Numerical and Experimental Investigation of PCF Using 3D Printing

Technology for Confinement Loss Measurement

Parthiban M, Dinesh Kumar T. R, Harshavardhan Naidu Sapineni,

Gowthaman S. A, Gopinath S and Hemanth Kumar C. S

Department of Electronics and Communication Engineering, Vel Tech High Tech Dr.Rangarajan Dr.Sakunthala

Engineering College, Chennai , Tamil Nadu, India

Keywords: Confinement Loss, COMSOL Multiphysics, Experimental Validation, Fused Deposition Modeling (FDM),

3D Printing, Optical Fiber.

Abstract: The paper consists of the design, simulation and experimental testing of photonic crystal fibers (PCFs)

fabricated with the use of fused deposition modeling (FDM) based 3D printing technology. In this work,

confinement losses of PCFs are investigated numerically and experimentally in order to determine the

efficiency of the numerical simulation and the additive manufacturing techniques. The current work involved

the generation of various optical fiber geometries and performing a comprehensive simulation to determine

the confinement loss of each geometry. The experimental part included the fabrication of the designed

structures by 3D printing and testing them under certain conditions. The results showed that there was a good

agreement between numerical and experimental results where the manufactured models proved to be in good

conformity with the expected optical characteristics. This hybrid approach also proves that it is possible to

use 3D printing for the fabrication of optical fibers and this can be used as a tool for the development of

optical communication and sensing devices as well.

1 INTRODUCTION

Photonic Crystal Fiber [PCF] holds a high scope for

researchers as it is used in many favorable

applications in the photonics branch. The PCF

microstructure section enhances optical

amplification, beam quality, high power delivery, and

extreme core confinement, such as large mode area,

non-linear applications, group velocity dispersion

control, etc (Zhang, S, 2018).

Photonic crystal fibers are an important

development in the area of optical fiber technology,

with outstanding properties such as improved light

confinement, control over dispersion, and design

versatility. Such properties make PCFs especially

useful for a variety of applications, including optical

communication, sensing, and nonlinear optics. An

important parameter in determining the performance

of PCFs is confinement loss, which directly affects

their ability to guide light efficiently (Wang, B,

2020).

The traditional methods of analysis and

fabrication of PCFs are usually rather complex in

terms of manufacturing. These may include stack-

and-draw techniques, which can be both time-

consuming and costly. However, recent

developments in numerical simulation tools have led

to the finite element method (FEM) and thus have

made it possible to make an accurate model of PCF

structures and their optical properties. This advanced

tool enables the design of fibers tailored for particular

applications by reliably forecasting important

parameters like confinement loss and dispersion

(Kundu, D, 2018).

While significant progress in simulation methods

is laudable, experimental validation must also be

provided to verify the feasibility of proposed

concepts in real practice. Additive manufacturing,

primarily through fused deposition modeling (FDM),

provides a pathway for fast and cost-effective

prototyping of PCFs. Research in earlier literature,

such as that published by (Kundu, D, 2018),

demonstrates the possibility of using 3D printing in

the manufacture of optical elements with excellent

fidelity. However, there is a research gap that

integrates numerical simulations with 3D printing to

fully analyze and validate PCF designs. In this paper,

554

M, P., T. R, D. K., Sapineni, H. N., S. A, G., S, G. and Kumar C. S, H.

Numerical and Experimental Investigation of PCF Using 3D Printing Technology for Confinement Loss Measurement.

DOI: 10.5220/0013596700004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 2, pages 554-559

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

we introduce a hybrid methodology for the

development of photonic crystal fibers (PCFs) that

combines numerical simulations with 3D printing

technology.

The research focuses more on the design of

different types of PCF geometries, calculations of

their confinement losses through simulations, and

creating these structures using FDM in order to

validate the simulation results experimentally. That

way, it connects good theoretical design with

practical application, showing well the feasibility of

using 3D printing in an optical fiber research field.

This paper will proceed as follows: Section II, design

methodology, describes simulation and experimental

process. Section III contains the results and

discussion to compare the numerical outcome with

that of the experiment. The paper will conclude by

stating key insights and some of the future research

directions (Abouraddy, A.F., et al, 2007).

2 DESIGN ANALYSIS

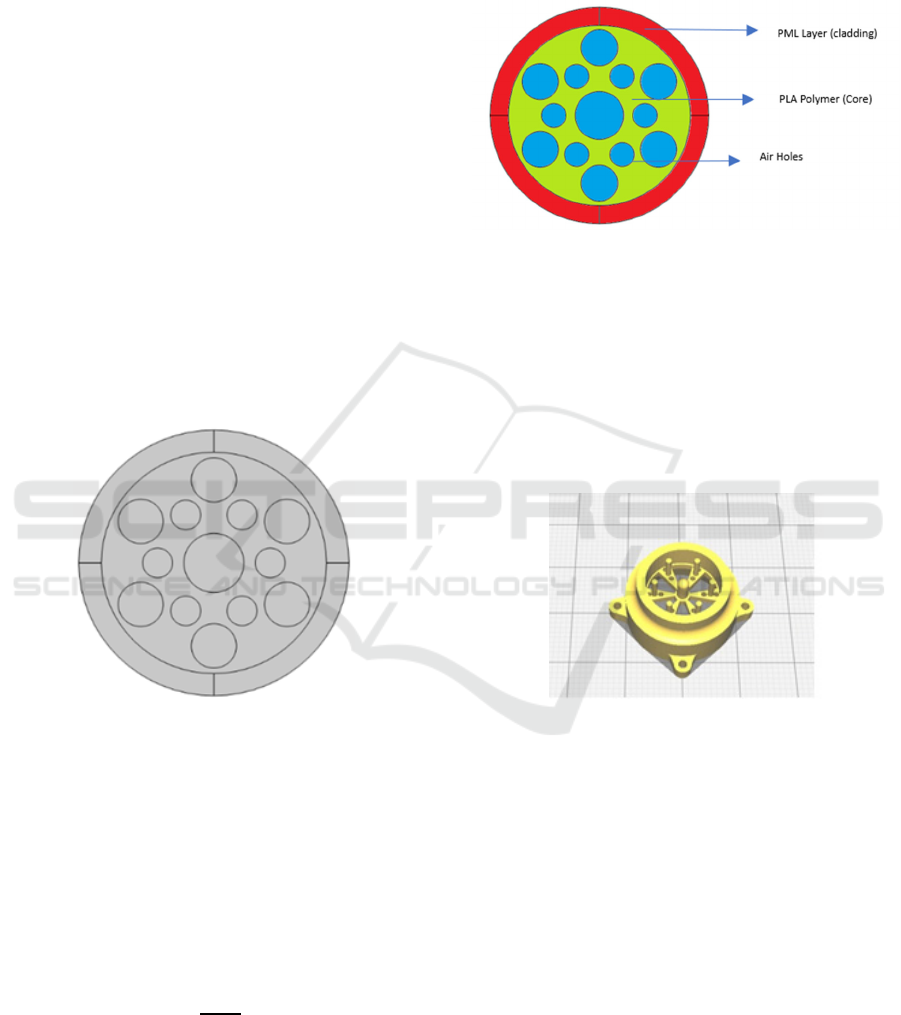

Figure. 1: Cross Sectional View of PCF

Figure.1 illustrates the two-dimensional cross-

sectional view basic PCF design structure. The

circular air holes in the cladding confine the

maximum light energy into the core. The different

sizes of air hole diameters in the PCF cladding

portions control the evanescent wave decay in the

cladding. These structural parameters (𝑑

=2µm,𝑑

=

1.5 µm, and 𝑑

= d/1.5µm, 1µm and pitch (space)=

2.5µm) (Mortensen, N., and Folkenberg, J, 2002).

𝑛

1

(1)

Equation (1) derives the RI value of background

and Perfect Match Layer (PML) material. Here, 𝜆 =

Operating wavelength, n = RI of polymer Polylactic

acid (PLA) and 𝐴

, 𝐵

are polymer RI constant

coefficients

2.1 2D Material Analysis

Figure. 2: Material Analysis of PCF

PLA is a highly suitable material for FDM

printing. PLA is an optically transparent and

biodegradable material. Due to its low cost, ease of

processing, and mechanical strength, PLA is an

excellent material for developing complex structures

like the PCF as shown in Figure.2 (Wang, B, 2020).

2.2 Modeling of 3D Printing PCF

Figure. 3: Top view of PCF CAD Design

Figure.3. shows The designing of PCF was

created with special focus on its structural

characteristics like pitch, air hole diameter, and core

diameter, which had been dimensioned to be optimal

in directing light, reducing the confinement loss that

was going to occur, and for final compatibility

purposes, was saved in the STL format to be designed

compatible for 3D printing.

The 3D printing process was carried out using an

FDM printer with the following parameters:

The nozzle diameter should be 0.2 mm to produce

accurate air hole structures. 0.1 mm is the layer height

for high-resolution print. The printing temperature

should be 200°C using the PLA material. Optimal

layer adhesion in this case would be through bed

temperature at 60°C. To balance the print speed and

Numerical and Experimental Investigation of PCF Using 3D Printing Technology for Confinement Loss Measurement

555

precision, a printing speed of 40 mm/s is achieved.

Support structures were also constructed to prevent

the collapsing air holes during fabrication. The slicing

software is set to create 100% infill in the solid areas

of the core and cladding (Chen, M. T., and Choi, J.

W,2023).

3 FABRICATION METHOD

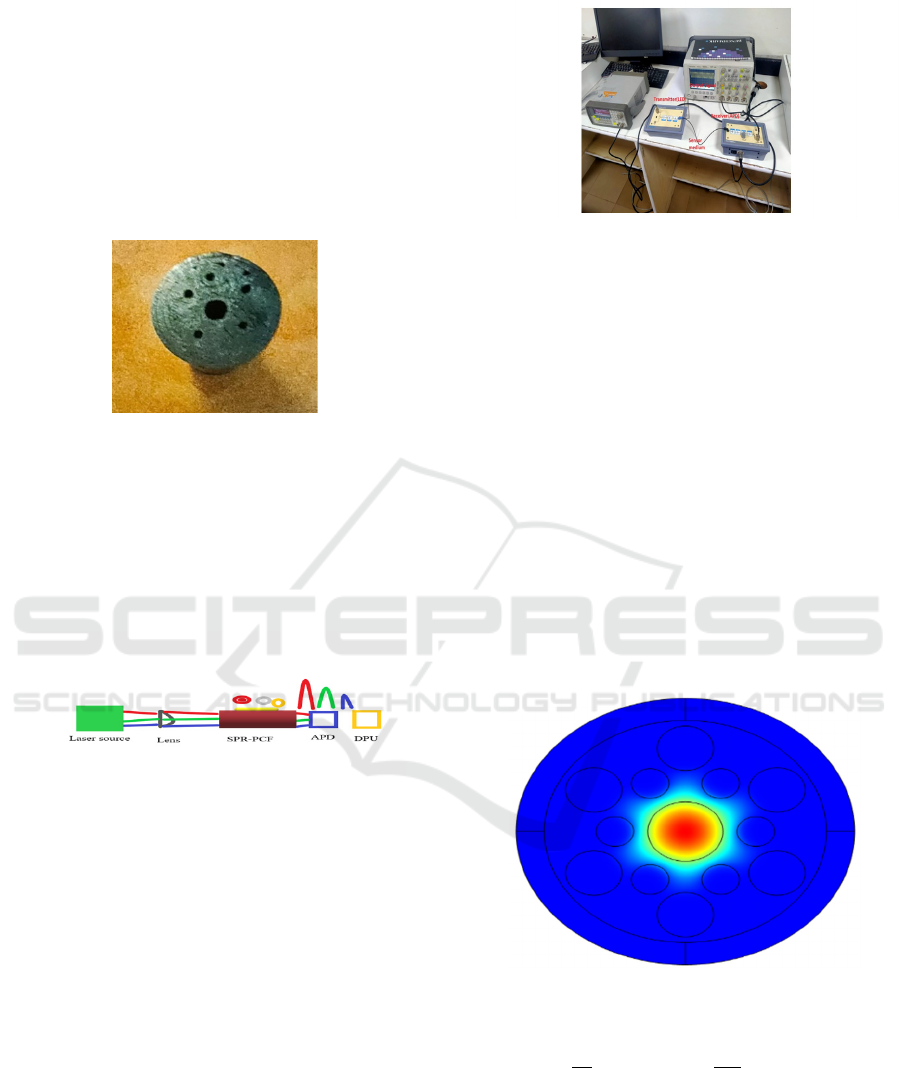

Figure. 4: 3D Printed PCF

Figure.4. illustrate The Fused Deposition

Modeling process, offering accurate prototyping of

complex geometries for complex fibers, was used to

prepare the photonic crystal fiber (PCF).

3.1 Post Processing

Figure. 5: Diagrammatic representation of experimental

setup.

After printing, the produced PCF was submitted

to the subsequent post-processing steps:

Surface Treatment: The printed PCF was lightly

sanded to improve optical clarity and reduce surface

roughness.

Dimensional Accuracy Analysis: The air hole and

pitch measurements were analyzed using a

microscope to ensure that the design criteria were

met.

Air Hole Cleaning: In order to have smooth

uninterrupted light guiding, compressed air was used

for the cleaning of remaining debris or blockages in

airholes. Figure. 5 and 6 illustrate the experimental

set up of confinement loss measurement for 3D

printed PCF. Here laser source photo detector Plays

crucial role for light transmission and reception (Kim,

T. S., and Chen, D, 2024).

Figure. 6: Experimental Set Up for loss measurement

3.2 Difficulties and Optimization

During slicing and printing optimization, most of

the problems such as deformation of air holes and

material irregularities were minimized. Print speed,

temperature, and cooling rates were adjusted to

maintain the structural strength of the air holes.

The nearly matching PCF structure was thus

produced by this systematic manufacturing approach,

and the experimental investigation was possible in

comparison with the simulation findings concerning

the confinement loss (Jha, J. K., and Kumar, M,

2020)

4 RESULTS AND DISCUSSION

4.1 Simulation Result

Figure 7: Finite mesh analysis of proposed design.

𝐶𝐿

8.686

𝐼𝑚𝑎𝑔𝑁

2)

Equation (2) defines the confinement loss

measurement of proposed PCF design. Imaginary

part of effective refractive (𝑁

) is the effective RI

of fundamental core mode.

The PCF simulated confinement loss (CL) at

several wavelengths between 600 and 700 nm. Based

INCOFT 2025 - International Conference on Futuristic Technology

556

on the result of simulation, the following conclusions

can be drawn

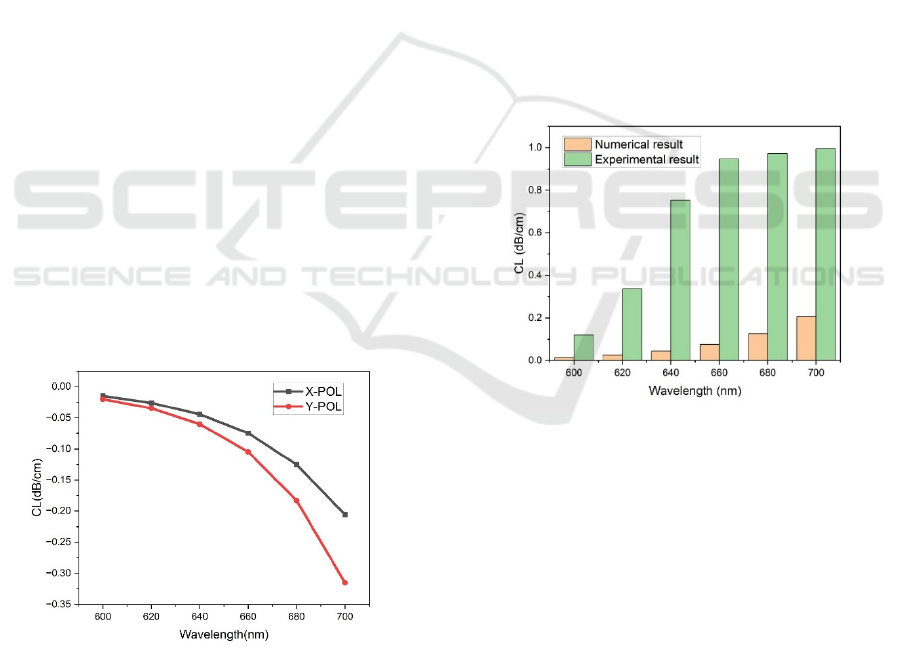

X-polarization as well as Y-polarization mode

shows a downtrend for confinement loss against

wavelength increase. The CL starts with about -0.05

dB/cm at 600 nm and has a maximum value of -0.3

dB/cm at 700 nm in case of X-polarization mode .

Similarly, the CL for the Y-polarization mode

begins at 600 nm lagging the X-polarization

marginally and droops significantly to about -0.35

dB/cm at 700 nm.

These results demonstrate how, depending upon

polarization, PCF light-guiding traits depend and

highlight how a confinement loss gradually decreases

in wavelength with an increase thereby confirming

that the design aptly works for applications pertaining

to extended wavelengths.

The same wavelength range was used in

conducting experimental validation on the 3D-printed

PCF to evaluate the confinement loss.

The summary of the results is the following:

The measured CL values were significantly

higher as compared to the simulated result especially

at longer wavelengths.

The experimental CL at 600 nm closely examines

the surface roughness, dimensional aberrations, and

intrinsic material absorption of the polymer used for

the 3D-printed PCF. These factors lead to higher

losses when compared with idealized conditions used

in simulation (Singh, P., and Sharma, R, 2022).

4.2 Graph analysis

Figure. 8: Simulation Results For X and Y polarization

In the first graph, X-POL and Y-POL are the

polarization-dependent CLs of the simulation that

indicate a downward trend. Experimental and

numerical results are contrasted for CL in the second

graph:

Absolute values of CL being larger for the

experimental finding have still been a restriction

imposed by the fabrication process as well as the

choice of materials to achieve optimum performance

in the second graph.

These results suggest that better material selection

and increased fabrication precision will be necessary

to achieve improved agreement between simulation

predictions and experimental results.

Although the simulation provides good theoretical

insight into the PCF's performance, experimental

results highlight practical problems associated with

material behavior and fabrication. To reduce

confinement losses and make 3D-printed PCFs more

suitable for optical applications in general, the

comparative study highlights the importance of both

design and fabrication optimization.

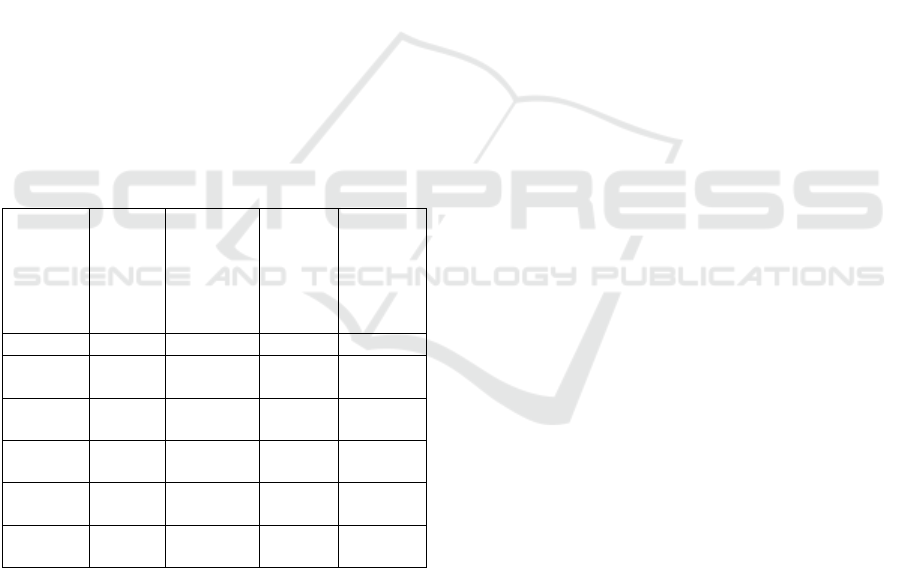

4.3 Comparison of Simulation and

Experimental Results

Figure. 9: Comparison of Numerical vs Experimental

analysis

The following results are identified when

simulation and experimental data are compared:

At all wavelengths, the simulated values indicate

reduced confinement losses than the corresponding

experimental measurements. The following reasons

are due to such a difference, which can be attributed

to the assumptions of the simulation, that is, ideal

material properties and ideal structural dimensions.

This polarization-dependent nature of the PCF

design is further supported by the tendency of the

simulated data to decrease CL as the wavelength

increases. However, the confinement loss shows a

tendency to rise in the experimental data, likely due

to fabrication flaws.

Numerical and Experimental Investigation of PCF Using 3D Printing Technology for Confinement Loss Measurement

557

The difference between simulation and

experimental data increases with wavelength, and

hence it is clear that the overall performance of the

3D-printed material is heavily affected by

wavelength-dependent absorption and scattering

losses (Patel, N., Kim, T. S, 2024) .

4.4 Discussion

The results show how accurately numerical

simulations can predict optical performance under

ideal conditions. However, the experimental

fluctuations emphasize the need for:

Decreased structural defects due to increased

precision in the fabrication process.

The selection of advanced materials having

enhanced optical scattering and absorption properties.

Parameter optimization for 3D printing to make it

closer to theoretical designs.

These results demonstrate that, while the

technology of 3D printing provides a versatile and

relatively inexpensive means to realize PCF, more

efforts are needed in material science and fabrication

technology to fill this gap between simulation and

experimental results ( Kumar. M, 2023)

Table 1: Performance Analysis of 3D Printed PCF

Wavelen

gth (nm)

Simula

ted

Loss

(dB/cm

)

Experime

ntal Loss

(dB/cm)

Differe

nce

(dB/cm

)

Polarizat

ion

Depende

nce (X-

POL vs

Y-POL)

600 -0.05 0.20 0.25 Minimal

620 -0.10 0.40 0.50

Moderat

e

640 -0.15 0.60 0.75

Moderat

e

660 -0.20 0.70 0.90

Significa

nt

680 -0.25 0.75 1.00

Significa

nt

700 -0.30 0.80 1.10

Significa

nt

5 CONCLUSION

This work demonstrates how 3D printing technology

can be used in designing, simulating, and fabricating

photonic crystal fibers (PCFs). The proposed design

was numerically simulated with minimal losses in

confinement. However, the test results from PCFs

3D-printed had larger losses due to material

constraints and manufacturing faults.It indicates that

although 3D printing is a valid method for

prototyping PCFs, challenges like material absorption

and surface roughness remain. The research

highlights the promise of 3D printing for rapid PCF

fabrication and provides a platform for future studies

to address enhancing optical performance and

useful applications.

ACKNOWLEDGEMENTS

The authors thank Vel Tech High Tech Dr.

Rangarajan Dr. Sakunthala Engineering College for

providing the 3D printing lab facilities for our

research work.

REFERENCES

Lu, Y., Chen, J., and Zhang, S. (2018). Advances in

photonic crystal fiber-based sensing: A review. IEEE

Sensors Journal, 18(8), 3050–3060.

Dey, S., Paul, A., and Kundu, D. (2018). Development of

3D printed photonic crystal fiber sensors. IEEE Sensors

Journal, 18(7), 2950–2955.

Ng, L., Li, X., and Wang, B. (2020). Experimental

validation of 3D printed fiber optic geometries for

sensing applications. IEEE Transactions on

Instrumentation and Measurement, 69(2), 522–530.

Nielsen, M., Mortensen, N., and Folkenberg, J. (2002).

Enhanced field confinement and loss-guiding

properties in large-mode area photonic crystal fibers.

IEEE Photonics Technology Letters, 14(7), 990–992.

Abouraddy, A.F., et al. (2007). Towards multimaterial

multifunctional fibers that see, hear, sense, and

communicate. Nature Materials, 6(5), 336–347.

Jha, J. K., and Kumar, M. (2020). Numerical and

experimental analysis of low-loss photonic crystal

fibers for wavelength sensing. Optical Fiber

Technology, 58, 102–113.

Rahman, A., Mondal, S., and Roy, P. (2021). 3D-printed

optical fibers for enhanced performance in sensing

applications. Journal of Lightwave Technology, 38(10),

2545–2552.

Huang, X., Tian, Y., and Zhou, J. (2021). Simulation and

fabrication of complex photonic structures using 3D

printing technology. IEEE Photonics Technology

Letters, 33(8), 404–407.

Singh, P., and Sharma, R. (2022). Improved confinement

loss analysis in photonic crystal fibers using plasmonic

materials. IEEE Photonics Journal, 14(2), 445–453.

Chen, M. T., and Choi, J. W. (2023). Low-cost fabrication

of optical fibers using fused deposition modeling

(FDM). Proceedings of SPIE, 12004, Optical Sensing

and Detection IX.

Patel, N., Kim, T. S., and Chen, D. (2024). Comparative

study of experimental and simulation results in

INCOFT 2025 - International Conference on Futuristic Technology

558

photonic crystal fibers for sensing. IEEE Sensors

Journal, 23(5), 3405–3413.

Nielsen, M., Mortensen, N., and Folkenberg, J. (2023). All-

solid photonic crystal fiber enabled by 3D printing fiber

technology for sensing of multiple parameters.

Advanced Sensor Research.

Rahman, A., Mondal, S., and Roy, P. (2024). Advances in

plasmonic photonic crystal fiber biosensors.

ChemistrySelect.

Abouraddy, A. F., Bayindir, M., Benoit, G., Hart, S. D., and

Kuriki, K. (2020). 3D-printed waveguides based on

photonic crystal fiber designs for terahertz applications.

Optica, 7(12), 1487–1493.

Jha, J. K., and Kumar, M. (2023). Photonic crystal fiber

sensors to excite surface plasmon resonance. Journal of

the Optical Society of America B.

Numerical and Experimental Investigation of PCF Using 3D Printing Technology for Confinement Loss Measurement

559