Contribution of Knowledge Management to Innovation Capabilities

in the Manufacturing Industry Through Machine Learning

Juan Ibujés-Villacís

a

and Michael S. Simba-Herrera

b

Facultad de Ciencias Administrativas, Escuela Politécnica Nacional, Quito, Ecuador

Keywords: Business Management, Innovation Capabilities, Knowledge Management, Manufacturing Industry,

Machine Learning.

Abstract: Knowledge management has been fundamental for organizations to improve their ability to innovate. The

objective of this research is to design and develop machine learning models that impact predictive analytics,

identifying the determinants of knowledge management (KM) that influence innovation capabilities (IC) in

the manufacturing industry. Given the quantitative nature of the research, in a first stage, information on

factors related to KM and IC was collected and processed. In a second phase, six models were developed to

predict which manufacturing companies innovate in their production processes based on a set of KM factors.

Information from 142 manufacturing companies in the province of Pichincha, Ecuador, was used for the study.

The results show that all the factors of KM contribute to innovation capabilities, with organizational structure,

technology, people and incentives standing out in particular. This study is pioneering in Ecuador and

reinforces the strategic value of corporate governance as a driver of industrial innovation and provides a useful

empirical framework to guide decision making and business policy formulation. In addition, this study

contributes to the field of knowledge management by providing empirical evidence on the key factors on

which manufacturing companies should focus their efforts to develop innovation capabilities in processes,

products and services.

1 INTRODUCTION

In the business context, innovation is a key

mechanism for generating new economic value, by

developing novel products, implementing efficient

production methods and boosting sales (Nakamori,

2020; Zawislak et al., 2018). This way of creating

economic value requires to be properly managed to

achieve business objectives.

According to the global innovation index,

Ecuador ranks 91st worldwide and 12th in the Latin

American and Caribbean (LAC) region (Dutta et al.,

2021). These positions reflect the low levels of

innovation present in the Ecuadorian business fabric,

which is consistent with the results of the latest

innovation survey, which determines that only 54.5%

of Ecuadorian companies carry out some type of

innovation (product, process, organizational or

marketing) (SENESCYT-INEC, 2015)

a

https://orcid.org/0000-0001-8439-3048

b

https://orcid.org/0009-0009-6978-9330

Low innovative capacity negatively affects the

competitiveness and sustainability of organizations in

developing countries (Qin, 2024) and represents a

particular challenge for Ecuadorian industry in the

context of the knowledge economy (Aguilar-Barceló

& Higuera-Cota, 2019; CEPAL, 2016). This problem

is addressed in this research from the perspective of

knowledge management (KM) in the industrial

setting.

Knowledge management allows the identification

and exploitation of best practices in the creation of

new products services, in addition to contributing to

the prevention of errors and rework (Pagani &

Champion, 2024). From this approach, many

organizations adopt strategies such as exploitation,

acquisition, sharing, exploration and exploitation of

knowledge in order to improve their business

management (Bolisani & Bratianu, 2018). However,

these strategies do not always translate into

Ibujés-Villacís, J. and Simba-Herrera, M. S.

Contribution of Knowledge Management to Innovation Capabilities in the Manufacturing Industry Through Machine Learning.

DOI: 10.5220/0013673000004000

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 17th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2025) - Volume 2: KEOD and KMIS, pages

357-369

ISBN: 978-989-758-769-6; ISSN: 2184-3228

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

357

innovative results, probably due to the absence of

tools that facilitate data-driven decision making.

The purpose of this research is to design and apply

machine learning models that allow predictive

analysis, identifying which manufacturing companies

have innovative capabilities (IC) based on their

knowledge management practices. This is a

pioneering study in the Ecuadorian context, since no

precedents have been found that integrate the

proposed models to predict innovative behavior based

on KM.

From a methodological perspective, the study has

a quantitative approach. A structured survey was

applied to a random sample of 142 manufacturing

companies in the province of Pichincha, Ecuador,

collecting information on factors related to KM and

IC, taking as reference previous studies (Ibujés-

Villacís & Franco-Crespo, 2024). With these data,

several multiple linear regression models were

developed, considering the KM variables as

independent variables and the IC variables as

dependent variables.

This study, by training algorithms with data from

medium-sized manufacturing companies, allows us to

identify the factors of KM that are determinants for

the development of innovation capabilities in this

sector. Its results provide relevant inputs for the

formulation of strategies aimed at fostering

innovation in products, services and processes

aligned with business objectives.

The article is structured as follows: first, a

conceptual framework on KM, IC and machine

learning is presented. Next, six multiple linear

regression (MLR) models are described to predict

variables associated with IC from factors related to

KM. Subsequently, algorithms are developed to

identify significant KM variables that impact

innovation within the manufacturing industry.

Finally, the results are discussed, conclusions and

limitations of the study are presented, and future lines

of research are proposed.

2 THEORETICAL ELEMENTS

2.1 Knowledge Management

In the field of organizational management, there is

practically consensus that at the present time, the

most important strategic resource of organizations is

(Bolisani & Bratianu, 2018; Davila et al., 2019;

Kesavan, 2021; North & Kumta, 2018). By such

virtue, KM is one of the most important

organizational capabilities of organizations to

innovate products and processes (Camisón-Haba et

al., 2019; Chang et al., 2017; Ode & Ayavoo, 2020).

KM is a multidimensional category that

encompasses important aspects related to the human,

technological and political dimensions, which

interact in the complex process of value creation in

organizations (Espindola & Wright, 2021; Manning

& Manning, 2020; Obeidat et al., 2016). According to

Ibujés-Villacís & Franco-Crespo (2024), KM is

represented by a series of variables grouped into

seven factors: Policies and strategies, Organizational

structure, Technology, People, Incentive systems,

Organizational culture, and Communication.

2.2 Innovation Capabilities

Joseph A. Schumpeter (1883-1950) understood

innovation as the introduction of new products or the

improvement of existing ones; the introduction of a

new or improved method of production; the opening

of a new market; the use of a new method of selling

or purchasing; the use of new raw materials or semi-

finished products; or the introduction of new forms of

organization of production (Nakamori, 2020;

Szczepańska-Woszczyna, 2021).

To innovate organizations, require new

capabilities that are related to the abilities to

continuously transform and exploit the potentiality of

organizational knowledge, with the objective of value

creation through the generation of significant changes

in products and processes (Kaur, 2019; Nakamori,

2020; OECD & Eurostat, 2018). By having these

capabilities, organizations develop new intra- and

inter- organizational learning systems, and focus

organizational management towards the market and

changing environments (Bogodistov et al., 2017;

Bykova & Jardon, 2018; Kodama, 2018; Salmador et

al., 2021)

According to Ibujés-Villacís & Franco-Crespo,

(2024), IC are represented by a series of variables

grouped into six factors: Research and Development,

Management capability, Resource availability, Talent

management, Staff skills, and Technological

capability.

2.3 Machine Learning

Machine learning (ML), predictive modeling and

artificial intelligence are closely linked concepts

(Shmueli et al., 2023). This field of study allows

computers to learn from data without the need to be

explicitly programmed. In this context, a computer

system improves its performance on specific tasks as

it accumulates experience (Akerkar, 2019).

KMIS 2025 - 17th International Conference on Knowledge Management and Information Systems

358

The process usually begins with the construction

of a model, a simplified representation of reality that

enables the identification of patterns and relationships

within the data (Burger, 2018; Kuhn & Silge, 2022).

Unlike dashboards, which provide a static view of

data, models enable dynamic analysis and prediction

of future trends (Burger, 2018). There are several

machine learning models, such as regression,

clustering, and neural networks, all based on

algorithms. To achieve the objective of this research,

a supervised learning algorithm was used by applying

a multiple linear regression model, a tool widely used

in predictive analytics in business (Pagani &

Champion, 2024; Weber, 2023).

Machine learning requires training models from a

set of data, usually a representative sample of the total

available. During this process, model performance is

evaluated based on error reduction and fit ability. If

errors persist, the model needs to be adjusted and

refined (Burger, 2018). A common practice in this

process is cross-validation, which consists of dividing

the dataset into subsets for training and testing, thus

allowing to improve the predictive ability and

generalization of the model (Burger, 2018; Hastie et

al., 2023).

2.4 Multiple Linear Regression

Multiple linear regression (MLR) is a statistical

technique used to model the relationship between a

dependent variable and two or more independent

variables. MLR seeks to find the best straight line (or

hyperplane in higher dimensions) that fits the data

optimally. This involves determining the coefficients

that minimize the difference between the values

predicted by the model and the actual values observed

in the data set.

Mathematically, the multiple linear regression

model is expressed as equation 1:

𝑌=𝛽

+𝛽

𝑋

+𝛽

𝑋

+⋯+𝛽

𝑋

+𝜀

(1)

Where

Y is the dependent variable.

𝑋1, 𝑋2, …., 𝑋𝑛 are the independent variables.

𝛽0, 𝛽1, 𝛽2, …., 𝛽𝑛 are the coefficients

representing the slope of each independent variable.

ϵ is the error term, which captures the variation

not explained by the model.

Multiple linear regression (MLR) is a statistical

technique useful for analyzing how multiple

independent factors simultaneously influence a

specific outcome. In this study, it is used to examine

and predict the relationship between dependent

variables associated with IC and independent

variables linked to KM, making it possible to identify

which KM practices have a significant impact on

strengthening innovation within the Ecuadorian

manufacturing sector.

The analysis focuses on a group of medium-sized

companies in the manufacturing sector located in the

province of Pichincha, Ecuador. In this context, the

dependent variables - detailed in Table 2 - reflect

different aspects of innovation capabilities such as

research and development (R&D). The independent

variables, presented in Table 1, represent different

dimensions of knowledge management implemented

by the organizations.

3 METHODOLOGY

This research has a quantitative approach, is

correlational, non-experimental and cross-sectional.

Figure 1 shows the complete process to achieve the

research objective, starting with the determination of

the sample and ending with the obtaining of results.

The methodology employed consists of six

stages: sample determination, data collection, data

exploration and preparation, modeling and analysis,

model training and validation, and finally, obtaining

results and proposals for action. This approach allows

for a rigorous and systematic treatment of the

information to ensure the validity of the conclusions.

3.1 Multiple Linear Regression

The study focuses on companies in the manufacturing

sector in the province of Pichincha, whose capital is

Quito, Ecuador's economic and political center. This

sector was selected because of its important

contribution to the national economy, representing

14.2% of the country's total production (MIPRO,

2021).

The study population is composed of medium-

sized active manufacturing companies with at least

five years of operation. These companies are

characterized by having between 50 and 199

employees, generating annual revenues between 1

and 5 million dollars and having assets of less than 4

million dollars (SUPERCIAS, 2021). According to

records available as of November 2020, there were

338 medium-sized companies in this sector that had

submitted their financial reports for 2019

(SUPERCIAS, 2020).

To calculate the sample size, proportional

probability sampling for finite population was

applied, using simple random selection without

replacement. This technique guarantees the

Contribution of Knowledge Management to Innovation Capabilities in the Manufacturing Industry Through Machine Learning

359

representativeness of the sample and ensures that all

units have the same probability of being selected

(Latpate et al., 2021; Lohr, 2019).

The final determination of the sample size (n) was

performed using Equation 2, based on the statistical

methods proposed by Lohr (2019) and Ott &

Longnecker (2016)

𝑛=

𝑍

𝑁𝑝𝑞

𝐸

𝑁−1

+𝑍

𝑝𝑞

(2

)

The parameters used to calculate the sample were:

N = 338 (population size), E = 10 % (margin of

sampling error), Z = 1.96 (95 % confidence level), p

= 0.5 (probability of success) and q = 0.5 (probability

of failure). With these values, a minimum sample size

of n = 75 companies was determined. However, the

study was conducted with 142 companies, far

exceeding the minimum requirement. This made it

possible to reduce the estimated sampling error to 6%,

maintaining the 95% confidence level.

3.2 Data Collection

Data collection was carried out through a survey

directed at senior executives of the companies

included in the study sample. A structured

questionnaire was applied, based on the innovation

management model proposed by Ibujés-Villacís &

Franco-Crespo (2022). The instrument assessed a

total of 85 items organized into two main sections: on

one hand, knowledge management (KM), represented

by 35 variables grouped into seven factors; and on the

other hand, innovation capabilities (IC), represented

by six key variables.

This questionnaire was subjected to content

validation by experts, considering four categories:

coherence, relevance, clarity and sufficiency of the

questions. To ensure these qualities, a pilot test was

conducted with the participation of ten experts from

academia and industry. Based on the validation and

the comments received, the suggested improvements

were incorporated and the final version of the

questionnaire was prepared.

To respond to the questionnaire, company

managers were asked to rate each of the items using

the psychometric instrument called Likert scale

(Bertram, 2018). A 10-point scale was used, with 1

representing very low agreement and 10 representing

very high agreement with the argument presented in

each item.

Table 1: Knowledge management factors and variables.

Knowledge management variables

Factor 1: Policies and strategies (PS)

Policies for the acquisition and generation of

organizational knowledge.

PS1

Policies for the storage, sharing and use of

organizational knowledge.

PS2

Implementation of properly documented processes,

procedures and routines

PS3

Establishment of alliances with public and private

organizations.

PS4

Development of dynamic plans to overcome internal

and external barriers.

PS5

Permanent focus on continuous improvement. PS6

Systematic combination of existing and new knowledge. PS7

Factor 2: Organizational structure (OS)

Internal organizational structures dedicated to research

and development.

OS1

Regulations established for the access and use of

knowledge.

OS2

Agility in the processes to access organizational

knowledge.

OS3

Facilities for the horizontal flow of knowledge within

the organization.

OS4

Facilities for the vertical flow of knowledge within the

organization.

OS5

Factor 3: Technology (TG)

Use of technology for the methodical storage of

knowledge.

TG1

Use of information systems for accessing, sharing and

utilizing the organizational knowledge.

TG2

Application of ICT for access, exchange and use of

knowledge.

TG3

Utilization of corporate social networks for

collaboration and knowledge of the environment.

TG4

Factor 4: Persons (PP)

Years of employee experience. PP1

Employees' level of education. PP2

Age of employees. PP3

Foreign language proficiency of employees. PP4

Gender diversity among employees. PP5

Factor 5: Incentive systems (IS)

Economic incentives for generating, sharing and using

knowledge.

IS1

Training offered as an incentive for generating, sharing

and using the knowledge.

IS2

Days off granted as an incentive for generating, sharing,

and using the knowledge.

IS3

Public recognition as an incentive for generating,

sharing and utilizing the knowledge.

IS4

Factor 6: Organizational culture (OC)

Importance of personal values. OC1

Positive attitude towards work. OC2

Respect for the company's principles and regulations. OC3

Application of best practices. OC4

Staff empowerment for decision making. OC5

Creation of a collaborative and synergistic work

environment.

OC6

Factor 7: Communication (CM)

Formal communication in the work environment. CM1

Informal communication in the work environment. CM2

Effective communication with all hierarchical levels. CM3

Fluent communication in physical and virtual spaces. CM4

KMIS 2025 - 17th International Conference on Knowledge Management and Information Systems

360

Table 2: Variables of innovation capabilities.

IC variables

Research an

d

Develo

p

ment

(

R&D

)

ca

p

abilit

y

RD

Mana

g

ement ca

p

abilit

y

MC

Resource availabilit

y

RA

Talent management HT

Staff skills SS

Technolo

g

ical ca

p

abilit

y

TC

The surveys were conducted using a Google form,

applied electronically from June to September 2021.

A total of 250 questionnaires were sent by e-mail to

the companies that were the subject of the study. Each

survey complied with ethical research standards:

informed consent, voluntary participation,

confidentiality and absence of physical or

psychological risk to participants.

3.3 Data Exploration and Preparation

Exploratory data analysis is a critical phase in the

modeling process as it provides valuable information

on the nature and quality of the data (Costa-Climent

et al., 2023). This phase is essential because its results

can influence decisions made during the modeling

process and improve the effectiveness and

interpretation of the resulting models.

Since both input and output variables are

quantitative, the multiple linear regression model

(MLR) was selected to analyze the relationship

between knowledge management variables and

innovation capabilities. The responses obtained in the

survey are on a scale of 1 to 10, so no obvious outliers

were identified. Consequently, it was not necessary to

perform histograms, boxplots or scatter plots to

explore the distribution of the data or to detect

possible outliers.

The relationships between each of the variables

that make up the different KM categories were

explored to detect multicollinearity of the

independent variables. Multicollinearity occurs when

two or more independent variables in a model are

highly correlated with each other (Lantz, 2023). The

presence of multicollinearity can cause several

problems in regression analysis, including instability

in coefficient estimation, increased coefficient

variance, and unreliable coefficients.

Correlation analysis between the KM variables

identified and eliminated 10 variables with

correlation coefficients greater than 0.7, indicating

high collinearity. As a result, 25 independent

variables were retained for further analysis.

3.4 Data Modeling and Analysis

The methodological approach adopted in this

research corresponds to supervised machine learning,

which consists of training models with labeled data,

i.e., with known values for both independent and

dependent variables (Burger, 2018).

To evaluate the impact of KM on IC in the

manufacturing industry, we chose to use a MLR

model. This choice is based on two main reasons:

first, the quantitative nature of all the variables

involved; second, the availability and sufficiency of

the data set, which allows adequate implementation

and validation of the proposed model.

The formal structure of the model is presented in

Equation 1. Six multiple linear regression models

were developed, the details of which are presented in

Table 3.

Table 3: Multiple linear regression models.

Model IC Knowledge management factors

Dependent

variable

(

Y

)

Independent variables (X)

1 Y1= RD

PS2, PS3, PS4, PS4, PS5, PS7,

OS1, OS2, OS4, OS5, TG3,

TG4, PP1, PP2, PP3, PP4, PP5,

IS1, IS2, IS3, IS4, OC1, OC5,

CM1, CM2, CM3

2 Y2= MC

3 Y3= RA

4 Y4= HT

5 Y5= SS

6 Y6= TC

3.5 Training, Validation,

Evaluation and Adjustment

The database used contains 142 records and 31

variables, of which 25 are associated with KM and six

with IC. To evaluate the performance of the

predictive model, the data were divided into two

subsets: training data (80 %) and test data (20 %).

To ensure a robust evaluation of the predictive

model and reduce the risk of overfitting, it was

necessary to apply a technique to estimate its

performance more reliably. In this study, cross-

validation was used, a common method in statistics

and machine learning that allows the predictive

capacity of a model to be evaluated. This technique

consists of dividing the data set into multiple training

and test subsets, training and evaluating the model on

different combinations of these subsets (Boehmke &

Greenwell, 2020). In particular, the K-fold technique

was applied, with ten folds, which allowed obtaining

more stable estimates by averaging the results of each

iteration, thus strengthening the validity of the

analysis.

Contribution of Knowledge Management to Innovation Capabilities in the Manufacturing Industry Through Machine Learning

361

A recipe was used to define a sequence of data

preprocessing steps, systematically applied to the data

sets prior to modeling. This recipe acted as a

standardized template, ensuring consistency in data

pre-processing. A workflow was then built to

implement the MLR, integrating both the model and

the steps defined in the recipe. This approach allowed

the model to be trained and evaluated in a consistent

and reproducible manner.

Model validation was carried out by calculating

the root mean squared error (RMSE), an indicator that

measures the dispersion of the residual errors. The

RMSE is obtained by calculating the root mean

square error between the model predictions and the

actual values observed in the test set. This value

provides a direct estimate of the average magnitude

of the prediction errors (Kuhn & Silge, 2022).

Where n is the number of observations in the test

set,

𝑦

are the actual values of the dependent variable

and 𝑦

are the predictions of the model for the

dependent variable. A model performs well the lower

the RMSE value and the closer this value resembles

the one obtained between the training and test data

(Kuhn & Silge, 2022). Both modeling and data

analysis were performed using the RStudio

programming language.

4 RESULTS

4.1 Relationship Between KM and

Research and Development

The relationship between KM and research and

development (R&D) was evaluated using a multiple

linear regression model RD=f(X)+ℇ. Table 4 shows

that two KM variables pertaining to factors such as

organizational structure and incentive system are

significant and have a direct relationship with R&D.

Table 4: KM variables that impact research and

development.

KM Coefficient Pr(>

|

t

|

)

OS1 0.28275 1.2e-05

IS2 0.22511 0.00073

Note: Adjusted R

2

=0.791; F=15.2; p-value (model)=< 2e

-16

.

The statistical results of the model indicate that it

is significant and viable as a whole. The model is

represented by the following function: RD= 0.28 OS1

+ 0.23 IS2, and presents an RMSE 1.29 which

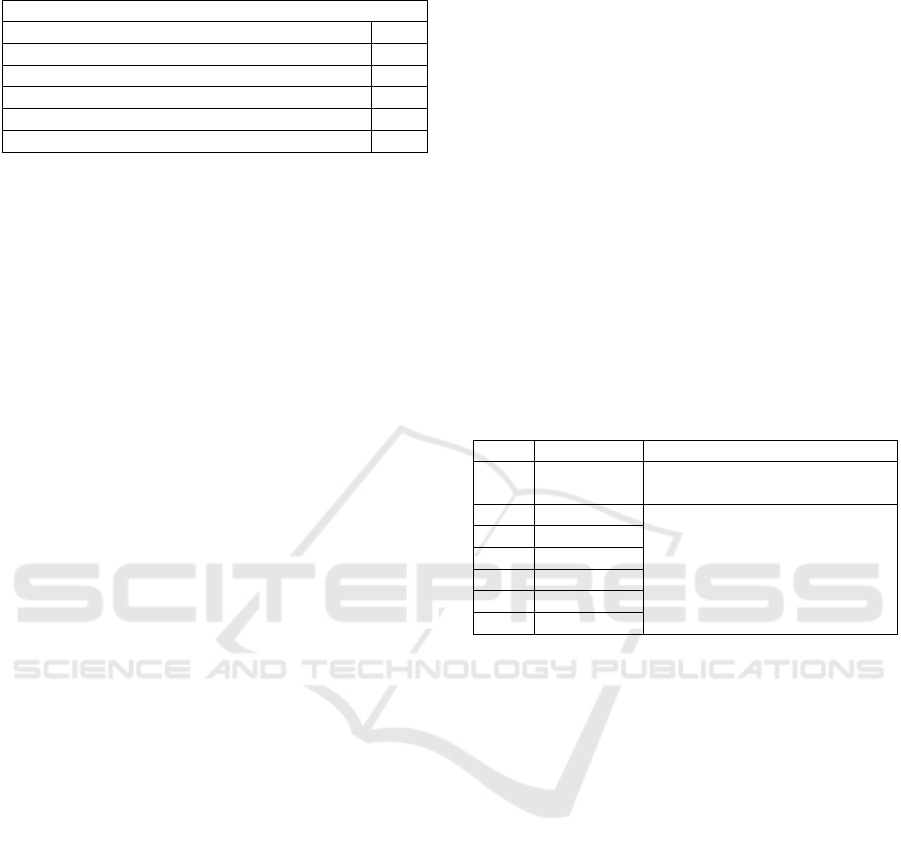

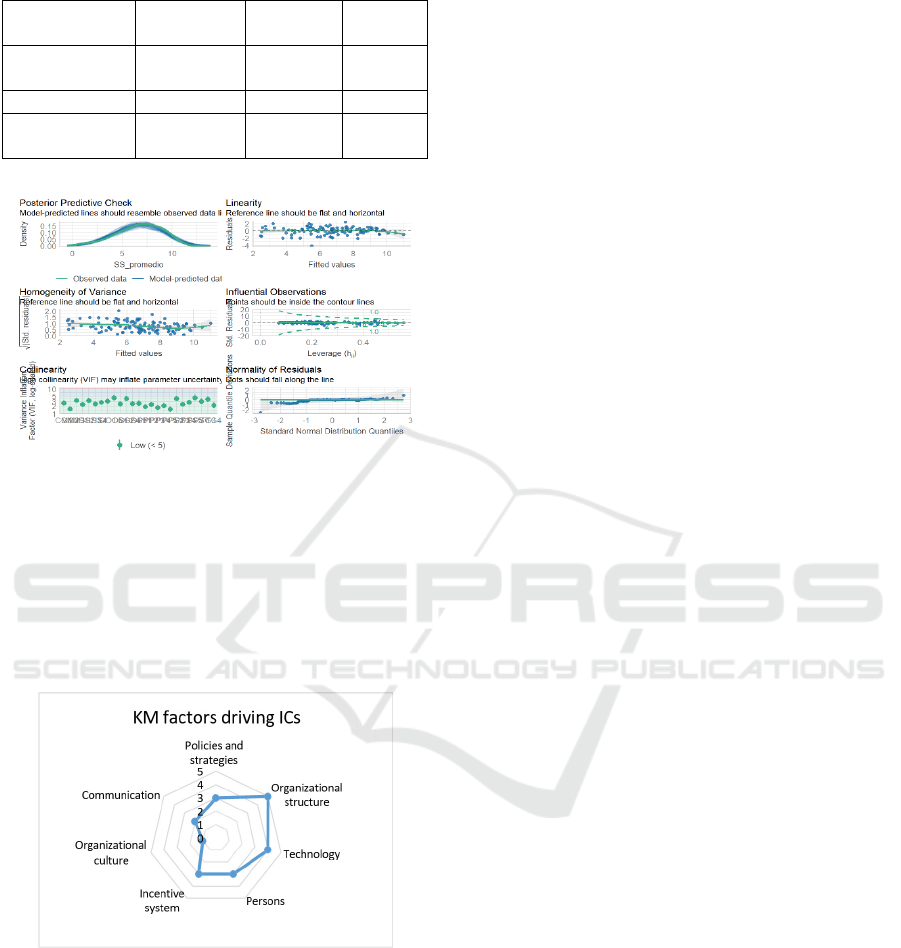

evidences a good fit of the model to the data. Table 5

reviews the statistical assumptions of the model,

while Figure 1 shows these results graphically.

Table 5: Statistical assumptions.

Supposed

Value

recommended

Value

obtained

Evaluation

N

ormality of

waste

P > 0.05 P=0.176 Ok.

Heterocedasticity P > 0.05 P=0.252 Ok.

Autocorrelated

residuals

P > 0.05 P= 0.184 Ok

Note: Statistics obtained from RSudio.

Figure 1: Graphs of statistical assumptions.

Note: Image obtained from RSudio.

4.2 Relationship Between KM and

Capacity Management

The relationship between KM and capability

management was assessed using a multiple linear

regression model MC=f(X)+ℇ. Table 6 shows that the

variable of KM belonging to the factor of

organizational structure is significant and have a

direct relationship with capability management. In

addition, a variable belonging to the Policies and

strategies category has a significant and indirect

relationship.

Table 6: KM variables that impact capacity management.

KM Coefficient Pr(>

|

t

|

)

OS1 0.17590 0.0074

PS2 -0.19049 0.0468

Note: Adjusted R

2

=0.699; F =11.3; p-value (model)=< 2e

-16

.

The statistical results of the model indicate that it

is significant and viable as a whole. The relationship

is expressed by the following function: MC = 0.18

OS1 - 0.19 PS2, and presents an RMSE of 1.38 which

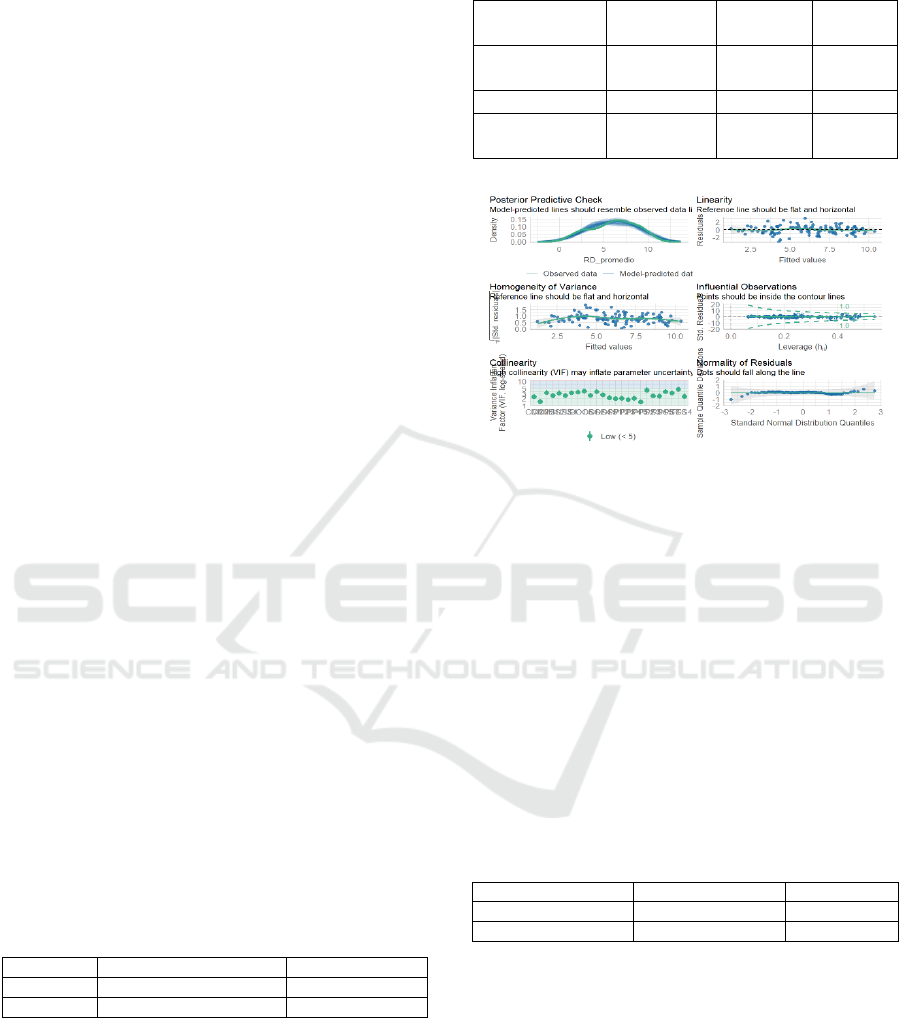

evidences a good fit of the model to the data. Table 7

reviews the statistical assumptions of the model,

while Figure 2 shows these results graphically.

KMIS 2025 - 17th International Conference on Knowledge Management and Information Systems

362

Table 7: Statistical assumptions.

Supposed

Value

recommended

Value

obtained

Evaluation

N

ormalit

y

of

waste

P > 0.05 P = 0.005 Warning

Heterocedasticity P > 0.05 P= 0.036 Warning

Autocorrelated

residuals

P > 0.05 P = 0.008 Warning

Note: Statistics obtained from RSudio.

Figure 2: Graphs of statistical assumptions.

Note: Image obtained from RSudio.

4.3 Relationship Between KM and

Resource Availability

The relationship between KM and resource

availability was evaluated using a multiple linear

regression model RA=f(X)+ℇ. Table 8 shows that a

variable of the KM belonging to the organizational

structure factor is significant and has a direct

relationship with the availability of resources.

Table 8: KM variables that impact resource availability.

KM Coefficient Pr(>

|

t

|

)

OS1 0.33728 6.9e-05

Note: Adjusted R

2

= 0.519; F = 5.84; p-value (model) = < 3.16e

-16

.

The statistical results of the model indicate that it

is significant and viable as a whole. The model is

represented by the following function: RA= 0.34

OS1, and presents an RMSE of 1.47 which

demonstrates a good fit of the model to the data. Table

9 reviews the statistical assumptions of the model,

while Figure 3 shows these results graphically.

Table 9: Statistical assumptions.

Supposed

Value

recommended

Value

obtained

Evaluation

N

ormalit

y

of

waste

P > 0.05 P= 0.444 Ok.

Heterocedasticity P > 0.05 P= 0.316 Ok.

Autocorrelated

residuals

P > 0.05 P = 0.002 Warning

Note: Statistics obtained from RSudio.

Figure 3: Graphs of statistical assumptions.

Note: Image obtained from RSudio.

4.4 Relationship Between KM and

Human Talent Management

The relationship between KM and human talent

management was evaluated using a multiple linear

regression model HT=f(X)+ℇ. Table 10 shows that

four KM variables belonging to the Policies and

Strategies, Organizational Structure, Technology,

and Incentive System factors are significant and have

a direct relationship with human talent management.

In addition, two variables belonging to the

Technology and People factors have a significant and

indirect relationship.

Table 10: KM variables that impact human talent

management.

KM Coefficient Pr(>

|

t

|

) KM Coefficient Pr(>

|

t

|

)

PS7 0.2687 0.0032 TG4 -0.1772 0.0051

OS1 0.1178 0.0481

PP3 -0.1914 0.0027

TG3 0.3611 7.6e-05

IS2 0.1771 0.0059

Note: Adjusted R

2

=0.782; F=16.8; p-value (model)=< 2e

-16

.

The statistical results of the model indicate that it

is significant and viable as a whole. The model is

represented by the following function: HT= 0.27 PS7

+ 0.12 OS1 + 0.36 TG3 - 0.18 TG4 - 0.19 PP3+0.18

IS2, and presents an RMSE 2.13 which evidences a

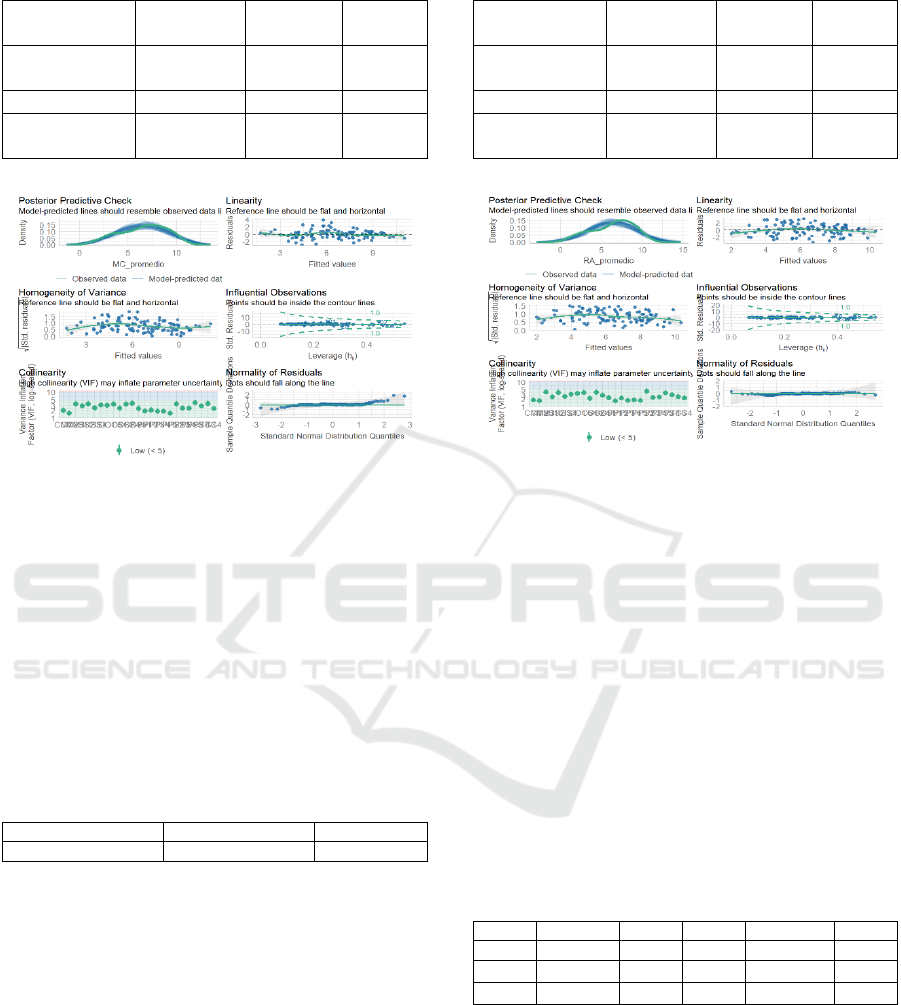

good fit of the model to the data. Table 11 reviews the

statistical assumptions of the model, while Figure 4

shows these results graphically.

Contribution of Knowledge Management to Innovation Capabilities in the Manufacturing Industry Through Machine Learning

363

Table 11: Statistical assumptions.

Supposed

Value

recommended

Value

obtained

Evaluation

N

ormalit

y

of

waste

P > 0.05 P= 0.263 Ok

Heterocedasticity P > 0.05 P= 0.195 Ok

Autocorrelated

residuals

P > 0.05 P= 0.080 Ok

Note: Statistics obtained from RSudio.

Figure 4: Graphs of statistical assumptions.

Note: Image obtained from RSudio.

4.5 Relationship Between KM and

Staff Skills

The relationship between KM and personnel skills was

evaluated using a multiple linear regression model SS=

f(X)+ℇ. Table 12 shows that six KM variables

belonging to the factors: Organizational Structure,

Technology, Incentive System, Organizational Culture

and Communication are significant and have a direct

relationship with personnel skills.

In addition, two variables belonging to the

factors: Policies and strategies, and People have a

significant and indirect relationship.

Table 12: KM variables that impact capacity management.

KM Coefficient Pr(>

|

t

|

) KM Coefficient Pr(>

|

t

|

)

PS2 -0.17438 0.0473 IS2 0.16199 0.0117

OS4 0.15421 0.0222

OC5 0.24729 0.0054

TG3 0.32457 0.0018

CM1 0.16080 0.0353

PP3 -0.14495 0.0190

CM2 0.12395 0.0146

Note: Adjusted R

2

=073; F=13; p-value (model)=< 2e

-16

.

The statistical results of the model indicate that it

is significant and viable as a whole. The model is

represented by the following function: SS= -0.18 PS2

+ 0.15 OS4 + 0.32 TG3 - 0.14 PP3 + 0.16 IS2 +

0.25 OC5 + 0.16 CM1 + 0.12 CM2, and presents

an RMSE 1.38 which evidences a good fit of the

model to the data. Table 13 reviews the statistical

assumptions of the model, while Figure 5 shows these

results graphically.

Table 13: Statistical assumptions.

Supposed

Value

recommended

Value

obtained

Evaluation

N

ormalit

y

of

waste

P > 0.05 P= 0.005 Warning

Heterocedasticity P > 0.05 P < 0.005 Warning

Autocorrelated

residuals

P > 0.05 P = 0.030 Warning

Note: Statistics obtained from RSudio.

Figure 5: Graphs of statistical assumptions.

Note: Image obtained from RSudio.

4.6 Relationship Between KM and

Technological Capabilities

The relationship between KM and technological

capabilities was evaluated using a multiple linear

regression model TC=f(X)+ℇ. Table 14 shows that

two KM variables belonging to the factors:

Technology and People are significant and have a

direct relationship with technological capabilities.

Table 14: KM variables that impact capacity management.

KM Coefficient Pr(>

|

t

|

) KM Coefficient Pr(>

|

t

|

)

TG3 0.43720 1.8e-05 PP4 0.16856 0.0024

Note: Adjusted R

2

=0757; F=14.8; p-value (model)=< 2e

-16

.

The statistical results of the model indicate that it

is significant and viable as a whole. The model is

represented by the following function: TC= 0.44 TG3

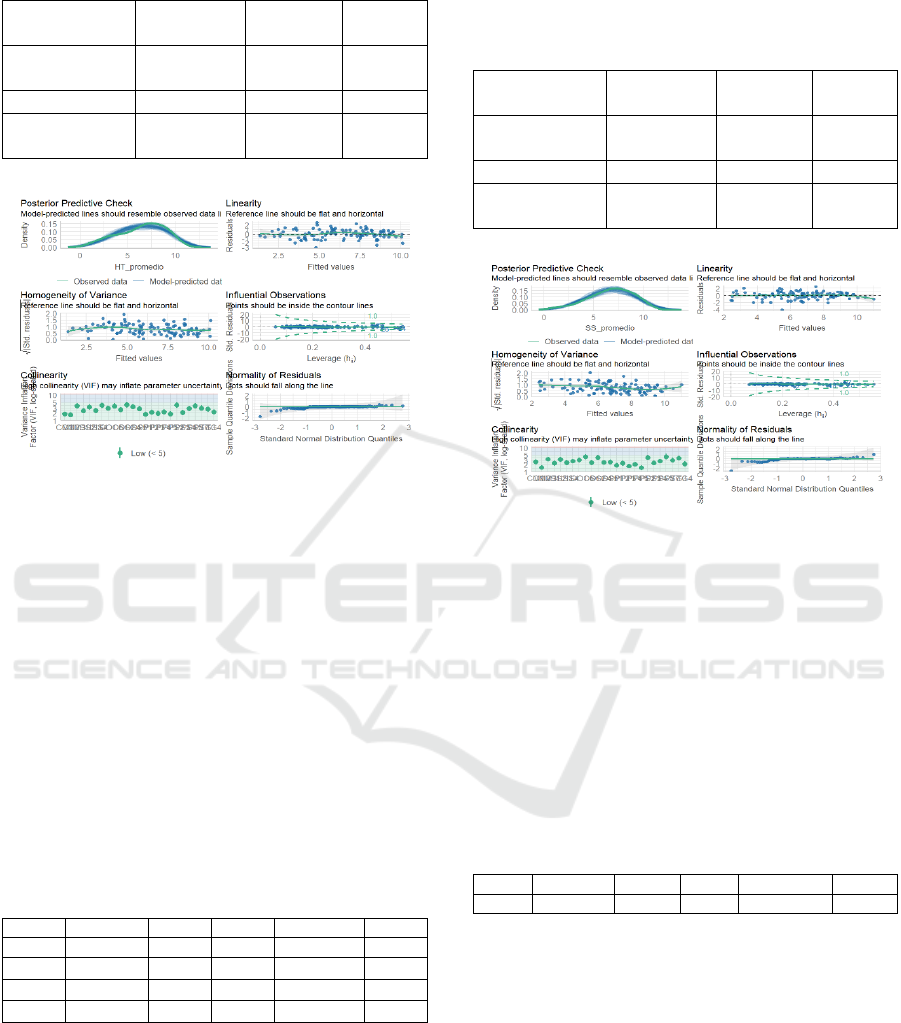

+ 0.17 PP4, and presents an RMSE 1.27 which

demonstrates a good fit of the model to the data. Table

15 reviews the statistical assumptions of the model,

while Figure 6 shows these results graphically.

KMIS 2025 - 17th International Conference on Knowledge Management and Information Systems

364

Table 15: Statistical assumptions.

Supposed

Value

recommended

Value

obtained

Evaluation

N

ormalit

y

of

waste

P > 0.05 P= 0.405 Ok.

Heterocedasticity P > 0.05 P= 0.440 Ok.

Autocorrelated

residuals

P > 0.05 P = 0.376 Ok

Note: Statistics obtained from RSudio.

Figure 6: Graphs of statistical assumptions.

Note: Image obtained from RSudio.

In summary, the results allow us to affirm that the

six models developed are viable. In all cases, the

RMSE values obtained with the training data were

similar to those obtained with the test data, which is a

favorable indication of the robustness of the models

and their adequate generalization capacity.

Figure 7: KM factors driving IC.

In addition, of the 35 KM variables, 12 have a

significant impact on the innovation capabilities of

manufacturing companies. Factors such as

Organizational Structure, Technology, People and

Incentive System are determinants for developing

innovation capabilities in the industrial

manufacturing sector, as shown in Figure 7. In

addition, the Variance Inflation Factor (VIF) was

found to be less than 5 in all six models, indicating

the absence of significant multicollinearity. Likewise,

a low correlation between the predictor variables was

verified and no outliers were identified that would

affect the analysis.

5 DISCUSSION

The results show that both organizational units

dedicated to R&D and training offered as an incentive

have a positive impact on IC in manufacturing firms.

This result supports what has been proposed by

Nonaka and Takeuchi (1995), who emphasize the

importance of structures that facilitate the creation

and transformation of knowledge, as well as by Teece

(2018) and Jiménez-Jiménez and Sanz-Valle (2011),

who point out that continuous training strengthens the

organizational dynamic capabilities needed to

innovate in competitive environments.

Regarding the relationship between KM and

capabilities management, the results show that

internal organizational units dedicated to R&D have

a positive and statistically significant impact on

innovation capabilities, in line with what was

proposed by Nonaka & Takeuchi (1995), who

emphasize the strategic role of structures that promote

knowledge creation. In contrast, policies related to the

storage, sharing and use of organizational knowledge

show a negative and significant impact, which could

reflect deficiencies in their design or an excessively

rigid implementation that limits organizational

flexibility and learning (Davenport & Prusak, 1998;

Teece, 2018).

Regarding the relationship between KM and

resource availability, the results are consistent with

previous findings in the academic literature: they

confirm the need to strengthen internal organizational

structures dedicated to R&D to boost IC development

within companies. Therefore, these results reinforce

the importance of strategically investing in such

structures as part of a comprehensive approach to

knowledge management for innovation.

The results also show that KM, when articulated

with practices such as the combination of existing and

new knowledge, the strengthening of internal R&D

structures, the use of ICT and incentivized training,

has a positive impact on innovation capabilities. This

finding is consistent with Nonaka and Takeuchi

(1995), who highlight the importance of integrating

tacit and explicit knowledge through organized and

technological environments, as well as with Teece

(2018) and Jiménez-Jiménez and Sanz-Valle (2011),

who emphasize the role of continuous training and

Contribution of Knowledge Management to Innovation Capabilities in the Manufacturing Industry Through Machine Learning

365

technological infrastructure as drivers of dynamic

capabilities.

On the other hand, negative effects associated

with the use of corporate social networks and the age

of personnel were observed. In the first case, although

some studies highlight their value for the informal

exchange of knowledge (Levy, 2009), others warn

that inappropriate use can lead to distraction or

dispersion of knowledge (Treem & Leonardi, 2012).

Regarding age, although experience is a relevant asset

(Kanfer & Ackerman, 2004), research has evidenced

that aging may be linked to lower technological

adaptability or resistance to change (Ng & Feldman,

2012). These findings suggest the need for strategies

that integrate generational diversity and optimize the

use of digital collaborative tools to enhance

organizational innovation.

Regarding the relationship between KM and

personnel skills, it was found that variables such as

the facilities for the horizontal flow of knowledge

within the organization; the application of ICT for

access, exchange and use of knowledge; the training

offered as an incentive to generate, share and use

knowledge; the empowerment of personnel for

decision making; formal and informal

communication in the work environment have a

positive and significant impact on the development of

innovation capabilities.

Although knowledge storage, sharing and use

policies, along with process documentation, are often

considered fundamental in KM (Davenport & Prusak,

1998), their negative impact on innovation may be

due to overly formalized and inflexible

implementation. This rigidity can limit autonomy,

inhibit creativity and move organizational practices

away from real collaborative dynamics (Nonaka &

Takeuchi, 1995; Teece, 2018). It is therefore

recommended to adopt a more adaptive and

participative approach, which transforms these

policies into facilitators of learning and innovation.

On the other hand, the results show that the

application of ICT and staff proficiency in foreign

languages have a positive and significant effect on IQ.

This finding coincides with Davenport and Prusak

(1998), who emphasize the key role of ICT in KM,

and with Cohen & Levinthal (1990), who point out

that language skills strengthen technological

absorptive capacity and organizational learning, key

factors for innovation.

5.1 Theoretical Implications

The results support Nonaka and Takeuchi's (1995)

proposals on the interaction between tacit and explicit

knowledge, and the role of organizational structures

in knowledge creation. In addition, the dynamic

capabilities model of Teece (2018), which relates

organizational infrastructure, learning and strategic

change, is empirically validated. The research

differentiates the positive impact of variables such as

R&D, training and ICT from the negative impact of

overly rigid policies and formal structures, providing

a more nuanced view of the functioning of KM.

Factors such as staff age and inadequate use of

internal social networks are introduced as potential

barriers to innovation, extending theories of

resistance to change and digital distraction. In

addition, the inclusion of language proficiency and

ICT management as predictors of innovation aligns

this research with the notions of "absorptive capacity"

proposed by Cohen & Levinthal (1990).

5.2 Practical Implications

Manufacturing companies should redesign their

knowledge storage and use policies, avoiding

rigidities that hinder creativity and organizational

learning. It is recommended to strengthen

organizational structures dedicated to R&D, as their

positive impact on innovation has been consistently

validated.

The training offered as an incentive should be

integrated as a systematic strategy to promote

innovation and not as an isolated benefit, as well as

technologies should be implemented with strategic

criteria, promoting the exchange of knowledge

without falling into the noise or digital distraction.

The companies analyzed should design programs

that integrate employees of different ages, promoting

the intergenerational transfer of knowledge and

reducing barriers to technological adoption. On the

other hand, encouraging foreign language proficiency

among staff can increase access to global knowledge

and improve technological absorption capacity.

6 CONCLUSIONS

The main objective of this study was the design and

development of predictive models by means of

multiple linear regression, applying supervised

machine learning techniques, with the purpose of IC

from the implementation of practices associated with

KM in companies of the manufacturing sector. In the

models developed, the independent variables

corresponded to KM dimensions, while the dependent

variables represented organizational IC.

KMIS 2025 - 17th International Conference on Knowledge Management and Information Systems

366

After the process of filtering and eliminating

variables with high collinearity, 25 variables linked to

seven key factors of corporate governance were

selected: policies and strategies, organizational

structure, technology, people, incentive system,

organizational culture and communication.

Innovation capabilities were operationalized through

indicators such as R&D capacity, management

capacity, resource availability, talent management,

personnel competencies and technological capacity.

Six regression models were developed, in which

12 KM variables with statistically significant effects

on IC were identified. Among the factors with the

greatest positive impact were organizational

structure, technology, people and incentives. These

results lead to the conclusion that the systematic,

coherent and strategic implementation of KM factors

in manufacturing companies can effectively predict

the development of innovation capabilities in

processes, products and services.

In summary, the findings of this research

reinforce the strategic value of KM as a driver of

organizational innovation and provide a useful

empirical framework to guide decision making and

the formulation of business policies that strengthen

competitiveness in the industrial sector.

6.1 Limitations and Future Studies

One of the limitations of this study is that corporate

governance is a relatively new topic for the

management of Ecuadorian business organizations.

This resulted in some difficulties in obtaining data

from the companies studied. To mitigate this

limitation, the surveys included sufficient

introductory information to facilitate respondents'

understanding and response to the questionnaire.

Based on the findings obtained in this research, it

is suggested to extend the methodological approach

by applying other machine learning algorithms, such

as neural networks, support vector machines (SVM)

or random forests, in order to contrast their predictive

capacity with the multiple linear regression models

used in this study.

On the other hand, it would be pertinent to expand

the context of application of the model to other

economic sectors, such as services, technology or

agribusiness, to evaluate the generalizability of the

results. Similarly, comparative studies between

countries or regions could provide a broader

understanding of how cultural, institutional and

technological differences affect the effectiveness of

KM practices on innovation capabilities.

REFERENCES

Aguilar-Barceló, J. G., & Higuera-Cota, F. (2019). Los

retos en la gestión de la innovación para América Latina

y el Caribe: un análisis de eficiencia. Revista CEPAL,

127, 1–20. https://www.cepal.org/es/publicaciones/

44570-retos-la-gestion-la-innovacion-america-latina-

caribe-un-analisis-eficiencia

Akerkar, R. (2019). Artificial Intelligence for Business.

Springer. https://doi.org/10.1007/978-3-319-97436-

1_3

Bertram, D. (2018). Likert Scales. http://poincare.

matf.bg.ac.rs/~kristina/topic-dane-likert.pdf

Boehmke, B., & Greenwell, B. (2020). Hands-On Machine

Learning with R. Taylor & Francis.

Bogodistov, Y., Presse, A., Krupskyi, O. P., & Sardak, S.

(2017). Gendering dynamic capabilities in micro firms.

RAE Revista de Administracao de Empresas,

57(3), 273–282. https://doi.org/10.1590/S0034-

759020170308

Bolisani, E., & Bratianu, C. (2018). Generic Knowledge

Strategies. In Emergent Knowledge Strategies (4th ed.,

Vol. 4, Issue July, pp. 147–174). Springer.

https://doi.org/10.1007/978-3-319-60657-6

Burger, S. (2018). Introduction to machine learning with

R : rigorous mathematical analysis.

Bykova, A., & Jardon, C. M. (2018). The mediation role of

companies’ dynamic capabilities for business

performance excellence: Insights from foreign direct

investments. the case of transitional partnership.

Knowledge Management Research and Practice, 16(1),

144–159. https://doi.org/10.1080/14778238.2018.

1428070

Camisón-Haba, S., Clemente-Almendros, J. A., &

Gonzalez-Cruz, T. (2019). How technology-based

firms become also highly innovative firms? The role of

knowledge, technological and managerial capabilities,

and entrepreneurs’ background. Journal of Innovation

and Knowledge, 4(3), 162–170. https://doi.

org/10.1016/j.jik.2018.12.001

CEPAL. (2016). Ciencia, tecnología e innovación en la

economía digital. La situación de América Latina y el

Caribe. In Segunda Reunión de la Conferencia de

Ciencia, Innovación y TIC de la (Comisión Económica

para América Latina y el Caribe. https://doi.

org/10.1017/CBO9781107415324.004

Chang, W. J., Liao, S. H., & Wu, T. Te. (2017).

Relationships among organizational culture, knowledge

sharing, and innovation capability: A case of the

automobile industry in Taiwan. Knowledge

Management Research and Practice, 15(3), 471–490.

https://doi.org/10.1057/s41275-016-0042-6

Cohen, W. M., & Levinthal, D. A. (1990). Absorptive

Capacity: A New Perspective on Learning and

Innovation. Administrative Science Quarterly, 35, 128–

152.

Costa-Climent, R., Haftor, D. M., & Staniewski, M. W.

(2023). Using machine learning to create and capture

value in the business models of small and medium-

sized enterprises. International Journal of Information

Contribution of Knowledge Management to Innovation Capabilities in the Manufacturing Industry Through Machine Learning

367

Management, 73(January), 102637. https://doi.org/10.

1016/j.ijinfomgt.2023.102637

Davenport, T. H., & Prusak, L. (1998). Knowledge

Generation. In Working Knowledge: How

Organizations Manage What They Know (p. 226).

Harvard Business School Press.

Davila, G., Varvakis, G., & North, K. (2019). Influence of

strategic knowledge management on firm

innovativeness and performance. Brazilian Business

Review, 16(3), 239–254. https://doi.org/10.15728/

bbr.2019.16.3.3

Dutta, S., Lanvin, B., Lorena, R., & Wunsch-Vincent, S.

(2021). Global Innovation Index 2021. In S. Dutta, L.

Rivera León, & S. Wunsch-Vincent (Eds.), Cornell,

INSEAD, WIPO (14th ed.). World Intellectual Property

Organization. https://doi.org/10.34667/tind.44315

Espindola, D., & Wright, M. (2021). Leading a Culture of

Change. In The Exponential Era (pp. 137–151). IEEE.

Hastie, T., Tibshirani, R., James, G., & Witten, D. (2023).

An Introduction to Statistical Learning. In Springer

Texts (2nd ed., Vol. 102).

Ibujés-Villacís, J., & Franco-Crespo, A. (2024).

Relationship Between the Factors that Influence the

Management of Innovation in the Manufacturing

Industry of Pichincha, Ecuador. Journal of Innovation

Management, 12(3), 24–55. https://doi.org/10.

24840/2183-0606_012.003_0002

Jiménez-Jiménez, D., & Sanz-Valle, R. (2011). Innovation,

organizational learning, and performance. Journal of

Business Research, 64(4), 408–417. https://doi.org/10.

1016/j.jbusres.2010.09.010

Kanfer, R., & Ackerman, P. L. (2004). Aging, Adult

Development, and Work Motivation. The Academy of

Management Review, 29(3), 440. https://doi.org/10.

2307/20159053

Kaur, V. (2019). Review of Literature. In Knowledge Based

Dynamic Capabilities. The Road Ahead in Gaining

Organizational Competitiveness (pp. 21–78). Springer.

https://doi.org/10.1007/978-3-030-21649-8

Kesavan, P. (2021). Literature Review. In Enablers of

organisational learning, knowledge management, and

innovation. Principles, process, and practice of

qualitative data (pp. 21–66). Springer. https://doi.org/

10.1007/978-981-15-9793-0

Kodama, M. (2018). Collaborative Dynamic Capabilities:

The Dynamic Capabilities View. In Collaborative

Dynamic Capabilities for Service Innovation - Creating

a New Healthcare Ecosystem (pp. 1–45). Palgrave

Macmillan. https://doi.org/10.1007/978-3-319-77240-0

Kuhn, M., & Silge, J. (2022). Tidy Modelling with R

(1st ed.). O’Reilly Media, Inc. https://www.tmwr.org/

Lantz, B. (2023). Machine Learning with R (4th ed., Vol. 4,

Issue 1). Packt Publishing Pvt Ltd. www.packt.com

Latpate, R., Kshirsagar, J., Kumar Gupta, V., & Chandra,

G. (2021). Simple Random Sampling. In Advanced

Sampling Methods (pp. 11–36). Springer. https://doi.

org/10.1007/978-981-16-0622-9

Levy, M. (2009). WEB 2.0 implications on knowledge

management. Journal of Knowledge Management,

13(1), 120–134. https://doi.org/10.1108/1367327091

0931215

Lohr, S. L. (2019). Simple Probability Samples. In

Sampling. Design and Analysis (2nd ed., pp. 25–72).

CRC Press.

Manning, M. Jr., & Manning, M. Sr. (2020). Knowledge

Assets Management. In Total Innovative Management

Excellence (TIME). The Future of Innovation (pp. 354–

398). CRC Press.

MIPRO. (2021). Cifras de industrias. In Gobierno

del Ecuador. https://www.produccion.gob.ec/wp-

content/uploads/2021/06/Presentación-Industria-Junio-

2021.pdf

Nakamori, Y. (2020). Innovation Theory. In Knowledge

Construction Methodology. Fusing Systems Thinking

and Knowledge Management (pp. 1–18). Springer.

https://doi.org/10.1007/978-981-13-9887-2_5

Ng, T. W. H., & Feldman, D. C. (2012). Evaluating Six

Common Stereotypes About Older Workers with Meta-

Analytical Data. Personnel Psychology, 65(4), 821–

858. https://doi.org/10.1111/peps.12003

Nonaka, I., & Takeuchi, H. (1995). The knowledge

Creating Company: How Japanese Companies Create

the Dynamics of Innovation. Oxford University Press.

North, K., & Kumta, G. (2018). Knowledge in

Organisations. In Knowledge Management. Value

Creation Through Organizational Learning (2nd ed.,

pp. 33–66). Springer. http://www.springer.com/series/

10099

Obeidat, B. Y., Al-Suradi, M. M., Masa’deh, R., & Tarhini,

A. (2016). The impact of knowledge management on

innovation: An empirical study on Jordanian

consultancy firms. Management Research Review,

39(10), 1214–1238. https://doi.org/10.1108/MRR-09-

2015-0214

Ode, E., & Ayavoo, R. (2020). The mediating role of

knowledge application in the relationship between

knowledge management practices and firm innovation.

Journal of Innovation and Knowledge, 5(3), 210–218.

https://doi.org/10.1016/j.jik.2019.08.002

OECD, & Eurostat. (2018). Oslo Manual 2018: Guidelines

for Collecting, Reporting and Using Data on

Innovation (4th ed., Issue October). OECD. https://doi.

org/10.1787/9789264304604-en

Ott, R. L., & Longnecker, M. (2016). Inferences About

Population Central Values. In An Introduction to

Statistical Methods & Data Analysis (Seventh, pp. 232–

299). Cengage Learning.

Pagani, M., & Champion, R. (2024). Artificial Intelligence

for Business Creativity. Routledge. https://doi.org/10.

4324/9781003287582

Qin, W. (2024). How to unleash frugal innovation through

internet of things and artificial intelligence: Moderating

role of entrepreneurial knowledge and future

challenges. Technological Forecasting and Social

Change, 202

(July 2023), 1–9. https://doi.org/10.

1016/j.techfore.2024.123286

Salmador, M. P., Kaminska, R., & McKelvey, B. (2021).

Digital dynamic capabilities. In Management in the Age

KMIS 2025 - 17th International Conference on Knowledge Management and Information Systems

368

of Digital Business Complexity (pp. 153–181).

Routledge. https://doi.org/10.4324/9780429278211

SENESCYT-INEC. (2015). Principales indicadores de

actividades de ciencia, tecnología e innovación. In

Secretaría de Educación Superior, Ciencia, Tecnología

e Innovación. https://www.ecuadorencifras.

gob.ec/documentos/web-inec/Estadisticas_Economicas/

Ciencia_Tecnologia-ACTI/2012-2014/presentacion_

ACTI.pdf

Shmueli, G., Bruce, P., DeoKar, A., & Patel, N. (2023).

Machine Learning for Business Analytics (Vol. 5, Issue

1). Wiley.

SUPERCIAS. (2020). Ranking de compañías. In Ranking

empresarial del Ecuador. https://appscvs.supercias.

gob.ec/rankingCias/

SUPERCIAS. (2021). Ranking de compañías. In

Superintendencia de Compañías, Valores y Seguros.

https://appscvs.supercias.gob.ec/rankingCias/

Szczepańska-Woszczyna, K. (2021). Innovation and

Innovativeness. Determinants of the Innovativeness of

an Organisation. In Management Theory, Innovation

and Organisation (pp. 95–140). Routledge.

https://doi.org/10.4324/9781003057123

Teece, D. J. (2018). The Foundations of Dynamic

Capabilities. In Dynamic Capabilities and Strategic

Management (pp. 82–112). Oxford University Press.

Treem, J. W., & Leonardi, P. M. (2012). Social media use

in organizations: Exploring the affordances of

visibility, editability, persistence, and association.

Communication Yearbook 36, 143–189. https://doi.

org/10.1080/23808985.2013.11679130

Weber, F. (2023). Artificial Intelligence for Business

Analytics: Algorithms, Platforms and Application

Scenarios. In Artificial Intelligence for Business

Analytics: Algorithms, Platforms and Application

Scenarios. Springer. https://doi.org/10.1007/978-3-

658-37599-7

Zawislak, P. A., Fracasso, E. M., & Tello-Gamarra, J.

(2018). Technological intensity and innovation

capability in industrial firms. Innovation &

Management Review, 15(2), 189–207. https://doi.

org/10.1108/inmr-04-2018-012.

Contribution of Knowledge Management to Innovation Capabilities in the Manufacturing Industry Through Machine Learning

369