A Depth Image Processing Algorithm for Monitoring Product Flow on a

Conical Feeder Unit of a Multihead Weigher

Julia Isabel Hartmann

a

and Christoph Ament

b

Chair of Control Engineering, University of Augsburg, Universit

¨

atsstraße 2, 86159 Augsburg, Germany

Keywords:

Depth Image Processing, Multihead Weigher, Feeder, Multi-Object Tracking.

Abstract:

Cameras are widely used as sensors in both industrial and research settings for tasks such as quality inspection,

measurement, process monitoring, and control. Depending on the application, customized image processing

algorithms are required to extract quantitative measurement data from captured images. This paper presents

a novel depth image-based data acquisition algorithm for tracking the motion of multiple products on the

rotating conical feeder unit of a multihead weigher, an industrial weighing system composed of multiple

load cells. The acquired depth image data can be used for the parameter identification and verification of a

model, which simulates particle motion on the feeder surface. Future work aims at implementing the image

processing algorithm on a programmable logic controller to enable real-time tracking and integration with the

control system of the multihead weigher in an industrial environment.

1 INTRODUCTION

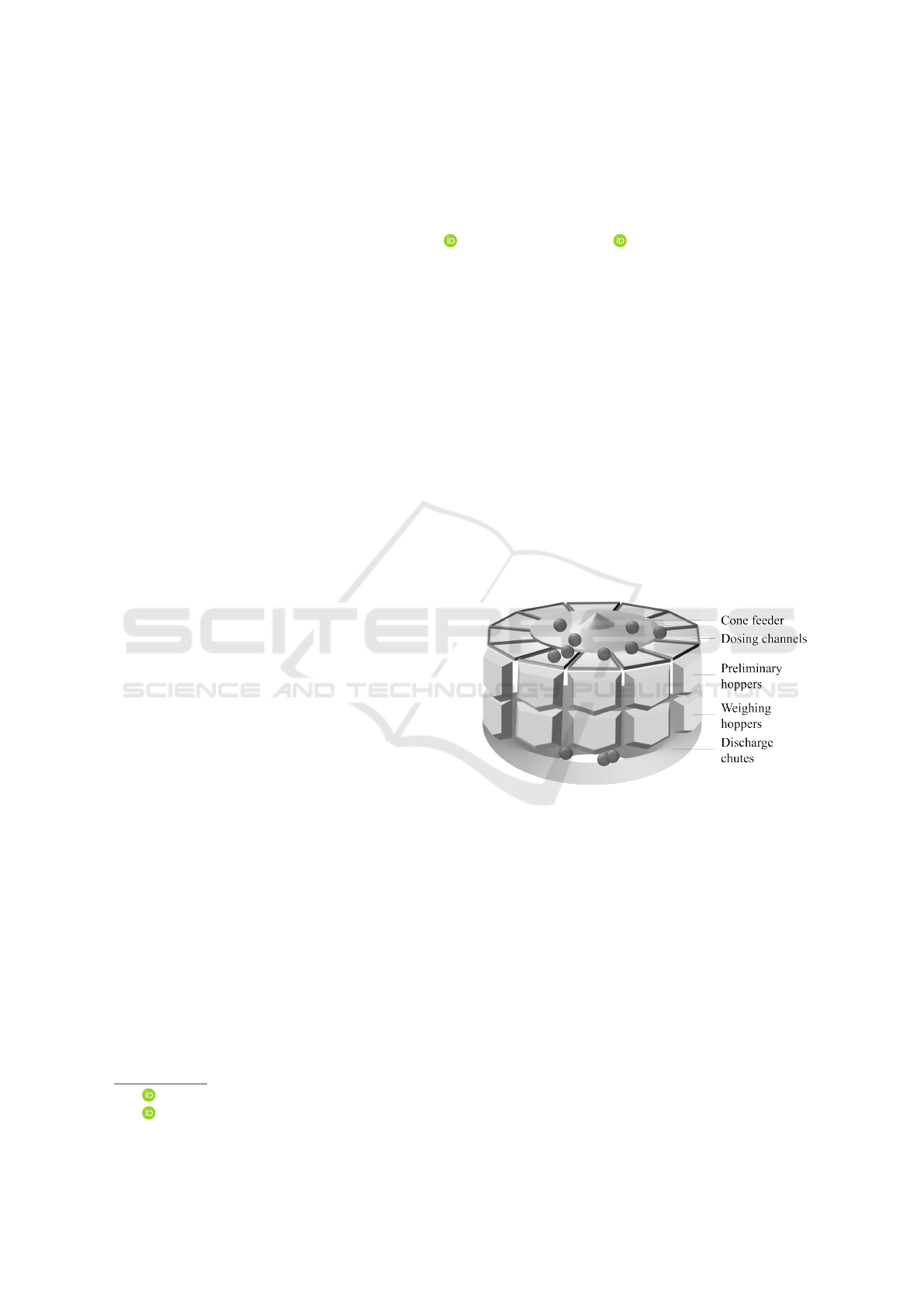

In the food industry, multihead weighers are often

used to weigh and proportion products to a specific

pack size. A multihead weigher represents an indus-

trial scale that enables the simultaneous weighing of

several partial amounts through multiple load cells.

Moreover, after weighing, the multihead weigher au-

tomatically combines a subset of the partial amounts

to a favorable weight. Within the multihead weigher,

the conical feeder unit is deployed at the beginning of

the product flow and distributes the falling products

radially outward into the dosing channels that lead

over preliminary hoppers to the weighing hoppers and

the load cells (see Figure 1). Thus, the feeder has

a profound impact on the product distribution among

the load cells. The weight distribution among the load

cells can, in turn, positively influence the combina-

tion process and the precise achievement of the target

weight. Furthermore, approaching the target weight

as closely as possible corresponds to a minimal prod-

uct giveaway and, thus, monetary savings.

Several aspects concerning the multihead weigher

have been addressed in the literature so far.

Machine topology. The determination of the op-

timal number of hoppers to be installed in a multi-

a

https://orcid.org/0009-0003-6848-833X

b

https://orcid.org/0000-0002-6396-4355

Figure 1: Layout of a multihead weigher.

head weigher has been formulated as a stochastic bi-

objective design optimization problem. This prob-

lem has been addressed using Monte Carlo simulation

techniques (van Niekerk et al., 2021).

Hopper setpoints. In each weighing cycle, a pre-

defined quantity of product is allocated to each weigh-

ing hopper, governed by its setpoint. To identify the

optimal hopper setpoints, various optimization strate-

gies have been applied, including Response Surface

Methodology (Beretta and Semeraro, 2012), heuristic

approaches (Del Castillo et al., 2017), gradient-based

algorithms, brute-force search, and random sampling

methods (Beretta et al., 2016). Furthermore, research

has been conducted on the use of both uniform and

variable setpoints across hopper subgroups (Garcia-

Diaz and Pulido-Rojano, 2020).

Hartmann, J. I. and Ament, C.

A Depth Image Processing Algorithm for Monitoring Product Flow on a Conical Feeder Unit of a Multihead Weigher.

DOI: 10.5220/0013678600003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 43-52

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

43

Subset combination. The selection of the opti-

mal combination of hopper fillings to achieve a to-

tal weight that closely matches a specified target is

a central problem of the multihead weigher. Various

algorithmic approaches have been proposed, includ-

ing bit-wise operation-based combination algorithms

(Keraita and Kim, 2007) and dynamic programming

techniques (Imahori et al., 2010; Imahori et al., 2012;

Imahori et al., 2014). Bi-objective optimization meth-

ods have also been employed to minimize weight

variability while simultaneously accounting for the

residence time of products in the hoppers (Pulido-

Rojano et al., 2015; Pulido Rojano and Garcia Diaz,

2019; D

´

ıaz et al., 2017). In systems with a double

hopper layer, the packaging process has been for-

mulated as both a single-objective (An et al., 2024;

Garc

´

ıa-Jim

´

enez et al., 2021) and a bi-criteria opti-

mization problem, with solutions developed using dy-

namic programming (Karuno et al., 2010) and brute-

force search (Garc

´

ıa-Jim

´

enez et al., 2023). The prob-

lem of optimal simultaneous packaging of two prod-

ucts has been addressed using dynamic programming

(Imahori et al., 2010; Imahori et al., 2012), while

mixture packaging of two different products has been

explored using both dynamic programming (Imahori

et al., 2014) and a greedy heuristic (Karuno and Naka-

hama, 2020).

Variability reduction. Variability in the weigh-

ing process has been quantitatively assessed using

the Percentage Variability Reduction Index (Salicr

´

u

et al., 1996; Barreiro et al., 1998). In particular, the

impact of specific packaging strategies on variability

has been evaluated through a Six Sigma methodology

(Pulido-Rojano and Garcia Diaz, 2014). Additionally,

modified control charts have been employed to mon-

itor package weights under novel packaging strate-

gies aimed at reducing variability (Garc

´

ıa-D

´

ıaz and

Pulido-Rojano, 2017).

Feeder unit modeling. A dynamic friction model

with contacts has been proposed to model the motion

of a particle on a conical feeder for the viscoelastic

case (Hartmann et al., 2023). The model encompasses

a specific kinematic model for the conical feeder to

constantly calculate the constraint position, velocity,

and, thus, forces. Specifically, the overall model is

a nonlinear parameter-varying (NLPV) model and its

varying parameters have been identified by a multi-

stage optimization approach, considering the varying

parameters as functions of the initial position and con-

trol input of the system (Hartmann and Ament, 2025).

For the multi-stage parameter identification ap-

proach, measurement data is required. Given the na-

ture of the problem, a camera-based sensing solu-

tion is considered suitable for capturing the product

flow on the feeder unit. A depth-sensing camera is

preferred over a conventional area scan camera, as

it enables future extensions of the system for esti-

mating product weight on the feeder. In this paper,

an automatic image processing pipeline is proposed

to obtain the large dataset required for the identifi-

cation approach by extracting motion data from the

captured images. Furthermore, the image processing

algorithm is planned to support process monitoring

and control of the feeder unit during operation in the

future. The image processing algorithm has been suc-

cessfully adapted by the authors to operate on color

images as well.

This paper is organized as follows. Section 2 de-

scribes the hardware setup and the design of experi-

ments. Section 3 details the data acquisition process

based on the depth-image processing algorithm. Sec-

tion 4 presents the extension of the proposed image

processing approach to color images. Finally, Section

5 concludes the paper and provides an outlook on fu-

ture work.

2 HARDWARE AND DESIGN OF

EXPERIMENTS

2.1 Hardware Setup

At the University of Augsburg, a demonstrator of the

feeder unit with a diameter of 45 cm is available for

experimental testing. The demonstrator is an exact

replica of the feeder component used in an industrial

multihead weigher system. In industrial applications,

both rotating and vibrating feeder variants are em-

ployed, depending on the type of product being han-

dled. This research project focuses specifically on

challenging, sticky products, which are typically con-

veyed using a rotating cone feeder.

The demonstrator consists of a stepper motor with

a gearbox that drives a metal cone feeder, capable of

reaching a maximum rotational velocity of 290

◦

s

−1

.

For sensing, an Intel RealSense D435 stereo camera

is employed. In addition to capturing depth images,

the camera provides color images via its integrated

RGB module. The depth output supports resolutions

Figure 2: Hardware setup with initial placement of the spec-

imen.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

44

up to 1280 × 720 px and frame rates of up to 90 fps,

with a depth accuracy of less than 2% at a distance of

2 m. In addition, the Intel RealSense software devel-

opment kit (SDK) is compatible with both MATLAB

and Python, facilitating integration into the data ac-

quisition and processing pipeline.

The D435 camera is selected for its wide depth

field of view (87

◦

× 58

◦

) and effective range of 0.3 m

to 3 m, which allows full coverage of the scene sur-

rounding the feeder without exceeding the spatial

constraints of the laboratory setup. The device is

mounted directly above the feeder, aligned vertically

downward, at a distance of 34.5cm from the apex of

the cone. The height of the cone is 6 cm.

To enhance image quality and avoid reflections,

the metal cone is covered with a matte black metal

foil. A foil seam running radially outwards from the

center to the cone edge is unavoidable, but is used

to align the cone with the start marker and to place

the specimen in the same position and orientation for

each measurement (see Figure 2).

2.2 Experimental Design

A small wooden plate (diameter: 3cm, height:

1.5cm, weight: 5.277g), which is covered by felt on

either side, is employed as a specimen. To control the

orientation of the specimen, an arrow marks the bot-

tom and angular orientation (see Figure 2).

Each experiment is conducted as follows. First, the

feeder foil seam is aligned with the start marker.

Then, the specimen is placed onto the foil seam with

the arrow pointing downwards. Finally, the depth

camera and data recording is started at a resolution

of 848 × 480 px and a frame rate of 90 fps and the

feeder is driven with a step reference velocity accord-

ing to the test plan. The reduced resolution is selected

because the maximum frame rate of 90 fps cannot be

achieved at the highest resolution. Nevertheless, the

chosen resolution provides sufficient spatial detail for

the task at hand.

As in the parameter identification reference (Hart-

mann and Ament, 2025), regarding the test plan,

a full factorial design is followed, which considers

the two explanatory variables motor angular veloc-

ity ω and initial distance ∆ between the center of

the feeder and the centroid of the specimen. The

centroid of the specimen is projected onto the cone

surface for measuring the initial distance ∆. The

target variable is the position of the centroid of

the specimen. Five different initial distances ∆

i

of

4.5cm, 7.5 cm, 10.5 cm, 13.5cm and 16.5 cm are

used. Furthermore, the angular velocity of the motor

is varied from 100

◦

s

−1

to 290

◦

s

−1

in steps of 10

◦

s

−1

in either rotational direction. Note, that 100

◦

s

−1

is

selected as the lowest speed because at 100

◦

s

−1

the

specimen remains at its initial radial position regard-

less of the initial distance. Finally, each test point is

repeated n = 3 times. In total, 600 measurements are

conducted.

In each experiment, the depth frames of the feeder

are captured, processed by means of the hole filling

filter of the Intel RealSense SDK, and the angular ve-

locity of the motor and the assigned timestamps are

recorded for a predefined recording time. Afterwards,

the recorded data are processed offline by the custom-

made depth image processing algorithm. Hereby, the

algorithm can automatically detect multiple objects

in a depth frame and assign them to motion tracks

through an assignment algorithm. Multiple object

and track assignment and handling using an Extended

Kalman filter (EKF) is implemented as described in

(MathWorks, 2025c; MathWorks, 2025d).

3 DATA ACQUISITION AND

IMAGE PROCESSING

ALGORITHM

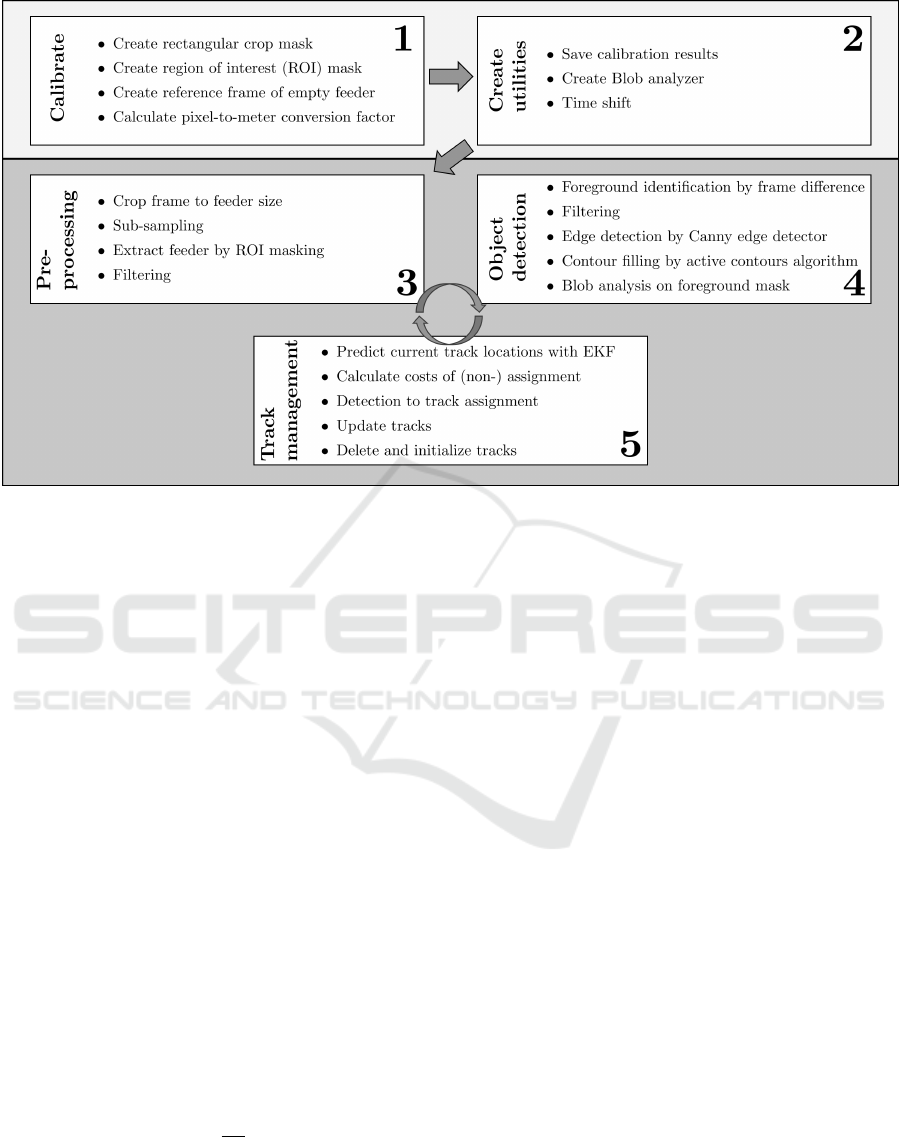

An overview of the depth image processing algorithm

is presented in Figure 3. The algorithm comprises

five main components. First, a calibration procedure

is performed. Subsequently, the necessary process-

ing tools and data structures are initialized. In the

next step, the depth frame is preprocessed to enhance

object visibility and enable reliable detection. After

object detection, the detections are assigned to exist-

ing tracks or used to initialize new ones. Finally, all

tracks, both active and inactive, are updated according

to the current results.

3.1 Calibration

For calibration purposes, a single depth frame show-

ing the empty feeder needs to be captured before or

after a measurement series. Based on this frame, a

semi-automatic calibration is performed once before

all measurements can be processed. At first, the left,

right, bottom, and top boundaries of the feeder are

defined manually as a rectangle to crop the frame to

the size of the feeder. Afterwards, the circular Hough

transform is applied to the cropped, sharpened, and

grayscale transformed frame to automatically identify

the circular boundary of the feeder, its center, and ra-

dius. If multiple circles are detected, the circle whose

center is closest to the center of the cropped image

is selected. If the selected circle is located too far

A Depth Image Processing Algorithm for Monitoring Product Flow on a Conical Feeder Unit of a Multihead Weigher

45

Figure 3: Image processing algorithm.

from the image center or its diameter is significantly

smaller than the width of the cropped image, the cal-

ibration is considered invalid, and manual calibration

is recommended. When a valid circle is identified,

a circular region of interest (ROI) mask is generated

based on the detected parameters. This mask is sub-

sequently used to isolate the feeder in later stages of

the image processing algorithm.

Moreover, for object detection, a reference frame

with the depth representation of the empty feeder

is necessary. For this purpose, the frame showing

the empty feeder is cropped to feeder size, median-

filtered to sub-sample and to reduce computational

burden, and small image defects, that have not been

removed by the initial hole filling of the Intel Re-

alSense SDK hole filling filter, are filled by sub-

sequent morphological image processing operations

(dilation with diamond-shaped structuring elements).

Next, an edge-preserving filtering using a bilateral fil-

ter with Gaussian kernels is performed to smooth the

image.

Finally, based on the reference frame, the pixel-to-

meter conversion factor c

f

is calculated with the cone

radius r

m

in meters and the radius r

px

of the identified

feeder boundary in pixels:

c

f

=

r

m

r

px

. (1)

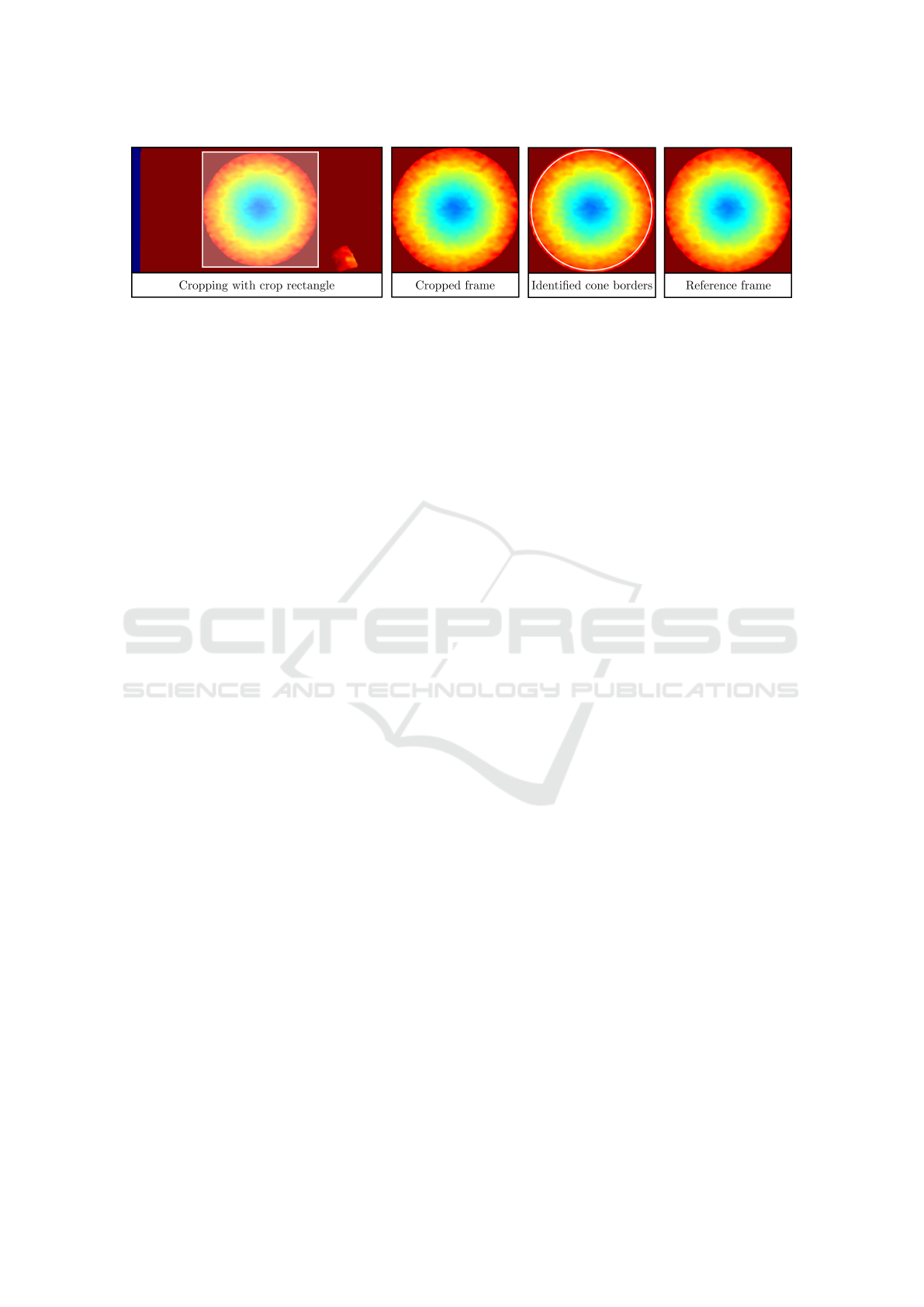

Figure 4 illustrates the calibration process. Ini-

tially, the original frame, which contains defects and

irrelevant information outside the conical region, is

cropped using the white crop rectangle, as shown in

the first image. The resulting cropped image is de-

picted in the second panel. Subsequently, the circular

boundary of the cone is defined either manually or

automatically using a circular Hough transform. The

region inside the white circle in the third image marks

the region of interest for each frame. Finally, the ref-

erence frame obtained after cropping and filtering is

presented in the rightmost image.

3.2 Create Utilities

The calibration results are stored as utilities and in-

clude the crop rectangle, the center and radius of the

feeder in pixels, the ROI mask, the reference frame,

and the conversion factor.

Furthermore, a Blob analyzer object with a mini-

mum Blob area of 300 px is needed to identify image

regions with similar properties and, thus, to detect ob-

jects. It should be noted that the minimum Blob area

is dependent on the physical size of the sample and

can be estimated in advance based on the image reso-

lution and the area occupied by the sample within the

image. In addition, defining a maximum Blob area

can be beneficial, as it reduces the number of detected

Blobs during object detection, thereby decreasing the

computational load by limiting the number of candi-

dates that require further analysis.

Furthermore, the recorded timestamps are shifted

to a start time of 0s, to represent the time passed since

the start of the recording.

Moreover, empty data structs are initialized for the

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

46

Figure 4: Calibration procedure.

tracks and deleted tracks. Each struct comprises sev-

eral fields storing information for object tracking:

• id: ID of the track,

• bbox: Current bounding box of the last detection,

• kalmanFilter: Kalman filter object for motion-

based object tracking,

• age: Number of frames since the track has been

initialized,

• totalVisibleCount: Number of frames in which

detections have been assigned to the track,

• consecutiveInvisibleCount: Number of consecu-

tive frames in which no detections have been as-

signed to the track,

• predictedCentroid: Predicted centroids of the de-

tections of this track,

• assignedCentroids: Centroids of the detections

assigned to the track,

• timeAssignedCentroids: Time stamps of the de-

tections assigned to the track,

• velocityAssignedCentroids: Rotational velocity of

the feeder, when the detection was assigned to the

track.

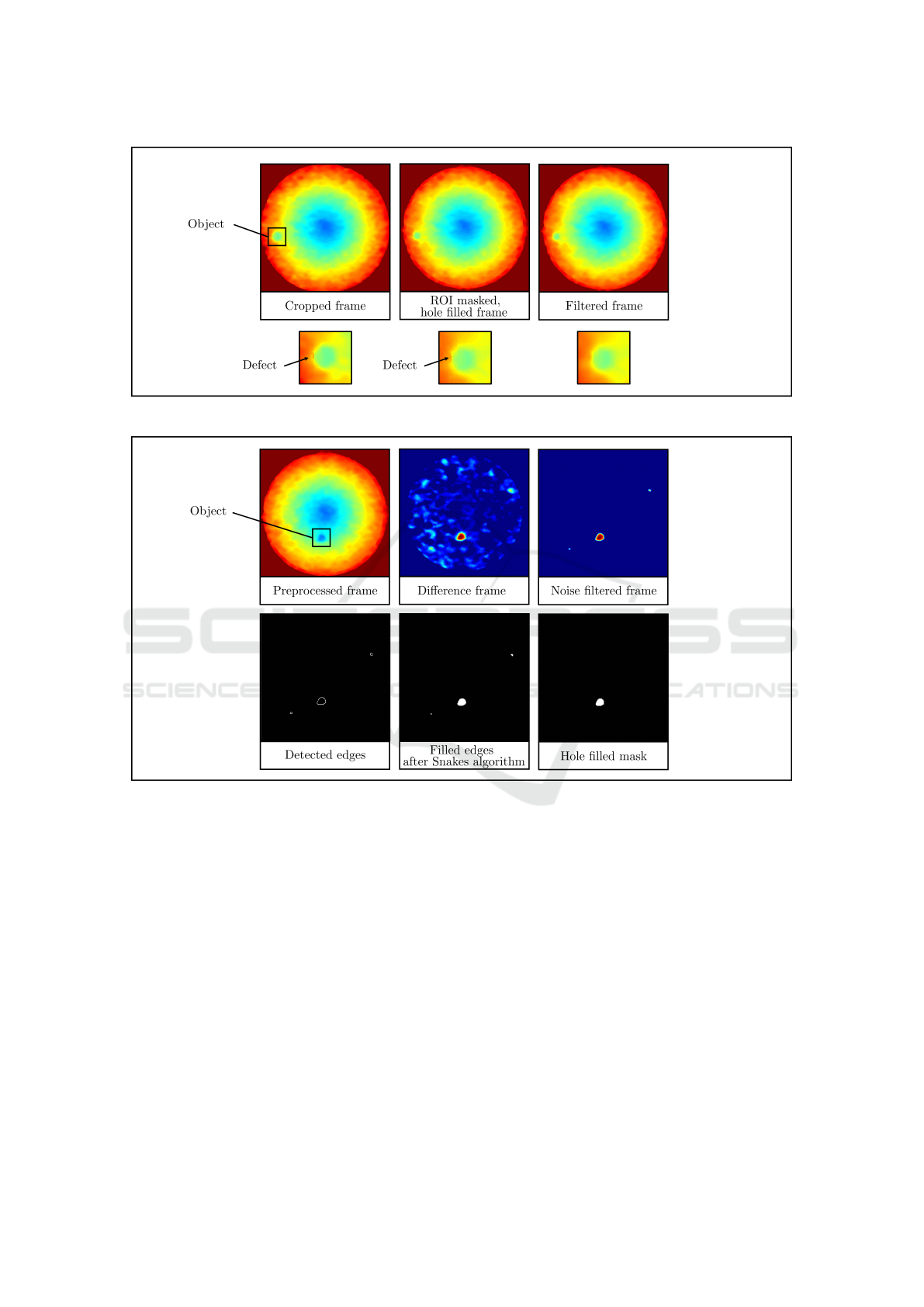

3.3 Preprocessing

From the preprocessing step onward, data are han-

dled frame by frame in a loop. At first, the frame

is cropped to feeder size and sub-sampled by a non-

zero median filtering. Then, the feeder image part is

extracted using the ROI mask. After the Intel Re-

alsense SDK hole filling filter remaining defects in

the depth image are filled by morphological dilation

and, if necessary, by inserting corresponding depth

values of the reference frame of the empty cone. Fi-

nally, edge-preserving filtering with Gaussian kernels

is performed to smooth the frame. Figure 5 illustrates

the preprocessing steps applied to a depth frame. Ow-

ing to the advanced filtering capabilities of the In-

tel RealSense SDK, the initial frame is of generally

high quality. A sample object, positioned near the left

boundary of the conical region, is highlighted with a

black bounding box. A minor image defect is visible

at the left edge of the object. Following region of in-

terest masking and morphological operations, the de-

fect is noticeably reduced. Subsequent application of

edge-preserving filtering further smooths and homog-

enizes the frame, effectively eliminating the defect.

3.4 Object Detection

The challenge in object detection lies in segmenting a

frame into the foreground (objects on the feeder) and

the background (the feeder itself). For this purpose, a

difference frame is calculated by subtracting the refer-

ence frame and the currently preprocessed frame. As

a result, the difference frame shows the deviation be-

tween the two frames, i.e. the foreground and, thus,

the objects on the feeder.

Then, the difference frame is refined by exclud-

ing negative depth values, noise (very small depth val-

ues), and all frame parts beyond the feeder boundary

by setting their depth values to 0. Next, a non-zero

median filter and an edge-preserving filter are applied

to reduce computational burden and enhance image

quality. In a subsequent step, the filtered frame is used

to detect edges through the Canny edge detector. Af-

terwards, the active contours (Snakes) region growing

technique is used to close the contour and fill it in.

Afterwards, small objects and holes are filled in by

a morphological opening with a disk-shaped structur-

ing element and a subsequent area opening operation,

which removes connected areas with less than a spec-

ified pixel size (150 px). The resulting binary mask is

the foreground mask of this frame.

Finally, Blob analysis is applied to the foreground

mask to find and analyze image areas with similar

properties (Blobs), which are the objects here. Then,

the identified Blobs are sorted out, in case they are

outside the cone boundaries, i.e. the distance between

the centroid of the blob and the cone center is larger

than the cone radius. Only for the remaining Blobs

a coordinate transformation is conducted to shift the

feeder center to the origin of the frame coordinate sys-

tem and to convert the positional values from pixel- to

A Depth Image Processing Algorithm for Monitoring Product Flow on a Conical Feeder Unit of a Multihead Weigher

47

Figure 5: Preprocessing procedure.

Figure 6: Object detection procedure.

meter-scale. For the subsequent steps, the centroids,

bounding boxes, and areas of the Blobs are saved and

called detections in the following sections.

Figure 6 shows the object detection procedure step

by step.

3.5 Track Management

The motion-based multiple object tracking and

Kalman filter-based object tracking are described

in (MathWorks, 2025c; MathWorks, 2025d) and

adopted in this paper. Thereby, the detection to track

assignment is enhanced by validity checks that ensure

physically reasonable behavior of the objects. The re-

sulting track management process is described in de-

tail next.

Detections need to be assigned to existing or

newly created tracks, and tracks need to be updated

or opened accordingly. For this, the current position

of all tracks is predicted using an Extended Kalman

filter (MathWorks, 2025c). Then, the costs of assign-

ing each detection to each track must be calculated.

The costs are calculated based on the distance d(z)

between the centroid z of the detection and the pre-

dicted location x of the track, taking into account the

state covariance P, the measurement noise R, and the

measurement model H (MathWorks, 2025b)

d(z) = (z − Hx)

⊤

Σ

−1

(z − Hx) + ln(det(Σ)) (2)

Σ = HPH

⊤

+ R. (3)

Hereby, validity checks are necessary to ensure that

a track cannot move inwards towards the feeder cen-

ter or move faster than the motor speed. To prevent

inward movement, the radial positions of the last as-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

48

signed detection of a track and the current detection

are compared. If the radial position of the detection

is smaller than the radial position of the track end mi-

nus a small offset of 5cm to compensate for measure-

ment noise, costs are set to a high penalty value of

100. Additionally, detections that would exceed the

maximum possible linear velocity v

max

resulting from

the surface velocity of the feeder in either the x- or

y-direction, when assigned to a track, incur penalty

costs of 100 as well. The maximum possible linear

velocity v

max

is calculated with the feeder rotational

velocity ω and the by the third dimension extended

current position r = [z

1

, z

2

, 0] of the detection

v

max

= ω × r. (4)

Finally, based on the assignment costs and the

fixed costs of 95 for non-assignment of a detec-

tion, the assignment problem is solved by a variant

of the Hungarian assignment algorithm (MathWorks,

2025a) and the assignments and unassigned detec-

tions are obtained. After this, the assigned tracks are

updated with the centroids of the assigned detections,

the current angular velocity of the feeder, and the

timestamp. In addition, the correction step of the Ex-

tended Kalman Filter is performed using the new de-

tection, while the age counter and total visible count

of the tracks are updated by 1 to monitor track lifes-

pan and visibility. The unassigned tracks need to be

updated as well by increasing their age and consecu-

tive invisible count by 1. A track is terminated and re-

moved if it has not been assigned a detection for more

than 20 frames, or if its visibility, defined as the ratio

of the number of frames in which it was visible to its

total age, falls below a predefined threshold of 60 %.

Once deleted, no further detections can be assigned to

the track. (MathWorks, 2025c)

Lastly, for each unassigned detection, a new track

is created and an Extended Kalman filter object is

initialized. For this purpose, a MATLAB Tracking

Extended Kalman filter is used with a constant

angular velocity model. The filter states are the

position r

x

in the x-direction and the y-direction r

y

in

meters, the velocity v

x

in x-direction and y-direction

v

y

in meters per second, and the angular velocity ω

in degree per second: x =

r

x

, v

x

, r

y

, v

y

, ω

.

A measurement corresponds to the position r of

the particle in all three spatial dimensions. The

z-position r

z

is needed for evaluating a cross product

in the subsequent steps. The state covariance is cho-

sen to P = diag

0.01, 1, 0.01, 1, 0.01

,

the process noise to Q =

diag

100, 0.01, 100, 0.01, 0.002

, and the

measurement noise to R = diag

100, 100, 100

.

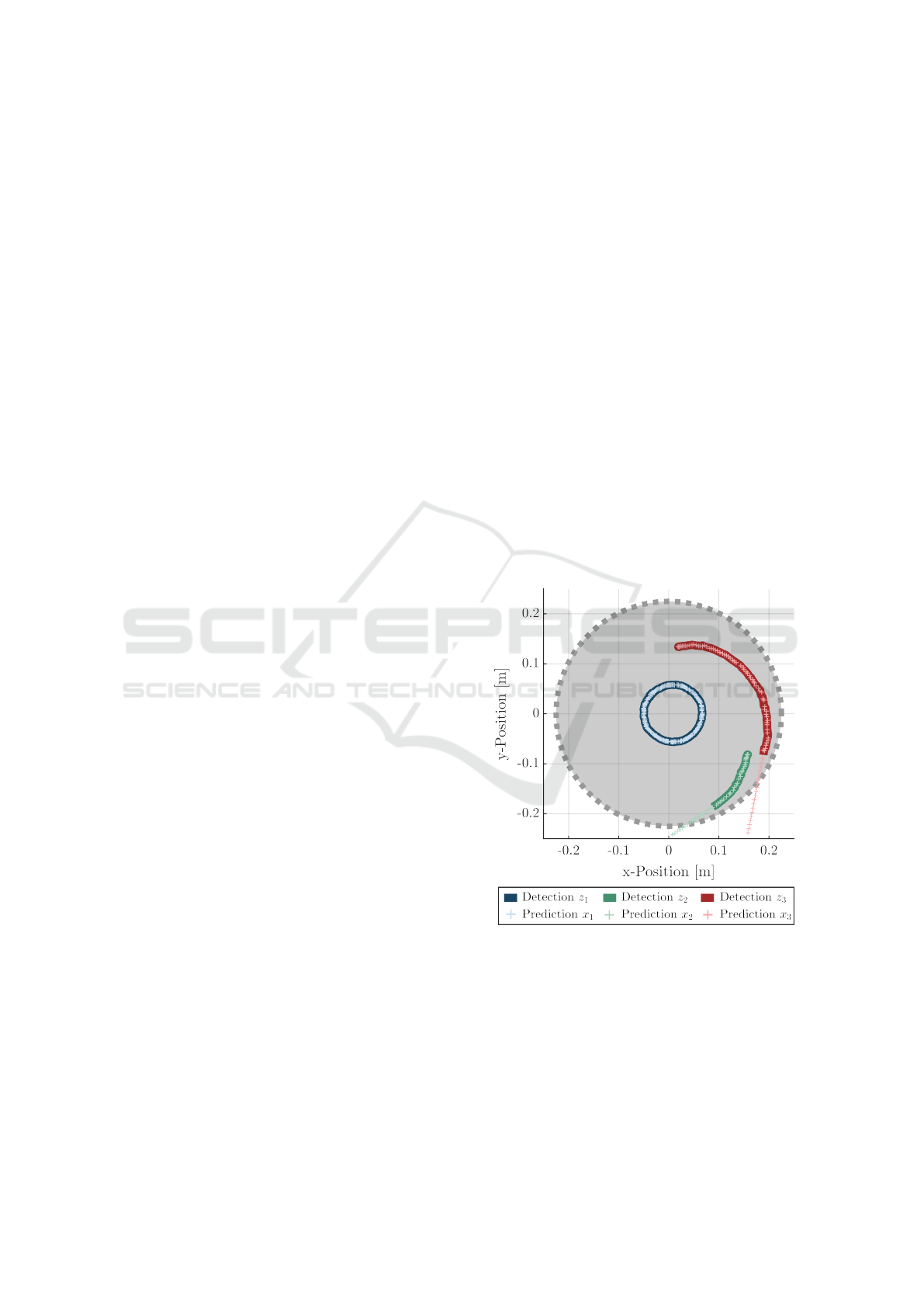

3.6 Multi-Object Tracking

Besides tests on a single specimen, the image pro-

cessing algorithm is evaluated using three samples of

similar type. The results of one experiment are pre-

sented in Figure 7. Each color represents a track, with

three tracks identified in total. Solid lines denote the

detections assigned to a track, while lighter-colored

plus signs indicate the corresponding Kalman filter

predictions. Each sample starts from a different ini-

tial position and exhibits either predominantly stick-

ing (blue) or sliding (green, red) behavior. The results

confirm that the algorithm successfully identified and

maintained three distinct tracks, each corresponding

to a specimen. The predictions closely follow the ob-

served motion and persist beyond the last detection,

until the track is formally terminated. This contin-

ued prediction appears consistent with the expected

object dynamics. However, for samples with varying

size or shape, the parameters of the Blob analysis and

filtering must be adapted to reliably distinguish valid

objects from noise. Additionally, scenarios involving

overlapping objects remain untested and present a di-

rection for future work.

Figure 7: Multi-object detection.

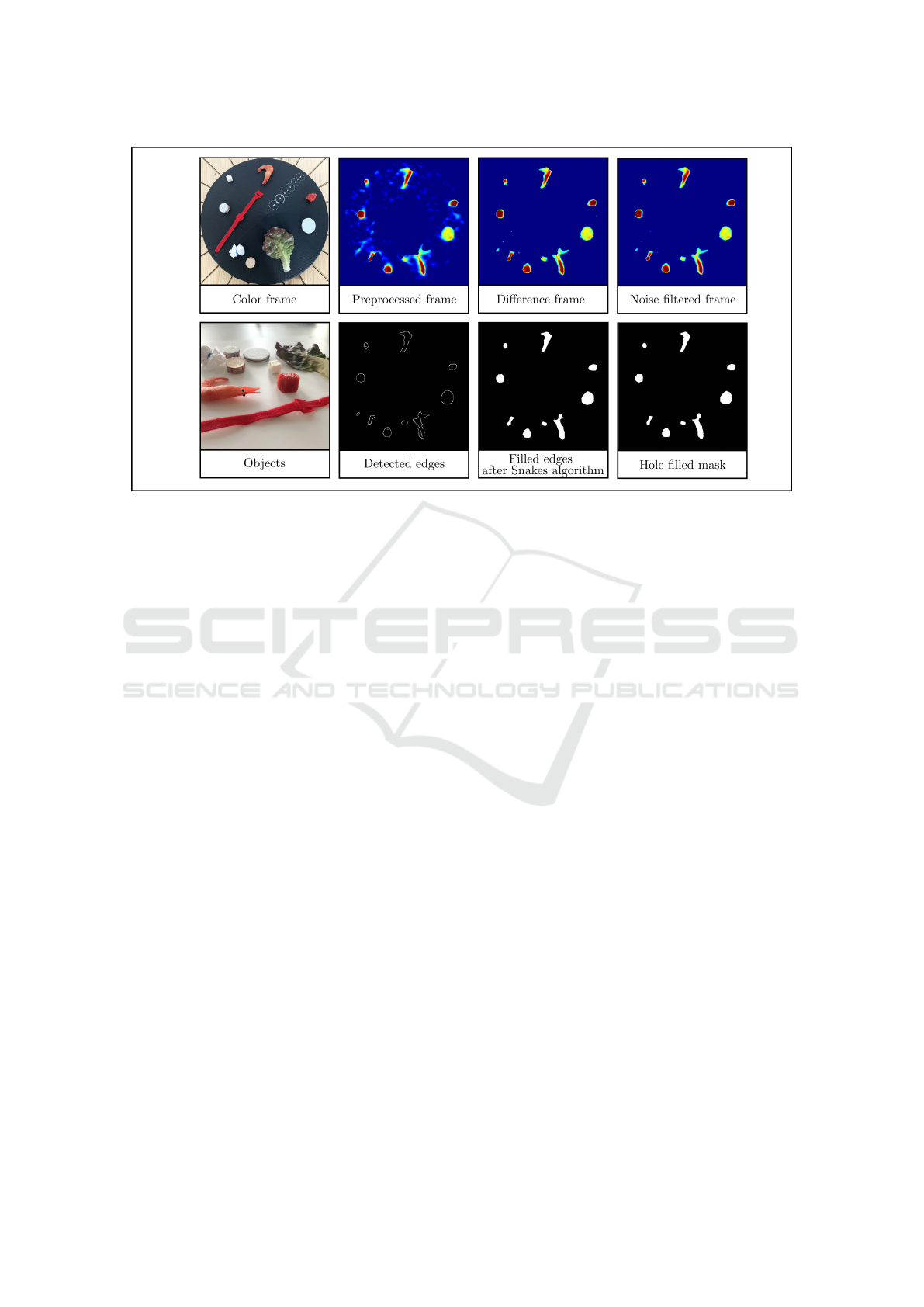

3.7 Detection of Different Objects

Although a round specimen is selected as the pri-

mary object for this study, the tracking algorithm is

not limited to spherical or circular shapes. To eval-

uate its generalizability, several static snapshots are

acquired using objects of varying shapes, surface ma-

terials, and heights. The test specimens include food

A Depth Image Processing Algorithm for Monitoring Product Flow on a Conical Feeder Unit of a Multihead Weigher

49

Figure 8: Object detection procedure for different objects.

dummies resembling a salad leaf, a shrimp, a piece

of meat, and a piece of feta cheese. Additionally,

wooden plates of different diameter, height, and sur-

face material, a small rice-filled bag, and a thin strip

of Velcro fastener tape are tested. As shown in Figure

8, all objects except for the thin Velcro fastener tape

are successfully detected. However, limitations arise

when the object thickness is too small, as observed

for the Velcro tape and the salad leaf. In particular,

the salad leaf is no longer detected as a single coher-

ent object.

4 EXTENSION TO COLOR

IMAGES

An adapted version of the proposed image processing

algorithm was also evaluated using color images. This

section outlines the necessary modifications required

to enable its application in the color image domain.

Calibration. In contrast to the depth image setup,

calibration for color images is more straightforward,

as no reference frame needs to be acquired. The re-

gion of interest mask is generated by identifying the

boundary of the cone feeder using circular Hough

transform applied to the binarized grayscale version

of the color image. The crop mask and the pixel-to-

meter conversion are determined analogously to the

depth image procedure.

Create utilities. The process of creating the utili-

ties remains unchanged.

Preprocessing. The preprocessing pipeline begins

by cropping the input image based on the defined

crop rectangle, followed by conversion of the cropped

color image to grayscale. The grayscale image is then

binarized, and the resulting binary image is masked

using the ROI mask. In initial tests, no additional fil-

tering was required, as the preprocessing output was

already of sufficient quality.

Object detection and tracking. Object detection is

carried out using Blob analysis on the preprocessed

binary frame. No further filtering or edge detection is

needed.

Track management. The track management logic

remains the same as in the original algorithm devel-

oped for depth images.

5 CONCLUSION

This paper presented an image processing algorithm

for multi-object tracking in depth images, specifically

designed for the application with a cone feeder of

a multihead weigher. The proposed method demon-

strates the feasibility of accurate offline object track-

ing and measurement data acquisition using a low-

cost, consumer-grade stereo camera. Additionally, a

pathway for extending the approach to color image

processing was outlined, enabling broader applicabil-

ity.

Despite the favorable price-performance ratio of

the selected hardware, particularly regarding reso-

lution and frame rate, several technical limitations

remain. These include non-deterministic frame ar-

rival, misordered timestamps, and the absence of a

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

50

GigE Vision interface, all of which currently restrict

real-time integration with a programmable logic con-

troller. Moreover, the Intel RealSense depth camera,

being a consumer-grade device, provides only lim-

ited depth accuracy (less than 2% at a distance of

2 m). In this study, it is employed for a preliminary

feasibility assessment of depth-based motion tracking

rather than for precise absolute height measurements.

For the intended application, high depth accuracy is

not critical, provided that the target objects are suffi-

ciently elevated to be reliably distinguished from the

feeder surface.

Due to the constraints of the research project, a

comparative evaluation with industrial-grade depth

cameras or stereo vision systems in terms of speed,

accuracy, and reliability was not feasible, as only the

Intel RealSense depth camera was available for inves-

tigation.

Nevertheless, the approach establishes a solid

foundation for future applications and developments.

The image processing algorithm is currently being

utilized for automatic parameter identification of a

nonlinear model describing particle dynamics on the

conical feeder, as demonstrated in (Hartmann and

Ament, 2025). Future work will focus on enabling

vision-based real-time control of the feeder unit.

This will require more sophisticated camera hardware

equipped with a GigE Vision interface to ensure de-

terministic data transmission and real-time compati-

bility with programmable logic controllers. Addition-

ally, porting the image processing algorithm to an em-

bedded programmable logic controller environment is

a necessary step toward industrial deployment.

Further research will explore automatic product

identification during the operation of the multihead

weigher. By leveraging depth data, projected object

area, and estimated material density, the method also

offers the potential for approximating the weight of

individual items. This capability could improve the

dynamic distribution of product weight into individ-

ual hoppers, ultimately contributing to more efficient

and adaptive packaging processes.

ACKNOWLEDGEMENTS

This work is part of the project “KiKO.BD - KI-

Kombinationswaage mittels Big Data” of the pro-

gramme “BayVFP F

¨

orderlinie Digitalisierung” of

Bavarian Ministry of Economic Affairs, Regional De-

velopment and Energy.

REFERENCES

An, P., Hong, C.-J., Ri, R.-Y., Yu, C.-J., and O, C.-

J. (2024). An improved single objective optimiza-

tion approach for double-layered multi-head weighing

process. Mathematical Modelling and Applications,

9(3):61–69.

Barreiro, J. J., Gonz

´

alez, C., and Salicr

´

u, M. (1998). Opti-

mization of multiweighing packing proceedings. Top,

6(1):37–44.

Beretta, A. and Semeraro, Q. (2012). On a rsm approach

to the multihead weigher configuration. In Volume

1: Advanced Computational Mechanics; Advanced

Simulation-Based Engineering Sciences; Virtual and

Augmented Reality; Applied Solid Mechanics and Ma-

terial Processing; Dynamical Systems and Control,

pages 225–233. American Society of Mechanical En-

gineers.

Beretta, A., Semeraro, Q., and Del Castillo, E. (2016). On

the multihead weigher machine setup problem. Pack-

aging Technology and Science, 29(3):175–188.

Del Castillo, E., Beretta, A., and Semeraro, Q. (2017). Op-

timal setup of a multihead weighing machine. Euro-

pean Journal of Operational Research, 259(1):384–

393.

D

´

ıaz, J. C. G., Rojano, A. P., and Bosch, V. G. (2017).

Bi-objective optimisation of a multihead weighing

process. European J. of Industrial Engineering,

11(3):403.

Garc

´

ıa-D

´

ıaz, J. C. and Pulido-Rojano, A. (2017). Mon-

itoring and control of the multihead weighing pro-

cess through a modified control chart. DYNA,

84(200):135–142.

Garcia-Diaz, J. C. and Pulido-Rojano, A. D. (2020). Perfor-

mance analysis and optimisation of new strategies for

the setup of a multihead weighing process. European

J. of Industrial Engineering, 14(1):58–84.

Garc

´

ıa-Jim

´

enez, R., Garc

´

ıa-D

´

ıaz, J. C., and Pulido-Rojano,

A. D. (2021). Packaging process optimization in mul-

tihead weighers with double-layered upright and diag-

onal systems. Mathematics, 9(9):1039.

Garc

´

ıa-Jim

´

enez, R., Garc

´

ıa-D

´

ıaz, J. C., and Pulido-Rojano,

A. D. (2023). Bicriteria food packaging process opti-

mization in double-layered upright and diagonal mul-

tihead weighers. Journal of Computational and Ap-

plied Mathematics, 428:115168.

Hartmann, J. I. and Ament, C. (2025). Automatic parameter

identification of a nonlinear parameter-varying model

for a rotating cone feeder [accepted]. In IEEE/IFAC

9th International Conference on Control Automation

and Diagnosis (ICCAD’25).

Hartmann, J. I., Olbrich, M., Hamann, M., and Ament,

C. (2023). Simulation of particle motion on rotat-

ing cone feeder for a multihead weigher based on dy-

namic friction modeling. In 2023 IEEE/ASME Inter-

national Conference on Advanced Intelligent Mecha-

tronics (AIM), pages 138–143. IEEE.

Imahori, S., Karuno, Y., Nishizaki, R., and Yoshimoto, Y.

(2012). Duplex and quasi-duplex operations in au-

tomated food packing systems. In 2012 IEEE/SICE

A Depth Image Processing Algorithm for Monitoring Product Flow on a Conical Feeder Unit of a Multihead Weigher

51

International Symposium on System Integration (SII),

pages 810–815. IEEE.

Imahori, S., Karuno, Y., and Tateishi, K. (2014). Dynamic

programming algorithms for producing food mixture

packages by automatic combination weighers. Jour-

nal of Advanced Mechanical Design, Systems, and

Manufacturing, 8(5):JAMDSM0065–JAMDSM0065.

Imahori, S., Karuno, Y., and Yoshimoto, Y. (2010). Dy-

namic programming algorithms for duplex food pack-

ing problems. In 2010 8th IEEE International Confer-

ence on Industrial Informatics, pages 857–862. IEEE.

Karuno, Y., Nagamochi, H., and Wang, X. (2010). Opti-

mization problems and algorithms in double-layered

food packing systems. Journal of Advanced Mechan-

ical Design, Systems, and Manufacturing, 4(3):605–

615.

Karuno, Y. and Nakahama, O. (2020). An improved

performance of greedy heuristic solutions for a bi-

criteria mixture packaging problem of two types of

items with bounded weights. Journal of Advanced

Mechanical Design, Systems, and Manufacturing,

14(5):JAMDSM0066–JAMDSM0066.

Keraita, J. N. and Kim, K. H. (2007). A weighing algorithm

for multihead weighers. International Journal of Pre-

cision Engineering and Manufacturing, 8(1):21–26.

MathWorks (2025a). assigndetectionstotracks - as-

sign detections to tracks for multiobject track-

ing. https://de.mathworks.com/help/vision/ref/assign

detectionstotracks.html, 17.05.2025.

MathWorks (2025b). distance - con-

fidence value of measurement.

https://de.mathworks.com/help/vision/ref/vision.

kalmanfilter.distance.html, 17.05.2025.

MathWorks (2025c). Motion-based multiple object track-

ing. https://de.mathworks.com/help/vision/ug/motion-

based-multiple-object-tracking.html, 15.01.2025.

MathWorks (2025d). Use kalman filter for object track-

ing. https://de.mathworks.com/help/vision/ug/using-

kalman-filter-for-object-tracking.html, 15.01.2025.

Pulido Rojano, A. and Garcia Diaz, J. C. (2019). Opti-

misation algorithms for improvement of a multihead

weighing process. International Journal of Produc-

tivity and Quality Management, 1(1):1.

Pulido-Rojano, A., Garcia-Diaz, J. C., and Giner-Bosch, V.

(2015). A multiobjective approach for optimization

of the multihead weighing process. In 2015 Interna-

tional Conference on Industrial Engineering and Sys-

tems Management (IESM), pages 426–434. IEEE.

Pulido-Rojano, A. D. and Garcia Diaz, J. C. (2014). Op-

timization of multihead weighing process using the

taguchi loss function. In 8th International Conference

on Industrial Engineering and Industrial Management

XX International Conference on Industrial Engineer-

ing and Operations Management International IIE

Conference 2014, pages 305–312.

Salicr

´

u, M., Gonz

´

alez, C., and Barreiro, J. J. (1996).

Variability reduction with multiweighing proceedings.

Top, 4(2):319–329.

van Niekerk, J. E., van Vuuren, J. H., and Lindner, B. G.

(2021). Optimizing the number of hoppers on a multi-

head weighing machine. Journal of Industrial and

Production Engineering, 38(6):401–413.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

52