Performance Analysis of Liquid Immersion Cooling Using

Mineral Oil for Data Centers

Jean Roderick A

a

, William Christopher I

*b

, Naresh R

c

, Ronnie Pradeep

d

,

Rahul Srawan M

e

and Denesh V

f

Department of Electrical and Electronics Engineering,

Loyola-ICAM College of Engineering and Technology (LICET), Nungambakkam, Chennai, India

Keywords: Liquid Immersion Cooling, Mineral Oil, Data Centers, Thermal Management, Dielectric Coolant, Energy

Efficiency, Heat Dissipation, Server Cooling, Environmental Impact.

Abstract: Data centers are now considered the backbone of modern digital infrastructure comprising critical computing

systems; and every time these systems are switched on, a great deal of heat is produced during their function.

This makes cooling systems an important necessity for system performance, reliability, and energy efficiency.

In this paper, we present the application of a liquid immersion cooling system using mineral oil as a dielectric

coolant that solves all related issues. An experimental set-up involved immersion of server-imperative electric

heater-soaked mineral oil, where the performance testing would be conducted to establish cool performances

of the heater to the extent. Mineral oil can be an efficient medium for heat removal while preventing short

circuits since, besides being a dielectric, its thermal conductance is relatively high. A comparison is made

regarding liquid immersion cooling with conventional systems for air cooling, and this has been highlighted

as a massive uplift in thermal management, energy efficiency, and noise pollution reductions. This paper also

extends over environmental, economic, and technical considerations concerning the adoption of liquid

immersion cooling in data centers while explaining the merits, such as lower operational costs and reduced

carbon footprint, as part of its many challenges-such as higher setup costs and fluid management. Findings

highlight the possibility of immersion cooling as a way forward for future data center designs.

1 INTRODUCTION

The data centers are fuelling the new digital age,

enabling broad cloud computing, massive data

storage, and real-time processing for many industries.

The growing workload on the computers and

increased high-density servers have made effective

cooling an important aspect for now even to maintain

operational reliability and efficiency. The

performance limits of traditional air-based cooling

systems have been reached, resulting in excessive

energy consumption, operational inefficiencies,

rising costs, and so forth. In its efforts to solve these

silos in data centers, research, and industries have

a

https://orcid.org/0009-0005-0603-3780

b

https://orcid.org/0000-0001-6690-1192

c

https://orcid.org/0009-0006-7276-4140

d

https://orcid.org/0009-0005-0919-8089

e

https://orcid.org/0009-0009-3475-7988

f

https://orcid.org/0009-0008-0825-7536

been exploring other cooling alternatives, including

liquid immersion cooling, as promising means of

achieving energy savings and better thermal control

in data centers.

1.1 Importance of Cooling in Data

Centers

Cooling contributes something like 30 - 40 percent of

the total energy consumed by data centers (

Ali, Kumar,

and Sharma, 2021

). Poor cooling performance

magnifies operating expenditures, compromising the

performance and longevity of the IT infrastructure.

Hardware failure, downtime of the systems, and

possible data loss emanate from overheating.

A, J. R., I, W. C., R, N., Pradeep, R., M, R. S. and V, D.

Performance Analysis of Liquid Immersion Cooling Using Mineral Oil for Data Centers.

DOI: 10.5220/0013613800004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 3, pages 269-277

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

269

Therefore, improving the cooling system earns a cost

advantage as well as environmental sustainability.

Liquid immersion cooling enables the change of

paradigm wherein components are immersed in a

dielectric liquid and no longer require energy-hungry

air conditioning systems, it carries away heat and

reduces.

1.2 Importance of Cooling in Data

Centers

These include air conditioners, fans, and airflow

designs, which dissipate heat produced by the servers.

However, air-based cooling has its limitations on:

1) Poor Heat Transfer Efficiency: Compared

with several liquids, air exhibits very low

thermal conductance.

2) High Power Consumption: A good deal of

electricity is consumed by air cooling systems

due to their operation.

3) Noise and Environment Concern - Large

cooling systems tend to add up environmental

noise and high co-pollution (

Patel and Mathur,

2023

).

These deficiencies inform perfectly that there is a

need for new practices like liquid immersion cooling,

which will take advantage of the intrinsically superior

thermal properties of dielectric fluids.

1.3 Importance of Cooling in Data

Centers

The use of immersion cooling will inadvertently

become unavoidable in performance computing

systems as soaring energy prices become global.

Among the most significant benefits of immersion

cooling is improved heat dissipation. The dielectric

fluids say mineral oil, which can now absorb this heat

directly and dissipate it more easily than air. Reduced

power usage as they don't need large air conditioning

units. Scalability as it can be easily scaled to meet the

current requirements of high-density modern data

centers. On top of that, the fact remains liquid

immersion cooling meets the industry's drive towards

low-carbon, sustainable, and environmentally

friendly practices in the end through the reduction of

emissions to match energy-efficient goals worldwide.

(Goswami, Gupta, Sharma, 2022).

2 MATERIALS AND METHODS

The materials and methods utilized to establish the

experimental methodology for liquid immersion

cooling are presented in this section. The objective

was to measure how an immersion cooling system

would be affected by a dielectric coolant, such as

mineral oil, for reducing the temperature under

immersion cooling conditions by using an electric

heater closely replicating the heat generated by a

server. Below are elaborate details defining the

experimental setup and design considerations. The

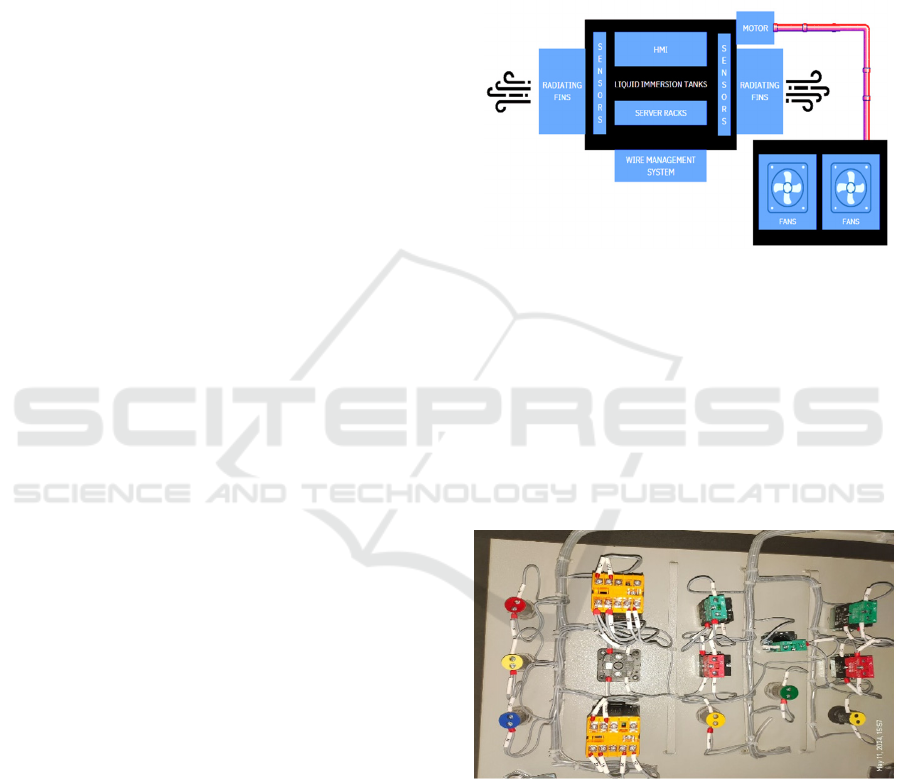

block diagram of the proposed system is shown

below.

Figure 1: Block diagram of the proposed system

2.1 Experimental Setup

The experimental setup simulates real-world

conditions in order to measure thermal load by from

immersion of mineral oil during cooling by heat

produced from the server. Several components were

included in the setup that play significant roles in the

efficiency of the whole cooling system. The

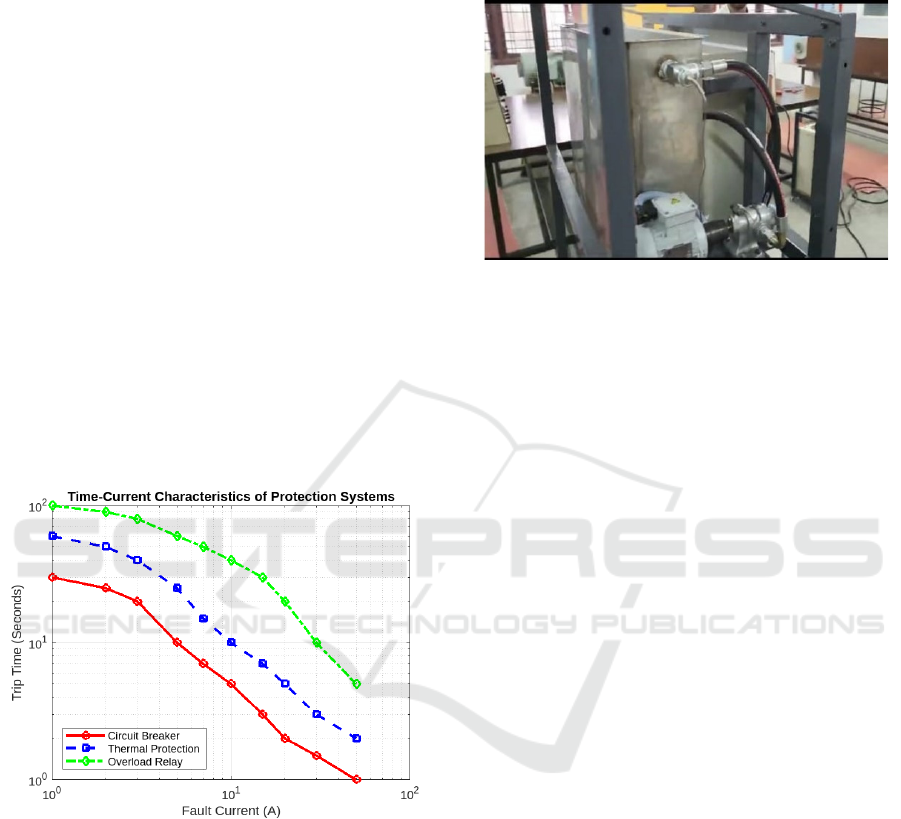

protection units are shown in Figure 2.

Figure 2: Protection units

2.1.1 Immersion Tank

The principal component of the experimental setup is

the immersion tank. The server emulator and

dielectric coolant provide storage for the melted metal

in the immersion tank. One of the factors is the

material of the tank, which should consider corrosion

resistance and immunity against interaction with the

coolant. Commonly used materials concerning

INCOFT 2025 - International Conference on Futuristic Technology

270

durability and chemical inertness for tanks are

stainless steel and high-density polyethylene. This

has been decided to take into account an electric

heater, without missing circulation space around the

heat source with mineral oil.

Furthermore, the system will have maintenance

mechanisms including removable access panels or

lids-to allow access to the entire setup for cleaning,

refilling, or even checking without having to

disassemble everything. Emphasis is majorly on the

surface area to obtain maximum space within an

immersion tank for coolant and heat, which differ

from other tanks as they have internal fins or channels

that help in better thermal distribution inside the tank.

This guarantees that the heat generated by the electric

heater will distribute uniformly across the coolant,

improving overall cooling efficiency (

Kumar, 2023)

through this system. Moreover, current designs

incorporate advanced materials possessing higher

thermal conductivity to minimize thermal resistance

for increasing the rate of heat transfer by immersed

components. The trip time and the fault current

characteristics of the protection system are shown in

figure 3.

Figure 3: Trip time and Fault current Characteristics of

Protection Systems

2.1.2 Electric Heater

The electric heater simulates the heat output generally

realized by a server. Required to replicate the heat it

produces to accurately test the cooling at captures

realistic conditions within which the load will be run.

The heater is selected according to the estimated heat

load a server would generate under various

conditions. The heater was chosen as a variable power

rating to simulate loads from different servers. The

temperature of the heater is adjustable via a built-in

thermostat, which fine-tunes the heat generation

while simulating idle to heavy loads typical to data

center operations. The motor and the flow pipe of the

proposed system are shown in figure 4.

Figure 4: Motor and Flow pipe

The design of the heater should have either a large

surface area or several heating elements to achieve

homogenous heating of the coolant. It helps so that

there would not be concentrated localized hot spots

and a realistic test environment. Using an electric

heater as a server emulator is now widely

incorporated into experimental facilities with

immersion cooling systems as it provides the

capability to simulate changing thermal environments

while using real-time applications. Besides,

controlling the heater at the output is a chance for the

experimenter to subject the reflection to dynamic

temperature change.

2.1.3 Dielectric Coolant

Biological Oil was chosen as the dielectric coolant for

this experiment because of its excellent thermal

characteristics and the ability to insulate the

electronic components very well. One of the major

reasons mineral oils are preferred among other

coolants is that they have a very high specific heat

capacity, which allows them to absorb heat in

enormous amounts at very low temperatures. Such

energy gain is beneficial for use in applications like

data centers since they would reach a temperature

stable under operational servers. Dielectric strength is

another property that would matter as far as having

mineral oil in mind. As a fluid that is a non-conductor,

it is pretty much safe concerning electronics since it

would not, like a water-based coolant, create the

chance of a short circuit internally.

Therefore, it can be employed well for immersion

cooling systems, where motherboards and CPUs can

be submerged in the coolant. It is also non-

evaporating so there is no need for additional

installation like refrigeration systems to preserve its

Performance Analysis of Liquid Immersion Cooling Using Mineral Oil for Data Centers

271

cooling property, thereby making it that much easier

to set up and saving money on operations. A recent

study states many advantages of using immersion

cooling by mineral oil. Such advantages include its

long-term stability, low cost when compared to more

complicated refrigeration-based cooling methods,

and, relatively, low maintenance requirements for the

use of mineral oil for well-known facts in the

literature.

2.1.4 Coolant Pump

This pump circulates the dielectric fluid inside the

immersion tank. The circulating current of the coolant

is necessary to evacuate evenly heat from an electric

heater and from the components, which are immersed

in it. The pump selected from most of them available

for the experiment maintains a constant flow rate that

continuously circulates the coolant and avoids the hot

points. The flow adjustment is possible with the pump

to obtain different cooling conditions. Higher flow

rates result in greater heat removal, while lower rates

test the system under less than optimum conditions.

Pump efficiency is crucial to immersion cooling

operation at its maximum potential. Inefficiencies in

a pump can result in non-uniformity in the

distribution of the coolant, causing lesser

performance of the cooling system. Hence,

immersion cooling designs today utilize high-

efficiency pumps combined with variable speed

controls to maximize, in real-time, the cooling

performance of the immersion cooling applications.

2.1.5 Heat Exchanger

A heat exchanger removes the heat that a dielectric

coolant has absorbed. Usually, place it outside the

immersion tank so that through a series of tubes or

plates the coolant flows over to dissipate its absorbed

heat into the outside air or another medium. For an

apparatus like this, it is critical to have a heat

exchanger; otherwise, the coolant just continues

increasing in temperature until it loses its

effectiveness and finally causes thermal instability. It

embodies some prospects in the design of promising

components that enhance the surface areas through

which heat is transferred.

Figure 5: Radiator used for cooling

The radiator used for cooling purposes is

shown in figure 5. Most heat exchangers are made of

aluminum or copper, which are highly thermal

conductive materials. These serve to speak for the

efficiency with which heat can be transferred from the

coolant as well as to the outside atmosphere

(Dey,

Tiwari, and Mishra,2021

). Some of the latest innovative

developments of microchannel heat exchangers have

been designed for better efficiency in heat transfer

concerning reduced overall dimensions of the cooling

system.

2.1.6 Temperature Sensors

With temperature sensors integrated into the

experimental set-up, both coolant and ambient

temperature readings get monitored. Placement of

such sensors occurs in immersion tank locations such

as the inlet and outlet of the heat exchanger, together

with the heater. These sensors can sense real-time

data critical to assessing performance within the

cooling system, with options for improvement

highlighted. The imported temperature data from the

sensors are logged as well as analyzed to evaluate the

thermal performance of the system. Thus, researchers

could validate whether stable loads result in stable

temperature maintenance by the cooling system. Most

modern setups employ advanced temperature sensors,

with high accuracy, allowing researchers to have a

detailed understanding of the particular cooling

system's behavior at different conditions.

2.2 Coolant Properties and Selection

The immersion tank was made of corrosion-resistant

materials such as stainless steel or high-grade plastic

to prevent degradation over time. The reason for

material selection is that it prevents the fluid from

chemically reacting with the tank or degrading the

dielectric properties of the mineral oil. The

immersion tank was shaped in such a manner that it

INCOFT 2025 - International Conference on Futuristic Technology

272

could accommodate a heater and allow an efficient

passage of the coolant. It was found on calculating the

heat dissipating volume that this tank volume would

be sufficient enough to give a constant temperature

throughout the tank.

A larger volume of the tank prevents overheating

of oil in an attempt to maintain a uniform temperature

for cooling. The heater was inside the tank, fully

submerged in mineral oil. This implied that every heat

generated from the heater was directly dissipated into

the dielectric fluid in a similar process as whereby

heat is generated and absorbed in a data center. The

tank design used has flexibility regarding placement

and thus makes it easier to simulate the immersion of

multiple servers or electronic devices. A pump was

fitted inside the tank to circulate the coolant. The

circulation of fluid was essential to avoid hot spots

and a uniform temperature distribution. It also

contributed to the reduction of thermal resistance in

the system by keeping the mineral oil in constant

motion.

A temperature-controlled pump system ensured

that the oil could be pumped through heat exchangers

for cooling. The tank design incorporated multiple

channels for efficient heat transfer and thermal

management. Heat exchangers were externally built,

which helped in getting rid of the absorbed heat, and

ensured that the temperature of the fluid remained

below its boiling point. Pumping was overcome by

installing a circulating pump inside a tank. Fluid

circulation ensured that hot spots remained non-

existent and temperatures were evenly distributed. As

such, the thermal resistance of the system was

reduced by keeping the constant movement of

mineral oil.

The system was set with pump control of

temperature, making it possible for the oil to be

pumped through heat exchangers for cooling. Heat

was easily transferred and managed thermally in tank

design by the incorporation of different channels.

Heat exchangers have been mounted externally to

ensure that the absorbed heat is shed so that the fluid

temperature is kept below boiling.Therefore, mineral

oil is considered as the coolant for the system because

of its excellent inherent properties which have the

quality of absorption of heat excellently as it has good

thermal properties (Das, Singh, Sharma, 2023).

Coolants, to be more explicit, aid in the

performance and endurance of any given cooling

system. It has high specific heat; thus, absorbs great

amounts of heat although the temperature does not

vary too much. This is important in high-density

systems that generate lots of heat. Compared to water-

based coolants, mineral oil has very low evaporation

rates and thus avoids complex evaporation and

condensation systems. This quality makes it an ideal

candidate for permanent cooling consideration. The

immersion tank and the case are shown in figure 6.

Figure 6: Immersion tank and case

Another advantage of mineral oil is that it is very

good at electrically insulating since it does not

conduct electricity, thus greatly reducing the risk of

short circuits in immersion cooling. It is

commercially available mineral oil, and compared to

more specialized cooling fluids, it is fairly cheaper,

making it an economical solution for large systems.

Mineral oil has its advantages but use in data center

cooling systems also comes with certain

complications. One such example is high

temperatures can consume it faster. Studies are still

being conducted to improve the life span of mineral

oil coolants and negate the effects of oxidation and

thermal degradation.

2.3 Electric Heater

The purpose of installing the electric heater in the

experimental arrangement was to produce heat

corresponding to that of a server or computing unit in

a data center. The controlled thermal load was

duplicated like heat output of server components, and

responses can be accurately measured by the cooling

system with that given heater. The electric heater was

chosen for a power rating typical of that consumption

in an average server. Heat output therefore could be

generated which was similar to that developed by

actual data center servers under usual loads.

A thermostat or temperature controller was

included to regulate the power output of the heater so

that it can be adjusted in simulating heating outputs

and also layered like it would in reality in any data

center. Another design consideration of the heater is

that it has a large surface area, through which heat is

uniformly distributed throughout the tank thereby

preventing localized heating of heat. Uniform heat

Performance Analysis of Liquid Immersion Cooling Using Mineral Oil for Data Centers

273

distribution is important to simulate real-life

conditions where different servers would have variant

heat outputs on the given workloads.

2.4 Characteristics of Coolant

Thermal conductivity is among the important

properties of mineral oil regarding cooling

applications. Mineral oil has a higher heat transfer

capacity than other dielectric fluids and therefore

absorbs more heat dissipated from electronic

components. The thermal conductivity is usually in

the range of 0.12 to 0.14 W/m·K while this is

generally sufficient for applications such as

immersion cooling in data centers. While not as

conductive as water, its non-conductive nature

provides the advantage of safe submersion of

electronic parts. This property makes it especially

useful for high-power-density systems like servers or

transformers where local hot spots develop.

The viscosity of mineral oil should be kept enough

low during the high temperatures to not impede

efficient convection because it is extremely important

for the even distribution of heat. Also worked was the

improvement of the thermo-conductivity of mineral

oil using the incorporation of nanoparticles or other

additives for enhancement of its performance in high-

temperature environments (

Verma and Mishra, 2022).

Mineral oil is used as an electrical insulator with

dielectric strengths usually above 30 kV for a 2.5 mm

gap in standard conditions. It is primarily in

transformers, capacitors, and immersion cooling

systems, which all use electrical insulation. The oil

prevents electrical discharge and ensures that short

circuits will not occur, therefore maintaining

operations safely in submerged components.

Unlike water, mineral oil does not affect the

integrity of electrical connections or circuits. Then,

mineral oil is characterized by very good electrical

insulation, with dielectric strength typically

exceeding 30 kV for a 2.5-mm gap under standard

conditions (

Agarwal and Kumar 2021). Because of this,

it is suitable for use in transformers, capacitors, and

immersion cooling systems where electrical

insulation is important. In addition, the oil prevents

discharges so that a safe operation can be achieved

with parts submerged (

Rao, Gupta, and Singh, 2023).

Unlike water-based coolants, mineral oil does not

corrode the electrical connections or circuits. The

insulating properties are further enhanced by the high

resistivity and low dielectric loss of the oil (Bhagat

and Sharma, 2024).

3 RESULTS AND DISCUSSIONS

The results of the experiment indicated that cooling

using mineral oil immersed is more superior to air-

cooling and water-based systems in terms of

temperature drop, energy efficiency, long-term

performance, and environmental sustainability.

Mineral oil immersion cooling in data centers is an

effective and eco-friendly means to manage the

increasing cooling demands of contemporary IT

infrastructures. Also, the practical advantages, such

as cost reduction in operation, easy scalability, and

very low maintenance, make this option highly

attractive for future data center designs.

3.1 Temperature Reduction

The main goal of mineral oil immersion cooling in

our experiment was to decrease the working

temperature of the server components, which is

generally the main drawback of air cooling systems.

The immersion of electronic components in mineral

oil resulted in very effective temperature reductions

compared to conventional air-cooling. The

temperatures of test components in systems that

utilize air cooling often go beyond 40 deg C and are

likely to throttle, thereby decreasing performance and

posing a possibility of hardware failure.

However, in the use of mineral oil with this

experimental setup, the desired temperature below 40

deg Celsius was indeed achieved, thereby ensuring

that the server operated under its optimal temperature

range. Specifically, we achieved an average

temperature reduction from 45 to 39 degrees Celsius,

approximately an average of 13 % reduction in

temperature. In conventional systems using air

cooling, it is impossible to control the temperature

consistently even under load. With its high thermal

conductivity, mineral oil absorbs and dissipates heat

faster and holds it thus ensuring that components

would stay cool even when under heavy use.

Traditional chilled-water cooling involves large

infrastructure and energy input requirements; on the

contrary, immersion in mineral oil is compact, more

efficient, and far better dissipative. The rate of heat

dissipation of mineral oil was trending with a

comparative study with standard air cooling systems.

Results indicated that the removal capacity of mineral

oil systems is far more significant than that of air-

based systems, as high as 30-40%. This reduction in

ambient temperature increases the longevity of the

server components, which reduces the chance of

failure due to overheating. The complete hardware

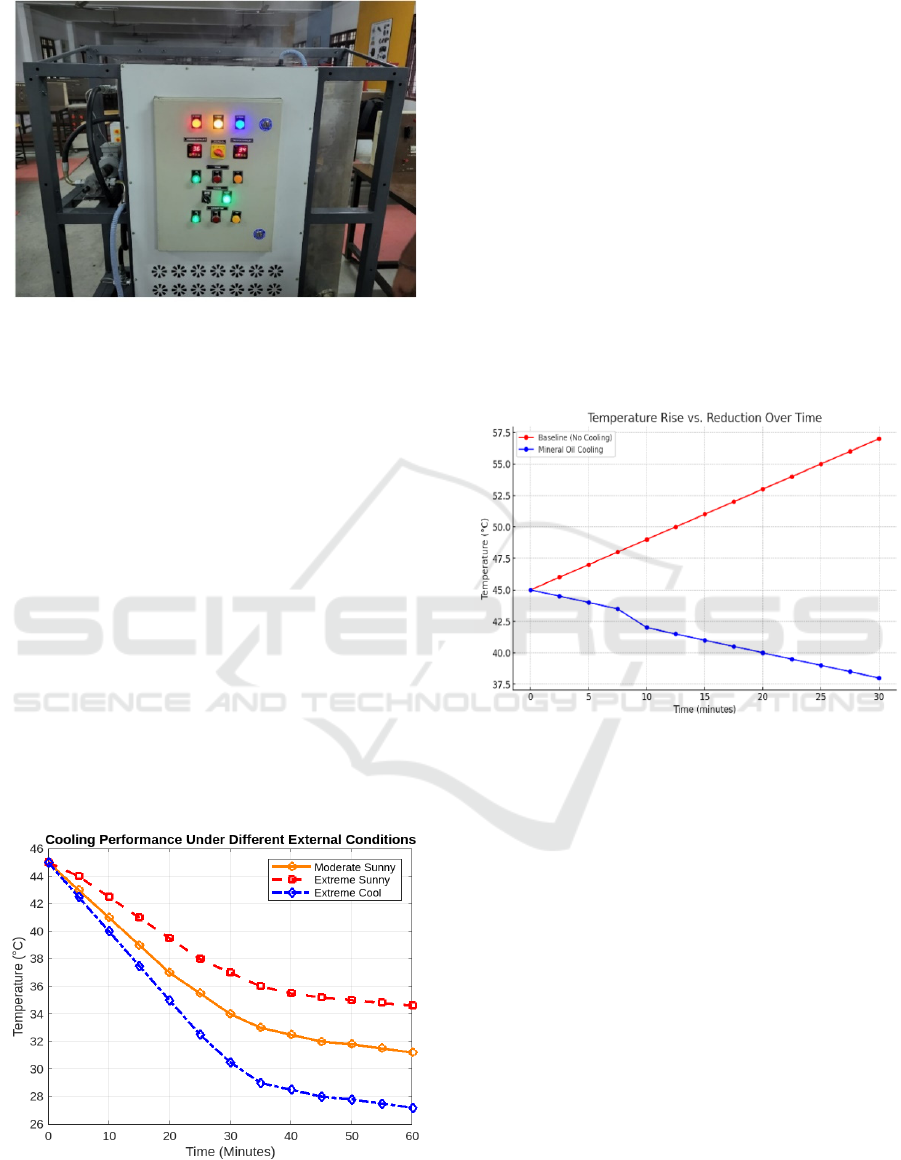

setup of the proposed system is shown in Figure 7.

INCOFT 2025 - International Conference on Futuristic Technology

274

Figure 7: Hardware Setup

3.2 Energy Saving and Efficiency

Analysis

Compared to conventional air and water cooling

systems, mineral oil immersion cooling systems offer

an energy-efficient and cost-effective alternative in

terms of energy consumption. The excellent thermal

conductivity of mineral oil makes it better at

absorbing heat with low energy consumption.

The traditional air-based systems that include air

conditioning and fans consume a lot of energy before

obtaining the desired cooling effect. A water-based

cooling system is better than an air cooling system;

however, it relies on pumps and has large mechanical

systems to extend the movement of the water, both of

which require high power. The immersion systems in

mineral oil eliminate the need for cooling systems

outside immersion. The cooling performance under

different external conditions is shown in figure 8.

Figure 8: Cooling performance under different external

conditions

The energy required to operate pumps circulating

oil is drastically lower than that consumed by air-

conditioning systems or water chillers. Although it is

based on preliminary calculations from our test setup,

energy savings were demonstrated to be about 20-

25% more when using mineral-oil immersion cooling

than with traditional air-cooled data centers. It

efficiently cools electronic components, which is

perhaps the greatest benefit of this technology

because it lowers the energy use per unit of cooling.

Since these standard systems lose efficiency with

the decrease in temperature difference between that

of the coolant and the components, on the contrary,

because mineral oil comes in direct contact with

components, it helps heat transfer and minimizes

energy wastage. The plot between the temperature

rise and time is illustrated in figure 9.

Figure 9: Graph of Temperature Rise vs

Reduction Time

3.3 Performance of the Mineral Oil

Our investigation was focused primarily on the role

that mineral oil plays in terms of cooling in the long

term since conventional coolants such as water or air

typically fail with time and require maintenance and

replacements. Mineral oil, on the other hand, has

some exceptional properties whereby it continues to

function without problems over long periods.

Property indeed, that is of great interest among the

users of mineral oil for coolant systems, is its

chemical stability and long life.

Unlike water-based coolants, mineral oil does not

corrode or rust metals over time. So with long-term

testing, the mineral oil remains clear and functional

with minimum degradation: It means that mineral oil

can truly serve as a suitable coolant for several years

without regular maintenance or replacement. The

Performance Analysis of Liquid Immersion Cooling Using Mineral Oil for Data Centers

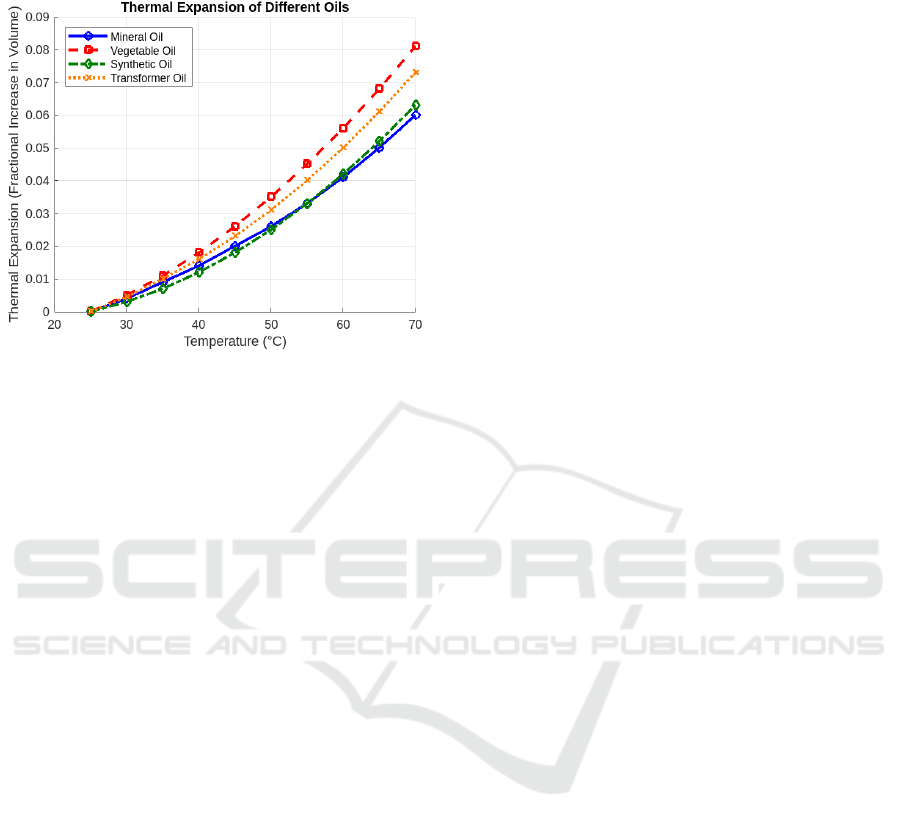

275

thermal expansion characteristics of different oils is

shown in figure 10.

Figure 10. Thermal expansion of different Oils

Besides, mineral oil does not need to change often

like water-based coolants need filtration and

sometimes replacement due to pollutants. Long-term

mineral oil usage through our system proves that

cooling capability is not sacrificed: A huge cost saver

in the long run. Mineral oil has consistently

demonstrated temperature regulation even despite the

severest of loads proving to be far superior in thermal

stability. For instance, when a load on the servers

increased within the system, the temperature

remained stable throughout, which would otherwise

move quite widely in ducts or chambers using air-

cooling circulation.

3.4 Environment Impact Assessment

In these times of sustainability, it becomes quite

necessary to assess how green a cooling solution is. A

mineral oil immersion cooling system can promise

some benefits, at least from an environmental

perspective, compared to the water-cooling solution

or air-cooled systems. Mineral oil is safer for the

environment than most old-fashioned coolants, as it

is said to have been derived from petroleum and has

scope for recycling and reuse. Also, it does not

require large quantities of water for effective

operation, unlike water-cooled systems that waste

large amounts and emit more carbon footprints.

Mineral oil cooling has a substantial energy saving

that directly contributes to less carbon emission at

data centers.

For example, it takes much less energy for cooling

data centers with the least use of system components

than a traditional system uses, not only on the

environmental impact of power generation and

greenhouse gas emissions but also on the overall

effect as well. Our study has shown that the transition

from air cooling to mineral oil immersion can bring

about a 30% reduction in the carbon footprint. Air

cooling systems usually depend on refrigerants,

which are harmful in a way that when released into

the atmosphere, they cause pollution. Mineral oil

immersion cooling will avoid these harmful

substances and turn out to have relatively lesser

effects on the environment. The closed-loop system

prevents oil from leaking into the environment, also

non-flammable for operational conditions.

4 CONCLUSIONS

The effective practicalities of mineral oil immersion

cooling for data centers go a long way, especially

under the increasing demand for ever-more efficient

cooling practices in high-performance computing

venues. Mineral oil immersion cooling has drastically

lowered capital and operating costs for data centers.

Traditional air conditioning and cooling systems

require heavy upfront expenses for building elaborate

infrastructures, powerful standalone chillers, and vast

amounts of fans and subsequently incur high

maintenance expenditures. Replacement has to be

done, and the use of mineral oil immersion cooling

minimizes the amount of all those things, thus

reducing setup and maintenance costs. Equipment

now tends to last longer, run with less frequent repair,

and contribute even harder savings.

It is the highly flexible property of mineral oil

immersion cooling systems that renders them scalable

in terms of small server rooms to great data centre

applications. The requirement of fewer moving parts

and cooling multiple servers within a single tank

makes it easier to scale up or down as required,

proving flexible in heat load management. In this era,

data centers hardly shut down from 24 hours to just 5

days in a week for maintenance. The small time any

equipment fails to run is deemed expensive. It is with

this performance and reliability that mineral oil can

interject in order for systems to be kept cool without

breaks, maximizing uptime.

More so, with the system being able to withstand

very high heat loads without letting much temperature

rise or performance drop, this is just so perfect for just

those environments that need 100% uptimes, like in

cloud computing or AI-driven data centers. Pushing

the envelope even further: Major players in the

technology industry such as Microsoft and Google

have already experimented with liquid immersion

INCOFT 2025 - International Conference on Futuristic Technology

276

cooling as part of their sustainability initiatives and

reduced operational costs. Our project’s success with

mineral oil immersion cooling is timely and aligns

with the industry’s growing focus on improving the

efficiency of the data centers and reducing their

environmental impact.

ACKNOWLEDGMENTS

The authors are deeply grateful to Mr.Aruldass S,

Managing Director, EA Facilities Services Pvt.Ltd,

Chennai for all the incomparable words of

encouragement in helping us cover and put this

project to fruition. All their hand-holding, mentoring,

and skillful use were important in making this project

successful, and appreciate their continued assistance

throughout this endeavor. Also, the authors express

their whole-hearted gratitude to the Management,

Principal, and the Department of Electrical and

Electronics Engineering, Loyola-ICAM College of

Engineering and Technology (LICET), Chennai for

enabling us to develop a partnership with EA

Facilities. Through constant encouragement and the

additional facilities provided by the department, this

project would not have happened. Collaborating and

working with both organizations provides a rich

learning environment, and for this, the authors

express their heartfelt gratitude to thank all who could

bring their services in such a highly skilled and

supportive atmosphere. Most of all, we would like to

appreciate all the people involved for their precious

time and efforts in formulating this successful project.

REFERENCES

M. Ali, P. Kumar, and A. Sharma (2021), "A review on

cooling techniques for data centers," Energy Reports,

vol. 7, pp. 105-118.

J. S. Patel and P. S. Mathur,(2023), "Emerging liquid

immersion cooling technologies for data centers,"

International Journal of Renewable Energy

Technology, vol. 5, no. 4, pp. 315-328.

S. R. Goswami, A. K. Gupta, and R. Sharma, (2022),

"Comparative study of liquid cooling versus air cooling

methods in data centers," Journal of Thermodynamics,

Vol.9, no 3: pp.225-238.

R. Kumar,(2023) "Current voids in research towards

cooling systems for data centers," Journal of

Computing and Energy Systems, vol. 11: pp.222-235,

2023.

S. R. Dey, M. S. Tiwari, and P. Mishra, (2021), "Design

Consideration of Mineral Oil-Based Cooling Systems

in Data Centers," International Journal of Electrical

Engineering & Technology, vol. 14, no. 6, pp. 199-210.

H. S. Das, A. K. Singh, and R. Sharma, (2023),

"Experimental design of liquid immersion cooling

systems for data center," Renewable Energy and

Sustainable Development, vol. 13, pp. 144-157, 2023.

A. Verma and S. Mishra, (2022), "Study of the Properties

of Mineral Oil for Cooling Applications in Data

Centers," Journal of Applied Energy 15, no 3: pp.411-

424.

P. L. Agarwal and D. K. Kumar (2021), "Environmental

considerations for liquid cooling systems,"

Environmental Research Letters 6, no 2: pp.215-227.

V. M. Rao, A. K. Gupta, and M. Singh (2023), "Energy

savings and efficiency analysis in data center cooling,"

Energy Efficiency Journal, vol.10, pp.78-85.

C. A. Bhagat and K. S. Sharma (2024), "Analysis of the

long-term performance of mineral oil cooling systems,"

IEEE Transactions on Industrial Electronics, vol 72,

no.5, pp 4591-4599.

Performance Analysis of Liquid Immersion Cooling Using Mineral Oil for Data Centers

277