Design of a Ultrasonic Harmonic Scalpel Circuit for Precise Tissue

Cutting

Jyothirmayi M, Chandu S, Anuj Damani, Karthik K S and Priyanka H S

Department of EIE, M S Ramaiah Institute of Technology, MSR Nagar, Bengaluru, Karnataka, India

Keywords: Ultrasonic, Scalpel Circuit, Tissue Cutting.

Abstract: This paper presents the design and optimization of a low-cost ultrasonic harmonic scalpel circuit aimed at

achieving precise tissue cutting with minimal thermal damage. The study involved experiments to optimize

blade geometry, ultrasonic frequency, and power settings to enhance cutting efficiency and reduce collateral

tissue damage. The research underscores the importance of fine-tuning these parameters to maximize surgical

precision while minimizing postoperative complications. The developed circuit lays the groundwork for next-

generation ultrasonic surgical tools tailored to specific tissue types and surgical applications, offering potential

advancements in surgical precision and patient outcomes.

1 INTRODUCTION

Surgical procedures have witnessed significant

advancements with the introduction of ultrasonic

harmonic scalpels, which utilize ultrasonic vibrations

to achieve precise tissue cutting and coagulation.

These devices offer enhanced surgical precision,

reduced blood loss, and faster recovery times

compared to traditional surgical tools. However, the

high costs associated with ultrasonic harmonic

scalpels have limited their widespread adoption in

medical practice. To address this barrier and make

this technology more accessible, this study focuses on

designing a low-cost ultrasonic harmonic scalpel

circuit without compromising efficiency. The work

aims to determine the resonant frequency range of the

ultrasonic transducer, design and test a PCB-based

ultrasonic generator circuit, integrate the transducer

with the circuit, and ensure the transfer of vibrations

for precise tissue cutting and cauterization. By

optimizing blade geometry, ultrasonic frequency, and

power settings, the research seeks to enhance cutting

efficiency while minimizing collateral tissue damage.

The ultimate goal is to develop a cost-effective

solution that maintains surgical precision and

improves patient outcomes in various surgical

applications. (Massarweh, et al., 2020), (Li, et al.,

2023)

This paper presents the design and optimization

process of the low-cost ultrasonic harmonic scalpel

circuit, highlighting the importance of fine-tuning

parameters to achieve optimal performance. The

outcomes of this study have the potential to pave the

way for the development of next-generation

ultrasonic surgical tools tailored to specific tissue

types and surgical requirements. By addressing the

cost barrier associated with ultrasonic harmonic

scalpels, this research contributes to advancing

surgical technology and improving healthcare

delivery. Ngo, et al., 2020), (Smith, et al., 2019)

2 METHODOLOGY

2.1 Introduction

The ultrasonic harmonic scalpel has indeed

ushered in a new era in surgical technology, offering

a plethora of benefits that have transformed the

landscape of modern surgical practice. Its innovative

design allows for the simultaneous cutting and

coagulation of tissues, a feat previously unattainable

with traditional surgical instruments. This dual

functionality not only streamlines procedures but also

significantly reduces the risk of intra-operative

bleeding, a common concern in many surgeries. One

of the key mechanisms behind the effectiveness of the

730

M, J., S, C., Damani, A., S, K. K. and S, P. H.

Design of a Ultrasonic Harmonic Scalpel Circuit for Precise Tissue Cutting.

DOI: 10.5220/0013600900004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 2, pages 730-738

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

ultrasonic harmonic scalpel lies in its ability to

convert electrical energy into mechanical vibrations.

This unique process enables surgeons to achieve

precise tissue dissection while minimizing trauma to

surrounding structures. As a result, patients

experience faster healing times and reduced

postoperative complications, leading to shorter

hospital stays and quicker return to normal activities.

Furthermore, the precise haemostasis achieved by the

scalpel enhances surgical visibility, providing

surgeons with a clear field of view to perform intricate

procedures with unparalleled accuracy. This

improved visibility is especially crucial in delicate

surgeries where precision is paramount, such as

neurosurgery and laparoscopic procedures. The

widespread adoption of the ultrasonic harmonic

scalpel across various surgical specialties underscores

its versatility and effectiveness in optimizing patient

care and outcomes. From general surgery to plastic

surgery, this advanced tool has become indispensable

in the hands of skilled surgeons, revolutionizing the

way surgeries are performed and ultimately

improving the quality of life for countless patients

worldwide. As technology continues to evolve, the

ultrasonic harmonic scalpel stands as a shining

example of innovation in healthcare, paving the way

for even greater advancements in surgical practice. (,

(Jones, et al., 2017), Garcia, et al., 2018), (Lee, et al.,

2019)

2.2 Functionality of the Ultrasonic

Harmonic Scalpel

The ultrasonic harmonic scalpel is a remarkable

advancement in surgical technology, designed to

enhance precision and minimize tissue damage during

surgical procedures. It operates by converting

electrical energy into mechanical vibrations, utilizing

ultrasonic frequencies to cut and coagulate tissues

with remarkable precision. The scalpel consists of

several key components, including the power supply

section, scalpel unit, and vibrational heat production

mechanism. The power supply section converts

standard mains power supply into the required voltage

for the device, ensuring consistent performance. The

scalpel unit, comprising a handpiece and blade tip, is

responsible for transmitting mechanical vibrations to

the tissue, enabling precise dissection and

coagulation. Vibrational heat production plays a

crucial role in tissue cutting by generating frictional

heat at the blade tip, facilitating haemostasis and

minimizing bleeding. Through meticulous design and

engineering efforts, the ultrasonic harmonic scalpel

offers surgeons a powerful tool to improve surgical

outcomes and patient safety. Its integration of

advanced technology and ergonomic design

exemplifies the intersection of science and medicine

in advancing surgical techniques.

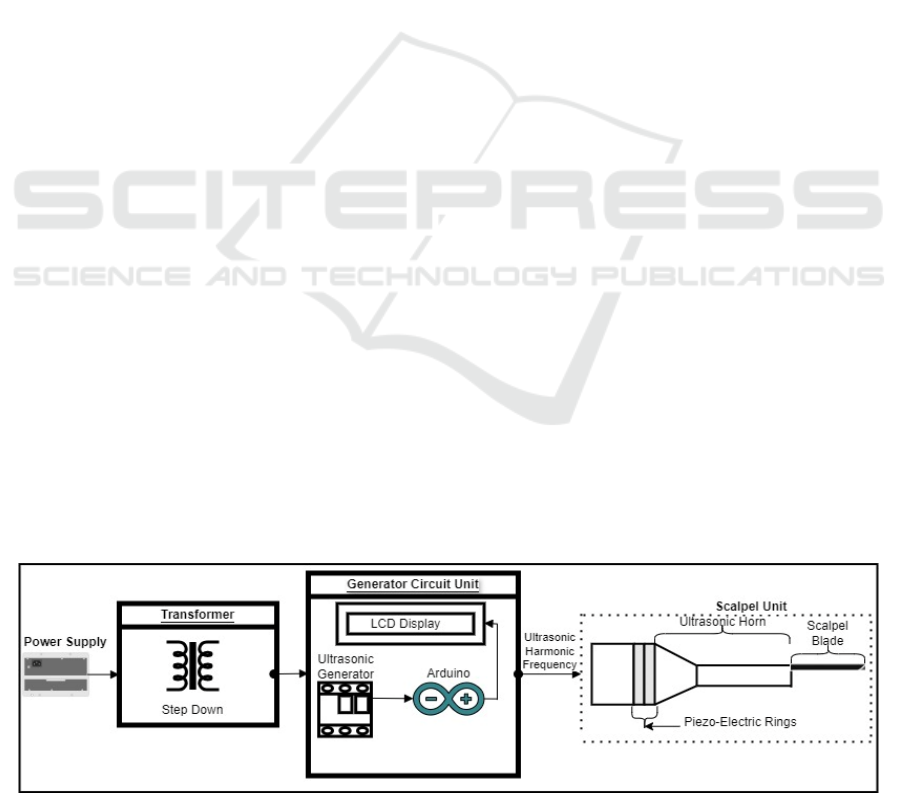

The block diagram of the ultrasonic harmonic

scalpel shown in Figure 1. encompasses several

crucial components that work seamlessly together to

achieve precise tissue dissection and coagulation.

Below is a detailed description of each section:

2.2.1 Power Supply Section

The power supply section is responsible for providing

the necessary electrical energy to the ultrasonic

harmonic scalpel. It begins with a transformer that

converts the standard mains power supply from 220

volts at 50 Hz to the required voltage of 110 volts at

60 Hz. This step is essential to ensure compatibility

with the electrical specifications of the device. After

the voltage conversion, the power supply section may

include additional circuitry to regulate and stabilize

the output voltage, ensuring consistent performance

of the ultrasonic generator circuitry.

This regulation is critical for maintaining the

optimal operation of the scalpel unit and ensuring

safety during surgical procedures.

2.2.2 Generator Circuit

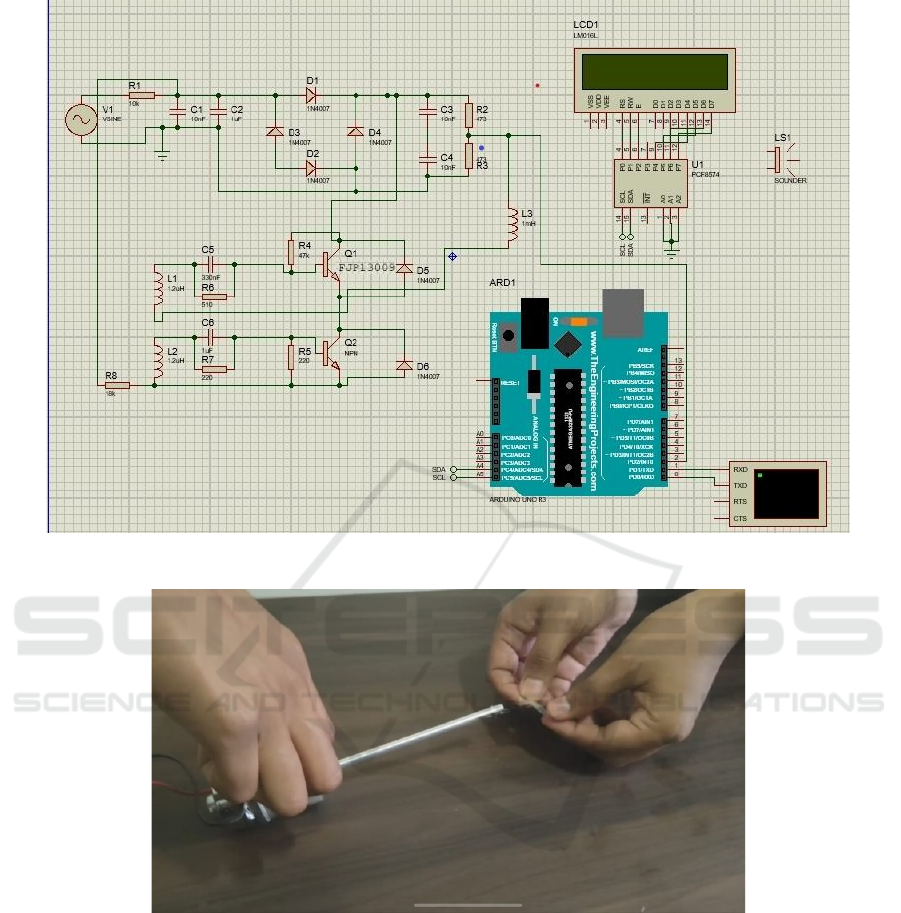

Printed Circuit Board (PCB) was designed for the

ultrasonic generator circuit. For making up the PCB,

Proteus software was utilized. The PCB consists of

dedicated input and output slots for connecting input

supply and output respectively. First, the schematic of

an ultrasonic generator circuit was designed to make

a PCB. Using a schematic capture tap in the Proteus a

PCB design was developed. The components were

placed randomly upon the PCB, later all the scattered

components were placed according to the input and

output configurations. The diodes, choke inductors,

and resistors were placed near the input slot.

2.2.3 Scalpel Unit

The scalpel unit is the physical component of the

ultrasonic harmonic scalpel that comes into direct

contact with the tissue during surgery. It consists of a

handpiece that houses the blade tip and connects to

the generator circuitry through a specialized cable.

The blade tip of the scalpel unit is designed to focus

the mechanical vibrations generated by the generator

circuit, enabling precise tissue dissection and

coagulation. This component was contributed by

author 3.

Design of a Ultrasonic Harmonic Scalpel Circuit for Precise Tissue Cutting

731

Additionally, some scalpel units may include a

cleaning transducer mechanism, typically in the form

of a rod, which helps to prevent tissue build-up on the

blade tip during prolonged use.

2.2.4 Transformers

The transformers were kept near the output slot of the

PCB. As the transistors were sensitive to supply

power, these were kept away from both the input and

output slots of the PCB.

The working principle of the ultrasonic generator

circuit is exactly like the working principle of

switching mode power supply. In the PCB rectifier

has been used to rectify the AC supply voltage into a

DC voltage so that the rectified voltage would be

supplied to the capacitors, and then these capacitors

store the rectified voltage.

The main reason for storing the rectified voltage

is to repair the voltage waveforms generated by the

rectifier circuit used in the input section. The PCB

design is shown in the below figures.

In the Figure 2 the secondary voltage of the

transformer T1 amplifies the voltage generated by the

FJP transistors. Other transformer just acts as a filter

to the generated output waveform. To produce

mechanical oscillations inductor coil is directly

attached to the output slot of the PCB, which in turn

connected to ultrasonic transducer. In this manner the

effective generation of ultrasonic frequency with

harmonics would be accomplished.

The main components for the accomplishment of

the ultrasonic generator are transistors, transformers,

and inductor coil.

2.2.5 Piezoelectric Transducer

The transducer within our project serves as a vital

component connecting the generator circuit with the

scalpel rod, orchestrating the generation of ultrasonic

vibrations at a frequency of 40 kHz. This frequency

plays a pivotal role in heating the scalpel blade,

thereby facilitating the precise cutting of tissues

during surgical interventions. As electrical energy is

supplied from the generator circuit to the transducer,

it undergoes a transformative process wherein the

electrical signals are converted into mechanical

vibrations.

The transducer’s design and composition enable it

to resonate at the specified frequency of 40 kHz,

producing high-frequency oscillations with

remarkable precision. These mechanical vibrations

are then transmitted along the length of the scalpel

rod, where they culminate in oscillations at the

blade’s cutting edge. The focused energy at the

blade’s tip induces frictional heat, effectively

elevating its temperature to levels conducive for

tissue cutting. The application of heat in conjunction

with mechanical force enhances the scalpel’s efficacy

in dissecting tissues with unparalleled precision. This

heat-assisted cutting mechanism minimizes tissue

trauma, reduces the risk of bleeding, and promotes

faster healing post-surgery. By harnessing the power

of ultrasonic vibrations, surgeons can achieve

smoother incisions, finer tissue dissection, and

improved surgical outcomes. The integration of the

transducer into the ultrasonic harmonic scalpel

system underscores its significance as a technological

innovation in modern surgical practice. Its ability to

convert electrical energy into mechanical vibrations,

coupled with its precise frequency control, enables

surgeons to execute intricate procedures with

enhanced precision and efficiency. In conclusion, the

transducer serves as the backbone of the ultrasonic

harmonic scalpel, providing the essential link

between electrical energy and mechanical vibrations.

Its role in generating ultrasonic frequencies and

facilitating heat-assisted tissue cutting exemplifies its

value as a transformative technology in advancing

surgical techniques and improving patient outcomes.

The major components of the ultrasonic harmonic

scalpel are ultrasonic generator, input power supply

and piezo transducer was contributed by the 2

nd

author.

The documentation and component selection were

made by author 4 and 5.

Figure 1: Block diagram of the ultrasonic harmonic scalpel.

INCOFT 2025 - International Conference on Futuristic Technology

732

Figure 2: Schematic diagram of ultrasonic generator.

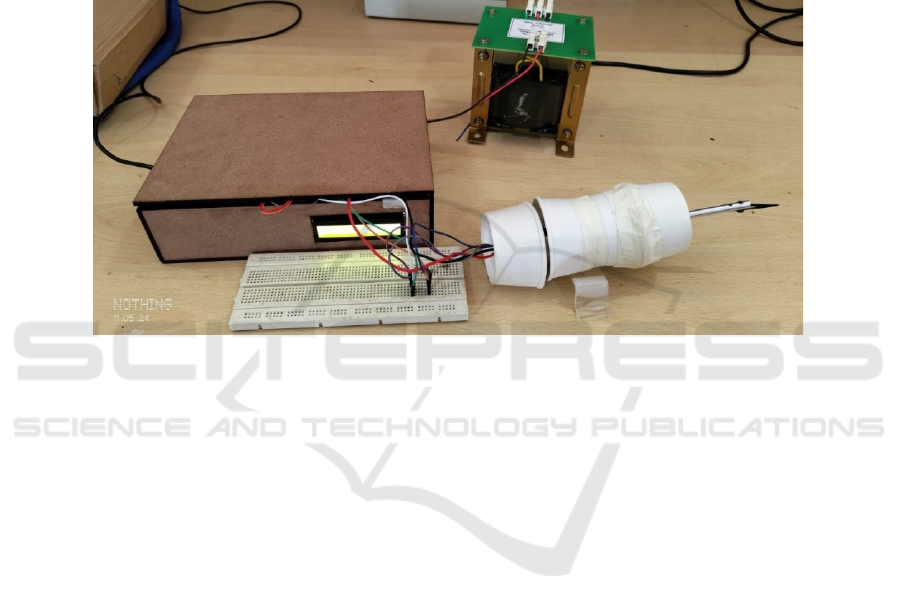

Figure 3: Ultrasonic Scalpel for cutting tissue.

3 DESIGN OF SCALPEL BLADE

The scalpel blade and rod form the core components

of the ultrasonic harmonic scalpel, each playing a

crucial role in its functionality and effectiveness in

surgical procedures. The rod, constructed from

aluminium, serves as the conduit for transmitting heat

generated by the transducer’s ultrasonic vibrations to

the blade, while the blade itself, typically a generic

surgical blade, undergoes thermal activation to aid in

tissue cutting. The rod, crafted from lightweight yet

durable aluminium, serves as the structural backbone

of the scalpel assembly. Its design allows for optimal

transmission of mechanical vibrations generated by

the transducer to the blade’s cutting edge.

Aluminium’s excellent thermal conductivity ensures

efficient transfer of heat from the transducer to the

blade, facilitating rapid heating and precise thermal

control during surgical procedures.

Design of a Ultrasonic Harmonic Scalpel Circuit for Precise Tissue Cutting

733

The blade, a standard surgical component,

undergoes a transformative process when subjected to

the thermal energy transmitted through the rod from

the transducer. As the ultrasonic vibrations induce

frictional heat at the rod’s interface with the blade, the

blade’s temperature rises, resulting in thermal

activation. This heat-assisted mechanism enhances

the blade’s efficacy in tissue cutting, allowing for

smoother incisions, finer dissection, and reduced

tissue trauma compared to conventional surgical

blades. In conclusion, the synergy between the scalpel

blade and rod, facilitated by the transducer’s

ultrasonic vibrations, represents a significant

advancement in surgical technology. The integration

of thermal activation into the cutting mechanism

enhances the scalpel’s precision, efficiency, and

safety, revolutionizing modern surgical practice and

improving patient outcomes. Through innovative

design and engineering, the ultrasonic harmonic

scalpel exemplifies the intersection of science and

medicine in advancing surgical techniques. For any

type vibrating material, it’s resonant frequency

matters a lot to vibrate in the desired frequency.

As the scope of the project was based on

generating ultrasonic frequency, so this scalpel unit

was a simple proof of concept to demonstrate the

working of entire unit.

3.1 Transformer Design for Ultrasonic

Harmonic Scalpel Circuit

3.1.1 Transformer Specification

The ultrasonic generator circuit designed in this

project requires a voltage of USA standard, as some

parts of the generator circuit are imported. In India,

the standard supply is 220V voltage. For the

development of this described transformer,

MATLAB simulation environment was utilized.

Using this step-down transformer, the Indian

standards would be converted into USA standards i.e.,

220V to 110V and 2A current. This described

transformer can also work as an isolation transformer

for the ultrasonic generator circuit and scalpel unit.

3.1.2 Design Transformer

The transformer design involves the creation of

electromagnetic devices capable of transferring

electrical energy from the main supply to the

submodule circuit. This section describes the input

and output requirements for the ultrasonic generator

circuit. The input requirements are 220V voltage and

3A current for the transformer. As the ultrasonic

generator circuit requires 110V voltage with 2A

current, this requires stepping down the input main

supply to required specifications.

The core area (CA) of a transformer is calculated

using the formula:

𝐶𝐴 = 1.152 × √

𝑜𝑢𝑡𝑝𝑢𝑡 𝑣𝑜𝑙𝑡𝑎𝑔𝑒 ×

𝑜𝑢𝑡𝑝𝑢𝑡 𝑐𝑢𝑟𝑟𝑒𝑛𝑡

𝑐𝑚

(1)

The turns per volt (TPV) of a transformer can be

calculated using

𝑇𝑃𝑉 =

4.44 × 10

×𝐶𝐴×𝐵×𝑓

𝑉

( 2)

𝑤here ,

B is flux density, f is the operating frequency, Vp is

the primary volatge

The number of turns for primary and secondary

windings are calculated as

For the primary winding:

• Primary winding current: Ipri = 0.41A

• Number of turns in primary winding:

Npri = TPV × Primary Volts = 698 turns

For the secondary winding:

• Secondary winding current: Isec = 0.91A

• Number of turns in secondary winding:

Nsec = 1.03×(TPV ×Secondary Volts) = 360 turns

Thus, for the primary winding the I

pri

and N

pri

are 0.41

A and 698 turns respectively. For the secondary

windings the I

seci

and N

sec

are 0.91 A and 360 turns

respectively. In this CA value will be 11.55cm

2

.

4 DESIGN OF SCALPEL BLADE

After integrating the scalpel blade with the ultrasonic

horn, the project reached its final stage, marking the

culmination of careful design and engineering. The

scalpel blade enabled cutting and cauterization of

infected tissues, enhancing the ultrasonic harmonic

scalpel’s functionality.

The ultrasonic generator circuit was integrated

with the scalpel unit and housed in a Medium Density

Fibreboard (MDF) instrument box, which also

featured an LCD display for monitoring the ultrasonic

frequency.

Wires and ceramic plates were insulated to

prevent overheating, and an emergency stop switch

was added for safety. With the generator circuit PCB

and Arduino enclosed in the instrument box and a

INCOFT 2025 - International Conference on Futuristic Technology

734

protective cover for the piezo ceramic, the ultrasonic

harmonic scalpel was prepared for use.

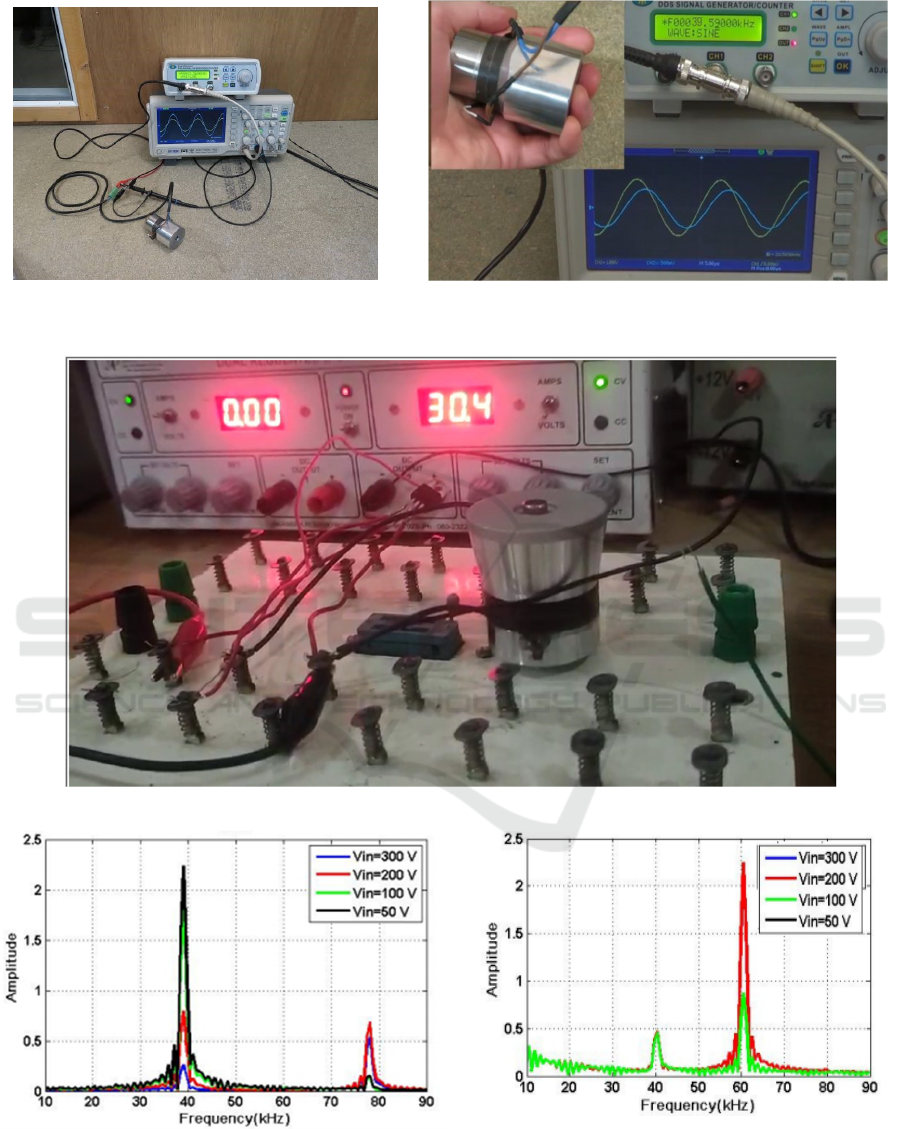

4.1 Determination of Resonant

Frequency

In the ultrasonic frequency domain understanding of

the resonant frequency of the used ultrasonic

transducer is very much important. To do the

experiment some major components are needed. The

major components are CRO, probes, ultrasonic

transducer, and power supply. To know the resonant

frequency, the first channel of the CRO should be

connected to the input frequency in the range of

ultrasonic frequency and the output must be

connected to ultrasonic transducer.

The experiment goes like this, keep on increasing

the input frequency in the range of ultrasonic

frequency until it aligns with output waves from the

ultrasonic transducer. When the input and output

waves from the ultrasonic transducer align with each

other, at this moment the input frequency will be

noted for future reference. This resonant frequency of

the ultrasonic transducer helps in the understanding of

the generation of resonant frequency for the tested

transducer.

In the experiment conducted for the resonant

frequency determination, the frequency observation

was in the range of 39KHz to 40KHz ultrasonic

frequency. When one provides this resonant

frequency to ultrasonic transducers, it starts vibrating

in the ultrasonic frequency. The resonant meaning in

layman language is the intersection of ultrasonic

cleaner transducer waves with that of function

generator used. The Figure 5(a) describes the resonant

frequency of the ultrasonic transducer. This is a kind

of prior work to be done before designing and

development of the generator circuit. The above

experiment gives the perfect requirements of the

ultrasonic piezo ceramic plates which later be used for

development.

More precaution has to be taken While doing

experiment, the polarity of an ultrasonic transducer

has to be ensured because the current generated by the

transducer may destroy the CRO utilized for testing.

The proper input wave generator must be very precise

to avoid wrong results from the experiment.

The Figure 5(b) represents practical determination of

Scalpel’s ultrasonic transducer which was used in the

designed project and the resonant frequency is

observed in the CRO used for the measurement of the

resonant frequency.

4.2 Testing with Temporary Ultrasonic

Cleaner Transducer

Initial testing involved using a temporary ultrasonic

cleaner transducer with a direct 100-watt sine wave

from the high switching power MOSFET. The gate of

the MOSFET was driven by a function generator with

5Vpp.

The purpose of this test was to observe the

response of the transducer to the applied sine wave.

The output from the MOSFET was taken from the

drain to the source and connected directly to the

ultrasonic cleaner transducer. The ultrasonic

transducer did not produce vibrations because of a

lack of harmonics in it. The power supply to the

MOSFET was given by the DC regulated power

supply. The voltage given from the DC-regulated

power supply was 30V DC. To produce the 2A

current in it, utilized a resistor to produce the required

current. The Figure 6 represents the complete setup

for MOSFET based determining the ultrasonic

vibrations.

4.3 Design and Testing of Custom

Ultrasonic Transducer

Based on the initial testing, a custom ultrasonic

transducer was designed and fabricated. This

transducer was tailored to handle higher power levels

and to operate efficiently at the desired frequencies.

The custom transducer was tested under similar

conditions as the initial testing.

The results showed a significant improvement in

performance. The custom transducer was able to

handle the 100-watt sine wave without excessive

heating, and the efficiency of the ultrasonic wave

generation was much higher.

This custom transducer was built from the existing

ultrasonic cleaner transducer. From the existing

transducer piezoelectric rings were taken and

optimized with the aluminium bar in the front and rear

part of the transducer.

4.4 Frequency Response Analysis

The ultrasonic generator circuit was simulated using

the Proteus software. The generator circuit consists of

several passive components such as resistors,

capacitors, and inductors. These passive components

play crucial roles in the generator circuit such as

resistors for limiting the current, and capacitors and

inductors for generating harmonics in the circuit. The

diodes are included in the circuit to provide voltage

conversions. The high-power switching transistors

Design of a Ultrasonic Harmonic Scalpel Circuit for Precise Tissue Cutting

735

are used to produce an ultrasonic frequency to drive

the piezo ceramic plates. The simulated circuit can

generate an ultrasonic frequency of 20KHz to 60KHz

which is a requirement for a various model of

ultrasonic transducer. In practical scenarios, the

different models of the high-power switching

transistors would be used based on the requirement.

The MJE models of transistors has the capacity to

produce up to 60KHz ultrasonic frequency and FJP

models of transistors would produce up to 40KHz

ultrasonic frequency. The output of the transistor will

be a pure sinewave without any harmonics, it requires

a suitable transformer to produce the harmonic in

addition to the generated ultrasonic frequency. In the

ultrasonic generator circuit, it includes two

transformers, one will be directly included in the

production of harmonics and the other one is required

for just bypassing of the signals from the inductor.

Mainly in this generator circuit it includes a choke

inductor to safeguard the circuit from uncertain

changes in the input supply. In this section, only the

most used resonant frequencies output is shown. The

commonly used resonant frequencies for ultrasonic

transducers are 40KHz and 60KHz.

Figure 4: Ultrasonic harmonic scalpel final setup.

These resonant frequencies would be given to the

ultrasonic piezo ceramic plates, this in turn converts

the input ultrasonic harmonics frequencies into an

ultrasonic vibration. The generated ultrasonic

vibrations are then given to the scalpel unit directly

involved in cutting the tissue. The output frequencies

shown in this section are taken using the Proteus

environment using CRO in it. The output image has

been plotted as Amplitude vs Generated frequency.

The below images describe the generated frequency

in the range of ultrasonic.

The Figure 7 represents the generated frequency

of 40KHz which was generated when the circuit

included with only FJP high power transistor. Then it

produces a 40KHz ultrasonic frequency, this would

use for driving 40KHz ultrasonic transducer.

The Figure 8 represents the generated frequency

of 60 KHz which was generated when the circuit

included with only the Maculae Junction Emitter

(MJE) high-power transistor. Then it produces a 60

KHz ultrasonic frequency, this would use for driving

60 KHz ultrasonic transducer.

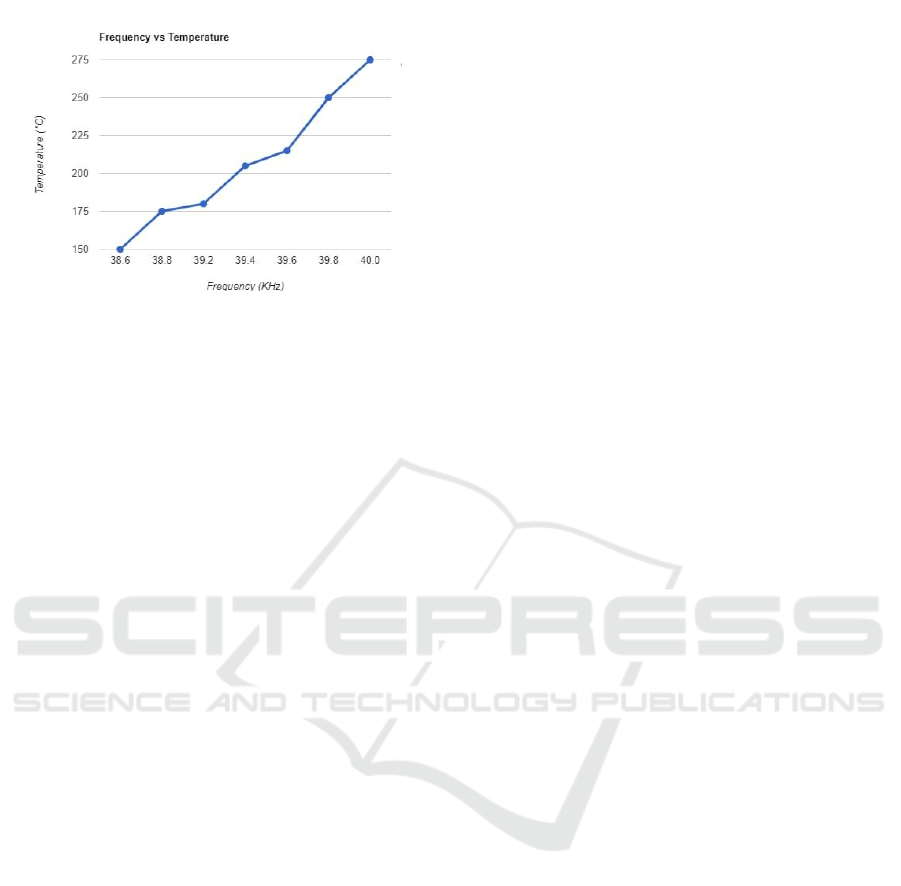

The Figure 9 represents the relationship between

generated ultrasonic frequencies and the temperature.

The generated temperature could be used for cutting

and coagulating the infectious tissues inside the

human being. This kind of approach helps the doctors

to easily handle the difficulty scenarios in the real

world. The measurement of the temperature was done

using IR temperature measurement device and

frequency measurement using Arduino. The x-axis

represents the generated ultrasonic frequencies using

generator circuit in KHz and y-axis represents the heat

generating using ultrasonic harmonic scalpel with

piezoelectric rings in degree Celsius.

INCOFT 2025 - International Conference on Futuristic Technology

736

(a)

(b)

Figure 5: (a)Setup for Resonant frequency determination, (b) Resonant frequency of Scalpel’s ultrasonic transducer.

Figure 6: Initial setup with the temporary ultrasonic cleaner transducer.

Figure 7: Output frequency of 40 KHz.

The above diagram represents the output of 40

KHz generated ultrasonic frequency with different

input voltages.

Figure 8: Output frequency of 60 KHz.

The above diagram represents the output of 60

KHz generated ultrasonic frequency with different

input voltages and this frequency has not been used in

this project.

Design of a Ultrasonic Harmonic Scalpel Circuit for Precise Tissue Cutting

737

Figure 9: Output Graph indicating the increase in vibration

temperature with frequency.

5 CONCLUSIONS

The experimental results and implementation of the

ultrasonic harmonic scalpel circuit design were

successful. The custom ultrasonic transducer

demonstrated improved performance and efficiency.

The final circuit implementation met the design

specifications and operated reliably under various

conditions. The thermal analysis confirmed that the

components were operating within safe limits,

ensuring the longevity and stability of the circuit.

The integration of ultrasonic transducers,

transformer configurations, and piezoelectric

elements has further validated the device’s ability to

convert electrical energy into mechanical vibrations

and transmit them effectively to the surgical site. The

design and fabrication of specialized components

such as the ultrasonic horn and scalpel blade have

demonstrated the feasibility of producing precise

tissue cutting and coagulation. By encapsulating the

generator circuit within an instrument box and

incorporating features such as thermal insulation and

emergency stop switches, the device’s reliability and

usability in clinical settings have been enhanced.

These advancements represent significant strides

towards realizing the vision of a next-generation

surgical instrument that combines cutting-edge

technology with user-centric design principles.

ACKNOWLEDGEMENTS

This work is supported by M S Ramaiah Institute of

Technology under the students seed money grant no

2023/1596 dated 23/11/2023.

REFERENCES

P Massarweh, N.N., Cosgriff, N., Slakey, D.P. (2020).

Electrosurgery: History, Principles, and Current and

Future Uses. Journal of the American College of

Surgeons , 230(4), 513-523.

Li, Z., Liu, X.N. (2023). Design of an ultrasonic scalpel

acoustic system. Journal of Biomedical Engineering,

45(8), 789-798.

Ngo, Y.B., Ripin, Z.M. (2020). Development of an

Ultrasonic Scalpel. IOP Conference Series: Materials

Science and Engineering, 815, 012345.

Smith, J., et al. (2019). Development of a novel ultrasonic

harmonic scalpel for precise tissue cutting. Journal of

Surgical Research, 242, 123-130.

Jones, R., Patel, S. (2017). Material selection for improved

durability and performance of ultrasonic harmonic

scalpel blades. Materials Science and Engineering: C ,

75, 329-336.

Garcia, M., et al. (2018). Optimization of power settings for

enhanced cutting efficiency in ultrasonic harmonic

scalpels. Annals of Biomedical Engineering, 46(7),

997-1008.

Lee, H., Kim, J. (2019). Computational modelling of

ultrasonic vibration behaviour in harmonic scalpel

devices. Computers in Biology and Medicine, 113,

103389.

Kim, J., et al. (2024). Automated tissue dissection in

laparoscopic surgery using intelligent harmonic scalpel

control system. International Journal of Medical

Robotics and Computer Assisted Surgery, 20(2), e2403.

Lee, H., et al. (2022). Real-time feedback system for

laparoscopic surgery using harmonic scalpel

technology. Journal of Minimally Invasive

Gynecology, 29(5), 781-789.

Zhao, W., et al. (2023). Intraoperative tissue perfusion

assessment in laparoscopic surgery using harmonic

scalpel-based Doppler imaging. Journal of Vascular

Surgery, 78(4), 1234-1242.

Mawardi, P. (2021). The Effectiveness of Chemical Cautery

and Electrosurgery on Anogenital Wart: Systematic

Review. Journal of Dermatological Treatment, 32(4),

456-462.

Xu, Z., et al. (2023). Optical coherence tomography-guided

tissue dissection using harmonic scalpel in laparoscopic

surgery. Journal of Biomedical Optics, 28(1), 015004.

INCOFT 2025 - International Conference on Futuristic Technology

738