Battery Management System in Autonomous Drones

Mahip Nagori and Deepa Nath

Department of Electrical and Electronics Engineering,

Dr. Vishwanath Karad University MIT World Peace University, Kothrud, Pune, India

Keywords: Battery Management System, Autonomous Drone, Power Management, Safety Protocols, Voltage

Step-Down, Real-Time Monitoring, Mission-Critical.

Abstract: Autonomous drones are extremely adaptable flying devices that are being used more and more in mission-

critical sectors where reliability, safety, and operational efficiency are improved by reducing human

involvement. Applications including package delivery, obstacle avoidance, aerial surveys, environmental

monitoring, and disaster response that need extreme precision and quick decision-making depend heavily on

these drones. The Battery Management System (BMS), An essential circuit that ensures secure yet efficient

power usage while reducing battery-related dangers, is essential to their dependable operation. With

sophisticated multi-level protection circuits (over-current, overcharge/discharge, and thermal) and accurate

voltage and current sensing via a small, noise-resistant PCB layout, this study offers a revolutionary BMS

design specifically suited for autonomous drones. In contrast to traditional designs, the suggested BMS

seamlessly interacts with flight control systems by combining real-time monitoring with improved

communication capabilities via CAN protocol. This design greatly increases drone operational lifespan and

ensures mission success under difficult conditions by enhancing power management precision and system

robustness.

1 INTRODUCTION

Unmanned aerial vehicle (UAV) technology has

advanced quickly, which has accelerated its

incorporation into a variety of applications, such as

package delivery, disaster relief, agricultural

monitoring, and aerial surveillance (Bláha, Severa,

et al. , 2023), (Telli, et al. , 2023) Drones are still

primarily constrained by their reliance on lithium-

based batteries, which have a low energy density.

This makes it difficult to conduct continuous

autonomous operations because it limits flying times

to tens of minutes. Despite the potential benefits

offered by developing battery technologies,

technical and monetary obstacles continue to prevent

their broad implementation (Jiao, Zhang, et al. ,

2023), (Sarsembayev, Yazdi, et al. , 2022). Effective

Battery Management Systems (BMS) are necessary

to get around these restrictions. In addition to

monitoring cell voltage and temperature and

preventing battery-related risks including

overcharging, over-discharging, and overheating, a

BMS guarantees safe operation (Bláha, Severa, et al.

, 2023) (Sarsembayev, Yazdi, et al. , 2022)..

Additionally, sophisticated BMS designs include

functions like real-time communication with drone

control systems and cell balancing, which are

essential for prolonging battery life and guaranteeing

safe navigation during missions (Jiao, Zhang, et al. ,

2023), (Liu, Liu, et al. , 2018) .

Additionally, current

trends highlight effective, lightweight BMS systems

that are customized for the limitations of UAVsClick

or tap here to enter text..

Innovative methods to improve battery

management are highlighted in the literature now in

publication. To reduce downtime during recharge

cycles, for example, automatic battery swapping

systems and external charging stations have been

proposed (Sarsembayev, Yazdi, et al. , 2022)

Onboard BMS upgrades are a more practical way to

achieve higher flight efficiency and safety, but, as

these technologies increase operational complexity

and call for more infrastructure (Jiao, Zhang, et al. ,

2023), (Liu, Liu, et al. , 2018).

The design and deployment of a complete low-

voltage BMS specifically suited for autonomous

drones is presented in this study. Along with

sophisticated monitoring features, (Huang,

Simandjuntak, et al. , 2018) the system has

protection methods like heat, short-circuit, and

Nagori, M. and Nath, D.

Battery Management System in Autonomous Drones.

DOI: 10.5220/0013618000004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 3, pages 393-399

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

393

overcurrent safeguards. This BMS, which bridges

the gap between traditional designs and the changing

requirements of UAV technology, was created with

STM32 microcontrollers and optimized with

inexpensive components to assure safe, dependable

operations across a variety of applications.

2 LITERATURE REVIEW

This BMS's concepts of effective power use and real-

time monitoring are informed by the Droneport idea,

which was proposed by Bláha et al. (Bláha, Severa,

et al. , 2023) and focused on automated battery

management systems for UAVs. In their study of

UAV applications, Telli et al. (Telli, et al. ,

2023)emphasized the value of sophisticated BMS in

mission-critical situations when safety and

dependability are crucial.

The focus on integrating overcurrent, overcharge,

and heat protection in this design is consistent with

Jiao et al.'s(Jiao, Zhang, et al. , 2023) identification

of BMS research hotspots, including cell balance and

multi-level safety. The need of precise current

sensing and real-time data processing to maintain

battery health during operations was highlighted by

Sarsembayev et al. (Sarsembayev, Yazdi, et al. ,

2022) in their research on dynamic wireless power

transmission using LiPo battery modelling.

Liu et al. created an automated docking and

battery-swapping system for UAVs (Liu, Liu, et al. ,

2018)], emphasizing the significance of smooth

communication protocols like the CAN protocol used

in this BMS and automation in power management.

For drone-based inspections, Huang et al. (Huang,

Simandjuntak, et al. , 2018) developed intelligent

BMS designs, highlighting the need for adaptable

protection techniques in a range of environmental

circumstances.

In their discussion of drone BMS design

problems, Jadhav and Bhosale placed a strong

emphasis on reliable communication systems and

small PCB layouts. This is consistent with the multi-

layer PCB layout of the suggested design, which

improves electromagnetic compatibility and reduces

noise. The exact sensing circuits used in this research

were informed by Lakkireddy and Mathe's

(Lakkireddy and Mathe, 2022) suggested techniques

for precise voltage, current, and temperature

measurements utilizing linear optocouplers.

The incorporation of protective measures was led

by the industry standards for BMS examined by

Gabbar et al. (Gabbar, Othman, et al. , 2022), which

placed a strong emphasis on fault-tolerant designs

and adherence to safety procedures. Prognostics and

system health management strategies were

emphasized by Guo et al. (Guo, Li, et al. , 2021),

who also emphasized the importance of real-time

problem detection and reporting for this BMS's

communication capabilities.

The sophisticated balancing techniques employed

in this design to increase battery life were influenced

by the evaluation of battery balancing techniques

conducted by Scholarworks and Bartek (Bartek, , et

al. , 2019). Degradation prognostics for lithium-ion

battery packs were studied by Che et al. (Che, Deng,

et al. , 2020), which emphasized the project's

emphasis on predictive maintenance and

dependability.

The Zener diode-based design used in this BMS

was informed by Khan's (Khan, , et al. , 2022)

thorough analysis of overcharge prevention circuits.

The microcontroller-driven method for data

collection and real-time analysis was influenced by

Eskandari et al.'s(Eskandari, Venugopal, et al. , 2022)

discussion of enhanced battery electronics

integration. The effective and space-efficient layouts

of this project were guided by Bergström's emphasis

on compact PCB redesign methodologies.

To solve electromagnetic compatibility concerns

that are essential to dependable data transfer, Wey et

al. (Wey, Hsu, et al. , 2013) investigated EMI

avoidance in CAN-based cmomunication for BMS.

To provide insights into layout optimization for

reliable performance, Lee et al. (Lee, Yao, et al. ,

2017) investigated PCB ground regions and their

function in EMI suppression.

The goals of this BMS are in line with those of

Nizam et al.'s assessment of BMS design

considerations for lithium-ion batteries(Nizam,

Maghfiroh, et al. , 2020), which placed a strong

emphasis on efficiency and safety. To provide the

real-time monitoring and processing capabilities that

are essential to this architecture, Rabbani (Rabbani, ,

et al. , 2014) emphasized microcontroller-based data

gathering devices. A very dependable overcurrent

protection circuit was presented by Ding and Feng

(Ding, and, Feng, 2013), strengthening the hardware-

based security measures included in this BMS.

3 DESIGN ARCHITECTURE AND

FUNCTIONALITY OF THE BMS

By keeping an eye on vital battery factors like

voltage, current, and temperature, the BMS

guarantees peak performance, dependability, and

INCOFT 2025 - International Conference on Futuristic Technology

394

safety. The battery is protected under a variety of

operating scenarios by its sophisticated protective

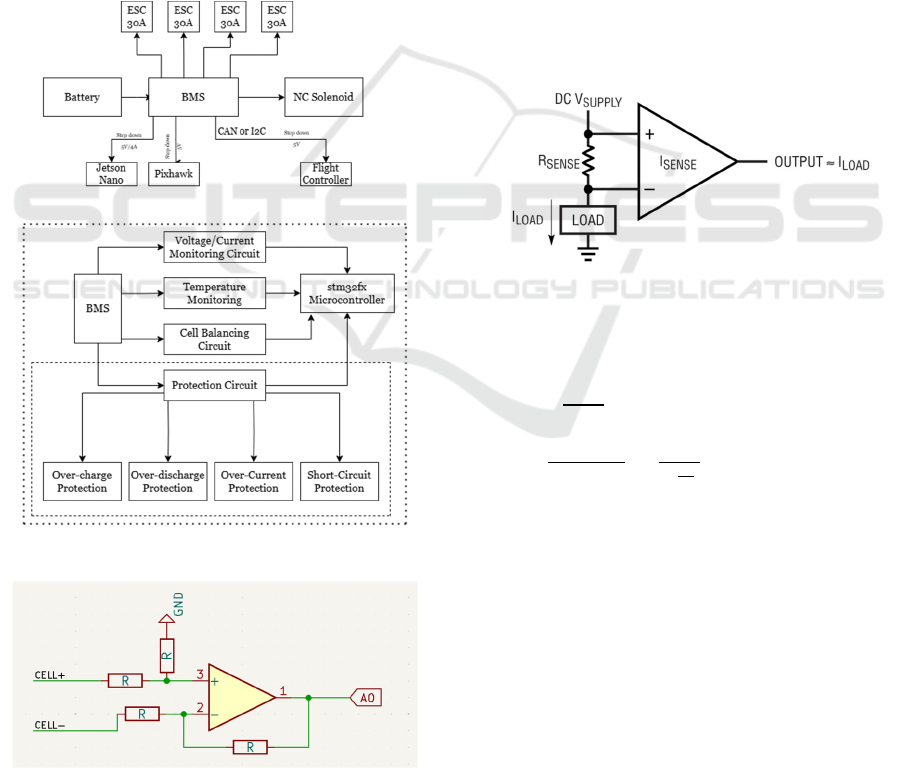

mechanisms as shown in figure 1, which guard

against overcharge, over discharge, overcurrent, and

thermal runawayClick or tap here to enter text..

Adaptive controls and emergency safety procedures

are made possible by its real-time communication

with the flight controller.

An op-amp-based subtractor circuit is used to

measure the voltage across each battery pack cell.

Compared to a basic voltage divider, this method

reduces mistakes and allows for exact differential

measurement by taking into consideration the

common ground shared by cells. Figure 2 gives a

rundown of the circuit used. To avoid overcharge

and over discharge situations, the voltage data is sent

in real time (Lakkireddy and Mathe, 2022), (Gabbar,

Othman, et al. , 2022).

Figure 1: BMS Block Diagram

Figure 2: Overview of single voltage cell (subtractor

circuit)

A shunt resistor connected to a current detecting

amplifier is used to measure current. This is very

similar to the voltage sensing circuit as the voltage

drop is very minimal across the shunt and that

voltage across the shunt is calculated using a

subtractor circuit, as depicted in figure 3, that value

is sent to the microcontroller and further the current

is calculated using ohms law. High-precision

amplifiers minimize power dissipation across the

resistor while enabling precise overcurrent condition

detection. The flight controller receives the real-time

current values (Guo, Li, et al. , 2021), (Bartek, , et

al. , 2019).

To identify temperature irregularities, NTC

thermistors are positioned thoughtfully across the

cells. When safe operating thresholds are surpassed,

protection mechanisms are activated through the

control systems by the temperature data that is fed

into the microcontroller's ADC for thermal

management and is sent to the flight controller

(Lakkireddy and Mathe, 2022), .

Figure 3: Overview of Shunt Placement (without

protection)

Calculation of temperature using a 12-bit ADC:

Vout =

… (1)

T = [(

) * (

)] - 273.15 (2)

T = Temperature in Kelvin

Vref = Reference voltage supplied to the

thermistor circuit

Vout = Measured voltage from the thermistor

𝛽 = Beta coefficient (a constant specific to the

thermistor type)

R0 = Nominal resistance of the thermistor at a

given temperature

R = Thermistor resistance at the recorded

temperature (calculated from Vout and circuit

resistance)

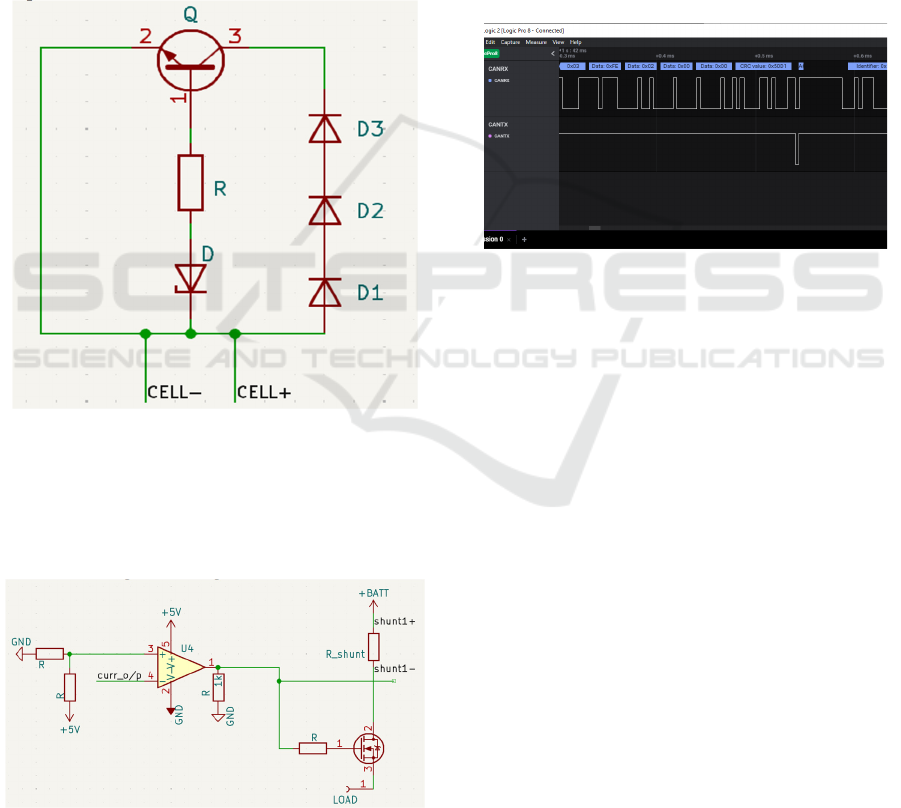

For the overcharge circuit each cell is connected

to a transistor-zener based circuit, which disconnects

charging path when specified voltage limits are

Battery Management System in Autonomous Drones

395

surpassed. The whole circuit is tuned for maximum

cell voltage charging limit, using zener diode, which

is connected to base of the transistor, when the diode

is activated (i.e., cell is fully charged) the transistor

redirects the charging current to a dummy load,

described in figure 4 below. This stops the cells

from overcharging and elongating the battery life .

In order to protect against overcurrent through a

comparator, which is also an opamp-based circuit,

the current sensing circuit compares the output

voltage, or the voltage relative to the current value

that the load is consuming, with a reference value, or

the voltage at the highest current value . When the

drain connects to the load, the comparator circuit's

output drives a MOSFET that is connected

Figure 4: Overview of overcharge circuit

to the shunt and determines whether current will

flow. The whole circuit is explained in figure 5.

When there is an overcurrent, the comparator output

drops, disconnecting the load by shutting off the

MOSFET (Ding, and, Feng, 2013).

Figure 5: Overview of Over-Current Circuit

To guarantee precise battery parameter

monitoring, the BMS's firmware controls data

collection, processing, and communication. ADC

peripherals transform analog inputs into calibrated

digital values by sampling signals (Rabbani, , et al. ,

2014) from temperature, voltage, and current

sensors. Error codes are produced for dangerous

situations once these variables are continuously

evaluated to identify threshold violations (Rabbani, ,

et al. , 2014) . Reactive measures like load reduction

and emergency landing are made possible via the

CAN system, which enables reliable, fast

communication of real-time data and fault codes to

the flight controller(Wey, Hsu, et al. , 2013). During

autonomous drone missions, this integration

guarantees effective operation, improves safety, and

preserves system reliability. A CAN data signal is

given below in figure 6.

Figure 6: CAN Reception Signal on Logic Analyzer

A PCB built for stability, compactness, and

electromagnetic compatibility houses the BMS.

High-current components are segregated to lessen

interference, and differential couples diminish noise

in sensor connections. Heat is dissipated during

high-current operations by thermal vias and heat

sinks. By offering low-impedance channels, ground

planes stabilize power during current fluctuations

and lessen noise in delicate circuits Click or tap here

to enter text.. Transient voltage spikes are filtered by

decoupling capacitors, and the microcontroller is

protected by reverse polarity diodes and connections

such as JST-XH, XT60, and Phoenix. The

autonomous drone's BMS is guaranteed to operate

dependably and safely owing to this architecture.

INCOFT 2025 - International Conference on Futuristic Technology

396

4 TESTING RESULTS AND

ANALYSIS

Figure 7: Load Current v/s Current Sense o/p Voltage

Figure 8: Load Current v/s OCP o/p

Figure 9: Load Current v/s Load Voltage

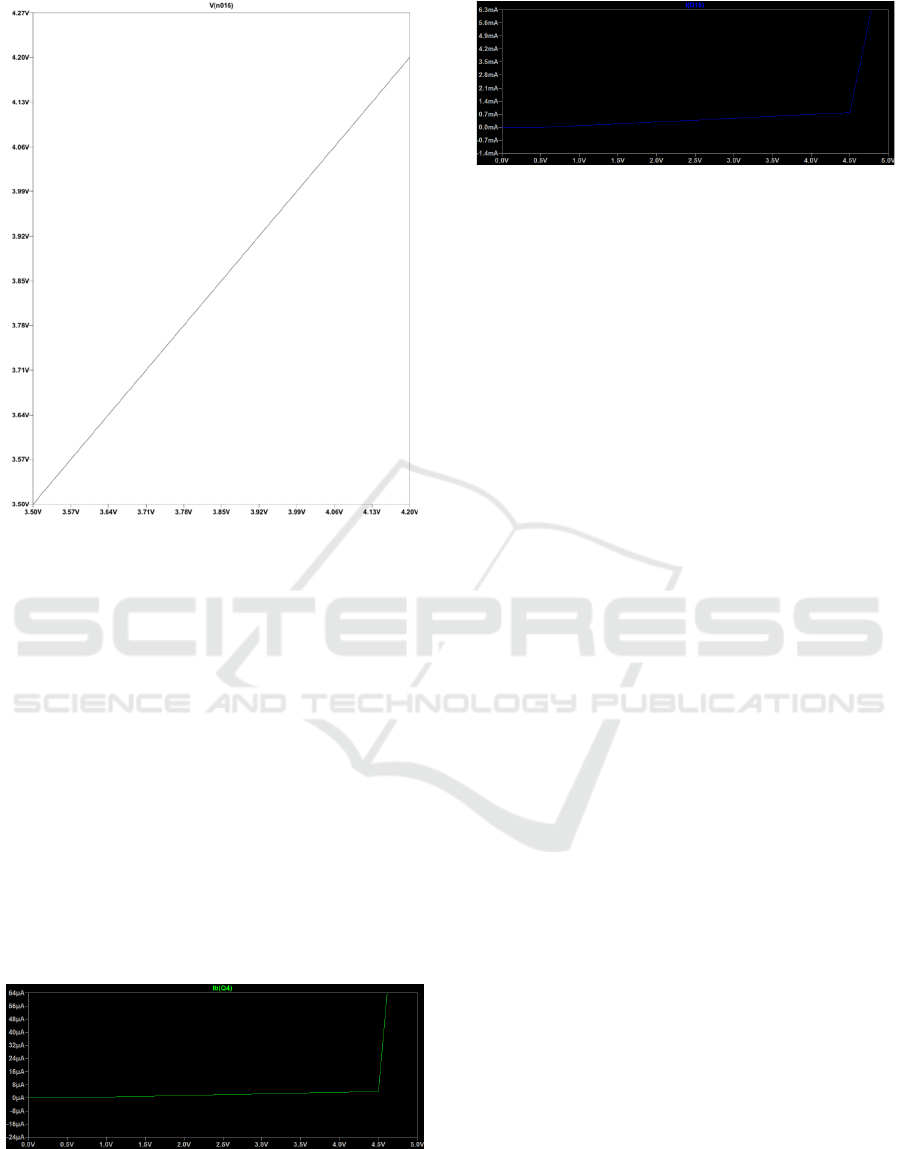

The Current Sensing and Overcurrent Protection

(OCP) circuit is demonstrated in the LTSpice

simulation. In order to identify overcurrent

situations, a subtractor circuit amplifies the voltage

across a shunt resistor network by ten and then

passes it via a comparator. The output plot in figure

7 displays the load voltage response, the amplified

sensing voltage, and the comparator's change from

high to low in figure 8 when the current above 30A.

Plot in figure 9 indicates that the NMOSFET shuts

off during overcurrent situations.

A subtractor topology is used in the Voltage

Sensing Circuit simulation for a 3S battery

arrangement to assess the voltages of individual cells

while taking the accumulated voltages of previous

cells into consideration. The circuit's precision in

detecting and adjusting cell voltages for ADC

interface with the microcontroller is validated by the

output plot in figure 10.

Battery Management System in Autonomous Drones

397

Figure 10: Cell Voltage v/s o/p of the Voltage Sense

Circuit

The overcharge protection circuit for a single cell

in a 3S battery system is shown in the LTSpice

diagram. It makes use of a transistor for switching, a

Zener diode for monitoring cell voltage, and a

dummy load to release extra power in the event of

overcharging.

As the Zener diode conducts at 4.2V, activating

the transistor, figure 11 displays an increase in the

base current of the transistor. Concurrently increase

in the current in the dummy load in figure 12

indicates that protection is engaged and the battery

cell is completely charged. The circuit's activation at

the designated threshold is confirmed by the cell

voltage plot.

Figure 11: Cell Voltage v/s Base Current

Figure 12: Cell Voltage v/s Dummy Load current

5 CONCLUSIONS

A key component of dependability, effectiveness,

and safety, the Battery Management System (BMS)

designed for autonomous drones guarantees

consistent performance in mission-critical

applications. The BMS offers real-time defect

detection and proactive reaction to critical

circumstances by combining accurate current and

voltage monitoring, thermal management, and

reliable communication via the CAN protocol. By

avoiding component damage and reducing hazards

like thermal runaway, advanced safety features, such

as overcurrent and overcharge protections, guarantee

safe operationClick or tap here to enter text..

Effective power distribution maximizes energy use

and prolongs battery life when paired with clear

visual indicators and fault reporting. Autonomous

drones can now do longer and more taxing jobs like

package delivery, environmental monitoring, and

disaster response thanks to this thorough and

creative design, which also increases their

operational reliability. By striking a balance between

technological advancement and real-world

implementation, the BMS raises the bar for

autonomous systems' efficiency and safety

REFERENCES

L. Bláha, O. Severa, M. Goubej, T. Myslivec, and J.

Reitinger, ‘Automated Drone Battery Management

System—Droneport: Technical Overview’, Drones,

vol. 7, no. 4, Apr. 2023, doi: 10.3390/drones7040234.

K. Telli et al., ‘A Comprehensive Review of Recent

Research Trends on Unmanned Aerial Vehicles

(UAVs)’, Aug. 01, 2023, Multidisciplinary Digital

Publishing Institute (MDPI). doi:

10.3390/systems11080400.

S. Jiao, G. Zhang, M. Zhou, and G. Li, ‘A Comprehensive

Review of Research Hotspots on Battery Management

Systems for UAVs’, 2023, Institute of Electrical and

Electronics Engineers Inc. doi:

10.1109/ACCESS.2023.3301989.

INCOFT 2025 - International Conference on Futuristic Technology

398

B. Sarsembayev, S. S. Heidari Yazdi, A. Kapanov, and M.

Bagheri, ‘LiPo Battery Modeling for Dynamic

Wireless Power Transfer in UAV Application’, in

2022 11th International Conference on Renewable

Energy Research and Application (ICRERA), 2022,

pp. 346–351. doi:

10.1109/ICRERA55966.2022.9922909.

Z.-N. Liu, X.-Q. Liu, L.-J. Yang, D. Leo, and H.-W. Zhao,

‘an Autonomous Dock and Battery Swapping System

for Multirotor UAV’, 2018, doi:

10.13140/RG.2.2.19437.90085.

D. Huang, S. Simandjuntak, V. Becerra, A. Fraess-

Ehrfeld, and H. Ma, ‘An Intelligent BMS for Drone-

Based Inspection of Offshore Wind Turbines’.

Jadhav, Vinay & Bhosale, Surendra. (2022). Battery

Management System for Drones.

G. R. Lakkireddy and S. E. Mathe, ‘A Strategy for

Measuring Voltage, Current and Temperature of a

Battery Using Linear Optocouplers’, World Electric

Vehicle Journal, vol. 13, no. 12, Dec. 2022, doi:

10.3390/wevj13120225.

H. A. Gabbar, A. M. Othman, and M. R. Abdussami,

‘Review of Battery Management Systems (BMS)

Development and Industrial Standards’, Jun. 01, 2021,

MDPI. doi: 10.3390/technologies9020028.

Wei. Guo, Steven. Li, and Qiang. Miao, 2019 Prognostics

and System Health Management Conference : PHM-

Qingdao : October 25-27, 2019, Qingdao, China.

IEEE, 2019.

S. Scholarworks@gvsu and W. Bartek, ‘Passive and

Active Battery Balancing Methods Implemented on

Second Use Lithium-ion Batteries’, 2020. [Online].

Available: https://scholarworks.gvsu.edu/theses/975

Y. Che, Z. Deng, X. Tang, X. Lin, X. Nie, and X. Hu,

‘Lifetime and Aging Degradation Prognostics for

Lithium-ion Battery Packs Based on a Cell to Pack

Method’, Chinese Journal of Mechanical Engineering

(English Edition), vol. 35, no. 1, Dec. 2022, doi:

10.1186/s10033-021-00668-y.

K. Khan, ‘Design and Implementation of a Battery

Overcharge protection Circuit’, 2024, doi:

10.13140/RG.2.2.23262.82245.

[ICNERE : the 4th International Conference on Nano

Electronics Research and Education : toward advanced

imaging science creation : 27-29 November 2018, S-

Port, Hamamatsu Campus, Shizuoka University,

Hamamatzu, Japan. Institute of Electrical and

Electronics Engineers, 2018.

ECTI-CON 2013 : 2013 10th International Conference on

Electrical Engineering/Electronics, Computer,

Telecommunications and Information Technology :

Krabi, Thailand : May 15-17, 2013. IEEE, 2013.

L. Ding and Q. Feng, ‘A high reliable over-current

protection circuit with low power consumption’, in

Proceedings - 2013 5th International Conference on

Intelligent Human-Machine Systems and Cybernetics,

IHMSC 2013, 2013, pp. 462–465. doi:

10.1109/IHMSC.2013.116.

G. Rabbani, ‘Microcontroller Based Data Acquisition

System’, 2014. [Online]. Available:

https://www.researchgate.net/publication/281443326

C.-L. Wey, C.-H. Hsu, K.-C. Chang, P.-C. Jui, and M.-T.

Shiue, ‘EMI Prevention of CAN-Bus-Based

Communication in Battery Management Systems’,

2013.

C.-H. Lee, C.-Y. Yao, H.-C. Li, D.-B. Lin, and H.-P. Lin,

‘The Study of PCB Ground Area and Location on EMI

Reduction Effectiveness’, 2017.

E. Bergström, ‘Redesign of a Printed Circuit Board for a

Battery Management System A Master Thesis within

Production Management’.

M. Nizam, H. Maghfiroh, R. A. Rosadi, and K. D. U.

Kusumaputri, ‘Battery management system design

(BMS) for lithium ion batteries’, in AIP Conference

Proceedings, American Institute of Physics Inc., Apr.

2020. doi: 10.1063/5.0000649.

R. Eskandari, P. Venugopal, and G. Rietveld, ‘Advanced

Battery Management Systems with Integrated Battery

Electronics’, in 2022 IEEE 20th International Power

Electronics and Motion Control Conference, PEMC

2022, Institute of Electrical and Electronics Engineers

Inc., 2022, pp. 55–61. doi:

10.1109/PEMC51159.2022.9962868.

Battery Management System in Autonomous Drones

399