CLIP-LLM: A Framework for Autonomous Plant Disease Management

in Greenhouse

Muhammad Salman

a

, Muhayy Ud Din

b

and Irfan Hussain

c

Department of Mechanical and Nuclear Engineering, Khalifa University of Science and Technology, Abu Dhabi, U.A.E.

Keywords:

VLM, LLM, Robotic Intervention, Symbolic Plan, CLIP.

Abstract:

Agricultural disease detection and intervention remain challenging due to complex crop health variations,

dynamic environmental conditions, and labor-intensive fieldwork. We introduce an end-to-end, platform-

agnostic robotic pipeline for autonomous disease detection and treatment systems, with a specific focus on

cassava leaves as an example. The pipeline integrates a vision-language perception module based on a pre-

trained Contrastive Language-Image Pre-training (CLIP) model, fine-tuned on an augmented dataset of cas-

sava leaf images for disease detection. High-level task planning is performed by a Generative Pre-trained

Transformer 4 (GPT-4), which interprets perception outputs and generates symbolic action plans (e.g., nav-

igate to target, perform treatment). The low-level control system is implemented in the PyBullet dynamic

simulator. We evaluated a vision-language model (VLM) perception and a Large Language Model (LLM)

based planning system (in a virtual environment with predefined 3D coordinates for plant and spray posi-

tions). The VLM achieved 83% classification accuracy in simulation and real-time tests with a static camera

produced classification accuracies of 70% Cassava Brown Streak Disease (CBSD), 65% Cassava Mosaic Dis-

ease (CMD) and 52% Cassava Bacterial Blight (CBB), and under dynamic camera it achieve the accuracy of

65% (CBSD), 52% (CMD), and 32% (CBB). Currently, our low-level controller executes the LLM-generated

plans with high precision (less than ±2 mm positioning error). These results demonstrate the viability of our

platform-agnostic modular architecture for precision agriculture that supports closed-loop robustness and scal-

ability.

1 INTRODUCTION

Food security remains one of the most crucial global

challenges. Reports suggest we need to produce 50%

more food by 2050 (Ranganathan et al., 2018). In the

United Arab Emirates (UAE), the agricultural sector

faces critical constraints due to its arid climate, lim-

ited arable land, and significant dependence on con-

trolled environments such as greenhouses. Extreme

weather conditions, including intense heat and lim-

ited freshwater resources, further challenge sustain-

able crop cultivation. Although greenhouse farming

offers a practical way, the sector continues to struggle

with low productivity, high operational costs, and in-

creased vulnerability to plant diseases(Arshad et al.,

2025; for International Peace, 2023). Conventional

approaches to plant health management such as man-

ual disease detection and intervention are labor inten-

a

https://orcid.org/0000-0002-5818-1364

b

https://orcid.org/0000-0001-6214-1077

c

https://orcid.org/0000-0003-2759-0306

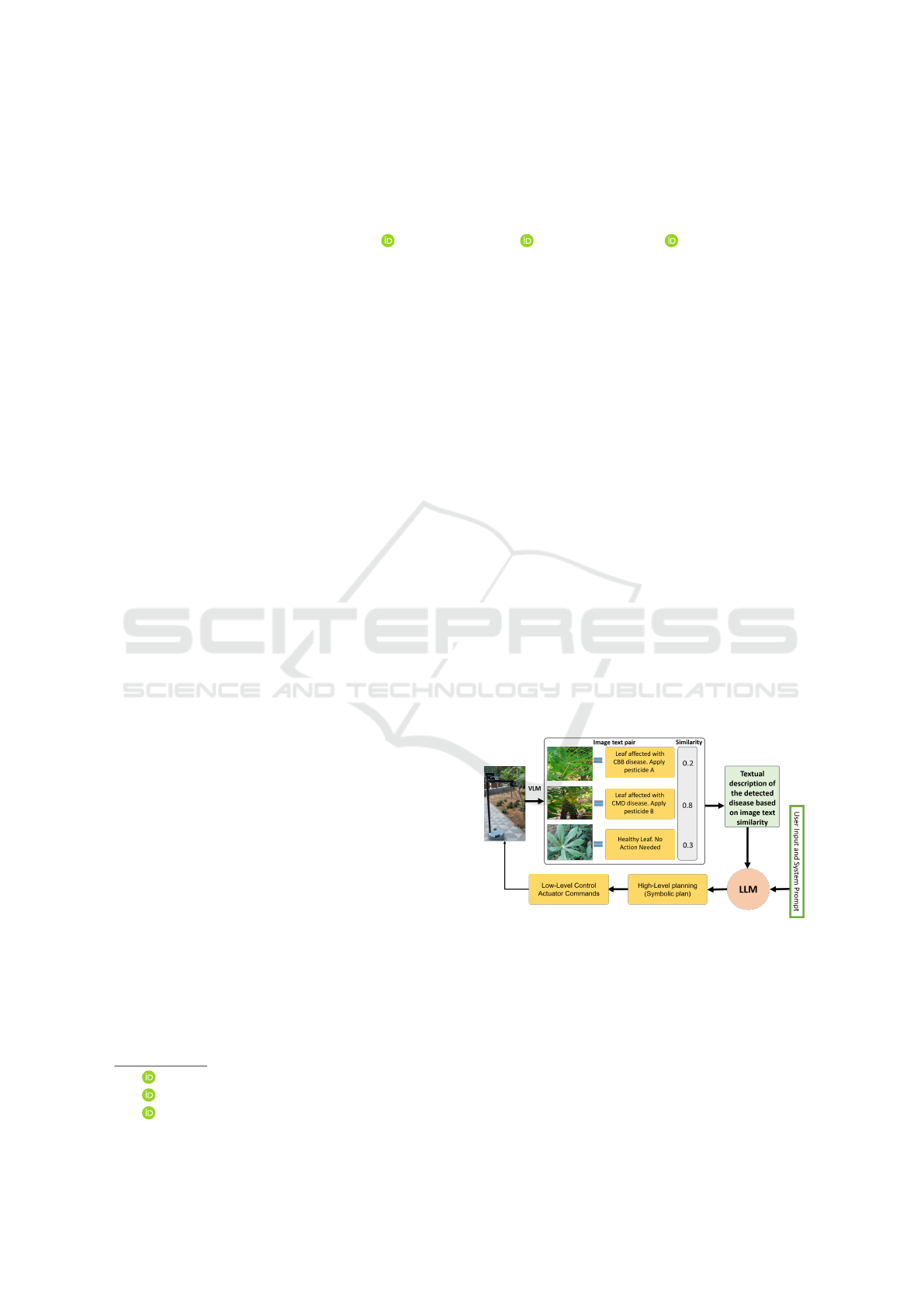

Figure 1: Workflow of the AI-driven autonomous disease

response system: CLIP-based image-text similarity iden-

tifies diseases (e.g., CBB/CMD) and recommends actions

(e.g., Pesticide A/B). The LLM generates a high-level sym-

bolic plan, which is decomposed into sub-tasks (e.g. spray-

ing) and executed via low level control.

sive(Achard, 2025; Tech, 2025), inefficient, and in-

adequate for the scale and environmental demands of

UAE agriculture. Therefore, there is a critical need to

integrate advanced technologies to enhance the pro-

202

Salman, M., Din, M. U. and Hussain, I.

CLIP-LLM: A Framework for Autonomous Plant Disease Management in Greenhouse.

DOI: 10.5220/0013674200003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 202-210

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

ductivity, efficiency, and sustainability of greenhouse-

based food production in the region.

In the last decade, many Iot-based smart solu-

tions have been presented for optimized greenhouse

environment (Maraveas et al., 2022), (Sinha et al.,

2019),(Farooq et al., 2022). Despite the adoption of

Iot platforms (O’Grady et al., 2019), growth and own-

ership remained a challenge. Recently, many studies

have been carried out to understand the importance of

AI-driven innovations in greenhouse agriculture. Ho-

seinzadeh et al. (Hoseinzadeh and Garcia, 2024) did a

detailed analysis of the sustainability and energy effi-

ciency of these technologies in the greenhouse. Mar-

aveas et al. (2022) (Maraveas, 2022) offer a compre-

hensive review of state-of-the-art research on employ-

ing AI in smart greenhouses to optimize crop yields,

enhance water and fertilizer efficiency, reduce pests

and diseases, and promote agricultural sustainabil-

ity. Previous works have also explored the application

of machine learning and computer vision techniques

for disease detection and robotic platforms to auto-

mate intervention tasks. Vision-based AI models have

achieved success in identifying plant diseases through

image analysis. For instance, Zhao et al. (Zhao et al.,

2021) proposed a double GAN framework, with one

GAN dedicated to detecting healthy leaves and the

other to identifying diseased ones. Similarly, Amrani

et al. (Amrani et al., 2024) introduced a CNN-based

Bayesian model for pest detection and size estima-

tion. YOLOv3 framework empowered by residual

attention modules also introduced for the detection

purpose (Saoud et al., 2023). However, these meth-

ods face limitations due to the cost of expert annota-

tions and poor generalization across crops and envi-

ronments.

Recent advances in large language models

(LLMs) and vision language models (VLMs) have

opened new opportunities to address data scarcity

and domain-specific challenges in agricultural appli-

cations. Emerging VLMs such as Flamingo (Alayrac

et al., 2022), CLIP (Radford et al., 2021) and Instruct-

BLIP (Dai, 2023) have shown promise through mul-

timodal pre-training, allowing for quick adaptability.

However, their potential within agricultural contexts

remains largely underexplored. Foundational stud-

ies have highlighted the applicability of vision lan-

guage frameworks to plant phenotyping tasks, includ-

ing zero-shot insect detection (Feuer et al., 2024).

Based on these developments, the AgEval benchmark

(Arshad et al., 2024) systematically evaluates VLMs

such as GPT-4o and the Claude 3.5 Sonnet. The

results of these evaluations indicate that VLMs can

achieve competitive performance, such as a 73. 37%

F1 score in 8-shot settings, while requiring orders of

magnitude fewer examples than conventional meth-

ods. These findings validate the promise of VLMs

as scalable solutions for greenhouse automation and

precision agriculture.

In Agri-robotics, research has primarily focused

on executing predefined interventions. A study

by Oliveira et al. (Oliveira et al., 2021) pre-

sented a ground robot capable of performing semi-

autonomous farm operations, such as detection, clas-

sification, and weed cutting. Similarly, many re-

search studies have been conducted over the years,

showing the impact of robots in different agricul-

tural tasks, including disease detection, spraying, har-

vesting, and predefined intervention tasks (S

´

anchez-

Molina et al., 2024), (Meshram et al., 2022). How-

ever, these systems often operate independently, lack

contextual adaptability, and do not integrate detection

results into actionable and meaningful intervention

plans. This gap underscores the need for a unified ap-

proach that combines disease detection with context-

aware planning for robotic interventions.

To address these challenges, this work introduces

an innovative AI-driven pipeline for greenhouse op-

erations that integrates multimodal AI models like

CLIP (Radford et al., 2021) and GPT-4, to robustly

detect diseases and generate symbolic plans for inter-

vention. The symbolic plan is being executed by low

level control modular functions as shown in Figure

1. By bridging the gap between detection, interven-

tion, and execution, the pipeline autonomously con-

verts real-time detection outputs into precise, action-

able strategies that robots can execute efficiently. The

comparison between traditional methods used and our

AI framework is given in Table 1. The key contribu-

tion of this work is the development of an AI-driven

framework for autonomous disease detection and in-

tervention in greenhouse environments. The main

contribution is followed by;

• Unified perception-to-control pipeline

We present a novel end-to-end robotic framework

that integrates a fine-tuned CLIP vision-language

model with GPT-4 as a symbolic task planner,

plus low-level modular controllers in simulation.

By grounding CLIP’s outputs in predefined 3D

coordinates, our system reliably maps language-

specified objects and actions to robot motions,

achieving high accuracy in both vision-language

classification and execution.

• Development of LLM-based Planning Module

We develop a structured prompt that transforms

the CLIP perception results into a concise sym-

bolic action sequence. By constraining the output

format of GPT-4, our prompt generates a fixed-

length plan that the robot can directly follow.

CLIP-LLM: A Framework for Autonomous Plant Disease Management in Greenhouse

203

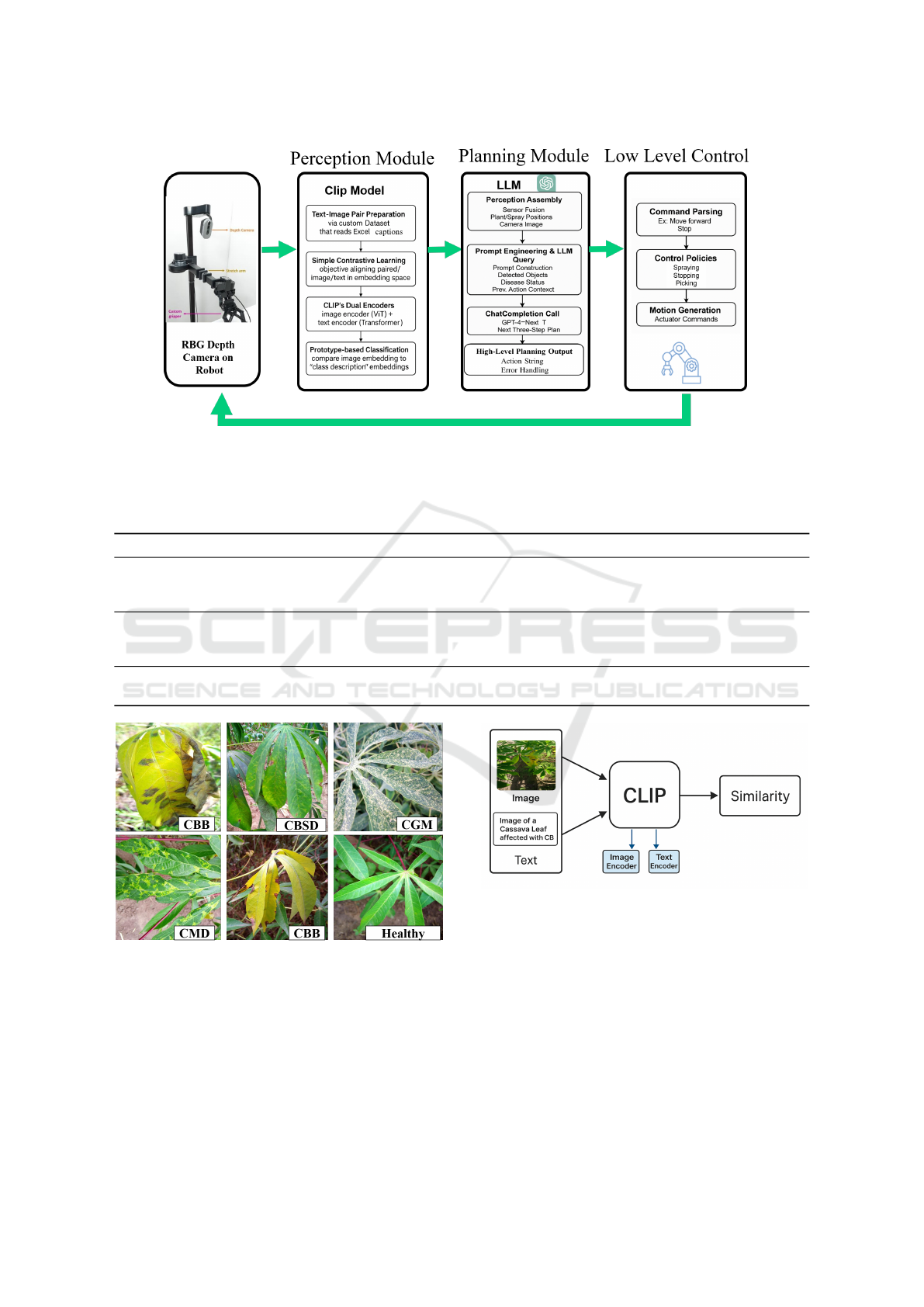

Figure 2: End-to-end AI-driven greenhouse framework: CLIP model aligns image-text embeddings (ViT + Transformer) for

disease detection via prototype-based classification. GPT-4 generates symbolic plans using sensor-fused data (plant positions,

disease status) and contextual prompts, parsed into actuator commands (spraying, motion) for robotic execution. Robot image

from (Mohsan et al., 2025).

Table 1: Comparison of Disease Detection and Response: Traditional vs. our AI-Driven Framework.

Aspect Traditional Methods AI-Driven Framework

Detection Manual visual inspection by farmers; subjec-

tive, time-consuming, and error-prone (Achard,

2025).

CLIP-based perception module: Automated

disease detection via multimodal AI (vision

+text). Achieves 85% accuracy.

Response Time Days to weeks (delays exacerbate crop loss)

(Achard, 2025).

Intervention plan: Robotic interventions. GPT

step by step plans context-aware actions (e.g.,

“spray after detection”).

Precision Blanket spraying (wastes 40% + resources)

(Tech, 2025).

Targeted interventions: AI prescribes exact

location (e.g.fungicide for Plant 23).

Figure 3: Dataset Images. Cassava Bacterial Blight (CBB),

Cassava Mosaic Disease (CMD), Cassava Brown Streak

Disease (CBSD) and Cassava Green Mite (CGM)

2 METHODOLOGY

This section details our approach to achieve AI-driven

framework for autonomous disease detection and in-

Figure 4: CLIP model taking as input an image of leaf and

the corresponding text prompt “Image of a Cassava Leaf

affected with CBB,” and computing a similarity score be-

tween the two modalities.

tervention. Figure 2 illustrates the three main modules

of this framework.

Perception module serves as the foundational sen-

sory and analytical layer of our system. They en-

able the framework to interpret the greenhouse en-

vironment and plant conditions, feeding critical data

into downstream decision-making and robotic inter-

vention processes.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

204

Figure 5: High-level and Low-level Plan execution based on LLM output

Planning module serves as the decision-making core

of the framework. It translates raw perceptual data

(from sensors and vision models like CLIP) into

structured, actionable plans for robotic interventions.

Control module acts as the execution layer that trans-

lates high-level plans (generated by the GPT-based

planning module) into precise, low-level commands

for robots and actuators. It ensures that symbolic ac-

tions are physically executed accurately, safely, and

efficiently in dynamic greenhouse environments.

2.1 VLM-Based Perception Module

This section outlines our vision-language perception

framework, which is organized into two parts: first,

dataset preparation; and second, the perception mod-

ule itself.

2.1.1 Dataset Preparation and Classification

In this study, we curated publicly available data to val-

idate our pipeline. To develop and test our approach,

we used the Cassava Leaf Disease dataset from Kag-

gle (Kaggle, 2020), Kaggle data Link, which contains

approximately 21,000 images spanning five classes:

Cassava Bacterial Blight (CBB), Cassava Mosaic Dis-

ease (CMD), Cassava Brown Streak Disease (CBSD),

Cassava Green Mite (CGM), and healthy leaves. The

dataset image of each class can be seen in the Figure

3. We organized these images into five class-specific

folders (four disease classes and one healthy class)

and applied data augmentation, including random ro-

tations, flips, and color jitter, to expand the dataset to

approximately 35,000 samples. This enriched dataset

provides a robust foundation for training and evaluat-

ing our multimodal disease-detection pipeline.

2.1.2 Perception Module

Our VLM-based perception system utilized a

pre-trained CLIP model, which we subsequently

fine-tuned on the Cassava Leaf Disease dataset to

establish a robust multimodal framework for disease

detection. The system employs a dual-encoder ar-

chitecture where images and textual descriptions are

processed through separate but coordinated encoders

that map both modalities to a shared 512-dimensional

embedding space. The image encoder utilizes a

Vision Transformer (ViT-B/32) architecture that

divides input images into 32×32 patches, applies

linear projection, and processes them through 12

transformer layers to extract visual features. Simulta-

neously, the text encoder processes natural language

descriptions through a transformer-based architec-

ture with positional embeddings and self-attention

mechanisms, capable of handling sequences up to 77

tokens.

The training methodology implements a con-

trastive learning approach where paired image-

caption data is used to learn meaningful represen-

tations, as shown in Figure 4. The system pro-

cesses cassava leaf images resized to 224×224 pix-

els alongside corresponding disease descriptions ex-

tracted from Excel files that contain expert-annotated

captions. During forward propagation, both image

and text features are normalized using L2 normal-

ization to ensure unit vectors, followed by the com-

putation of a similarity matrix using cosine similar-

ity. The optimization process utilizes the Adam opti-

mizer with a conservative learning rate of 5× 10

−6

to

CLIP-LLM: A Framework for Autonomous Plant Disease Management in Greenhouse

205

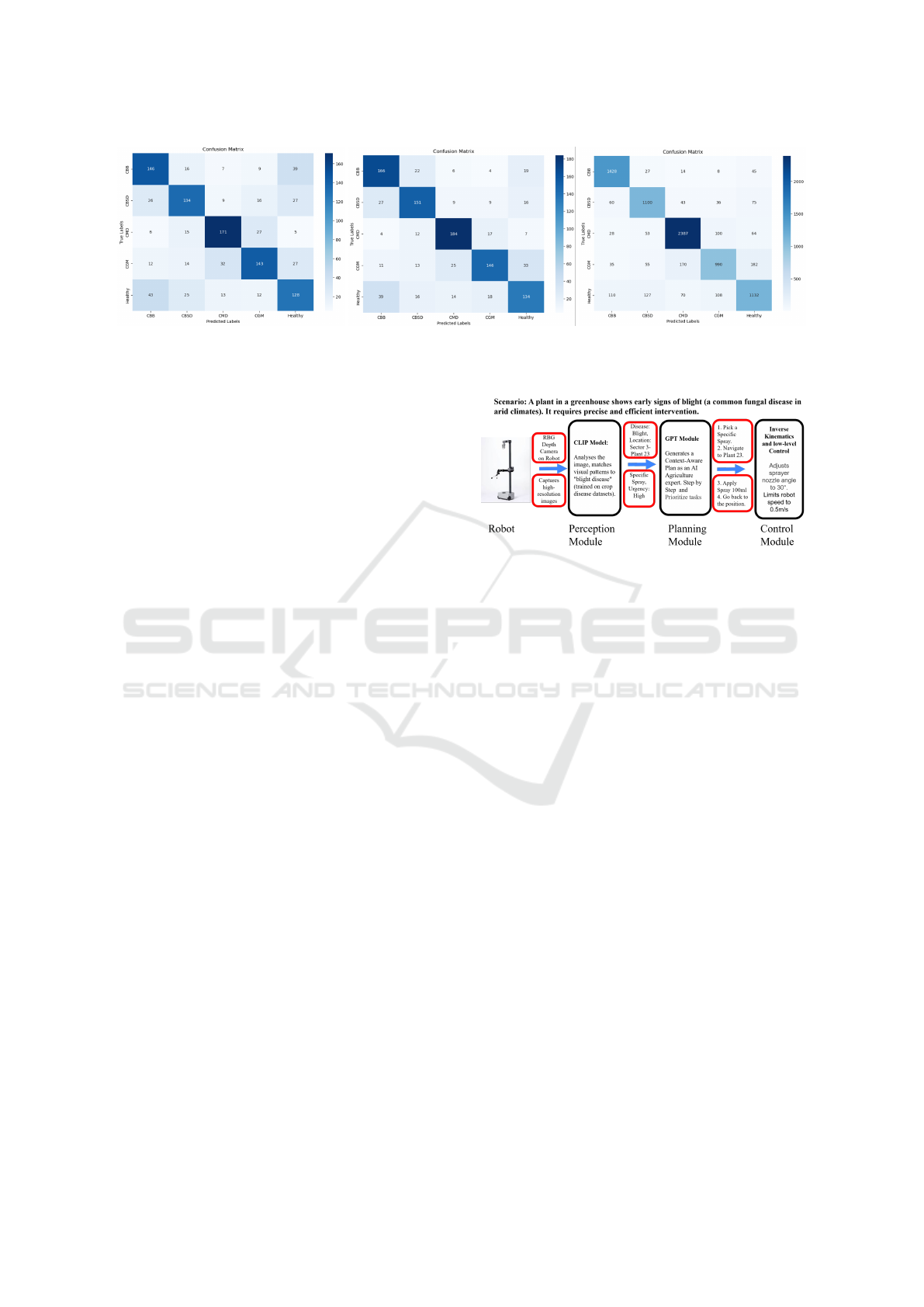

Figure 6: Left side Confusion Matrix shows CNN (MobileNet) performance, Middle Confusion Matrix shows CLIP model

performance for the original dataset, and Right side Confusion Matrix shows CLIP model performance for the Augmented

dataset.

fine-tune the pre-trained CLIP weights over 50 epochs

with a batch size of 16. For inference, the system

implements zero-shot classification by pre-computing

text embeddings for predefined class descriptions.

2.2 LLM-Based Planning and Control

This module represents the cognitive and execution

backbone of the robotic system, bridging high-level

decision-making with precise physical control. The

LLM-based planning component utilizes OpenAI’s

GPT-4 to generate intelligent action sequences based

on VLM perception data, including the detection of

plant diseases and object positions. When the sys-

tem identifies a diseased plant, the LLM formulates a

comprehensive action plan: navigate to the plant posi-

tion, save the disease position, move to the spray bot-

tle location, and return to apply treatment as shown

in Figure 5. The language model processes percep-

tion outputs containing plant coordinates, spray bot-

tle locations, and camera imagery to determine the

most appropriate sequence of actions, considering the

previous action to maintain contextual awareness and

prevent redundant operations.

The low-level control execution system translates

these high-level commands into precise robotic move-

ments using PyBullet physics simulation. The mod-

ule employs inverse kinematics calculations to de-

termine joint positions for the robot arm, enabling

accurate positioning of the end-effector at target lo-

cations. The system implements step-by-step mo-

tion control, monitoring real-time position feedback

to ensure the robot reaches each waypoint with spec-

ified precision thresholds. Object manipulation ca-

pabilities include simulated grasping through con-

straint creation, allowing the robot to pick up and

carry the spray bottle. The integration of multiple

execution functions (Plant-Location, Spray-Location,

Pick-spray) provides specialized handling for differ-

ent phases of the task, with each function tailored

Figure 7: Example case-study for understanding only.

Workflow for the AI-Framework in the greenhouse.

to specific operational requirements such as approach

heights and precision tolerances.

By bridging multimodal AI perception, adap-

tive reasoning, and resource-efficient execution, this

framework addresses the unique agricultural chal-

lenges for autonomous greenhouse management. An

example can be seen to understand the workflow of

the pipeline in the Figure 7. It shows example sce-

nario (only for understanding the pipeline), how all

the three modules will interact with each other to give

us an end-to-end AI based solution.

3 RESULTS AND DISCUSSION

This section presents the key performance evaluation

metrics for the VLM and offers a detailed analysis of

both simulation and experimental results.

3.1 Performance Evaluation

The performance evaluation was conducted using a

comprehensive dataset of cassava leaf images catego-

rized into five classes: CBB , CBSD , CMD , CGM ,

and Healthy. The evaluation protocol employed both

labeled and unlabeled images, with the training phase

utilizing image-caption pairs for contrastive learning

and the testing phase performing zero-shot classifi-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

206

Figure 8: Real-time disease detection with Static Camera. (a) CBSD disease detected with 69.7% (b) CMD disease detected

with 65.08% (c) CBB disease detected with 52.71%.

Figure 9: Real-time disease detection with moving Camera.

CBSD disease detected with 65%, CMD disease detected

with 51.45%, CBB disease detected with 32%.

cation on images without associated captions. Clas-

sification accuracy was computed as the percentage

of correctly predicted test samples, while precision,

recall, and F1-score were calculated using weighted

averages across all classes to account for potential

class imbalances. The confusion matrix analysis pro-

vided detailed insights into class-wise performance,

revealing the system’s ability to distinguish between

different disease types and healthy leaves. Precision

scores indicated the reliability of positive predictions

for each disease class, while recall scores measured

the system’s capability to identify all instances of spe-

cific diseases.

3.2 Results Discussion

Table 2: Performance comparison of different models.

Model Accuracy Precision Recall F1-

Score

Mobile-Net 65.52% 0.66 0.66 0.66

CLIP 70.87% 0.71 0.71 0.71

CLIP-Aug 83.17% 0.83 0.83 0.83

The comparative analysis of the three models reveals

significant performance differences in cassava disease

detection as shown in Table 2. MobileNet, serving

as our baseline, achieved an accuracy of 65.52% with

precision, recall, and F1-scores all converging at 0.66.

These results demonstrate a moderate detection ca-

pability with relatively balanced performance across

all metrics, indicating consistent yet limited discrim-

ination ability across different disease classes. The

CLIP model showed substantial improvement over

MobileNet, achieving 70.87% accuracy with all met-

rics (precision, recall, and F1-score) reaching 0.71.

This represents an improvement of approximately

5.35 percentage points in accuracy and 0.05 in all

other metrics. The confusion matrix in Figure 6 anal-

ysis reveals that CLIP maintained better class bal-

ance with reduced misclassification rates, particularly

showing improved recognition of CMD with 184 cor-

rect predictions compared to MobileNet’s weaker per-

formance in this class. The model demonstrated good

discrimination between CBSD and healthy samples,

with relatively clear diagonal patterns in the confu-

sion matrix.

CLIP-Aug (CLIP with augmentation) demon-

strated the most impressive performance, achieving

83.17% accuracy with precision, recall, and F1-scores

all reaching 0.83. This represents a substantial im-

provement of 17.65 percentage points over MobileNet

and 12.3 percentage points over standard CLIP. The

confusion matrix for CLIP-Aug shows the darkest di-

agonal pattern among the three models, indicating

significantly improved correct classifications. No-

tably, CLIP-Aug achieved 2387 correct predictions

for CMD, substantially higher than both MobileNet

171 and CLIP 184. The model also demonstrated

superior performance in classifying healthy samples

with 1132 correct predictions compared to 128 for

MobileNet and 134 for CLIP.

The progressive improvement from MobileNet

to CLIP to CLIP-Aug suggests that the pre-trained

language-vision capabilities of CLIP (fined tuned on

Cassava leaf dataset) provide meaningful advantages

CLIP-LLM: A Framework for Autonomous Plant Disease Management in Greenhouse

207

Figure 10: Implementation of LLM based planning with low level control based on perception input in simulation environ-

ment.

for cassava disease detection, while data augmenta-

tion further enhances the model’s robustness and gen-

eralization ability. The balanced metrics across pre-

cision, recall, and F1-score for all models indicate

consistent performance without significant bias to-

ward any particular class, though the absolute values

clearly favor CLIP-Aug. These results demonstrate

that CLIP-based approaches, particularly when com-

bined with appropriate data augmentation strategies,

can significantly outperform traditional CNN archi-

tectures like MobileNet for agricultural disease detec-

tion tasks.

To test the real-time effectiveness of Clip-Aug,

two different scenarios (Static and Dynamic camera)

has been designed. In the Static-camera scenario

shown in Figure 8, where the RGB-D camera remains

fixed and leaves are manually presented before it, the

CLIP-Aug pipeline demonstrates robust disease iden-

tification: CBSD is detected with an average confi-

dence of 70%, CMD at 65%, and CBB at 52%. These

results reflect the efficacy of contrastive image–text

embedding under ideal capture conditions (sharp,

well-framed, and high–signal-to-noise images) allow-

ing the Vision Transformer to extract features with-

out distortion or blur. The fixed viewpoint minimizes

geometric and photometric variability, enabling the

model’s dual encoders to align each leaf image ac-

curately to its corresponding caption prototype with

minimal mismatch (Vasiljevic et al., 2016).

By contrast, in the dynamic-camera scenario,

where the robot and thus the RGB-D camera moves

around a static leaf, performance degrades to 65% for

CBSD, 52% for CMD, and only 32% for CBB. This

drop can be attributed largely to motion-induced blur,

which smooths high-frequency details crucial for dis-

ease lesion detection. As the camera travels, slight vi-

brations and egomotion introduce spatial distortions

and inconsistent lighting, increasing image noise and

reducing the model’s ability to discriminate subtle

color and texture cues (Tanaka et al., 2022). More-

over, dynamic frames often capture leaves at subop-

timal angles, causing partial occlusion of symptoms

and misalignment with the text embeddings learned

during training on frontal, well-centered views (Kara-

han et al., 2016).

The simulation results in Figure 10 validate the

framework’s ability to translate LLM-generated plans

into precise robotic actions, even when tested in

a virtual environment without real plants or spray

hardware. The LLM (GPT-4) demonstrated context-

aware planning based on the perception module out-

put by decomposing the agricultural task into logi-

cal steps—navigating to the diseased plant ([0.5, -

0.83, 0.07]), retrieving the spray bottle ([-0.28, -

0.83, 0.07]), and applying treatment—while adhering

to practical constraints (e.g., avoiding plant damage,

ensuring secure grip). The system’s spatial reason-

ing is evident in its precise navigation to 3D coordi-

nates, with positional errors under ±2 mm, confirm-

ing robust inverse kinematics and closed-loop feed-

back. While we use the simulation environment,

this approach strengthens validation by isolating al-

gorithmic performance from hardware-specific vari-

ables, ensuring repeatability and safety during test-

ing. The seamless execution of plans (“Target posi-

tion reached”) and task completion (“Ending simula-

tion as instructed”) prove the framework’s platform-

agnostic adaptability, a critical feature for scaling in

diverse environments.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

208

4 CONCLUSION AND FUTURE

WORK

This paper presented a novel, end-to-end framework

for automated plant disease detection and interven-

tion in agricultural environments. Our approach suc-

cessfully integrated three key modules: VLM-based

disease detection using CLIP, LLM-based planning

with GPT-4, and low-level robotic control execution.

The CLIP-based cassava disease detection algorithm

demonstrated significant improvements over baseline

methods, achieving 83.17% accuracy with consistent

precision, recall, and F1-scores of 0.83. Most no-

tably, our CLIP-Aug model outperformed the Mo-

bileNet baseline by 17.65 percentage points, show-

ing particularly strong performance in CMD detec-

tion with 2387 correct detections compared to Mo-

bileNet’s 171. The LLM-based planning module ef-

fectively translated disease detection results into co-

herent action sequences, demonstrating the ability to

generate contextually appropriate plans for plant nav-

igation and treatment application. Our simulation ex-

periments validated that the generated plans could be

successfully executed by the low-level control sys-

tem, with the robot accurately navigating to specific

3D coordinates, manipulating objects like spray bot-

tles, and performing targeted treatment applications.

For future work, we plan to incorporate a large-

scale dataset from SILAL, one of the largest green-

house operations in the UAE. We will extend our

pipeline to real greenhouse environments by integrat-

ing the large-scale plant dataset and deploying the

system. To mitigate dynamic-camera performance

degradation, we plan to incorporate motion-aware im-

age deblurring and fine-tune the CLIP encoder on

blurred and off-angle augmentations.

ACKNOWLEDGMENTS

This publication is based upon work supported by the

Khalifa University of Science and Technology under

Award No. RC1-2018- KUCARS and Autonomous

Underwater Robotic System for Aquaculture Appli-

cations: 8474000419.

REFERENCES

Achard, S. (2025). Indoor farming in the uae: A breakdown

in 2025. Details labor dependency (1 worker/500m²)

and high operational costs for climate-controlled sys-

tems.

Alayrac, J.-B., Donahue, J., Luc, P., Miech, A., Barr,

I., Hasson, Y., Lenc, K., Mensch, A., Millican, K.,

Reynolds, M., et al. (2022). Flamingo: a visual lan-

guage model for few-shot learning. Advances in neu-

ral information processing systems, 35:23716–23736.

Amrani, A., Diepeveen, D., Murray, D., Jones, M. G., and

Sohel, F. (2024). Multi-task learning model for agri-

cultural pest detection from crop-plant imagery: A

bayesian approach. Computers and Electronics in

Agriculture, 218:108719.

Arshad, M. A., Jubery, T. Z., Roy, T., Nassiri, R., Singh,

A. K., Singh, A., Hegde, C., Ganapathysubramanian,

B., Balu, A., Krishnamurthy, A., et al. (2024). Ageval:

A benchmark for zero-shot and few-shot plant stress

phenotyping with multimodal llms. arXiv preprint

arXiv:2407.19617.

Arshad, M. A., Jubery, T. Z., Roy, T., Nassiri, R., Singh,

A. K., Singh, A., Hegde, C., Ganapathysubramanian,

B., Balu, A., Krishnamurthy, A., et al. (2025). Lever-

aging vision language models for specialized agricul-

tural tasks. In 2025 IEEE/CVF Winter Conference

on Applications of Computer Vision (WACV), pages

6320–6329. IEEE. Discusses AI-driven disease detec-

tion challenges in resource-scarce environments like

the UAE.

Dai, W. (2023). Teaching Language Models to See: Build-

ing Robust and Versatile Vision-Language Models.

PhD thesis, Hong Kong University of Science and

Technology (Hong Kong).

Farooq, M. S., Javid, R., Riaz, S., and Atal, Z. (2022).

Iot based smart greenhouse framework and control

strategies for sustainable agriculture. IEEE Access,

10:99394–99420.

Feuer, B., Joshi, A., Cho, M., Chiranjeevi, S., Deng, Z. K.,

Balu, A., Singh, A. K., Sarkar, S., Merchant, N.,

Singh, A., et al. (2024). Zero-shot insect detection

via weak language supervision. The Plant Phenome

Journal, 7(1):e20107.

for International Peace, C. E. (2023). Climate change and

vulnerability in the middle east. Highlights how cli-

mate stressors exacerbate disease risks in UAE agri-

culture due to extreme heat and poor governance.

Hoseinzadeh, S. and Garcia, D. A. (2024). Ai-driven in-

novations in greenhouse agriculture: Reanalysis of

sustainability and energy efficiency impacts. Energy

Conversion and Management: X, 24:100701.

Kaggle (2020). Cassava Leaf Disease Classifica-

tion. https://www.kaggle.com/competitions/

cassava-leaf-disease-classification. Accessed:

[Insert Date Accessed].

Karahan, S., Yildirum, M. K., Kirtac, K., Rende, F. S., Bu-

tun, G., and Ekenel, H. K. (2016). How image degra-

dations affect deep cnn-based face recognition? In

2016 international conference of the biometrics spe-

cial interest group (BIOSIG), pages 1–5. IEEE.

Maraveas, C. (2022). Incorporating artificial intelligence

technology in smart greenhouses: Current state of the

art. Applied Sciences, 13(1):14.

Maraveas, C., Piromalis, D., Arvanitis, K. G., Bartzanas, T.,

and Loukatos, D. (2022). Applications of iot for op-

CLIP-LLM: A Framework for Autonomous Plant Disease Management in Greenhouse

209

timized greenhouse environment and resources man-

agement. Computers and Electronics in Agriculture,

198:106993.

Meshram, A. T., Vanalkar, A. V., Kalambe, K. B., and

Badar, A. M. (2022). Pesticide spraying robot for pre-

cision agriculture: A categorical literature review and

future trends. Journal of Field Robotics, 39(2):153–

171.

Mohsan, M. M., Hasanen, B. B., Hassan, T., Din, M. U.,

Werghi, N., Seneviratne, L., and Hussain, I. (2025).

Swishformer for robust firmness and ripeness recogni-

tion of fruits using visual tactile imagery. Postharvest

Biology and Technology, 225:113487.

O’Grady, M., Langton, D., and O’Hare, G. (2019). Edge

computing: A tractable model for smart agriculture?

Artificial Intelligence in Agriculture, 3:42–51.

Oliveira, L. F., Moreira, A. P., and Silva, M. F. (2021). Ad-

vances in agriculture robotics: A state-of-the-art re-

view and challenges ahead. Robotics, 10(2):52.

Radford, A., Kim, J. W., Hallacy, C., Ramesh, A., Goh, G.,

Agarwal, S., Sastry, G., Askell, A., Mishkin, P., Clark,

J., et al. (2021). Learning transferable visual models

from natural language supervision. In International

conference on machine learning, pages 8748–8763.

PmLR.

Ranganathan, J., Waite, R., Searchinger, T., and Hanson, C.

(2018). How to sustainably feed 10 billion people by

2050, in 21 charts. World Resources Institute, 5.

S

´

anchez-Molina, J. A., Rodr

´

ıguez, F., Moreno, J. C.,

S

´

anchez-Hermosilla, J., and Gim

´

enez, A. (2024).

Robotics in greenhouses. scoping review. Computers

and Electronics in Agriculture, 219:108750.

Saoud, L. S., Niu, Z., Sultan, A., Seneviratne, L., and Hus-

sain, I. (2023). Adod: Adaptive domain-aware object

detection with residual attention for underwater envi-

ronments. In 2023 21st International Conference on

Advanced Robotics (ICAR), pages 633–638. IEEE.

Sinha, A., Shrivastava, G., and Kumar, P. (2019). Archi-

tecting user-centric internet of things for smart agri-

culture. Sustainable Computing: Informatics and Sys-

tems, 23:88–102.

Tanaka, R., Nozaki, S., Goshima, F., and Shiraishi, J.

(2022). Deep learning versus the human visual sys-

tem for detecting motion blur in radiography. Journal

of Medical Imaging, 9(1):015501–015501.

Tech, N. (2025). Scalability and cost-effectiveness of con-

trolled environment agriculture for medicinal plants.

Nexsel Blog. Analyzes labor automation gaps and ini-

tial setup costs (e.g., 90water savings vs. high energy

demands).

Vasiljevic, I., Chakrabarti, A., and Shakhnarovich, G.

(2016). Examining the impact of blur on recog-

nition by convolutional networks. arXiv preprint

arXiv:1611.05760.

Zhao, Y., Chen, Z., Gao, X., Song, W., Xiong, Q., Hu,

J., and Zhang, Z. (2021). Plant disease detection us-

ing generated leaves based on doublegan. IEEE/ACM

Transactions on Computational Biology and Bioinfor-

matics, 19(3):1817–1826.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

210