Performance Analysis of 3D-Printed X-Band Horn Antenna Coated with

Different Conductive Materials

D. Nagaraju

1

a

, Kodari Rakesh Yadav

1 b

and Devajji Haneesh Reddy

2 c

1

Department of Electronics and Communication Engineering, Sanskrithi School of Engineering, Puttaparthi, Sri Sathya Sai

District, India

2

Department of Electronics and Communication Engineering, Nitte Meenakshi Institute of Technology, Bengaluru, India

Keywords:

3D Printing, X-Band Horn Antenna, Additive Manufacturing, Conductive Coating, Copper Plating, Gain,

Reflection Coefficient, VSWR.

Abstract:

This study evaluates the performance of 3D-printed X-band horn antennas, focusing on designs fabricated with

additive manufacturing (AM) methods and coated with various conductive materials. Conductive coatings like

silver paint, copper tape, and copper plating were applied to examine their effects on antenna performance.

Key metrics assessed include gain, reflection coefficient, and voltage standing wave ratio (VSWR). Findings

indicate that the copper-plated antenna demonstrates superior performance, with the highest gain and lowest

reflection coefficient among all tested materials.

1 INTRODUCTION

Antennas are critical in communication systems, es-

pecially in satellite and wireless communication. X-

band antennas are preferred for high-frequency app li-

cations like radar, telecommunications, and weather

monitoring due to their directivity, low power loss,

and high gain(A. I. Dimitriadis, 2 017). Tra ditional

metallic fabrication methods result in heavy, costly

designs. This research explores AM techniques

as lightweight, cost-effective alternatives(M. Kilian,

2017). Conductive coatings—silver paint, copper

tape, and coppe r plating—are applied to determine

which offers the best antenn a performance( S. Ver-

ploegh, 2017).

Be advised that papers in a tec hnically unsuitable

form will be returned for retyping. After returned the

manuscrip t must be appropriately modified.

1.1 Motivation

Exploring AM e nables lightweight, customizable an-

tenna designs that are not feasible with c onventional

manufacturing. Testing different conductive coatings

may lead to an accessible, high-frequency antenna so-

a

https://orcid.org/0000-0002-6156-5596

b

https://orcid.org/0000-0002-5385-0805

c

https://orcid.org/0009-0007-8602-0257

lution, re ducing the n eed for metals and costly ma-

chining. Potential applications extend to aerospace,

telecommunications and defense industries.

1.2 Problem Statement

Tra ditional metal-based antennas are heavy and

costly, with limited scalability. This study investi-

gates wh e ther 3D-printed antennas with cond uctive

coatings can retain high gain, low reflection coeffi-

cient, and effective impedance matching, providing a

viable, lightweight alternative .

Table 1: Developing Antenna Specifications.

1 Frequency (8-12) GHz

2 Height 1.016 cm

3 Width 2.286 cm

4 Return loss (-25 to -50) dB

5 Antenna Gain (10-25) dB

6 VSWR 1

Based on the requirement a WR-90 Rectangu-

lar waveguide is selected as the operating frequency

range is in the frequency range of X band 8 to 12 GHz.

594

Nagaraju, D., Yadav, K. R. and Reddy, D. H.

Performance Analysis of 3D-Printed X-Band Horn Antenna Coated with Different Conductive Materials.

DOI: 10.5220/0013597900004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futur istic Technology (INCOFT 2025) - Volume 2, pages 594-597

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

2 LITERATURE REVIEW

Horn antenn as have been developed since the 20th

century f or radar and satellite applications, with Roy

et al. documenting their evolution(H. Yao, 2017). Yao

et al. demonstrated the use o f copper-based coatings

on 3D-printed antenna s, achieving competitive gain

and reflection coefficients in Ka-band applications.

Chuma et al. found that copper-plated 3D-printed an-

tennas perform well at X-band frequencies, with su-

perior impedance matching over alternatives like sil-

ver paint or copper tape.

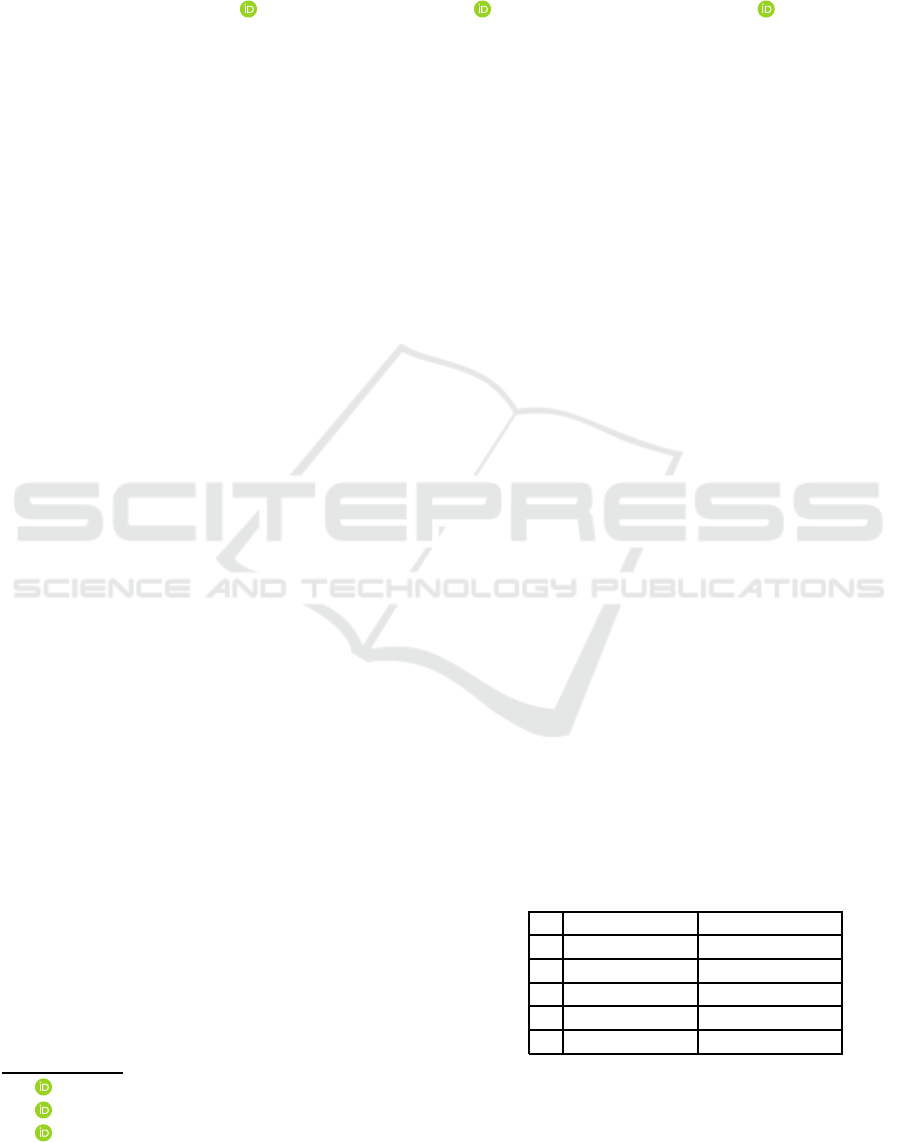

Figure 1: Pyramidal Horn Antenna

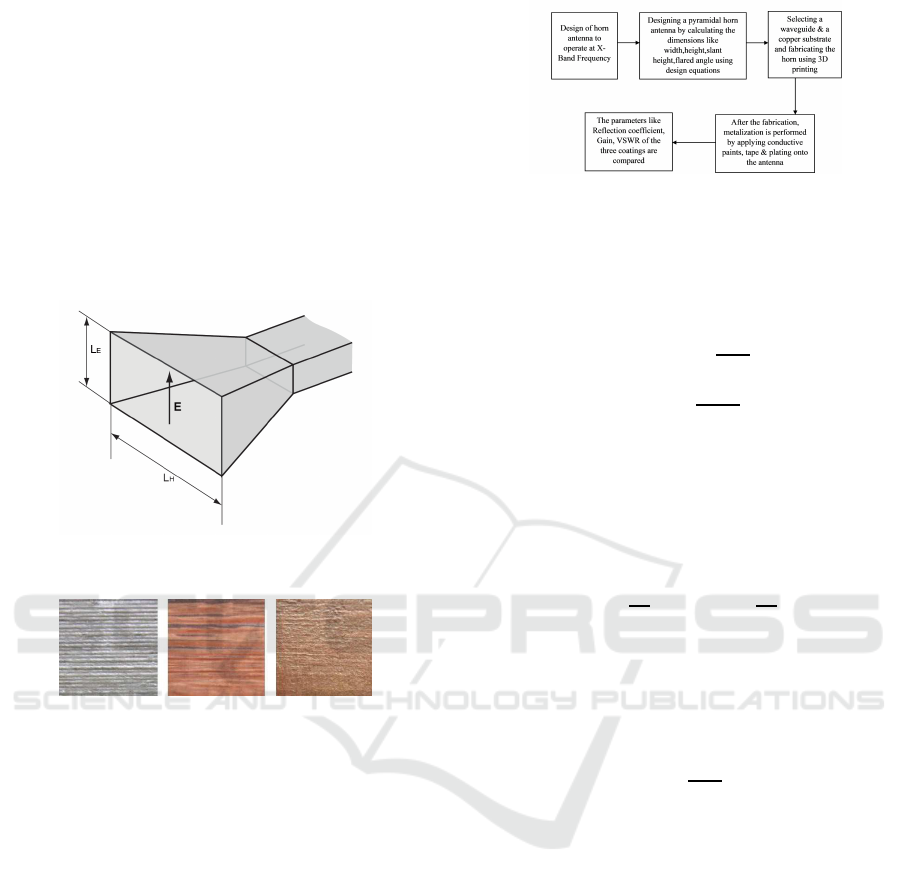

Figure 2: Different types of coatings used

3 METHODOLOGY

3.1 Design and Fabrication

Three identical horn antennas were design e d with

CAD and fabrica te d using Fused Deposition Model-

ing (FDM) with ABS plastic. Each was coated with

silver paint, cop per ta pe, or copper plating(S. Ver-

ploegh, 2017). A carbon layer was added before elec-

troplating for improved adhesion on th e copper-plated

antenna.

3.2 Designing of Pyramidal Ho rn

Antenna

The design of a pyramidal horn antenna involves pre-

cise calculations to ensure efficient signal propagatio n

and minimal reflection lo sses. The following param-

eters are critical to the design process:

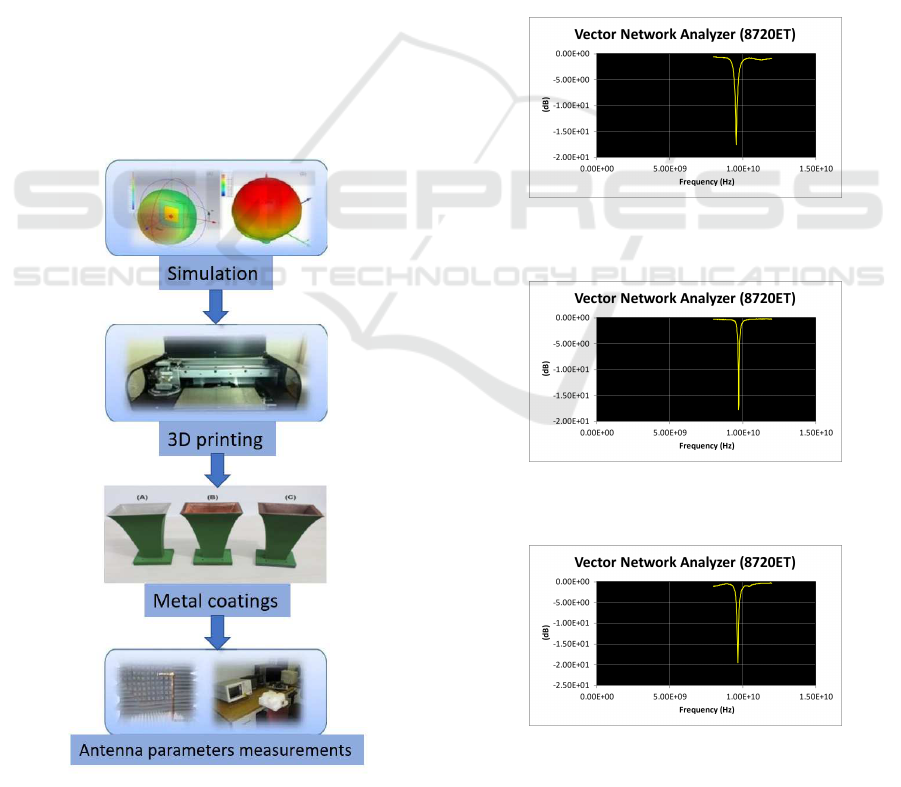

Figure 3: System Design

3.2.1 Flared Dimensions

The flared angle of the horn antenna is calculated us-

ing:

Ψ

e

= tan

−1

B

1

2L

E

(1)

where:

B

1

=

p

2λL

E

and L

E

is the slant height in the E-plane.

3.2.2 Aperture Dimensions

The aperture dimensions f or the E-plane and H-plane

are given by:

a =

λ

0

2

and b =

λ

0

4

(2)

where λ

0

is the free-space wavelength.

3.2.3 Directivity

The directivity of the horn antenna is calculated as:

D =

4πA

λ

2

(3)

where A is the aperture area and λ is the operating

wavelength.

3.3 Simulation and Testing

HFSS software simulated g ain, VSWR, and r e flection

coefficient for each coating. The test was performe d

with a Vector Network Analyzer (VNA), which mea-

sures return loss, impedance matching, an d radiation

patterns. Simulated and measured results were com-

pared for accuracy.

3.4 Mapping of the Design into

Software

The designed pyramidal horn antenna was imple-

mented using HFSS (High-Frequency Structure Sim-

ulator). The mapping process involved the following

steps:

Performance Analysis of 3D-Printed X-Band Horn Antenna Coated with Different Conductive Materials

595

3.4.1 3D Model Creation

The CAD model of the antenna was created based on

the calculated parameters. The software allowed for

precise modeling of flare angles, aperture dimensio ns,

and waveguide sections.

3.4.2 Material Assignment

Material properties such as conductivity and permit-

tivity w e re assign e d to the model. For example:

σ

copper

= 5.8 × 10

7

S/m (4)

3.4.3 Boundary Conditions and Excitation

Boundary conditions were set to mimic real-world en-

vironm ents. Waveguide port excitation was applied at

the input to simulate signal propagation.

3.4.4 Simulation Setup

The frequency range was set to 8GHzto 1 2 GHz, and

performance metrics such as gain, S11, and VSWR

were analyzed.

Figure 4: Antenna Fabrication Process

4 RESULTS AND DISCUSSION

4.1 Gain Comparison

The copper-plated ante nna showed the highest gain,

probably due to copper’s high conductivity and mini-

mized r e sistive losses(E. L. Chuma, 2019). Silver and

copper tape coatings showed lower gain, which could

be attributed to challenges in uniformity and conduc-

tivity(D. Nagaraju, 2021a).

The gain of the horn antenna was observed to be

highest for coppe r-plated designs:

G = 20 dB at 10 GHz (5)

4.2 Reflection Coefficient (S11)

Figure 5: Reflection coefficient of silver painted horn An-

tenna

Figure 6: Reflecti on coefficient of Copper taped horn An-

tenna

Figure 7: Reflection coefficient of Copper plated horn An-

tenna

Copper-plated antennas had the lowest reflection

coefficient (S11) values, with le ss sign a l loss c om-

INCOFT 2025 - International Conference on Futuristic Technology

596

pared to silver paint and copper tape, whose S11

values were higher due to surface roug hness(D. Na-

garaju, 2021b).

The reflection coefficient values for the different

coatings are

S11

copper

= −15 dB (6)

S11

silver

= −10 dB (7)

4.3 VSWR

VSWR results for the copper-plated antenn a indicated

near-ideal impedance matching with VSWR close to

1. Silver and copper tape coatings had slightly higher

VSWR values, reducing transmission efficiency.

The re sults obtained from simulations and practi-

cal measurements are summarized below.

The VSWR values ind ic a te efficient impedance

matching for copper plating:

VSWR

copper

= 1.2 (8)

VSWR

silver

= 1.5 (9)

4.4 Radiation Patterns

The radiation patterns were consistent with theoreti-

cal predic tions, showing high directivity in the ma in

lobe for all designs.

5 CONCLUSION

This study demonstrates the effectiveness of cop-

per plating for 3D-printed X-band antennas, sup-

porting the feasibility of AM as a lightweight, cost-

efficient alternative. Future studies can explore new

condu c tive materials, printing techniques, an d hybrid

materials to optimize antenna performance.

REFERENCES

A. I. Dimitriadis, e. a. (2017). Polymer-based additive man-

ufacturing of high-performance waveguide and an-

tenna components. In Proceedings of the IEEE. IEEE.

D. Nagaraju, N. P. G. (2021a). Design and simulation of

a compact 5.4ghz h-shaped slot antenna for rf energy

harvesting systems. In IOP Conf. Ser.: Mater. Sci.

Eng. IOP Publishing.

D. Nagaraju, N. P. G. (2021b). Design and simulation of

a multiband slot antenna for gps/wlan/wimax systems

using cst. In IOP Conf. Ser.: Mater. Sci. Eng. IOP

Publishing.

E. L. Chuma, Y. Iano, L. L. B. R. (2019). Performance

analysis of x band horn antennas using additive man-

ufacturing. In Journal of Microwaves. Journal of Mi-

crowaves.

H. Yao, S. Sharma, R. H. (2017). Ka band 3d printed horn

antennas. In IEEE. IEEE.

M. Kilian, e. a. (2017). Waveguide components for space

applications manufactured by additive manufacturing

technology. In IET Microwaves, Antennas & Propa-

gation. I ET.

S. Verploegh, e. a. (2017). Properties of 50–110-ghz waveg-

uide components fabricated by metal additive manu-

facturing. In IEEE Trans. on Microwave Theory and

Techniques. IEEE.

Performance Analysis of 3D-Printed X-Band Horn Antenna Coated with Different Conductive Materials

597