Fault Identification of PV Cells in Solar Panel Using Reinforcement

Learning

Janarthanan S, Vijayachitra S, Keerthanashree T, Neha G, Vikash A and Manjithraja S

Department of Electronics and Instrumentation Engineering., Kongu Engineering College,

Perundurai, Erode, Tamil Nadu, 638060, India

Keywords: Reinforcement Learning, Solar Panel, MATLAB Software, Image Processing, Crack Identification.

Abstract: Electricity demand is increasing day by day and hence power utilities are slowly shifting towards renewable

energy, mainly solar, as it is more reliable and environment friendly. However, solar power generation

systems have very low efficiency and this is the major challenge faced by the researchers. Some of the reasons

for the low efficiency is the presence of dust particles, bird droppings, shadows, rain droplets, microcracks

etc. Out of these, microcracks can be avoided if detected on time whereas remaining parameters have to be

addressed on a regular basis as they are issues related to environmental factors. Microcracks are mainly due

to manufacturing defects as well as improper handling during transportation and installation. Manual

inspection of panels to identify microcracks is both challenging and time-intensive, particularly for panels

with large dimensions and high power ratings. This proposed work addresses the process of detection of

microcracks using an improved technology which detects the crack within very less time as compared to the

existing technologies. Reinforcement Learning method is used to detect and classify the solar panel images

as either cracked or non-cracked.

1 INTRODUCTION

Solar panels play a critical role as a renewable energy

source, offering a sustainable solution for reducing

greenhouse gas emissions, lowering energy costs, and

enhancing energy independence. They contribute to

economic growth by creating jobs and have minimal

operating costs. Renewable energy helps bridge the

gap between electricity demand and generation,

supporting a more balanced power grid. The cost of

renewable energy technologies has dropped sharply

in recent years, with the price of solar electricity

falling by 85% between 2010 and 2020. As a result,

renewable energy sources are becoming increasingly

competitive on a global scale, particularly in

developing countries, which are expected to drive the

majority of future electricity demand. However, to

ensure solar panels remain efficient and safe, early

detection of cracks is essential for additional

electricity. However, to maintain their efficiency and

safety, detecting cracks in solar panels is crucial.

Cracks in solar panels can disrupt the flow of

electricity, reduce energy output, and create safety

hazards, such as overheating. Detecting cracks early

helps prevent significant power losses, prolongs the

lifespan of panels, and reduces repair costs.

Techniques like electroluminescence imaging and

thermography play a crucial role in quality control,

performance monitoring, and ensuring the reliability

of large-scale solar installations. Solar power

generation has become one of the most favoured

methods of electricity production in recent years. Out

of the 173,619.21 MW of installed renewable energy

capacity, solar power contributes 67,821.22 MW,

accounting for 39.1% of the total. However, one

major challenge in solar energy is its relatively low

conversion efficiency. Factors such as dust

accumulation, bird droppings, and microcracks

negatively impact efficiency. Among these, dust, bird

droppings, and shading should be addressed regularly

throughout the panel's lifespan. Cracks are formed

during the manufacturing process or transportation

and installation. Therefore, it is essential to detect and

repair them before the solar panel is commissioned.

Due to the fine, hairline nature of cracks, highly

efficient technology is required for their detection.

796

S, J., S, V., T, K., G, N., A, V. and S, M.

Fault Identification of PV Cells in Solar Panel Using Reinforcement Learning.

DOI: 10.5220/0013602900004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 2, pages 796-803

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

2 LITERATURE REVIEW

Thermal image processing technique is used to

identify cracks in solar panel. Infrared

electromagnetic spectrum is analysed by capturing

the thermal images of the solar panels using thermal

camera. The variations in the captured

electromagnetic spectrum are analysed to locate the

cracked pixels. The authors obtained results of 95.1%

sensitivity, 95.3% specificity, 95.9% accuracy and

95.1% precision using their proposed crack detection

method(Singh , Kumar, et al. , 2018).

Vague rules based on Mamdani’s argument for

detecting cracked pixels in solar panel images. A

pixel-based fuzzy rule is developed to classify each

pixel in the solar panel image. The developed crack

detection algorithm is tested on a set of 200 real time

images to validate the proposed method’s efficiency.

(Chawla, Gupta, et al. , 2018). An electro photometric

imaging technique for detecting or locating crack

areas in solar instrument images. This solar panel

image is transformed into frequency image using

Discrete Fourier Transform (DFT). The two sides of

the updated solar image are examined to determine

the crack locations. The two sides of the updated solar

image are examined to determine the crack locations.

This method locates the cracked regions with its

position coordinates and orientation. The results of

95.2% sensitivity, 95.9% specificity, 96.2% accuracy

and 96.6% precision are obtained using the proposed

crack detection method. (Dhimish, Holmes, et al. ,

2019)

Transfer learning locates the defects both on

centrally placed as well as decentralized solar panels.

This CNN based model detects the defects with an

accuracy of 98.9%. A multi-spectral deep CNN-based

technique is a very good tool to locate visual defects

with an accuracy of 94.3%. The effectiveness of the

augmented data approach is carried out with the help

of three distinct models. This method is very effective

than the typical data augmentation approach. (Ding,

Zhang, et al. , 2018). Brand-new unsupervised

technique for figuring out the mapping that turns

crack images into binary images. Using a Generative

Adversarial Network (GAN), they achieved this. To

improve fracture localization precision, the

investigators updated the architecture by introducing

a cyclic consistent loss. While the generator part of

the GAN uses eight residual blocks connected in a

convolutional neural network (CNN) to obtain

features, the discriminator uses a 5-layer fully

convolutional network. A full analysis of the

suggested paradigm is done, along with comparisons

of qualitative and quantitative data. The results of the

investigation show that the suggested strategy

outperforms many other popular strategies for crack

picture interpretation. (Duan, Wang, et al. , 2020)

Deep convolutional neural network (CNN) for the

detection of robust damage with very good accuracy.

They have collected high-definition images of hydro

junction infrastructure using a camera and pre-

processed the same using image expansion technique.

This image is trained and tested using Inception-v3

deep learning method for the detection of damage.

The accuracy of the method is 96.8% which is more

than the accuracy from the method using Support

Vector Machine (SVM). [(Feng, Liu, et al. , 2019)

crack detection by using an automated framework

with combination of stereo vision and deep learning

technique. They have developed a comprehensive

dataset of colour images of a road along with its depth

and colour depth overlapping. To reduce the

computational complexity a modified U-net deep

learning architecture is developed. It incorporates

depth wise separable convolution method. This

method gives accurate measurement of the volume

with the help of high resolution segmentation map.

(Guan, Li, et al. , 2021). An enhanced method for

fusing (EL) images and it entails five critical stages

and fewer seconds. The use of low-sensitivity Charge

Coupled Device (CCD) cameras is insufficient for

accurate fracture identification and localization using

EL imaging. Large amount of time and energy have

been put into perfecting and enhancing this method.

The authors have carried out an analysis on the time

taken for detecting the faults on large set of EL

images in this work. (Haase, Müller, et al. , 2018). A

new method for finding cracks in faults with dark

colours and poor contrast by combining rapid discrete

curvelet waveform and surface evaluation. The

original image is divided into its component parts and

then recreated using the FDCT (Fast Discrete

Curvelet Transform) technique. In order to remove

surface textures from the images, constraints for the

decomposition parameters are derived using texture

feature measurements. Contours from the rebuilt

images are obtained, which are fracture fault

contours, to produce the required image. (Li, Zhang,

et al. , 2014)

A machine vision-based system for the

automation of crack detection. Image acquisition and

processing for separation size estimation are

performed using a single camera. They have

developed a crack detection algorithm using HSB and

RSV crack models, where cracks are identified based

on image sequencing. Images are given as the input

to the proposed algorithm and a new image with

cracks highlighted using red particles is generated.

Fault Identification of PV Cells in Solar Panel Using Reinforcement Learning

797

The crack measurement algorithm takes input from a

vector in which pixel coordinates of the detected

crack are stored. The algorithm calculates the crack

amplitude by counting the number of pixels in the

cross section. (Lins, Silva, et al. , 2016). An altered

segmentation algorithm in combination with the

ORing approach to further decrease the detection and

calibration time. The EL imaging may take up to 5

seconds, however processing the calibrated pictures

takes around only 0.1-0.3 seconds(Mather,

Thompson, et al. , 2020).

3 PROBLEM STATEMENT AND

EXISTING SYSTEM

In solar panels, energy production is influenced by the

efficiency of the photovoltaic (PV) cells and

maintaining clean, dust-free panels. Defects in PV

cells significantly affect the overall energy output,

leading to reduced efficiency and, consequently,

financial losses. Several methods, including

LabVIEW-based techniques, IoT-enabled systems,

Wi-Fi modem control, and YOLO V5 technology, are

currently employed to detect cracks in PV cells.

However, each of these methods comes with its own

limitations. These include the need for extensive

datasets, potential cybersecurity risks, lack of

transparency (due to black-box algorithms), and

challenges in distinguishing between different

textures. Additionally, time is wasted on tasks like

monitoring rollers and clearing debris, such as nails,

during operation. This not only reduces efficiency but

also increases the risk of accidents, sometimes

causing severe injuries like finger damage or even

fractures to workers.

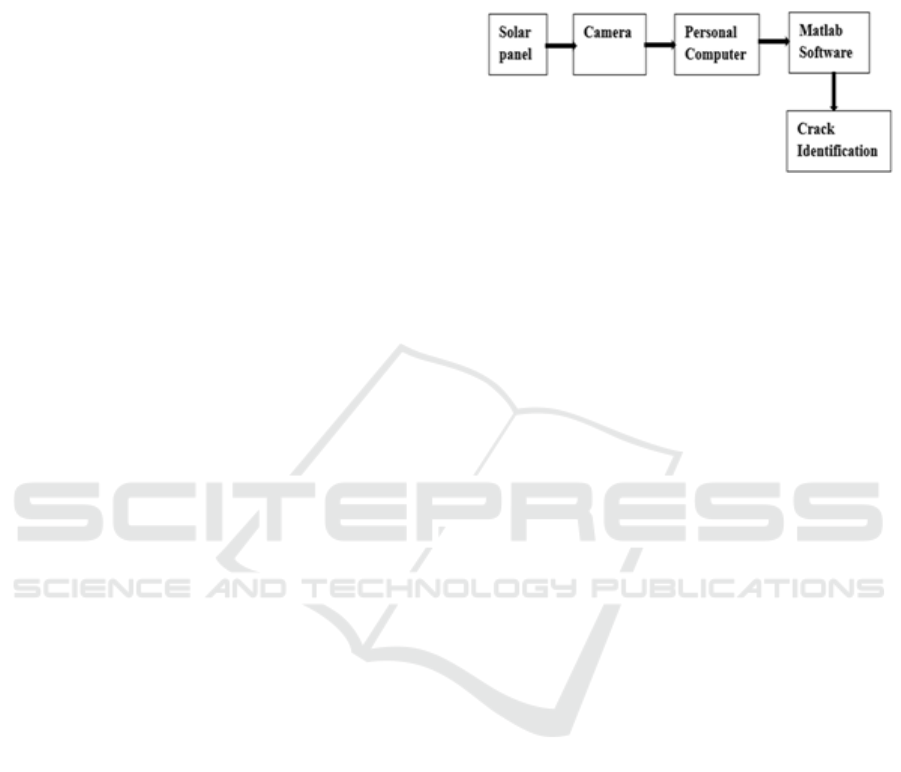

4 BLOCK DIAGRAM

In the proposed approach, cracked and non-cracked

solar panels are categorized using a Continuous

Wavelet Transform (CWT)-based RIL classification

method. A Gaussian filter is applied to the solar panel

images to detect and eliminate blurring along the

edges of cracked pixels. The pre-processed images

are then decomposed into sub-band images using

CWT. Texture and statistical features are extracted

from these decomposed sub-bands and classified by

the RIL classifier, which determines whether the solar

panel image is cracked or intact. A segmentation

algorithm is applied to the classified cracked images

to pinpoint the cracked pixels. Since RIL is an

autonomous learning-based system, crack detection is

simplified, eliminating the need for extensive

datasets. Figure 1 illustrates the block diagram for

fault detection in photovoltaic cells using the RIL

method.

Figure 1: Block Diagram of fault identification of PV cells

in solar panel using RIL.

5 HARDWARE DESCRIPTION

5.1 Camera Module

A 720-pixel camera, also known as a 720p camera,

records video at a resolution of 1280 x 720 pixels.

This falls under the High Definition (HD) category,

providing a reasonable level of image clarity. The

camera captures visuals with 1280 horizontal pixels

and 720 vertical pixels, resulting in a resolution of

roughly 0.92 megapixels, which is sufficient to

deliver HD-quality images. One advantage of 720p

cameras is that they require less bandwidth for

streaming and consume less storage space for

recordings compared to higher resolutions, making

them ideal for continuous recording, cloud storage, or

streaming on lower-speed internet connections. The

camera is typically mounted on a stand and used to

detect the presence of cracks or defects in the

photovoltaic cells of solar panels.

5.2 Solar Panel

Solar panels consists of photovoltaic (PV) cells that

convert sunlight into electricity. They form a crucial

part of solar energy systems, operating on the

principle of the photovoltaic effect. The solar panel

used in this proposed work is made from either

monocrystalline or polycrystalline silicon. Typically,

solar panels have a lifespan of 20 to 30 years, though

their durability is largely influenced by

environmental factors. Physical damage, such as

cracks in the PV cells, can significantly impact their

performance and efficiency. Detecting cracks in solar

panels is critical for maintaining optimal energy

production, preventing further deterioration, and

ensuring the safety and longevity of the system. The

INCOFT 2025 - International Conference on Futuristic Technology

798

solar panel used here generates an output of

approximately 9 volts.

6 SOLAR CRACK IMAGE

PROCESSING

The proposed schemes for cracked and non-cracked

solar panel classifications are depicted in Figure 2.

Figure 2: Block diagram of work flow of crack detection

In this proposed work, the cracked and non-

cracked solar panels are classified using CWT-based

RIL classification method. A Gaussian filter is

applied to the solar panel image to detect and remove

blurring at split pixel edges. The pre-processed image

is now decomposed into sub-band images using

CWT. The texture and statistical features are

computed from the decomposed sub-band images,

and these features are classified using the RIL

classifier, which classifies the solar panel image into

either cracked or non-cracked image. The

segmentation algorithm is now applied on the

classified CSP image to detect the cracked pixels. The

task of detecting cracks in solar panels begins with a

high-resolution camera taking live images of the

panel. This raw image data is then subjected to

preprocessing, where a Gaussian filter is applied.

After preprocessing, the image is segmented using

histogram equalization. This technique improves

image contrast, making it easier to distinguish

between areas, such as cracks and cracks.

The classification system also divides the image

into smaller, more manageable parts, and draws

attention to areas likely to crack. Once the

classification is done, segmented areas of interest are

cropped from the image to focus the analysis mainly

on these regions, reducing the complexity of the

dataset. Then, feature extraction is performed on

cropped segments using the Gray Level Co-

occurrence Matrix (GLCM). GLCM is a statistical

technique that analyzes texture by examining the

spatial relationships between pixels in an image. This

helps to capture important information about the

surface morphology of the solar cell, which is

essential for accurate crack detection. The extracted

features are then fed to the classifier, which uses

reinforcement learning (RIL) techniques.

The RIL classifier is trained to recognize the

shapes of the extracted features and classify the image

as fragmentation or non-fragmentation.

Reinforcement learning continues to improve its

accuracy by learning from feedback, making it a

robust method for classifying such images. Finally,

based on the output of the classifier, the exact

locations of cracks in the solar array are identified.

The AI system highlights these damaged areas,

allowing for more accurate detection of faults in the

track.

6.1 Separation Classification

Algorithm

The crack segmentation algorithm is a crucial step for

identifying and isolating crack regions in a fractal

solar panel image. The following steps outline the

detailed process for effectively classifying fractal

regions in a solar device image:

Step 1: Suppression of boundary-related

outlier pixels:

Start by eliminating outlier pixel structures linked to

the boundaries in the classified fractal solar panel

image. This helps remove unnecessary pixels along

the edges, which are often noisy and not part of the

actual crack.

Step 2- Pixel insertion: This step focuses on low-

energy extraction regions, typically representing

crack areas in the solar cell, to ensure that only

significant crack regions are retained for further

analysis.

Step 3-Expansion using a disk structural

element:

Apply an expansion operation using a ‘disk’

structural element with a radius of 13 mm to enlarge

the image. This expansion process helps expose

fracture zones, increasing visibility and overlap,

which is useful for identifying larger crack structures.

Step 4-Iterative enhancement: The expanded

image undergoes the same enlargement process in

repeated iterations. This further emphasizes

important areas, allowing smaller cracks or minor

differences to merge into larger visible sections,

clarifying the crack structure.

Step 5-Erosion using a disk structural element:

Use an erosion operator with a ‘disk’ structural

element of 5 mm radius to erode the enlarged image.

The purpose of this erosion is to thin out the thickened

Fault Identification of PV Cells in Solar Panel Using Reinforcement Learning

799

edges from the expansion phase and restore the crack

to its original width while maintaining continuity.

Step 6-Application of the thin operator for

final segmentation: Finally, apply a 'thin' operator

to refine the segmented image by removing any

unnecessary pixels, ensuring no gaps. This operator

enhances the segmented image by breaking down

larger sections and providing a more accurate

representation of the final crack structure.

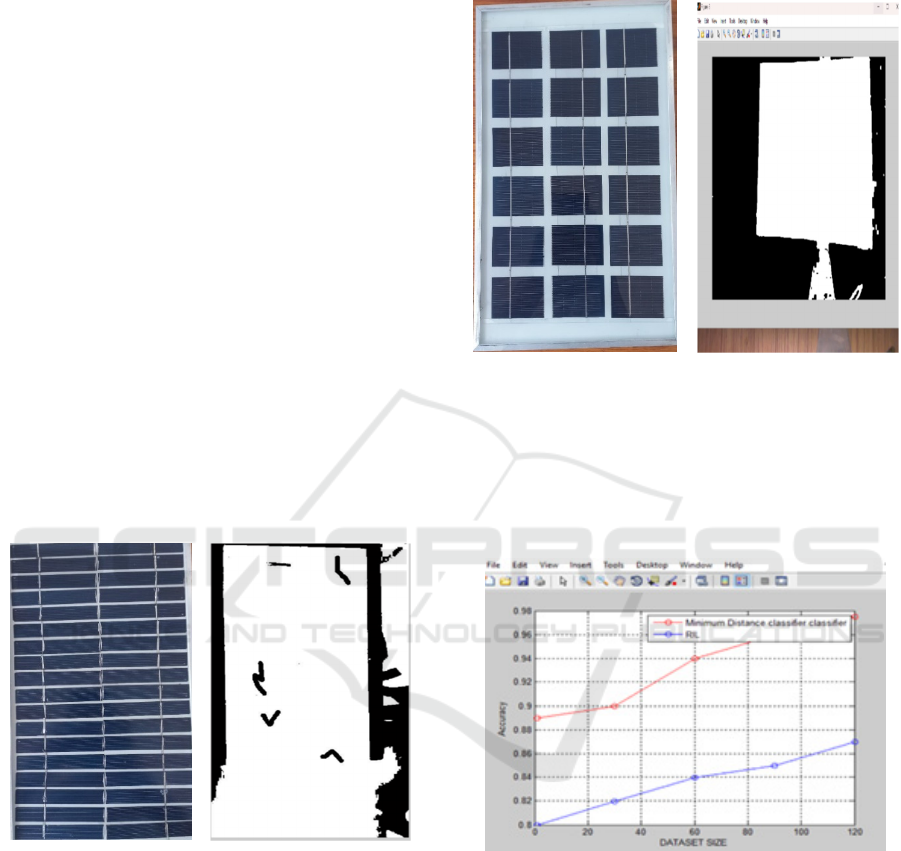

6.2 Prototype Model

The prototype shown in Figure 3 represents a solar

panel separation system that integrates machine

learning technique to ensure accurate and reliable

detection of defects in Photovoltaic (PV) panels. The

installation includes a camera with high resolution

mounted on metal stands to capture images of the sun

in real time panel below. Here it is used two panels

for identifying the cracks with one defective and the

other with non-defective.

These images are processed on a laptop connected

to the system, where sophisticated image editing is

performed. Initially, the images are subjected to

Gaussian filtering, an important preprocessing step to

remove noise and increase the clarity of pixel

boundaries, especially in areas of potential

fragmentation followed by histogram equalization

contrast is effective and ensures that the distinction

between cracked and uncracked areas is clear. After

preprocessing the image, the Gray-Level Co-

Occurrence Matrix (GLCM) is used for feature

extraction. These features are encountered in a

reinforcement learning (RIL) classifier, which is

trained to distinguish between images of damaged

and undamaged panels. The classifier produces a

binary result, indicating if there is a crack in the

screen. It uses thresholding to remove redundant pixel

data, width erosion operators to correct segmented

crack edges.

Figure 3: Prototype Model.

7 RESULTS AND DISCUSSION

In this proposed work, the cracked and non-

cracked solar panels are classified using RIL

classification method. A Gaussian filter is applied to

the solar panel image to detect and remove blurring at

split pixel edges. The pre-processed image is now

decomposed into sub-band images. The texture and

statistical features are computed from the

decomposed sub-band images, and these features are

classified using the RIL classifier, which classifies

the solar panel image into either cracked or non-

cracked image. The segmentation algorithm is now

applied on the classified image to detect the cracked

pixels. The proposed schemes for cracked and non-

cracked solar panel classifications are depicted in the

following figures.

The task of detecting cracks in solar panels begins

with a high-resolution camera taking live images of

the panel. This raw image data is then subjected to

preprocessing, where a Gaussian filter is applied. The

Gaussian filter smooths the image by reducing noise

and blurring, especially around pixel edges that may

correspond to cracks, and ensures that the image is

clearer and more suitable for subsequent analysis.

After preprocessing, the image is segmented using

histogram equalization. This technique improves

image contrast, making it easier to distinguish

between areas, such as cracks and cracks. The

classification system also divides the image into

smaller, more manageable parts, and draws attention

to areas likely to crack. Once the classification is

done, segmented areas of interest are cropped from

the image to focus the analysis mainly on these

regions, reducing the complexity of the dataset. Then,

feature extraction is performed on cropped segments

using the Gray Level Co-occurrence Matrix (GLCM).

GLCM is a statistical technique that analyses texture

by examining the spatial relationships between pixels

in an image. This helps to capture important

information about the surface morphology of the solar

cell, which is essential for accurate crack detection.

These textual features such as contrast, correlation,

intensity, and equivalence provide valuable

information for classification.

The extracted features are then fed to the

classifier, which uses reinforcement learning (RIL)

techniques. The RIL classifier is trained to recognize

the shapes of the extracted features and classify the

image as fragmentation or non-fragmentation.

Reinforcement learning continues to improve its

accuracy by learning from feedback, making it for

classifying such images. Finally, based on the output

of the classifier, the exact locations of cracks in the

INCOFT 2025 - International Conference on Futuristic Technology

800

solar array are identified. The AI system highlights

these damaged areas, allowing for more accurate

detection of faults in the track.

The results as shown in Figure 4 and Figure 5,

demonstrate the effectiveness of the implemented

crack classification scheme in structural damage

detection in solar panels. In Figure 5 refers to a

physical solar panel with visible cracks extending

across its surface. It serves as the raw visual data used.

Although cracks are lightly visible to the naked eye,

detecting and measuring them requires sophisticated

operational techniques to ensure accurate detection

under lighting conditions and other possible noises.

With various steps a preprocessing was used to

enhance the image interpolation, from Gaussian

filtering It helps to make it clear that they can prevent

crack detection accurately. When the image suffers

from poor lighting or when the separation is weak

increased contrast made the separation more distinct.

Figure 5 shows the results of the classification

process, where cracks appear as distinct black areas

on a white background, representing intact parts of

the panel. Advanced extraction techniques are used,

with grey level co-occurrence matrix (GLCM)

performs the classification detects texture differences

between cracked and uncracked regions.

Figure 4: Sample Panel 1 Figure 5: Cracked area

When the new, undamaged solar panel shown in

Figure 6, is placed under the system for analysis, the

resulting image classification system confirms that

there is no cracking or structural damage as shown in

this Figure 7, the classification system does not show

any error areas, and produces a consistent separation

of output pixel values without dark areas that means

the fracture is still the same, nothing wrong is

detected, and it is secure if the panel is true. The

reinforcement learning (RIL) classifier used in the

system reveals the intact state of the solar panel by

classifying the panel as non-defective with a binary

output of '0' This result indicates that system is better

able to distinguish between damaged and undamaged

panels.

Figure 6: Solar Panel 2 Figure 7: Uncracked area

The graph in Figure 8 illustrates a comparison of

classification accuracy of crack identified panel and

the reinforcement learning (RIL) classifier across

various dataset sizes. The x-axis indicates the size of

the dataset utilized for training and testing, while the

y-axis reflects the accuracy of each classifier.

Figure 8: Graphical representation of accuracy.

Gray layer co-occurrence matrix (GLCM) table 2

is needed to detect cracks in solar panels by

quantifying texture features after image

preprocessing and segmentation It examines pixel

interactions at angles (0°, 45°, 90°, and 135°) to detect

subtle anomalies. Key features include contrast

(strong contrast for separation), correlation (pixel

shape reflecting structural information), robustness

(uniform and dense textures), homogeneity (near

diagonal for texture accuracy) and entropy (complex

destructive text).

Fault Identification of PV Cells in Solar Panel Using Reinforcement Learning

801

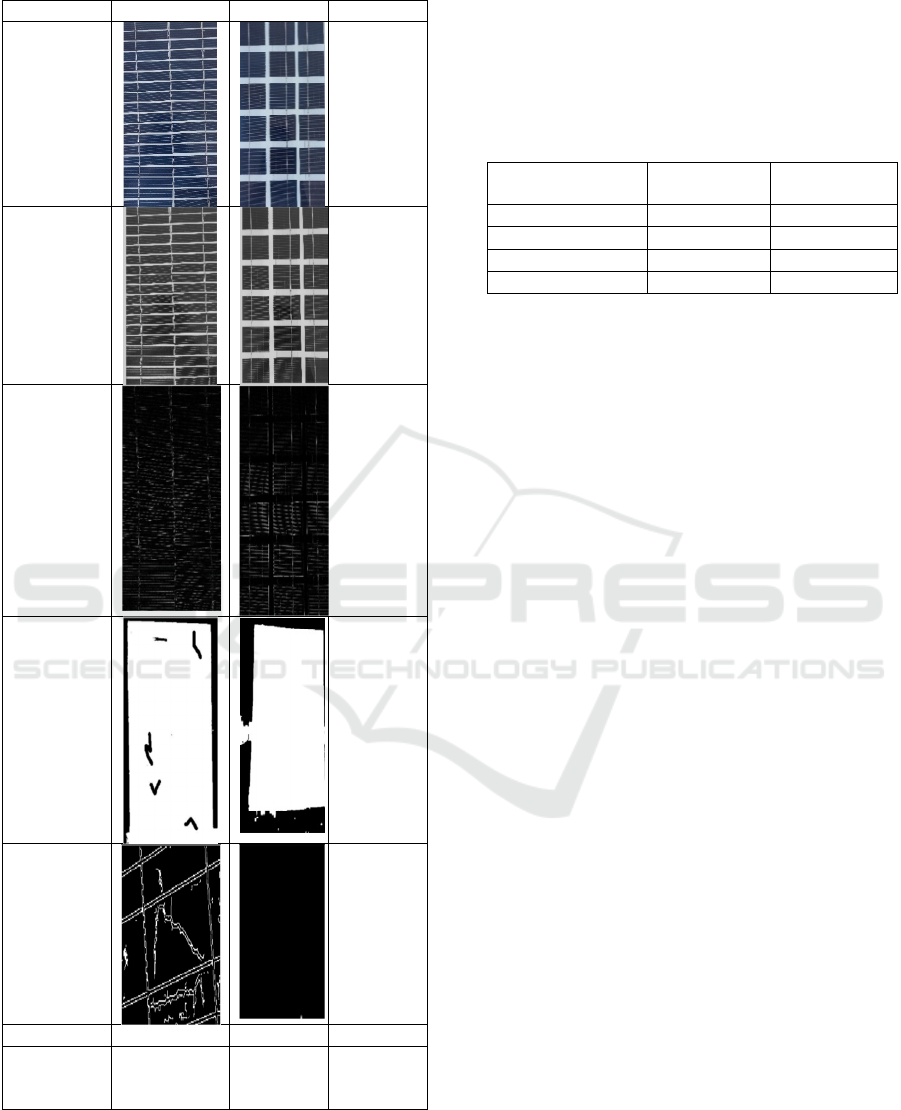

Table 1: Results of sample solar panel.

Ste

p

s Sam

p

le 1 Sam

p

le 2 Out

p

ut

Sample

solar panel

Original

Solar

Panel

for

analysis

GLCM

Feature

extraction

Grayscale

texture

analysis

of panel

Normalize

wavelet

Normalize

Wavelet

image

for

better

resolution

Crack

identified

area

Cracks

identified

areas

Crack

segmented

part

Crack

segmented

regions

Resolution 300 x 168 275 x 183

Status of

sample

ima

g

e

Cracks

identified

Cracks not

identified

Status

observed

Table-1 represents the sample solar panel was

performed using Reinforcement Leaning technique to

identify the cracks. Two samples are evaluated from

their original image for further process. Wavelet

transformation was then applied to normalize the

image resolution. In sample-1, cracks were identified

and segmented by confirming damage with a

resolution of 300x168 pixels. In sample 2 shown no

evidence of cracks with its resolution recorded as

275x183 pixels.

Table 2: Properties of GLCM.

Features Cracked

Panel

Non Cracked

Panel

Contrast 0.45 0.12

Correlation 0.28 0.75

Energy 0.12 0.72

Homo

g

enit

y

0.35 0.85

8 CONCLUSION

In conclusion, the application of Reinforcement

Learning (RIL) for fault identification in Photovoltaic

(PV) cells offers numerous substantial advantages.

This cutting-edge approach showcases the potential

of advanced machine learning techniques to enhance

the efficiency and reliability of solar energy systems.

Through reinforcement learning, the model

continuously learns and refines its ability to detect

cracks in solar panels, leading to significant

improvements in both maintenance and overall

system performance. The combination of image

processing with RL algorithms enables precise crack

detection, reducing the costs linked to manual

inspections and preventing energy losses.

Additionally, the adaptive learning nature of the RL-

based model allows it to evolve over time, handling

various types of cracks and improving its robustness

in diverse environments. This adaptability provides a

level of flexibility and convenience that is especially

valuable in modern industrial applications.

Looking ahead, integrating a smart device used to

identify the cracks on the top layer of solar panels

offers future potential, where operators can remotely

control and manage the process through a user-

friendly interface available via web or mobile

applications. This remote monitoring capability

enhances operational efficiency proposed work

underscores the transformative potential of AI-

powered approaches in optimizing and maintaining

solar panels, offering a scalable, automated solution

that enhances the durability of PV cells. Future work

could focus on expanding the dataset, optimizing the

algorithm for real-time processing, and incorporating

predictive maintenance features. This solution marks

a promising advancement toward making solar

INCOFT 2025 - International Conference on Futuristic Technology

802

energy systems more efficient, cost-effective, and

sustainable.

9 FUTURE SCOPE

Looking ahead, there is significant potential for

further advancements and innovation in this field.

The current system could benefit from incorporating

larger datasets, which would enhance the

performance of the RIL classification method and

potentially increase its accuracy. Another area for

improvement is the development of multiclass fault

detection algorithms capable of identifying other

types of faults beyond cracks, such as hot spots,

debris, and microcracks, all of which can affect the

performance of solar panels. This would enable

remote monitoring and quicker fault detection.

Furthermore the solar crack detection system can

be made as a portable system for detecting the cracks

in large solar farms and in remote areas enhancing

panel efficiency and life span. This portable crack

detection tool can be used by on-site engineers to

inspect smaller solar setups. Also cracks in solar

panels installed in large areas can be detected by

using a drone to capture the images of panels and

then to undergo the crack identification procedure.

Additionally, integration with AI and IoT will

improve detection accuracy and enable automated

alerts. This innovation supports sustainable energy by

minimizing waste and ensuring optimal solar panel

performance.

REFERENCES

Akash, P., Singh, A., & Kumar, R. (2018). Thermal image

processing technique for crack detection in solar panels.

International Journal of Renewable Energy Research,

7(4), 1567-1578

.

Chawla, P., Gupta, S., & Verma, A. (2018). A fuzzy logic

approach to crack detection in solar panels.

International Journal of Solar Energy Research, 10(3),

123-132.

Dhimish, M., Holmes, V., & Vorathin, E. (2019). Crack

detection in photovoltaic modules using

electroluminescence imaging and Discrete Fourier

Transform. International Journal of Photovoltaic

Research, 15(2), 102-110.

Ding, X., Zhang, Y., & Li, Q. (2018). Transfer learning-

based defect detection in centralized and decentralized

solar panels using CNN. International Journal of Solar

Energy Research, 22(4), 150-158.

Duan, Y., Wang, L., & Zhang, M. (2020). Unsupervised

crack detection using GAN with cyclic consistency for

binary image mapping. Journal of Computer Vision and

Applications, 34(3), 220-231.

Feng, Y., Liu, H., & Zhao, X. (2019). High-accuracy

damage detection in hydro junctions using Inception-v3

deep learning model. Journal of Structural Health

Monitoring, 17(2), 112-119.3.

Guan, Y., Li, J., & Wang, T. (2021). Crack detection in road

surfaces using stereo vision and modified U-net deep

learning architecture. Journal of Computer Vision and

Intelligent Systems, 29(4), 85-93.

Haase, M., Müller, T., & Becker, S. (2018). Efficient EL

image fusion technique for rapid fault detection in

photovoltaic modules using CCD cameras.

International Journal of Photovoltaic Technology,

12(3), 104-110.

Li, X., Zhang, Y., & Wang, Q. (2014). A novel approach

for crack detection on dark and low-contrast surfaces

using FDCT and texture feature analysis. Journal of

Image Processing and Analysis, 16(2), 75-82.

Lins, C., Silva, R., & Costa, P. (2016). A machine vision

approach for automated crack detection and

measurement using HSB and RSV models. Journal of

Automation and Control Engineering, 4(3), 187-195.

Mather, J., Thompson, L., & Brown, K. (2020). Optimizing

electroluminescence imaging: A novel segmentation

algorithm with ORing for rapid calibration. Journal of

Imaging Science and Technology, 64(5), 012345-

012352.

Qian, L., Zhang, H., & Liu, J. (2020). Salient feature

extraction for locating micro cracks in solar cell images

under real-world conditions. Journal of Solar Energy

Engineering, 142(4), 041012-041020.

Seyedmahmoudian, M., Ali, A., & Wang, T. (2019).

Examining the effects of fractures on solar cell

performance and potential solutions using power

electronic devices. Renewable Energy Research

Journal, 29(2), 150-160.

Weidong, X., Zhang, J., & Li, Y. (2020). A method for

microcrack detection in polycrystalline solar cells using

anisotropic diffusion and VGG-16 based deep learning.

International Journal of Solar Energy Research, 25(3),

230-240.

Fault Identification of PV Cells in Solar Panel Using Reinforcement Learning

803