,

as well as from the polynomial functions

θ

1

,

θ

2

, and

θ

3

.

The ETBM parameters are extracted from (Ak-

barzadeh et al., 2020) where they are derived empir-

ically for Lithium-ion NMC battery of 5Ah capacity.

The parameters are listed in Table 2:

Table 2: Thermal parameters for ETBM model as extracted

from (Akbarzadeh et al., 2020).

Parameter Name Symbol Value Unit

Battery core heat capacity C

c

934.5 J/kg.K

Battery surface heat capacity C

s

1661.9 J/kg.K

Conductive heat resistance R

c

0.422 K/W

Convective cooling resistance R

u

0.559 K/W

Ambient temperature T

f

298.18 K

The parameters for the BN degradation models

that are used to model the SOHM in (3) for ∆

Q

, are

Health-Aware Charging of Li-Ion Batteries Using MPC and Bayesian Degradation Models

41

trained on simulated accelerated aging data with full

charge/discharge cycles. We accordingly modeled the

discrete loss of capacity ∆Q after each cycle.

•

For charging cycles, ∆

Q

follows a shifted exponen-

tial distribution, or ∆

Q − µ

C

∼ Exponential

(

λ

C

),

where

µ

C

= ∆Q

C,nom

+ α

C,V

(V −V

C,nom

) + α

C,I

(I −I

nom

).

(5)

•

For discharging cycles, ∆

Q

follows a Laplace dis-

tribution: ∆Q ∼ Laplace(µ

D

,b

D

), where

µ

D

= ∆Q

D,nom

+ α

D,V

(V −V

D,nom

) + α

D,I

(I − I

nom

).

(6)

The variable

V

represents the final voltage of the cycle

and is as such equivalent to the depth of charge/dis-

charge. The variable

I

represents the constant current

(either during constant load or in CC phase of CC-CV),

and is as such equivalent to C-rate. The values for the

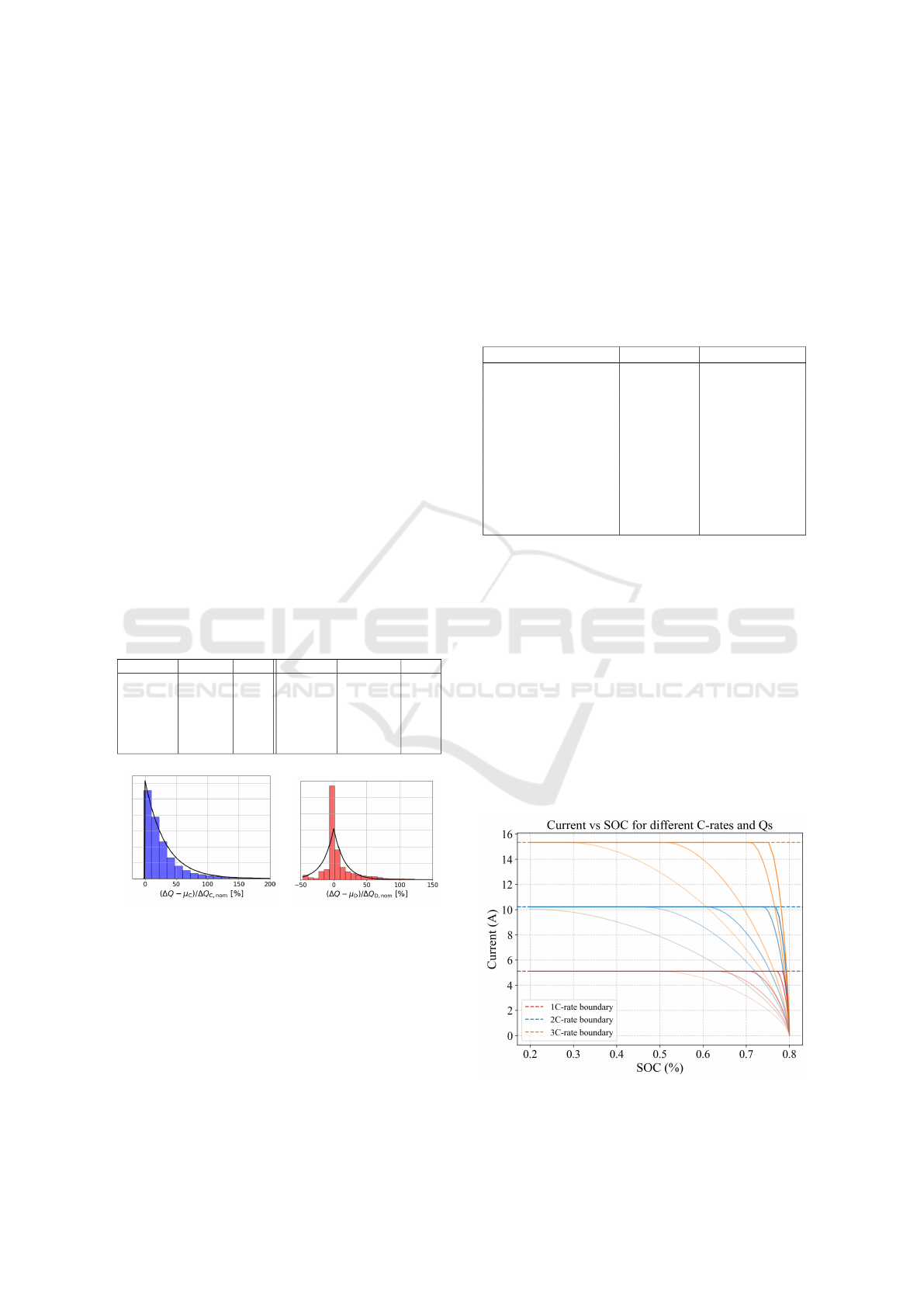

model parameters and nominal settings are shown in

Table 3, and the relative prediction error histograms

and corresponding modeled distributions in figure. 5.

Note the wide distributions of relative prediction er-

rors, which is due to the intrinsic stochasticity of the

degradation process. This emphasizes the importance

of correct uncertainty quantification.

Table 3: Model parameter values for degradation models.

parameter value unit parameter value unit

∆Q

C,nom

8.35e−6 Ah ∆Q

D,nom

1.21e−5 Ah

α

C,V

2.47e−5 Ah/V α

D,V

−2.83e−5 Ah/V

α

C,I

2.52e−6 Ah/A α

D,I

7.38e−6 Ah/A

V

C,nom

3.9 V V

D,nom

3.25 V

I

nom

4 A b

D

1.93e−6 Ah

1/λ

C

2.71e−6 Ah

Figure 5: The histograms for the relative prediction errors

of ∆

Q

and corresponding modeled distributions (black), for

charging (blue, left) and discharging (red, right).

4.3 Results

The MPC formulation 3.1 is implemented in

CasADi (Andersson et al., 2019) and Rockit frame-

work (Gillis et al., 2020) for testing in simulations in

Python. To solve the optimization, we used the interior

point based IPOPT solver (Wächter and Biegler, 2006)

interfaced with CasADi. The simulation was carried

out on a PC with an Intel(R) Core(TM) Ultra 7 155H

and 32GB memory.

The parameters selected for the controllers are de-

tailed in Table 4. As can be seen, we calculated our

charging profiles using various C-rates, as well as dif-

ferent weights for how much to promote fast charging.

This allows us to validate the robustness of our method

under different conditions.

Table 4: Overview of MPC formulation parameters for the

health-aware charging.

MPC parameters symbol value

Symbolic framework - CasADi

Solver - IPOPT

MPC Horizon N

h

250 samples

Time for trajectory T 3600s

C-rates I

max

[1,2, 3] C

SOC constraints [s

min

,s

max

]

T

[0.2,0.8]

T

SOC charging ref. s

f inal

0.8 → 80%

Initial Temperature T

init

297 K

Weight (SOH deg.) Q

soh

10

−3

Weight (∆u) Q

u

10

−2

Weight (fast charging) Q

s

[10

−4

,10

−3

,10

−2

,1,10]

The simulations are performed with optimal health-

aware charging at different C-rates, aiming to bring

SOC from 0.2 to 0.8 (i.e. from 20% to 80%.) This

approach follows recommendations suggesting that

at low operating SOCs, significant degradation may

occur due to rapid volume expansion (Bazlen et al.,

2022). Figure 6 shows the simulated results of Current

vs SOC achieved with the optimal control at differ-

ent C-rates and with different weights

Q

s

. The trans-

parency of the curves decreases as the weight

Q

s

is

increased. It can be seen that the control yields a set of

charging profiles, that all bring the SOC to the desired

value according to the allowed C-rate, but at different

rates depending on the choice of Q

s

.

Figure 6: Simulation results for charging currents vs. SOC

at 1C, 2C and 3C rates with varying Q

s

.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

42

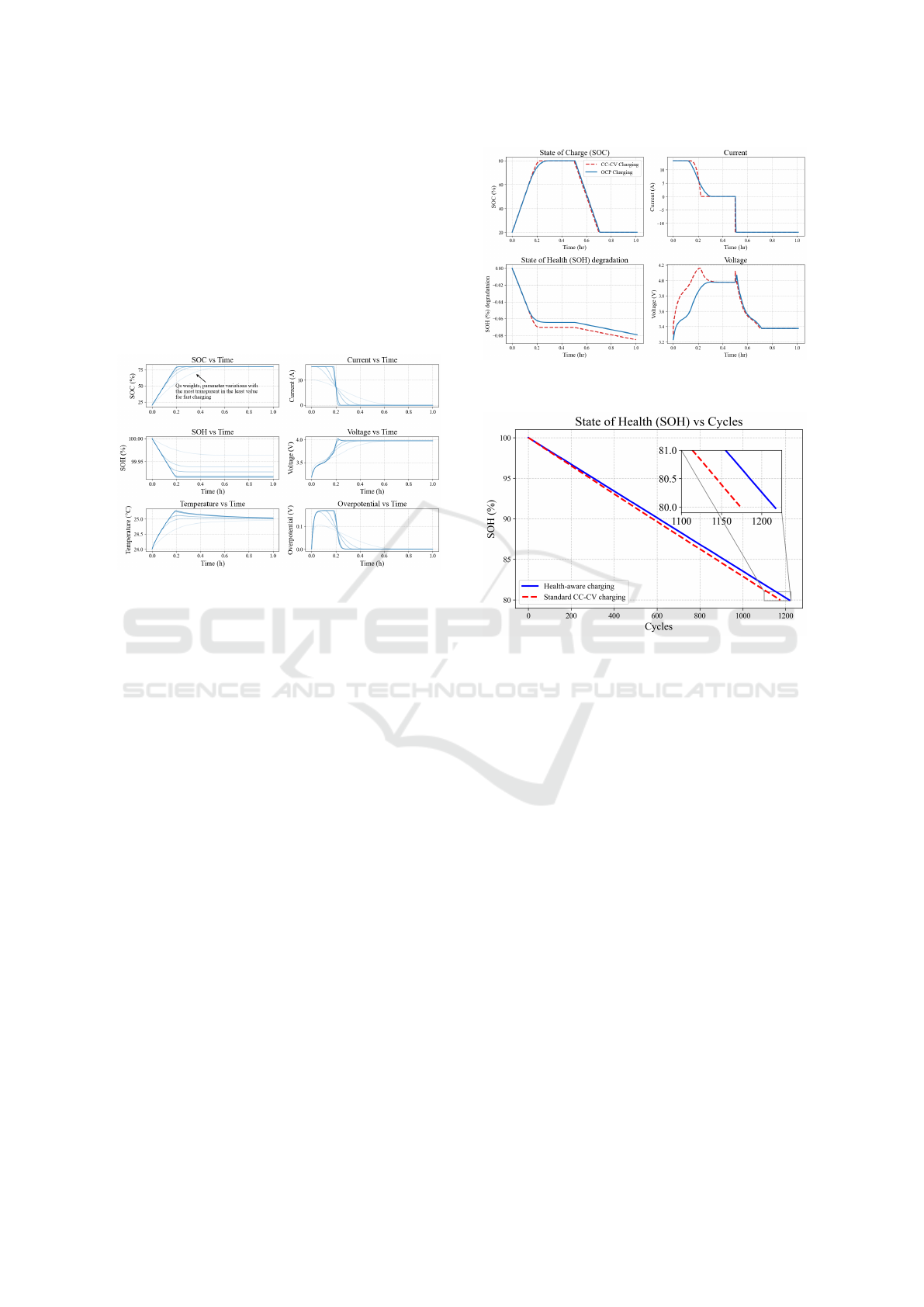

Figure 7 shows the corresponding trajectories of

the SOCs, SOHs and Voltage along with optimal charg-

ing current as a function of time, for the 3C rate. Again,

as

Q

s

increases, the curves become less opaque. It can

be observed that the fastest charging has the highest

SOH degradation. Note that in this graph we have

shown the 3C rate. This is the one we would use

for health-aware but still fast charging, since for fast

charging according to “IEC6581-1 EV charging mode

4” the entire battery has to be charged within 15-20

minutes (Van Den Bossche, 2010).

Figure 7: Simulation results of the optimal input and states:

SOC, SOH, Voltage, Temperature and Overpotential for 3C

fast charging with varying Q

s

.

In order to further validate our proposed approach,

we compare the health-aware charging protocol to the

conventional CC-CV charging strategy. Here we have

used both to charge the SOC from 20% to 80%, assum-

ing an initial SOH of 100%. After charging, we then

discharged using a 3C discharge profile, like in (Ab-

dollahi et al., 2016). The result of this comparative

analysis for a cycle is shown in Figure 8. The SOH

degradation for CC-CV charging is determined post-

process, once the charging profile has been established.

As illustrated in the figure, the CC-CV method results

in noticeably higher degradation. This increased degra-

dation can be attributed to an overshoot in terminal

voltage and the absence of an integrated SOH model

during the charging process, indicating suboptimal

charging.

Next, we simulate a prolonged sequence of charge

cycles, where in between the cycles we also estimate

the changes in SOH with the BN approach described

above. To make this a realistic sequence we use

data from the Urban Dynamometer Driving Schedule

(UDDS), developed by the Environmental Protection

Agency (EPA) that simulates city driving conditions.

The UDDS driving cycle is a standardized driving cy-

cle used for vehicle testing (Plett, 2004). From it, we

derive the scaled discharge current profiles from the

speed profile of UDDS, and then repeat it to generate

Figure 8: Charge and Discharge cycle comparison of Health-

aware optimal charging with standard CC and CV.

Figure 9: Comparison of Health-Aware and Standard CC-

CV Charging Methods with UDDS discharge cycles with

control model in loop.

a longer sequence of typical discharge cycles.

Remark 4. In the Health-aware optimization formu-

lation, the

SOH

0

is not fixed to the initial cycle value.

Instead, it is updated dynamically at the beginning of

each new charge cycle or just before the new MPC

horizon. This allows the charging current to adapt

to the current health state of the battery, keeping the

charging profile efficient.

On applying our health aware charging strategy

at 3C rate, the battery’s degradation is reduced, as is

illustrated in figure 9. It achieves this by dynamically

utilizing the current states and optimizing the charging

profile, while still minimizing the SOH degradation

during charging. In contrast, the standard CC-CV

charging method follows a fixed rule-based approach,

applying a constant current followed by a constant volt-

age, without taking the battery’s health into account.

This can lead to faster degradation. As compared to the

standard CC-CV charging, the health-aware optimal

charging lasts for approximately 2.5% more cycles.

Finally, we study how the proposed health-aware

controller would react in realistic conditions, in closed

Health-Aware Charging of Li-Ion Batteries Using MPC and Bayesian Degradation Models

43

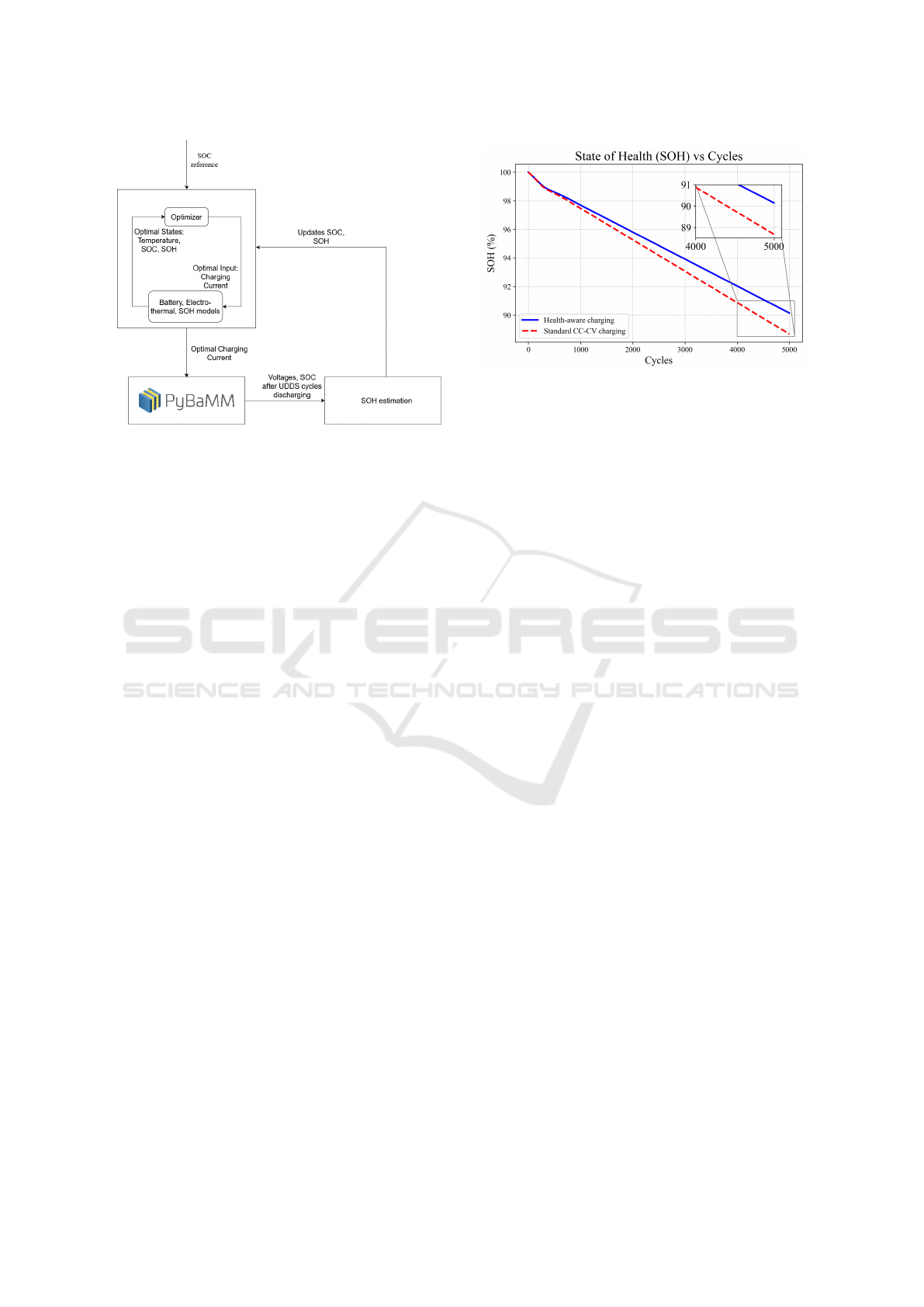

Figure 10: Configuration with PyBaMM emulation in the

loop.

loop, with imperfect models. To do so, we have set

up the configuration as shown in Figure 10, with the

controller actions being applied to the high-fidelity

PyBaMM model, and receiving updates from it, to

which the controller then reacts.

Remark 5. In the closed-loop simulations, the ex-

pected degradation prediction is transformed into the

change in SOH for the degradation penalizing term.

Initially, the health-aware optimal control gives an

optimal charging current profile, for a specified SOC

reference and the system’s present states, including the

temperature, SOC, overpotential, and SOH. It should

also be noted that the control is calculated using the

models from section 2, which are far simpler than the

full PyBaMM model. This profile is then applied to

the PyBaMM model. The simulation outcomes, which

provide updated SOC and SOH estimates, are fed back

into our health-aware optimal control optimizer.

Remark 6. It should be noted that the the discharge

cycle in these simulations has a lower DoD during

the UDDS discharging profile, and so eventually the

charging has a less depth of charge. This choice is

driven by the need for stable PyBaMM in closed loop

simulations.

Figure 11 shows the SOH degradation over a span

of 5000 cycles for both the charging strategies i.e.,

CC-CV charging and Health-aware charging. It can

be observed that Health-aware charging retains ap-

proximately 90% of its SOH, while CC-CV falls to

approximately 88.7%. It is also evident that Health-

aware charging had approximately 600 more cycles

than CC-CV method before reaching 90% SOH. This

disparity occurs because the CC-CV charging strategy

is purely voltage and C-rate without regard to the state

of health or degradation impacts. While, the health-

Figure 11: Comparison of Health-Aware and Standard CC-

CV Charging Methods with UDDS discharge cycles with

PyBaMM in closed-loop.

aware charging explicitly considers battery’s updated

SOH during optimization. Due to this, the charging

current prevents excessive degradation and prolongs

battery. Eventually, the figure highlights the impact of

considering SOH in Health-aware charging leading to

better performance than standard CC-CV.

5 CONCLUSION

This paper presents a health-aware MPC based battery

charging approach integrating electrical, thermal and

degradation dynamics via Bayesian Networks. We

validated our approach through high-fidelity simula-

tions and it demonstrated reduced SOH degradation

compared to standard CC-CV methods. The differ-

ence represents a significant enhancement in life-cycle

sustainability especially for long-term applications.

We expect SOH estimation and corresponding

charging profiles to become increasingly important,

due to (i) the increasing utilization of e.g., EVs, but (ii)

as battery passports gradually become standardized, to

keep track of battery health, since then there will be

extra incentives to ensure batteries are not degraded

by inefficient charging.

While the proposed approach demonstrates promis-

ing results in high-fidelity simulations, real-world ex-

perimental validation is essential to assess its robust-

ness, practical feasibility and generalization. Future

work will focus on implementing the methodology on

actual battery systems, with significant emphasis on

developing and validating robust estimators. Further-

more, the current deterministic control formulation

does not utilize the uncertainty propagation from the

BN degradation model. Future work will address these

gaps by integrating stochastic MPC strategies.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

44

ACKNOWLEDGMENT

This research was supported by Flanders Make, the

strategic research centre for the manufacturing industry

in Belgium, in the framework of the OptiBATT_IRVA

project.

REFERENCES

Abdollahi, A., Han, X., Avvari, G., Raghunathan, N., Bal-

asingam, B., Pattipati, K. R., and Bar-Shalom, Y.

(2016). Optimal battery charging, part i: Minimiz-

ing time-to-charge, energy loss, and temperature rise

for ocv-resistance battery model. Journal of Power

Sources, 303:388–398.

Agency, I. E. (2024). Global ev outlook 2024: Moving

towards increased affordability.

Akbarzadeh, M., Kalogiannis, T., Jaguemont, J., He, J., Jin,

L., Berecibar, M., and Van Mierlo, J. (2020). Ther-

mal modeling of a high-energy prismatic lithium-ion

battery cell and module based on a new thermal char-

acterization methodology. Journal of Energy Storage,

32:101707.

Andersson, J. A., Gillis, J., Horn, G., Rawlings, J. B., and

Diehl, M. (2019). Casadi: a software framework for

nonlinear optimization and optimal control. Mathemat-

ical Programming Computation, 11:1–36.

Bazlen, S., Heugel, P., von Kessel, O., Commerell, W., and

Tübke, J. (2022). Influence of charging protocols on the

charging capability and aging of lithium-ion cells with

silicon-containing anodes. Journal of Energy Storage,

49:104044.

Birkl, C. R., Roberts, M. R., McTurk, E., Bruce, P. G., and

Howey, D. A. (2017). Degradation diagnostics for

lithium ion cells. Journal of Power Sources, 341:373–

386.

Cai, Y., Che, Y., Li, H., Jiang, M., and Qin, P. (2021).

Electro-thermal model for lithium-ion battery simu-

lations. Journal of Power Electronics, 21(10):1530–

1541.

Christophersen, J. P. (2015). Battery test manual for electric

vehicles, revision 3. Technical report, Idaho National

Lab.(INL), Idaho Falls, ID (United States).

den Boef, P., Cox, P. B., and Tóth, R. (2021). Lpvcore:

Matlab toolbox for lpv modelling, identification and

control. IFAC-PapersOnLine, 54(7):385–390.

Erdinc, O., Vural, B., and Uzunoglu, M. (2009). A dynamic

lithium-ion battery model considering the effects of

temperature and capacity fading. In 2009 International

Conference on Clean Electrical Power, pages 383–386.

IEEE.

Gillis, J., Vandewal, B., Pipeleers, G., and Swevers, J. (2020).

Effortless modeling of optimal control problems with

rockit. In 39th Benelux Meeting on Systems and Con-

trol, volume 138. Elspeet, The Netherlands.

Hoekstra, F., Donkers, M., and Bergveld, H. (2023). Rapid

empirical battery electromotive-force and overpotential

modelling using input–output linear parameter-varying

methods. Journal of Energy Storage, 65:107185.

Hostens, E., Eryilmaz, K., Vangilbergen, M., and Ooijevaar,

T. (2024). Bayesian networks for remaining useful

life prediction. In PHM Society European Conference,

volume 8, pages 11–11.

Klein, R., Chaturvedi, N. A., Christensen, J., Ahmed, J.,

Findeisen, R., and Kojic, A. (2011). Optimal charging

strategies in lithium-ion battery. In Proceedings of the

2011 american Control Conference, pages 382–387.

IEEE.

Li, Y., Li, K., Xie, Y., Liu, J., Fu, C., and Liu, B. (2020).

Optimized charging of lithium-ion battery for elec-

tric vehicles: Adaptive multistage constant current–

constant voltage charging strategy. Renewable energy,

146:2688–2699.

Lu, Y., Han, X., Li, Y., Li, X., and Ouyang, M. (2024).

Health-aware fast charging for lithium-ion batteries:

Model predictive control, lithium plating detection,

and lifelong parameter updates. IEEE Transactions on

Industry Applications.

O’Kane, S. E., Ai, W., Madabattula, G., Alonso-Alvarez,

D., Timms, R., Sulzer, V., Edge, J. S., Wu, B., Offer,

G. J., and Marinescu, M. (2022). Lithium-ion battery

degradation: how to model it. Physical Chemistry

Chemical Physics, 24(13):7909–7922.

O’Kane, S. E., Campbell, I. D., Marzook, M. W., Offer,

G. J., and Marinescu, M. (2020). Physical origin of the

differential voltage minimum associated with lithium

plating in li-ion batteries. Journal of The Electrochem-

ical Society, 167(9):090540.

Plett, G. L. (2004). Extended kalman filtering for battery

management systems of lipb-based hev battery packs:

Part 3. state and parameter estimation. Journal of

Power sources, 134(2):277–292.

Qin, Y., Zuo, P., Chen, X., Yuan, W., Huang, R., Yang, X.,

Du, J., Lu, L., Han, X., and Ouyang, M. (2022). An

ultra-fast charging strategy for lithium-ion battery at

low temperature without lithium plating. Journal of

Energy Chemistry, 72:442–452.

Sulzer, V., Marquis, S. G., Timms, R., Robinson, M., and

Chapman, S. J. (2021). Python battery mathemati-

cal modelling (pybamm). Journal of Open Research

Software, 9(1).

Tomaszewska, A., Chu, Z., Feng, X., O’kane, S., Liu, X.,

Chen, J., Ji, C., Endler, E., Li, R., Liu, L., et al. (2019).

Lithium-ion battery fast charging: A review. ETrans-

portation, 1:100011.

Van Den Bossche, P. (2010). Iec 61851-1: Electric vehicle

conductive charging system-part 1: General require-

ments. In 2, pages 1–99. Iec.

Wächter, A. and Biegler, L. T. (2006). On the implemen-

tation of an interior-point filter line-search algorithm

for large-scale nonlinear programming. Mathematical

programming, 106:25–57.

Wassiliadis, N., Kriegler, J., Gamra, K. A., and Lienkamp,

M. (2023). Model-based health-aware fast charging

to mitigate the risk of lithium plating and prolong the

cycle life of lithium-ion batteries in electric vehicles.

Journal of Power Sources, 561:232586.

Health-Aware Charging of Li-Ion Batteries Using MPC and Bayesian Degradation Models

45

Xavier, M. A., de Souza, A. K., and Trimboli, M. S. (2020).

A split-future mpc algorithm for lithium-ion battery

cell-level fast-charge control. IFAC-PapersOnLine,

53(2):12459–12464.

Xavier, M. A. and Trimboli, M. S. (2015). Lithium-ion

battery cell-level control using constrained model pre-

dictive control and equivalent circuit models. Journal

of Power Sources, 285:374–384.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

46