Eccentricity-Based Diameter Measurement: A Novel Approach for

Quality Control

Jayant Kulkarni

a

, Sanika Patankar

b

, Ananya Sharma

c

, Atharva Ansingkar

d

,

Sarvesh Bajare

e

and Sarthak Biyani

f

Department of Instrumentation and Control, Vishwakarma Institute of Technology, Pune, India

Keywords: Eccentricity, Line-of-Sight Angle, Improved Accuracy, Perspective, Quality Control, Mechanical Industry.

Abstract: On-line diameter measurement is essential in producing round extruded products, as defects can lead to

significant losses in production effort and resources. Traditional mechanical sampling inspections have been

replaced by contact-free, inline measurement systems that continuously monitor diameter along the

production line. While these systems effectively detect circular shapes and measure radius, they often struggle

with position artifacts, leading to measurement errors. To achieve improved accuracy and precision, it is

crucial to incorporate considerations of non-orthogonality into the image processing algorithm. Methods such

as feature extraction and image segmentation are utilized to identify abnormalities. Additionally, integrating

machine learning models enables real-time quality assessment and automated decision-making. However, the

Hough Circle Transform, though effective for detecting circles, has limitations, including sensitivity to noise,

computational intensity, and challenges in identifying occluded or imperfectly circular objects. This paper

proposes a novel method to measure the diameter of a circle based on its eccentricity. The method involves

analyzing captured images for edge detection and eccentricity measurement at various angles relative to the

camera lens. Additionally, it establishes a relationship between the line-of-sight angle, the eccentricity of the

perceived ellipse, and the diameter of the actual circle. The results obtained are compared with those achieved

using the Hough Circular Transform (HCT), demonstrating improved accuracy with the proposed method.

This study presents a practical solution for enhancing quality control in the mechanical industry, addressing

current needs with an inclusive and error-resistant approach.

1 INTRODUCTION

Accurate circle detection is a critical challenge in

computer vision that plays a vital role in object

recognition and decision-making systems, with wide-

ranging applications across various practical

domains. A broad spectrum of applications such as

optical character recognition used in banks, drone

vision, biomedical scans recognition, vectorization of

hand-drawn sketches, quality control of

manufactured products and components, crowd

management in surveillance video, etc (Le, Duan, et

al. 2016).

a

https://orcid.org/0000-0001-8154-2271

b

https://orcid.org/0000-0002-9179-6379

c

https://orcid.org/0009-0005-7198-6908

d

https://orcid.org/0009-0008-0841-8010

e

https://orcid.org/0009-0007-3871-6943

f

https://orcid.org/0009-0003-5089-8082

With the extended scope of applications, so does

the need for circle detection algorithms to improve

their performance. The vast range of applications

poses a greater challenge for an integrative approach.

An example would be rounded objects in three

dimensions like shadows and illumination from

angles and intensity such as shaded and unshaded

sources which can lead to under or over exposed

details on digital images (Mehmood, Khan et al.

2019), with which the accuracy may suffer from

detection. Controlled conditions may somehow

dampen some of these effects, but they cannot prevent

distortions in perception or difficulties with sorting

and classification because of different object

Kulkarni, J., Patankar, S., Sharma, A., Ansingkar, A., Bajare, S. and Biyani, S.

Eccentricity-Based Diameter Measurement: A Novel Approach for Quality Control.

DOI: 10.5220/0013651100004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 3, pages 741-748

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

741

perspectives. These can therefore defeat the purpose

of simulating an image which is as similar as possible

to the actual one (Teo, Heeger, et al. 1994). The

Hough Transform is a very traditional circle-

detection algorithm (Ou, Deng, et al. 2022); it has,

however, particularly important limitations as for

tasks which are prone to perception distortions with

orientations of the objects or non-orthogonal

placement relative to the camera.

One of the ways through which these challenges

overcome is use of the measures of ellipticity of

shapes. Such might be among the best pictures that

are used to represent the distorted circle in images

(Singh, et al. 2020). Innovative methods have to

come into place since successful production in most

cases has its basis in novel approaches other than the

conventional algorithms and traditional techniques

(Somwang, Muangklang, et al. 2019). This study

aims to address these limitations by including

advanced algorithms adapted to perception-related

issues, thus enhancing the reliability of circle

detection in varied conditions. Another feature used

in the system is the utilization of machine learning

algorithms in minimizing the errors of measurement

perceived for circular objects. The designed system

was mainly to be used in manufacturing mechanical

components. An axial joint (Cholke et al. 2024) was

analyzed in simulated environments where a radius

and a circumference of circular ends of the joint were

measured on both sides by using the application of

image processing techniques. Those results were

compared with already predefined values of used

parameters. The above-stated results were accurate

up to the nearest expected tolerance; therefore, they

were close to the expected results.

In general, this will enhance and automate the

quality control process for better precision, speed,

and cost efficiency. The system provided herein in a

design environment that is tailored for the precise

capture, processing, and classification of objects

effectively addresses the key obstacles while meeting

the objectives of this study. This proposed system is

a feasible solution with promising applications in the

mechanical manufacturing industry.

2 LITERATURE REVIEW

Quality control within the manufacturing industry has

been traditionally a labor-intensive process through

manual inspection to determine defects and ensure

consistency. This has all changed with the advent of

image processing, as this approach now makes it

possible for fast, accurate, and near-real-time

assessment of production lines through the detection

of shapes such as the circular Hough Transform

developed, as described by B. S. Singla et al., as an

appropriate circle-detecting technique. However, the

stretched ellipses are not included, and the transform

is selective only for the circles (Singh, et al. 2020)

which negates the perceived view of the circle as a

result of positioning. Another intriguing approach is

by Changsheng Lu et al. (Lu, Xia, et al. 2017) who

utilize the arc-support line segment (LS) technique

that identifies arc-like line segments through areas

where a set of points reveal a gradient angle with

varied changes in curve form. This method differs

arc-support LS from regular line-support regions that

include points with approximately aligned gradient

angles and a linear distribution. Still, the main

weakness of this method is that it fails to classify

ellipses as circles when they do not lie orthogonally

in front of the camera, which in most cases means it

is rather inefficient in cases with non-uniform

orientation of the object. Theoretically, this procedure

can be generalized to circles, ellipses, conics in

general, and curves of any number of parameters.

However, the parameter space increases

exponentially with every additional parameter, so the

technique becomes not so efficient in terms of storage

and computational time when a curve requires more

than four or five parameters that introduce new

memory processing challenges for real-time

applications. Getting fewer parameters for better

detection image enhancement is also an equally

important task, as mentioned and discussed by

Yousaf Mehmood et al. (Mehmood, Khan et al.

2019).

Great advancement is brought about through the

integration of machine learning algorithms (Cholke

et al. 2024), improving the system for real-time

analysis and promoting more accurate detection, with

automatic decisions in this regard, thus attaining

much more efficient and reliable quality control.

Fikret Ercan et al. and Tiantian Hao et al. (Ercan,

Qiankun, et al. 2020), (Hao, and Xu, 2022) these

early circle detection methods, especially through

genetic algorithms and learning automata techniques,

prove to be computationally intensive when detecting

several circles in an image. Of late, with the rise in

the use of deep learning algorithms, more

effectiveness in object detection is marked in

complex environments. Ercan et al. can get higher

accuracy using fewer layers and quicker processing

speed of networks in even challenging scenarios, such

as under-water images with poor illumination

conditions. Hao et al. proposed a circle detection

model based on the combination of CNN via the

INCOFT 2025 - International Conference on Futuristic Technology

742

method of edge feature extraction and FCOS

detection network. However, the above methods are

silent in the face of other challenges such as detecting

ellipses as circles when objects oriented non-

orthogonally with respect to the camera due to

variations in depth and positioning. A more

sophisticated approach could include elliptical

perception into the process of detection in order to

achieve a greater level of accuracy under the same

scenarios.

Our proposed approach overcomes several

limitations that remain in the circle detection methods

of current approaches. Most of the available methods

have overlooked the impact of environmental factors-

illumination intensity and direction-leading to

erroneous results in cases where they are applied in

real-world environments. The approach developed

works under controlled conditions that prevent the

implementation of inaccuracies with regard to depth

capture and remove variation in shadow. Further,

whereas most vision algorithms dismiss the

orthogonality of objects with the camera lens, our

approach incorporates this, which would be

characterized to be a flaw in perception due to non-

alignment. Furthermore, since we realize that the

circles are only seen as ellipses at any nonorthogonal

view angles, we associate eccentricity with the

relative orientation of the object with respect to the

camera and attain more accurate classification of the

ellipses that are probable to be circles with exact

diameter measurement. This is a holistic solution,

which is a great improvement in quality control

systems, especially the mechanical industry, where

measurements are always critical. The approach our

circle detection method provides will improve on

accuracy and reliability in general quality control

processes, thus contributing to more efficiency and

reduced costs of production.

3 METHODOLOGY

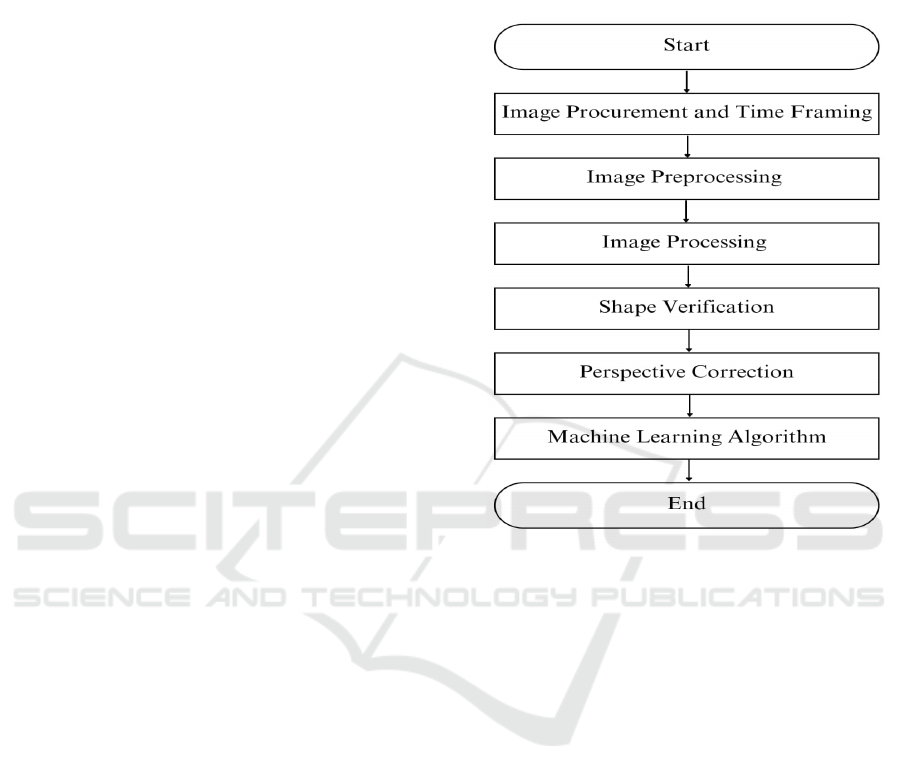

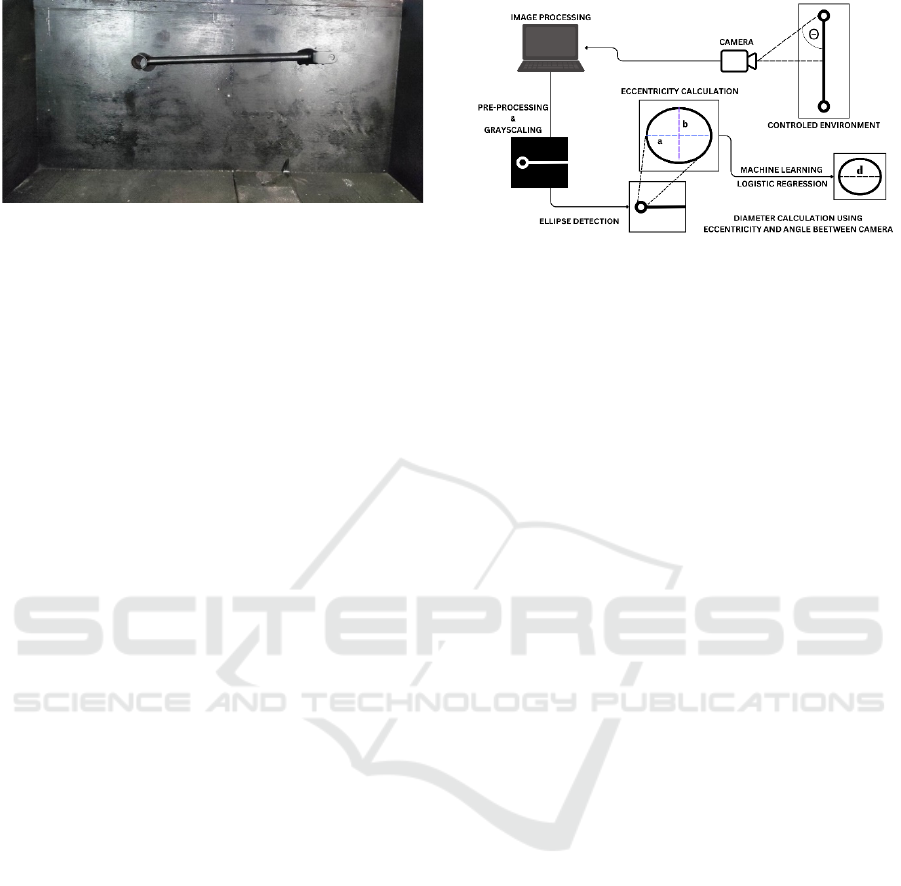

The proposed system's process flow, shown in Fig. 1,

offers a clear, step-by-step summary of processes,

showing how tasks and data move through various

phases. Fig. 2 presents the hardware structure of the

proposed system, offering a visual representation of

the design and logical flow. This highlights the

smooth integration of components to ensure efficient

functionality. Additionally, Fig. 3 illustrates the

system's architecture, showing the integration

between components for constructive functionality.

3.1 Hardware Setup

The proposed system operates within a controlled

environment.

Fig. 1: Process Flow of Proposed Quality Control System

Key features of the hardware setup are as follows:

The setup is isolated from ambient light by

enclosing it in a black box, ensuring complete

blockage of external illumination.

Reference (Cholke et al. 2024) thoroughly

explains the constrained setup where the

internal lighting is carefully measured and

maintained at an optimal level using the light

intensity testing setup.

The object of experimentation—a mechanical

rod with rings on each end—is positioned

orthogonally to the camera within a measured

distance which, with balanced and appropriate

lighting on both sides. This distance between

the rod and camera is unchanged throughout

the experiment.

The camera is connected to the processing unit

through a LAN cable for data communication

and M12 8-pin barrel cable for power supply.

Eccentricity-Based Diameter Measurement: A Novel Approach for Quality Control

743

Figure 2: Hardware Setup

This entire setup ensures that physical parameters

remain constant, supporting consistency and accuracy

in the results.

3.2 Software Setup

The software setup seamlessly integrates with the

hardware by processing images captured within the

controlled environment, ensuring systematically

organized, high-quality data for accurate and reliable

analysis.

3.2.1 Procuring Images and Time Framing

Images of the mechanical rod are captured within the

controlled environment using a high-resolution

industrial camera with a 3-megapixel sensor. Each

image is carefully tagged with relevant metadata and

timestamped to facilitate detailed and accurate

analysis in subsequent processing st ages. This

approach ensures that all captured data is

systematically organized, enabling efficient tracking

and comparison across different time frames for

enhanced analytical accuracy.

3.2.2 Image Preprocessing

In our project workflow, image preprocessing was the

first major step where raw images were refined so that

they could be of quality and consistency. Brightness

and contrast were adjusted, colors normalized, and

excess data filtered out. These steps produced

uniform images data, which led to better accuracy in

subsequent stages, such as feature extraction, object

detection, and measurement, hence always leading to

reliable and accurate analytical results.

Figure 3: Architecture of Proposed Quality Control

System

3.2.3 Image Processing

After the pre-processing step, the image was

first converted to grayscale, simplifying the

algorithm and reducing computational

requirements by transforming the image from

3-channel RGB format into a single-channel

grayscale format, then blurring was done with

the median filter with kernel size 3x3 to

suppress noise. The Median kernel used for this

system is shown in Equation 1.

𝑥1 𝑥2 𝑥3

𝑥4 𝑥5 𝑥6

𝑥7 𝑥8 𝑥9

The Hough Gradient method is then applied to

identify circle center candidates and measure

the distance from each side of the detected

edge, using the Canny method around the

center.

This iterative action of finding the ideal

distance which would suit to be the radius

creates a list of “n” tuples where the circle C is

represented by the parameter tuple

(xcenter,ycenter,r) in which xcenter and

ycenter denote the coordinates of the circle's

center, and r represents its plausible radius. The

distance from the image center to the center

detected center is also measured and stored for

calculation in subsequent steps.

3.2.4 Axis Identification and Foci

Calculation for Ellipse Verification

For each detected center, all listed radius values are

doubled and assessed as potential lengths of the major

and minor axes, where the major axis is the longest

and the minor axis is the shortest, with both axes

perpendicular to each other, as required by the

x

5 = Median(

{

x

1,x2,x3,x4,x5,x6,x

7

,x8,x9

}

) (1)

INCOFT 2025 - International Conference on Futuristic Technology

744

properties of an ellipse. Finally, the foci are

calculated using Equation 2, where c represents the

distance from the center, and a and b denote the

lengths of the semi-major and semi-minor axes,

respectively. The existence of these foci confirms that

the detected values correspond to an ellipse.

𝑐 √𝑎

𝑏

2

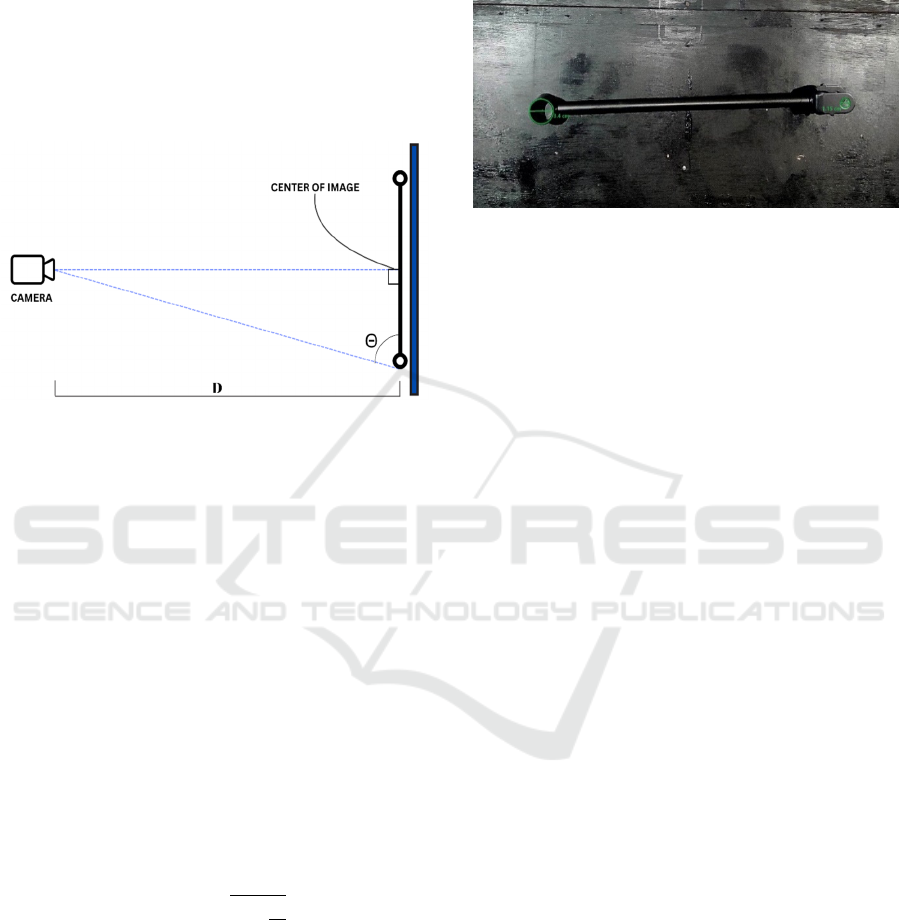

Figure 4: Camera and Line of sight angle relationship

3.2.5 Calculating Ellipticity and Camera-

Angle Relationship Using Geometric

Analysis

Using these verified values, the ellipticity e of the

ellipse is calculated as shown in Equation 3. Next, the

straight-line distance from the center of the ellipse to

the camera, along with the angle Θ it forms with the

image plane as shown in Fig. 4, is determined using

the Pythagorean theorem. This calculation is possible

because the orthogonal distance from the rod to the

camera is known, and the distance from the image

center to the detected center was established in the

previous step. This step also establishes a relationship

between the ellipse's ellipticity and its angle relative

to the camera.

𝑒

1

(3)

𝑒,cosΘ ∝ 𝑑 (4)

3.2.6 Perspective Correction Using Logistic

Regression

Using these parameters, e, and Θ, the multivariable

logistic regression model takes these values as inputs.

This model, based on labelled data and guided by

Equation 4 with d being the diameter of the circle,

will determine if the center found along with the

measured ellipse values correspond to a true circle

with predicted diameter that happens to appear

elliptical due to the perspective it is viewed from.

Figure 5: Correctly Detected circle diameter on rod using

Proposed Method

Finally, the measured diameter of circles is

annotated on the image accurately as shown in Fig. 5.

This integrated proposed process helps to determine

if the detected ellipses are true circles with precision

diameter prediction.

4 RESULTS AND DISCUSSIONS

Suitable Environmental Conditions: The control of

environment used in the controlled environment setup

was responsible for the accuracy and consistency of

the results obtained. The perfect control of

environmental parameters helped assure that physical

conditions were stable during the experiment, and

thus, led to reliable and reproducible results. As

alterations in depth perception because of light can

pose a challenge in the proposed flow, controlling the

ambient light with an enclosure and installation of

lights with fixed illumination proved to be of

immense benefit. The controlled setting thus proved

instrumental in achieving consistent and accurate

measurements, further validating the findings as

repeatable. This setup is considerably recommended

for the mechanical industry to achieve proper quality

control-that is why it becomes so invaluable in its

application, especially for ensuring the highest

standards of mechanical manufacturing processes.

Verifying the presence of Ellipse: In order to

verify the existence of an ellipse, the given problem

was actually important to determine if the circle was

to be well defined. The identification of axes and foci

calculation are important steps in this verification

process. This phase of the methodology brings a

differentiating factor between the proposed method

and other methods currently in use within the

industry. With rigorous identification of an ellipse

Eccentricity-Based Diameter Measurement: A Novel Approach for Quality Control

745

before finding the circle, the method strengthens the

reliability and accuracy of the findings. Ability to

detect slight changes in the characteristics of the

ellipse allows for more accurate quality control,

particularly in industries requiring precision, such as

the mechanical and manufacturing industries.

Final calculation: The relationship found then

forms the core of the proposed algorithm, which

significantly generalizes what has been previously

known. It led to the understanding of how the

eccentricity of an observed ellipse is connected with

the angle at which the center of this ellipse makes

with the camera lens. As the experiment results show,

with further movement of the circular part of the rod

away from the center, it started behaving like an

ellipse, which has its eccentricity close to the value

one. The eccentricity will be zero for a circle that is

exactly at the center. This relationship thus offers

deeper insight to the geometrical behavior of the

object and forms a solid ground for further refinement

of the quality control process. Thus, this proposed

method brings clarity and precision in the

identification of even minor deviations in the object

for maintaining high-quality standards in production

environments.

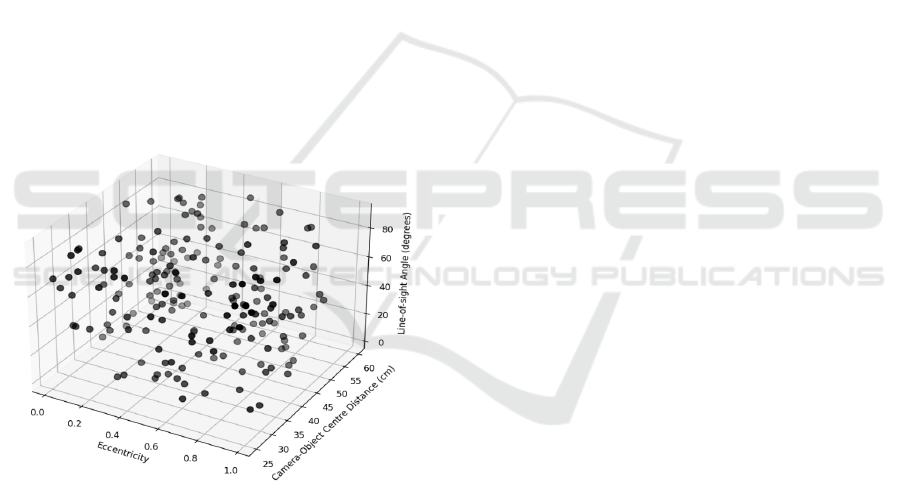

Figure 6: Plot of Multivariable Logistic Regression Model

Machine Learning Outcome: The observations

made and structured into a dataset provided

foundational results that confirmed the relationship

discussed in Equation 1. This dataset served as the

basis for further analysis, offering valuable insights

that are crucial for improving the accuracy of the

quality control system. The plot of Logistic

Regression in fig. 6 shows 200 sample data points

correctly tagged for building the model. It shows how

the multiple variables are co-related. The derived

relationship is crucial and base for measuring

diameter for further test objects. Machine learning

algorithms applied to this data enhanced the system's

predictive capabilities, making it more adaptive and

efficient. As the system processes more data, it

improves its ability to identify patterns and

anomalies, thereby achieving higher precision in

quality control. Additionally, it aids in detecting edge

cases, ensuring that after a certain extent perceived

ellipse is correctly identified as a true ellipse and not

mistakenly classified as a circle. This approach not

only validates the underlying theory but also

demonstrates the power of integrating advanced data

analytics in industrial applications. The positive

results validate the potential of machine learning to

optimize processes, contributing to reduced defects

and greater consistency in production lines.

5 SYSTEM COMPARISION

A comparison was done against the Standard Hough

Circular Transform, and it was presented showing the

ability of the proposed system to easily outperform

the simple implementation of this standard method

and overcome challenges and drawbacks associated

with the standard method.

5.1 Handling Skewed Perception

Skewed perception refers to the distortion or

misrepresentation of an object or feature in the image

due to various camera angle, lens distortion, or object

orientation. Since this rod placement is distorted, the

HCT fails to correct perspective. Instead, with the

proposed method, all these problems are handled by

extra processing steps to correct the skewed

perception. It takes into consideration the orientation

of the object, and the angle of the camera to apply the

geometric transformations or corrections for

realignment of the object with the image. The method

proposed here adjusts the distorted view of the rod by

compensating for angular misalignment and works

well to ensure accurate detection and representation

of circular features. More importantly, this allows

more reliable analysis even with an imperfectly

placed object, making the system more robust and

accurate compared to the traditional HCT approach.

5.2 Managing False Positives and False

Negatives

The standard approach suffers from high false

positives and false negatives for detection of the

actual circles as "not circles" and vice versa. This

misclassification would arise from any inadequacy in

INCOFT 2025 - International Conference on Futuristic Technology

746

handling variations in object appearance, orientation,

and lighting conditions, which directly affect the

accuracy of such traditional techniques. The proposed

method corrects some of the problems of the standard

Figure 7: Detection Comparison of HCT and Proposed

Method

method, by checking for eccentricity along with

center and radius determination. This way, it

correctly identifies even true circles, especially those

having an eccentricity of zero; these are usually

classified as false positives by the standard Hough

Circular Transform (HCT) method. In addition, by

making a rigid determination of several parameters

before creating classifications, the proposed method

reduces the occurrence of false positives. As shown

in Fig. 7 the proposed method correctly outlines the

detected edge as it is perceived as an ellipse rather,

the HCT method sticks to marking a circle missing

the actual edge and inaccurately providing the

diameter value further. It leads to this holistic

assessment to be duly optimized thresholds in

detecting circular objects from non-circular ones in

this system.

Table 1: System Comparison with Error Percentage.

x Actual

Diamete

r

Detected

Diamete

r

Error

Percenta

g

e

HCT 3.4 c

m

3.15 c

m

7.35%

Proposed

Metho

d

3.4 cm 3.36 cm 1.17%

5.3 Accuracy, Precision and

Adaptability

The proposed method demonstrates significant

improvements in accuracy, precision, and

adaptability over the standard Hough Circular

Transform (HCT). By incorporating additional

parameters such as eccentricity, alongside center and

radius, the proposed system accurately identifies

circles with an eccentricity of zero, which are often

misclassified by the HCT. As presented in Table I, if

a sample circle of actual diameter 3.4 cm is to be

detected, then it is observed that the proposed method

is more precise as compared to HCT, with the

percentage error being 1.17% and, for the HCT

method, 7.35%. Increased precision reduces

misclassifications due to false positives and false

negatives, thus improving the reliability of the

classification.

The proposed method also has the adaptability

shown in its optimized thresholds and then dealt with

variations in the said lighting, orientation, and

positioning. Unlike the standard method, which is

sensitive to changes in environmental conditions, the

proposed approach remains adaptive and consistent

with different setups involved. This adaptability not

only ensures accuracy and precision in controlled

conditions but also makes the method versatile for

broader applications within the mechanical industry

and quality control environments.

6 CONCLUSIONS

The study concluded with a detailed approach to

automatic quality inspection in mechanical

manufacturing, with added improvement in circle

detection accuracy irrespective of orientation and

levels of lighting. Combining geometric analysis,

eccentricity checks, and machine learning capabilities

Eccentricity-Based Diameter Measurement: A Novel Approach for Quality Control

747

into the system made it strong against those

traditional methods that the Hough Circular

Transform approaches tend to falter with perspective

distortions. The results confirm that this method

improves precision, reduces false detections, and

adapts effectively to real-world production

environments. With this in mind, the comprehensive,

error-resistant approach presented here seems

particularly promising for the optimization of quality

control processes toward higher efficiency and

reliability in manufacturing.

REFERENCES

P. K. Singh et al. (eds.), Recent Innovations in Computing,

Lecture Notes in Electrical Engineering 701,

https://doi.org/10.1007/978-981-15-8297-4_33.

Ou, Y.; Deng, H.; Liu, Y.; Zhang, Z.; Ruan, X.; Xu, Q.;

Peng, C. AFast Circle Detection Algorithm Based on

Information Compression. Sensors 2022, 22, 7267.

https:// doi.org/10.3390/s22197267.

T. Le and Y. Duan, "Circle detection on images by line

segment and circle completeness," 2016 IEEE

International Conference on Image Processing (ICIP),

Phoenix, AZ, USA, 2016, pp. 3648-3652, doi:

10.1109/ICIP.2016.7533040.

C. Lu, S. Xia, W. Huang, M. Shao and Y. Fu, "Circle

detection by arc-support line segments," 2017 IEEE

International Conference on Image Processing (ICIP),

Beijing, China, 2017, pp. 76-80, doi:

10.1109/ICIP.2017.8296246.

P. C. Teo and D. J. Heeger, "Perceptual image distortion,"

Proceedings of 1st International Conference on Image

Processing, Austin, TX, USA, 1994, pp. 982-986 vol.2,

doi: 10.1109/ICIP.1994.413502.

W.O. BARBOSA, & Vieira, Antonio. (2019). On the

Improvement of Multiple Circles Detection from

Images using Hough Transform. TEMA. 20. 331-342.

10.5540/tema.2019.020.02.0331.

M. F. Ercan, A. L. Qiankun, S. S. Sakai and T. Miyazaki,

"Circle detection in images: A deep learning approach,"

Global Oceans 2020: Singapore – U.S. Gulf Coast,

Biloxi, MS, USA, 2020, pp. 1-5, doi:

10.1109/IEEECONF38699.2020.9389048.

Y. Mehmood, U. S. Khan and J. Iqbal, "Fast, Optimal

Algorithm for Real Time Image Enhancement," 2019

International Conference on Robotics and Automation

in Industry (ICRAI), Rawalpindi, Pakistan, 2019, pp. 1-

5, doi: 10.1109/ICRAI47710.2019.8967364.

P. Somwang and E. Muangklang, "Image Processing for

Quality Control in Manufacturing Process," 2019 16th

International Conference on Electrical

Engineering/Electronics, Computer,

Telecommunications and Information Technology

(ECTI-CON), Pattaya, Thailand, 2019, pp. 782-785,

doi: 10.1109/ECTI-CON47248.2019.8955421.

Tiantian Hao, De Xu, “Circle Area Detection Based on

Convolutional Neural Networks,” 2022 IEEE

International Conference on Mechatronics and

Automation (ICMA), pp. 1-6, doi:

10.1109/ICMA54519.2022.9856373.

P. C. Cholke et al., "Quality Control for Small Multi

Domain Industries Using Image Processing," 2024 MIT

Art, Design and Technology School of Computing

International Conference (MITADTSoCiCon), Pune,

India, 2024, pp. 1-5, doi:

10.1109/MITADTSoCiCon60330.2024.10575801.

INCOFT 2025 - International Conference on Futuristic Technology

748