Process Chain for Artificial Intelligence-Based Demand Forecasting

and Procurement Scheduling

Maximilian Hohn

a

, and Philipp Maximilian Sieberg

b

Chair of Mechatronics, University of Duisburg-Essen, Lotharstr. 1, 47057 Duisburg, Germany

Keywords: Artificial Intelligence, Machine Learning, Supplay Chain Management, Risk Management, Predictive

Analytics, Probabilistic Modeling, Demand Forecasting, Procurement Scheduling, Procurement Planning,

Logistics, Inventory Management, Business Intelligence, Explainable AI.

Abstract: This position paper introduces a conceptual general process chain for leveraging artificial intelligence (AI) in

demand prediction and procurement scheduling for small and medium-sized enterprises (SME). While AI

offers significant advantages, such as reducing inventory costs, improving delivery reliability, and optimizing

logistics, its adoption in SME is hindered by limited expertise, restricted access to AI tools, and psychological

barriers like trust and acceptance. The proposed framework integrates probabilistic modeling, clustering

algorithms, feature extraction methods and temperature scaling to enhance prediction accuracy and efficiency.

By aggregating demand forecasts, the system enables risk-adjusted and cashflow-optimized scheduling. A

preliminary result is presented, demonstrating robust predictions within confidence intervals. While the

findings are preliminary, this paper highlights the transformative potential of AI in SME scheduling and

outlines future research directions, including model optimization and the integration of explainable AI

methods to further enhance traceability and user acceptance.

1 INTRODUCTION

The field of artificial intelligence (AI) has emerged as

a pivotal technology for numerous automated systems

and data-driven algorithms, offering significant

potential for enhancing business processes across

various sectors, including large corporations and

small- and medium-sized enterprises (SME).

According to an expert survey, the foremost

opportunities for AI in SME are projected to lie in the

domains of optimizing distribution and logistics and

enhancing process efficiency (Lundborg et al., 2023;

WIK GmbH, 2019). While the processing of goods

can vary significantly depending on the specific

industry, many procurements and scheduling

processes in the manufacturing industry maintain a

high degree of similarity. These processes are often

driven by factors such as market conditions, order

volume, and company-specific circumstances. The

overarching objective of procurement scheduling is to

optimize service quality, particularly delivery

reliability while minimizing capital expenditures,

a

https://orcid.org/0009-0002-9580-7650

b

https://orcid.org/0000-0002-4017-1352

resource utilization and inventory holding costs.

While the prioritization of these factors varies across

individuals, their overall relevance remains consistent

across all domains. The economic activity of the

manufacturing industry is defined as the treatment or

processing of products for the purpose of

manufacturing or refining products. Procurement

planning and organization is a prerequisite for the

value creation process. In the context of SME,

procurement planning often consists of a separate

department that regulates procurement depending on

demand. The central task is to define the order

quantity and the order time and to organize the

transport to some extent. In SME, this process is

predominantly executed manually, relying on

employees' experiential knowledge. However, this

experiential knowledge is vulnerable to fluctuation

when employees depart from the company.

Moreover, complex issues such as market

fluctuations or demand variations may not be fully

integrated into employees' experiential knowledge.

Large volumes of data accumulate in the planning and

724

Hohn, M., Sieberg and P. M.

Process Chain for Artificial Intelligence-Based Demand Forecasting and Procurement Scheduling.

DOI: 10.5220/0013647700003967

In Proceedings of the 14th International Conference on Data Science, Technology and Applications (DATA 2025), pages 724-731

ISBN: 978-989-758-758-0; ISSN: 2184-285X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

purchasing departments, which are often incomplete,

inaccessible, or underutilized. The advent of

technological progress, the proliferation of data, and

the emergence of sophisticated algorithms in the big

data domain have rendered extensive analyses and

models viable tools for process optimization in

procurement scheduling. Given the capacity of

planners to consider a limited amount of data during

the decision-making process, the development of

prediction models and efficient algorithms for data

preparation and feature extraction is imperative to

optimize processes (Allal-Chérif et al., 2021;

Baryannis et al., 2019).

The integration of AI into various sectors of industry

and research has been a subject of considerable

interest in recent years. According to a McKinsey

report from 2023, the global potential of AI is 17.1 to

25.6 trillion dollars (roughly 20% of global GDP),

making it a significant economic opportunity in

today's economic landscape (Chui et al., 2023). The

effectiveness of AI in the domain of supply chain

management has been a subject of notable attention

(McKinsey & Company, 2021). However, the

implementation of AI in SME is hindered by several

obstacles, primarily the lack of specialized expertise

and the challenges in accessing AI as a service (WIK

GmbH, 2019). While prominent companies

successfully develop and utilize AI services, such as

Forecast Pro (Business Forecast Systems, Inc.,

2025), and proprietary AI solutions to enhance their

own processes, there is a paucity of interest in

disseminating this knowledge to the public.

The primary benefit of the framework to be

developed lies in the reduction of stock levels and the

increase in delivery reliability through the use of AI,

especially for SME. While the economic benefit of

reducing stock can be quantified using a capital

replacement rate, the economic benefit of increasing

delivery reliability is difficult to quantify. An increase

in delivery reliability has a positive effect on the

expansion, stability, and interdependence of business

relationships. The successful implementation of AI in

supply chain management has been shown to result in

a 15% reduction in logistics costs, a 35% decrease in

stock levels, and a 65% improvement in service

quality (McKinsey & Company, 2021). A recent

study by Samuels confirms that the integration of AI

into supply chain management improves demand

forecasting, inventory optimization and decision-

making. This leads to lower inventory levels, cost

savings and higher delivery reliability, as AI enables

accurate forecasting, minimizes stock-outs and

reduces excess inventory (Samuels, 2024).

Global economic uncertainties and supply chain

disruptions in recent years have increased the need for

smart warehousing systems. Reports such as the

OECD SME and Entrepreneurship Outlook show that

SME worldwide are struggling with supply

bottlenecks and inefficient warehousing strategies,

resulting in high storage costs and limited flexibility

(OECD, 2023). The use of AI-supported scheduling

has the potential to meet these challenges. It

facilitates the early recognition of situations such as a

drop in demand and the implementation of suitable

measures. While the majority of German companies

perceive AI as a potential benefit, only a small

percentage of companies currently utilize existing

methods (Bitkom e. V., 2022). In addition to the

challenge of adapting existing solutions to the needs

and resources of SME, psychological constructs such

as acceptance and trust in AI solutions must

increasingly be considered. Studies show that

acceptance of AI drops when users see it as a control

tool or fear losing decision-making power and jobs.

This is especially true in small and medium-sized

enterprises, where long-standing routines often make

employees less open to change. To foster acceptance

of AI, these aspects must be addressed in technical

development.

The process chain presented here aims to address the

following research questions regarding its application

in SME:

• Which combination of data preprocessing, model

architecture, and model training maximizes

prediction quality?

• To what extent does the proposed process chain,

in terms of accuracy, outperform established

forecasting models such as ARIMA and Prophet?

• How does AI-supported procurement scheduling

impact costs, stock levels, inventory turnover

time, and delivery reliability?

2 STATE OF THE ART

Baryannis et al. (Baryannis et al., 2019) highlight the

potential of AI in supply chain risk management but

point out a lack of research on proactive and

predictive AI applications, especially regarding

decision-making, prediction methods, and the

integration of different AI technologies. Their

findings emphasize the need for further investigation

Process Chain for Artificial Intelligence-Based Demand Forecasting and Procurement Scheduling

725

in these areas. For instance, Venkatesan, and Goh

(Venkatesan & Goh, 2016) developed a multi-criteria

mixed integer linear program (MILP) model to

identify the optimal selection of suppliers and the

allocation of order quantities under the risk of

disruption. The findings indicate that the likelihood

of supplier default exerts a more substantial influence

on the anticipated aggregate expenditures compared

to the suppliers' adaptability and the ensuing loss

expenses. Pareto-optimal solutions facilitate the

assessment of a diverse array of decision alternatives.

Nevertheless, the authors highlight several

limitations, including those pertaining to

deterministic demand or unchanging purchase costs,

underscoring the necessity for further research to

elucidate these domains. A comparison of different

AI-based forecasting methods to improve the

accuracy of demand forecasting in supply chains

shows that the use of artificial neural networks

significantly improves the accuracy of demand

forecasting for intermittent demand (Amirkolaii et al.,

2017). In the context of SME Wong et al. (Wong et

al., 2024) demonstrated the benefits of AI-based risk

management in terms of improving business

continuity through improved response to changes

caused by disruptions.

This paper aims to address the existing research gaps

by developing a software process chain for combining

probabilistic AI predictors, thereby combining the

advantages of big data and machine learning with

individual prioritizations. This integration process

serves to reduce risk and enhance traceability for the

user. Despite the limited attention devoted to human

factors in the introduction and utilization of AI

applications in recent years, these factors have

gradually emerged as a focal point of research

interest. However, a more comprehensive

understanding of influencing factors such as trust,

acceptance, and other psychological factors, which

have proven to be key factors for success in the

interaction with other technologies and have already

been mapped in various models, is still lacking

(Choung et al., 2023; Davis, 1989; Manchon et al.,

2021). In addition to AI-specific aspects such as

representation and the degree of machine intelligence

(i.e., its capabilities), findings in the area of trust

highlight the relevance of antecedents that shape the

cognitive and emotional trust of users. These include

the tangibility, transparency, reliability, and

immediacy of AI applications, together with the role

of anthropomorphism. Explainability has been

identified as another pivotal factor influencing trust in

AI applications (Ferrario & Loi, 2022). However, the

extant empirical findings are subject to certain

limitations, including small samples, cross-sectional

observations, and experimental studies with

constraints on field environments. The samples

considered also differ considerably, impeding the

attainment of generalizability. Nevertheless,

enhancing our understanding of these phenomena

appears to be of paramount importance, particularly

in the context of SME with limited staffing and lower

levels of specialization.

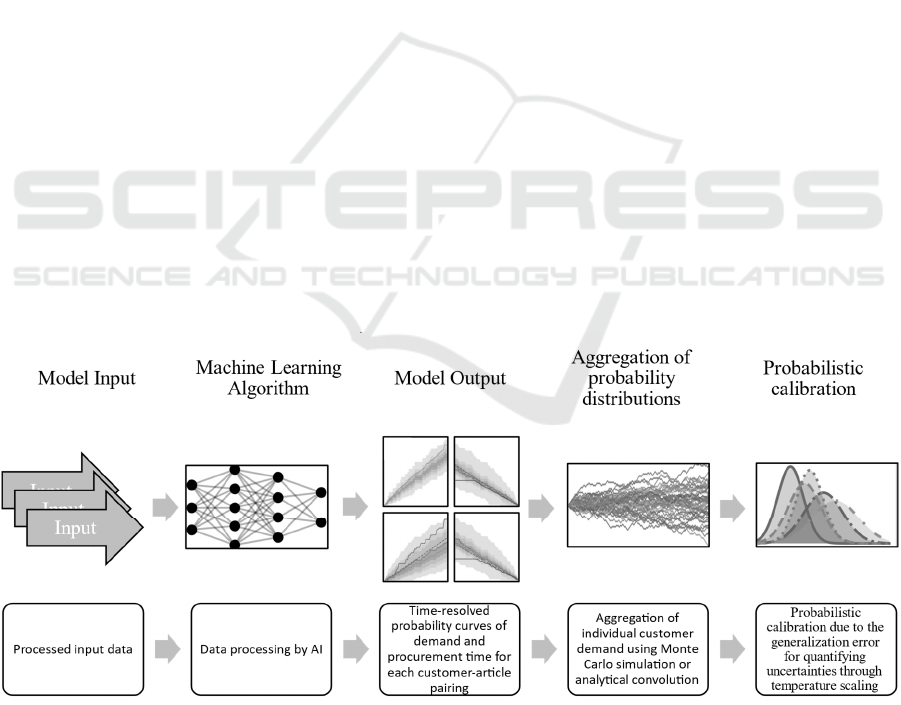

Figure 1: Process chain for predicting customer requirements and procurement times.

DATA 2025 - 14th International Conference on Data Science, Technology and Applications

726

3 METHODOLOGY

For developing the software framework, we focus on

an exemplarily SME, which is at the center of a

network of suppliers and customers. On the supplier

side, the procurement time as a function of the unit

quantity, and on the customer side, the quantity of

demand as a function of time are particularly relevant

for the scheduling tasks. There are often only a

limited number of data points available for individual

customers during the training period. Therefore, we

propose to train a machine learning algorithm not for

each individual customer, but to use a consolidated

model for all customers and all articles. Specific

customer and item parameters are then fed into the

machine learning algorithm as input. The prediction

for item demand can thus be made for each individual

customer and then aggregated at component level.

Figure 1 illustrates the process chain from data input,

through the machine learning algorithm, to the

processed model output. Each step of the process

chain will be presented in the following:

Model Inputs

All available and potentially relevant data should be

initially used as input variables. A post-analysis, for

example using SHapley Additive exPlanations

(SHAP) (Lundberg & Lee, 2017), makes it possible

to evaluate the influence of the input variables on the

target variables. By neglecting less relevant inputs,

model complexity can be reduced and efficiency

increased. The following model inputs, listed in Table

1, are initially and exemplarily used for prediction.

Table 1: Description of the input variables.

Input Description Format

Customer Since the model represents the demand of all customers within an organizational unit,

the customer identity is provided as a unique categorical variable.

One-hot

vector

Article Since the model represents the demand of all articles within an organizational unit, the

article identity is provided as a unique categorical variable.

One-hot

vector

Customer group Customers within an organizational unit are typically grouped. This grouping is

included in the model as a categorical variable.

One-hot

vector

Article group Articles within an organizational unit are typically grouped. This grouping is included

in the model as a categorical variable.

One-hot

vector

Historical demand

…

Historical demand contains information on patterns, trends, and seasonality. It can be

derived from actual deliveries and is provided to the model at three different levels:

… on customer

and article level

Historical demand for the specific customer and the specific article. Numerical

vector

… on customer

and article level

Historical demand of the specific customer for all other articles purchased. Numerical

vector

… on customer

level of the article

Historical demand of all other customers who purchase the specific article. Numerical

vector

Order frequency Number of times a customer has ordered an article within a defined period. Numerical

scalar

Average order

quantity

Mean order quantity of an article for a specific customer within a defined period. Numerical

scalar

Prediction

timestamp

Cyclic encoding of the time in the year. Numerical

vector

Start-of-

Production (SoP)

Difference between the SoP and the prediction timestamp. Numerical

scalar

Demand

announcements

In certain organizational units, demand is announced in advance. In this case, the

VDA4905 standard has been established. Both current and revised announcements are

included in the model.

Sparse

array

Customer

reliability

Based on historical demand announcements and actual demand, the reliability of the

announcements can be quantified numerically.

Sparse

array

External indices Publicly available indices provide information on global economic conditions,

industry trends, and logistics factors.

Numerical

vector

Process Chain for Artificial Intelligence-Based Demand Forecasting and Procurement Scheduling

727

Machine Learning Algorithms – Design of

Experiment

At the center of the proposed process chain is an AI-

based model that aims to map the relationship

between input and output data as accurate as possible

and has the highest possible generalization capability.

Established methods for trend prediction such as the

“Autoregressive Integrated Moving Average”

(ARIMA) (Shumway & Stoffer, 2017) and the open

source library Prophet (Taylor & Letham, 2018) are

initially used as a baseline. A central aspect of the

research question is the comparative performance

analysis between conventional methods and machine

learning based models. In order to achieve a high

model quality, a systematic test matrix is applied to

the task and examined with regard to its suitability.

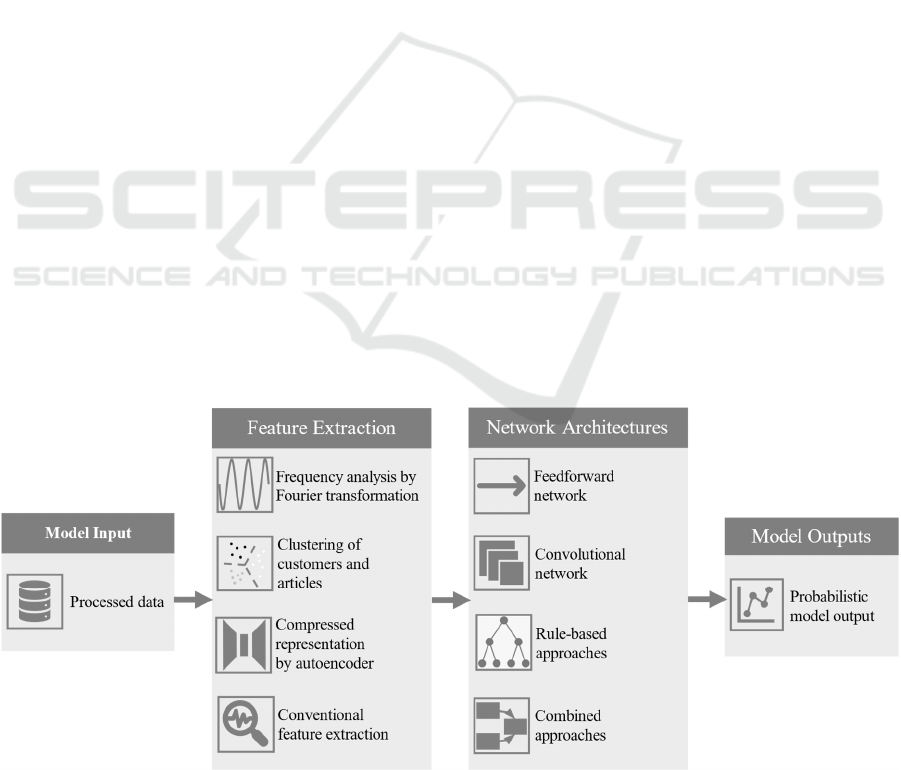

The overall structure is illustrated in

Figure

2.

Both customers and articles can exhibit similar or

contrasting patterns in terms of their input/output

behavior, which are systematically analyzed as part of

the feature extraction process by forming clusters.

Clustering algorithms such as k-Means (Lloyd, 1982)

or DBSCAN (Ester, M., Kriegel, H. P., Sander, J., &

Xu, X., 1996) are used to group customers and

articles. This improves the model's learning ability

and data structure. Since the demand announcements,

including past revised demand announcements, are in

a generalized format and in this case include a large

number of input dimensions, compression or

convolution can improve training and data structure.

This can be done on the feature extraction side by an

autoencoder that learns a dimension-reduced latent

representation of the input data (Hinton &

Salakhutdinov, 2006). This representation contains

almost the original information content and enables a

reduction in model size and more efficient

processing. Instead of dimension reduction at the data

pre-processing level, convolutional layers can also be

used at the network architecture level to enable

efficient data propagation. As a reference, the

convolutional networks are contrasted with pure

feedforward networks. Another decisive aspect is the

comprehensibility and explainability, which is crucial

for acceptance and trust in the AI application

(Afroogh et al., 2024). The probabilistic modeling of

the output contributes to the interpretability and

explainability of the model. In addition, architecture-

independent model-agnostic methods such as SHAP

can be used to increase transparency and

interpretability. Furthermore, rule-based machine

learning approaches with limited complexity can

provide additional insight into traceability and

explainability. Here, the advantages of traceability

have to be evaluated against any losses in model

quality. Although the processes of deliveries and

orders represent recurring events that could be

adequately modeled formally by recurrent neural

networks (RNNs), specific requirements speak

against the use of this architecture. A central aspect

of the problem is the need to generate not only point

predictions (quantities or points in time), but also

probability distributions for future events. This is

particularly crucial as decisions in procurement

scheduling are typically made under uncertainty. In

addition, the cumulative demand over a defined

period of time is more relevant than isolated

individual values, as this is directly linked to resource

planning and allocation. However, the feedback of

data within recurrent architectures poses considerable

challenges.

Figure 2: Design of experiment for machine learning algorithms.

DATA 2025 - 14th International Conference on Data Science, Technology and Applications

728

In particular, either a large number of possible

scenarios have to be modeled or probabilities cannot

be adequately taken into account. These limitations

would reduce the validity of the predictions and

impair the practical applicability of the model. For

this reason, approaches are preferred that can directly

predict probabilities for future periods on the basis of

historical data.

Model Output

Probabilistic modeling enables demand and

procurement time to be expressed as a function of

their probability of occurrence. This provides the

basis for risk- or cash flow-optimized procurement

scheduling and warehousing. A key advantage of this

approach lies in the subsequent adjustment of the

desired delivery reliability through user interaction.

Quantifying the risk increases transparency and

promotes acceptance and trust in the AI-based system

(Magnus Liebherr et al., 2025). Modeling multiple

output layers enables the simultaneous estimation of

multiple target values. Typically, the loss functions to

be minimized include the difference between the

target variable and the prediction. The output can be

calibrated to any quantile 𝑞 ∈ (0,1) by an

asymmetric

weighting of over- and underestimation:

𝐿

(

𝑦, 𝑦

)

=

𝑞 (𝑦−𝑦)

(

1 −𝑞

)(

𝑦−𝑦

)

,

𝑖𝑓 𝑦 > 𝑦

𝑒𝑙𝑠𝑒

(1

)

The choice of different weightings 𝑞 in several output

layers enables the simultaneous estimation of

different quantiles or confidence intervals. By

providing different confidence intervals and

interpolation methods, the user can interactively

explore risk-based scenarios and dynamically adapt

scheduling parameters to changing framework

conditions.

Aggregation of Probability Distributions

The AI-based model generates multivariate quantile

forecasts for each customer-article pairing. The

aggregated probability distributions of all customers

per article are primarily relevant for decision-making

in procurement scheduling. Depending on the number

of customers and the granularity of the quantiles,

these forecasts are calculated either analytically or

empirically: an analytical convolution combines the

individual distributions and calculates the resulting

overall distribution with mathematical precision:

𝑃

= 𝑃

∗𝑃

∗… ∗𝑃

(2

)

The convolution method is suitable due to the

computational complexity with a lower number of

customers and lower quantile granularity and

provides a mathematically exact calculation. The

Monte Carlo method approximates the resulting

distribution empirically by sampling. The calculation

effort can be reduced at the expense of accuracy.

These methods are based on the assumption of

stochastic independence between the probability

distributions generated by the AI. In a global market,

demand patterns can correlate due to common

economic factors. If these factors are not fully

integrated in the AI model, the premise of stochastic

independence does not apply. The resulting

systematic errors require an analysis that provides

information about the demand correlation of different

customers. Depending on the result of the analysis,

the systematic errors can be compensated by

integrating copula models, for example. If there is no

significant correlation between certain customers,

uncertainties can be compensated for by temperature

scaling.

Probabilistic Calibration

Despite the use of regularization methods, machine

learning algorithms have a tendency to overfitting,

especially in more complex architectures (Sun et al.,

2017). This overfitting leads to overconfident

predictions for test or validation data. Temperature

scaling offers an effective approach to improve

calibration by introducing a scalar parameter 𝑇 that

scales the output distribution of the logits.

Temperature scaling was originally developed for

classification models (Chuan Guo et al., 2017). In

2020, Utpala & Rai show that the concept can also be

applied to quantile calibrations in regression models

(Utpala & Rai, 2020). The temperature parameter 𝑇

is applied to the distribution function and can be

estimated based on past data.

4 INITIAL RESULTS AND

DISCUSSION

The process chain presented offers a generalized, AI-

based approach to forecasting demand and

procurement time. By integrating probabilistic

modelling, the aggregation of individual customer

demand at article level and temperature scaling, the

system enables a realistic quantification of

probabilities of occurrence and supports risk-adjusted

and cash flow-optimized scheduling. Both human

schedulers and downstream software agents can use

the AI-supported forecasts to optimize decisions,

increase delivery reliability and reduce storage costs.

Explicit risk quantification increases the transparency

of the system, thereby promoting user acceptance and

building trust.

Process Chain for Artificial Intelligence-Based Demand Forecasting and Procurement Scheduling

729

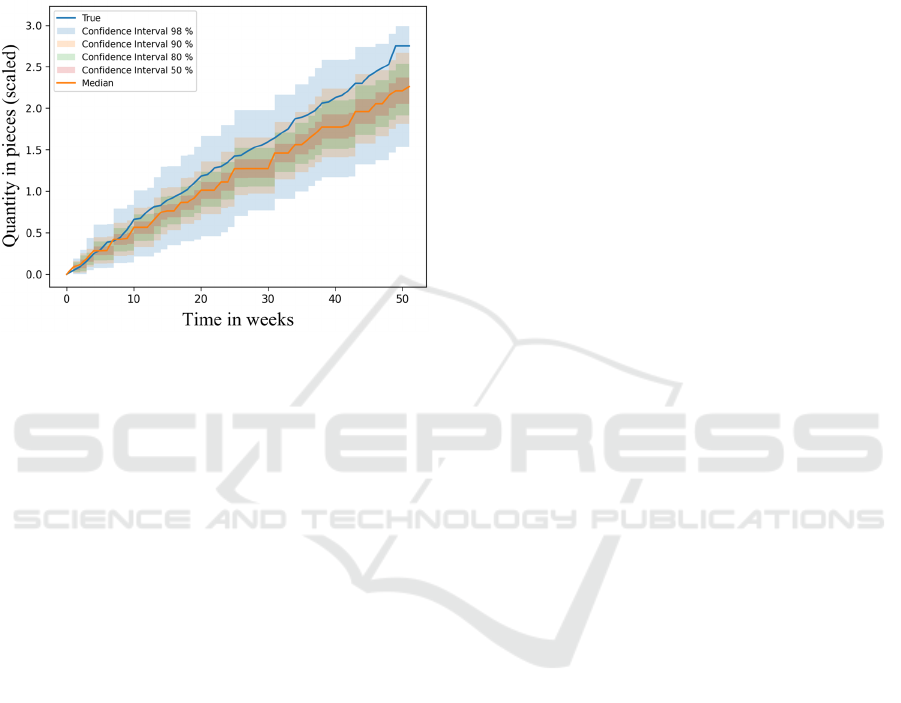

A first exemplary aggregated demand forecast over

52 weeks for a reference article (Figure 3) shows that

the spread of the confidence intervals increases with

increasing forecast horizon. In this case, the base

model slightly underestimates demand, but the actual

values are predominantly within the 90 % confidence

interval (without applying temperature scaling).

Figure 3: Exemplary aggregated demand forecast over 52

weeks.

The completion of the process chain includes a

systematic analysis and optimization of model

architectures and hyperparameters in order to further

increase the prediction quality. Future work will

address the adaptation of the process chain to the

prediction of procurement times, the integration of

explainable AI methods to increase traceability and

the extension to correlated demand patterns in global

supply chains using copula models. The presented

AI-based process chain makes the central advantages

of AI usable for SME in procurement scheduling by

enabling risk-conscious, efficient and transparent

scheduling, which both reduces storage costs and

sustainably increases delivery reliability.

REFERENCES

Afroogh, S., Akbari, A., Malone, E., Kargar, M., &

Alambeigi, H. (2024). Trust in AI: Progress, challenges,

and future directions. Humanities and Social Sciences

Communications, 11(1), 1–30. https://doi.org/10.1057/

s41599-024-04044-8

Allal-Chérif, O., Simón-Moya, V., & Ballester, A. C. C.

(2021). Intelligent purchasing: How artificial

intelligence can redefine the purchasing function.

Journal of Business Research, 124, 69–76.

https://doi.org/10.1016/j.jbusres.2020.11.050

Amirkolaii, K. N., Baboli, A., Shahzad, M. K., &

Tonadre, R. (2017). Demand Forecasting for Irregular

Demands in Business Aircraft Spare Parts Supply

Chains by using Artificial Intelligence (AI). IFAC-

PapersOnLine, 50(1), 15221–15226. https://doi.org/10.

1016/j.ifacol.2017.08.2371

Baryannis, G., Validi, S., Dani, S., & Antoniou, G. (2019).

Supply chain risk management and artificial

intelligence: state of the art and future research

directions. International Journal of Production

Research, 57(7), 2179–2202. https://doi.org/10.10

80/00207543.2018.1530476

Bitkom e. V. (2022). KI gilt in der deutschen Wirtschaft als

Zukunftstechnologie – wird aber selten genutzt

[Retrieved March 29, 2025].

Business Forecast Systems, Inc. (2025). forecast pro

[Retrieved April 26, 2025]. https://www.forecas

tpro.com/

Choung, H., David, P., & Ross, A. (2023). Trust in AI and

Its Role in the Acceptance of AI Technologies.

International Journal of Human–Computer Interaction,

39(9), 1727–1739. https://doi.org/10.1080/104473

18.2022.2050543

Chuan Guo, Geoff Pleiss, Yu Sun, & Kilian Q. Weinberger

(2017). On Calibration of Modern Neural Networks.

International Conference on Machine Learning, 1321–

1330. http://proceedings.mlr.press/v70/guo17a.html

Chui, M., Hazan, E., Roberts, R., Singla, A., Kate, S.,

Sukharevsky, A., Yee, L., & Zemmel, R. (2023). The

economic potential of generative A [Retrieved March

28, 2025]. https://www.mckinsey.com/~/media

/mckinsey/business functions/mckinsey digital/our

insights/the economic potential of generative ai the next

productivity frontier/the-economic-potential-of-

generative-ai-the-next-productivity-frontier

Davis, F. D. (1989). Perceived Usefulness, Perceived Ease

of Use, and User Acceptance of Information

Technology. MIS Quarterly, 13(3), 319. https://doi.

org/10.2307/249008

Ester, M., Kriegel, H. P., Sander, J., & Xu, X. (1996). A

density-based algorithm for discovering clusters in

large spatial databases with noise. Proceedings of the

Second International Conference on Knowledge

Discovery and Data Mining (KDD-96) (pp. 226-231).

https://cdn.aaai.org/kdd/1996/kdd96-

037.pdf?source=post_page--------------

Ferrario, A., & Loi, M. (2022). How Explainability

Contributes to Trust in AI. In 2022 ACM Conference on

Fairness, Accountability, and Transparency (pp. 1457–

1466). ACM. https://doi.org/10.1145/3531146.

3533202

Hinton, G. E., & Salakhutdinov, R. R. (2006). Reducing

the dimensionality of data with neural networks.

Science, 313(5786), 504–507. https://doi.org/10.1126/

science.1127647

Lloyd, S. (1982). Least squares quantization in PCM. IEEE

Transactions on Information Theory, 28(2), 129–137.

https://doi.org/10.1109/TIT.1982.1056489

DATA 2025 - 14th International Conference on Data Science, Technology and Applications

730

Lundberg, S., & Lee, S.‑I. (2017, May 22). A Unified

Approach to Interpreting Model Predictions.

http://arxiv.org/pdf/1705.07874

Lundborg, M., Papen, M.‑C. Dr., Roloff, M., Simons, M. J.,

& Stamm, P. (2023). Künstliche Intelligenz im

Mittelstand [Retrieved March 29, 2025]. https://

www.mittelstand-

digital.de/MD/Redaktion/DE/Publikationen/ki-Studie-

2023.pdf?__blob=publicationFile&v=4

Magnus Liebherr, Ellen Enkel, Effie Law, Mohammadreza

Mousavi, Matteo Sammartino, & Philipp Sieberg

(2025). Dynamic Calibration of Trust and

Trustworthiness in AI-Enabled Systems. International

Journal on Software Tools for Technology Transfer.

https://kclpure.kcl.ac.uk/portal/en/publications/dynami

c-calibration-of-trust-and-trustworthiness-in-ai-

enabled-sy

Manchon, J. B., Bueno, M., & Navarro, J. (2021). From

manual to automated driving: How does trust evolve?

Theoretical Issues in Ergonomics Science, 22(5), 528–

554. https://doi.org/10.1080/1463922X.2020.1830450

McKinsey & Company. (2021). Succeeding in the AI

supply-chain revolution [Retrieved March 28, 2025].

https://www.mckinsey.com/industries/metals-and-

mining/our-insights/succeeding-in-the-ai-supply-

chain-revolution#/

OECD. (2023). OECD SME and Entrepreneurship Outlook

2023. Retrieved March 29, 2025. https://www.

oecd.org/en/publications/oecd-sme-and-entrepreneur

ship-outlook-2023_342b8564-en.html, https://doi.org

/10.1787/342b8564-en

Samuels, A. (2024). Examining the integration of artificial

intelligence in supply chain management from Industry

4.0 to 6.0: A systematic literature review. Frontiers in

Artificial Intelligence, 7, 1477044. https://doi.org/10.33

89/frai.2024.1477044

Shumway, R. H., & Stoffer, D. S. (2017). Arima Models.

Time Series Analysis and Its Applications, 75–163.

https://doi.org/10.1007/978-3-319-52452-8_3

Sun, X., Sun, W., Ma, S., Ren, X., Zhang, Y., Li, W., &

Wang, H. (2017, November 25). Complex Structure

Leads to Overfitting: A Structure Regularization

Decoding Method for Natural Language Processing.

http://arxiv.org/pdf/1711.10331

Taylor, S. J., & Letham, B. (2018). Forecasting at Scale.

The American Statistician, 72(1), 37–45.

https://doi.org/10.1080/00031305.2017.1380080

Utpala, S., & Rai, P. (2020). Quantile Regularization:

Towards Implicit Calibration of Regression Models.

Venkatesan, S. P., & Goh, M. (2016). Multi-objective

supplier selection and order allocation under disruption

risk. Transportation Research Part E: Logistics and

Transportation Review, 95, 124–142.

https://doi.org/10.1016/j.tre.2016.09.005

WIK GmbH (Ed.). (2019). https://www.mittelstand-

digital.de/MD/Redaktion/DE/Publikationen/kuenstlich

e-intelligenz-im-mittelstand.pdf?__blob=publication

File&v=5 [retrieved March 28, 2025].

Begleitforschung Mittelstand-Digital.

Wong, L.‑W., Tan, G. W.‑H., Ooi, K.‑B., Lin, B., &

Dwivedi, Y. K. (2024). Artificial intelligence-driven

risk management for enhancing supply chain agility: A

deep-learning-based dual-stage PLS-SEM-ANN

analysis. International Journal of Production Research,

62(15), 5535–5555. https://doi.org/10.1080/00

207543.2022.2063089

Process Chain for Artificial Intelligence-Based Demand Forecasting and Procurement Scheduling

731