Analysing ML, DL Approaches for Real-Time Maintenance

Forecasting in Industrial Scenarios

Pranita Bhosale

1,2 a

and Sangeeta Jadhav

3a

1

D. Y. Patil Institute of Technology, Pimpri-Chinchwad, Pune, India

2

E&TC Department, Army Institute of Technology Dighi Hills, Pune, India

3

Department of IT Engineering, Army Institute of Technology, Dighi Hills Pune, India

Keywords: Predictive Maintenance, Plastic Extruder Machines, Temperature Sensors, Machine Learning (ML),

Probabilistic Neural Network (PNN), Real-Time Data.

Abstract: Predictive maintenance became increasingly crucial in large machines like extruder machines to ensure

optimal performance & prevent costly downtimes. Monitoring temperature is particularly critical in extruder

machines as it directly impacts product quality. To address this, real-time data from a plastic extruder machine

equipped with four temperature sensors taken into account to ensure precise temperature control for high-

quality output. The study analysed a dataset comprising 19679 rows of data, stored in an Excel sheet, using a

range of ML and DL algorithms. Primary focus was evaluating performance of these algorithms in predictive

maintenance tasks. Among the algorithms tested, the Probabilistic Neural Network, a type of ML algorithm,

demonstrated promising results. PNN achieved accuracy of 99.70%. PNN showed several advantages when

compared to other popular algorithms such as Backpropagation Neural Network, Convolutional Neural

Network, Support Vector Machine, Long Short Term Memory, and Bidirectional LSTM. PNN requires

minimal parameter tuning compared to complex algorithms like LSTM & Bi-LSTM, simplifying

implementation process. In conclusion, the research highlights the effectiveness of the PNN algorithm in

predictive maintenance tasks for extruder machines based on temperature sensor data. Its performance and

simplicity makes it a promising choice for real-time maintenance prediction, offering potential cost savings

and operational efficiency improvements in industrial settings.

1 INTRODUCTION

Maintenance management is one of the pivotal

operations in each industry since it enables better

performance and flexibility of equipment.

Operational Maintenance (OM) practices that follow

quick and inexpensive predetermined approaches to

problems based on analysis done over time often fails

to capture the situations that occur at the time leading

to un- scheduled downtimes and increased costs.

Also, the real time needs maintenance primarily

emphasized in periods where breakdowns in

equipment would cost delays in production or great

losses.

In contrast with others, through supporting day-

to-day operation this also focuses ensuring that all

existing issues related to equipment are repaired

1a

https://orcid.org/0000-0001-6796-0872

2a

https://orcid.org/0000-0002-0610-0374

before they worsen as in most situations where there

is a breakdown. Maintenance, be it corrective,

preventive or real-time involves the identification of

the presence of a defect followed by the necessary

repair actions. Real-time maintenance management

consists of data analysing, equipment monitoring, and

fast responding to all performance-related issues

emerging during the process.

Such alterations, however, cannot be made if only

periodic maintenance management systems are

utilized whereby a palate of issues is waited for until

they arise then rectified. But true to its name ‘real’

implies that effects of cutting back on resources at the

expense of safety of a facility or assets is minimized

through active restraint on damage potentially caused

by the cutting back. A strong predictive maintenance

764

Bhosale, P. and Jadhav, S.

Analysing ML, DL Approaches for Real-Time Maintenance Forecasting in Industrial Scenarios.

DOI: 10.5220/0013585300004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 1, pages 764-770

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

mechanism that cans add-on temperature trends,

diagnosis maintenance needs is the way to go.

The Probabilistic Neural Network (PNN) is a type

of machine learning algorithm known for its

effectiveness in handling noisy data and robustness

against outliers. Its architecture allows for efficient

processing of large datasets, making it suitable for

real-time maintenance predictions. PNN requires

minimal parameter tuning compared to more complex

algorithms, simplifying the implementation process.

This makes PNN an attractive option for industries

seeking to enhance their maintenance strategies

without incurring significant complexity. In this

paper, we explore the use of PNN for predictive

maintenance by analysing a dataset of temperature

readings from a plastic extruder machine. By

comparing PNN’s performance with other popular

algorithms such as Backpropagation Neural Network

(BPNN), Convolutional Neural Network (CNN),

Support Vector Machine (SVM), Long Short Term

Memory (LSTM), and Bidirectional LSTM (Bi-

LSTM), we demonstrate the advantages of using

PNN in this specific application. Our findings

highlight PNN’s potential to improve maintenance

prediction accuracy, ultimately contributing to cost

savings and operational efficiency in industrial

settings.

2 LITERATURE SURVEY

Predictive Maintenance (PdM) plays an important

role in the digital era of Industry 4.0. Researchers has

performed an extensive research devoted to PdM.

Research highlighted its potential benefits and

effective implementation strategies.

The study enhanced power transformer fault

diagnosis using an improved Probabilistic Neural

Network (PNN) model optimized with an enhanced

Gravitational Search Algorithm (GSA) featuring

chaos sequences (Wang, 2024). The study introduced

a parallel neural network (PNN) architecture for

accurate remaining useful life (RUL) estimation of

bearings, integrating 1D time series and 2D image-

based features for enhanced prediction efficiency

(Niazi, 2023). This study explored predictive

maintenance for lead-acid batteries in heavy vehicles

using LSTM neural networks and RSF models with

sparse, irregular operational data (Sergii, 2023). This

study integrated AI- driven monitoring algorithm

achieved high accuracy (0.97 with XG-Boost),

enhancing equipment reliability, reducing downtime,

and improving operational efficiency (Chen, 2023).

This study enhanced predictive maintenance in

Industry 4.0 by integrating machine workload data

into a Prognostics and Health Management (PHM)

algorithm (Converso, 2023). This systematic

literature review examined predictive maintenance

(PdM) in military contexts, highlighting challenges,

principles, application scenarios, and technical

methodologies (Jovani, 2023). This paper introduced

the adaptive Gaussian mixture scheme refined

probability distributions (Zhang, 2022), achieving

Quantitative and qualitative analyses highlighted the

potential and challenges, advocating for improved

data schemas and interoperability to advance PdM in

infrastructure facilities effectively (Seyed, 2022).

This study investigated the use of probabilistic neural

networks (PNNs) (Nashed, 2022). Results from case

studies on cover-plated beams and process pipework

demonstrated that these models effectively captured

variability in data distribution parameters, offering

more accurate fatigue predictions compared to

deterministic approaches. This paper surveyed ML

and DL methods for fault detection and diagnosis

(FD/D) in induction motors (IMs) within Industry 4.0,

highlighting DL’s dominance since 2015 (Drakaki,

2022). This study developed a predictive

maintenance system for the manufacturing industry,

utilizing historical sensor data to forecast equipment

failures and optimize maintenance schedules (Kane,

2022). The study proposed a high-level architecture

for AI-enabled EIS, highlighting challenges like cost

optimization and data interoperability, while

underscoring AI’s potential to enhance system

efficiency and innovation (Zdravkovic, 2021).

This paper proposed an efficient fault detection

and diagnosis model for PV systems, achieving

98.5% accuracy using three sequential PNN models

(H. Zu, 2020). This survey paper reviewed predictive

maintenance methodologies, highlighting the benefits

over traditional methods like cost savings and

preventing failures (Tyagi, 2020). This study

conducted a systematic review of literature on

predictive maintenance (PdM) within Industry 4.0,

focusing on machine learning and reasoning

applications (Dalzochio, 2020). This paper developed

machine learning- based Prognostic and Health

Management (PHM) models using sensor data to

diagnose faults in transformer systems within smart

grids (Li, 2018). HD Pass employed Apache Spark

for real-time predictive maintenance of HDDs in data

centres, aiming to pre-empt failures and optimize

reliability, resulted in reduced downtime, extended

equipment life, and enhanced operational efficiency

in cloud computing environments (Chuan_Jun Su,

2018). The researcher developed a method for rapid

fault detection and localization in power transmission

Analysing ML, DL Approaches for Real-Time Maintenance Forecasting in Industrial Scenarios

765

lines using three-phase voltage data to derive the

Concordia pattern and classify faults with a

Probabilistic Neural Network (PNN) (S. Mishra,

2016). The researcher introduced Self-Adaptive

Probabilistic Neural Net- works (SaPNN), which

autonomously adjusted the Spread parameter for

enhanced predictive accuracy in transformer fault

diagnosis (Yi-JH, 2016). The researcher developed a

fault diagnosis method for gears using vibration

analysis and wavelet transform for predictive

maintenance (Devendiran, 2015). The researcher

developed a MATLAB-based approach using

Independent Component Analysis (ICA) and

supervised learning classifiers, notably PNN, to

improve condition monitoring in power plants by

effectively detecting and categorizing bearing

malfunctions in noisy environments (Hameed, 2013).

The researcher developed two innovative approaches

for predicting meteorological time series data: an

Evolving Polynomial Neural Network (EPNN) and a

hybrid polynomial neural network with genetic

algorithm (PNN-GA), both achieving high accuracy

and outperforming traditional models (Mellit, 2010).

The researcher developed a neural network-based

method for monitoring machine health at the Refinery

of ‘Milazzo’ in Italy, successfully identifying faults

not covered in the training data (Crupi, 2004). The

researcher identified that traditional maintenance

scheduling was inadequate for high- reliability

industries, which required predictive maintenance

using advanced monitoring to predict failures and

prioritize maintenance (Mohammad Azam, 2002).

3 DATASET

Previously we worked on sample data set but this time

target was to work with real time data. For that

purpose, I have to finalize one equipment for further

research work. And positively we got the opportunity

to monitor the ma- chine health. The dataset used in

this study is sourced from ‘Radhan Plastics’, a

company established in 2008 as a Partnership Firm.

‘Radhan Plastics’ specializes in manufacturing films,

tubing, rolls, bags, and covers from materials such as

EVA (Ethyl Vinyl Acetate), VCI (Vapour Corrosion

Inhibitor), Bubble, LDPE. Their products are

available in various designs, colours, sizes, and

shapes to meet di- verse customer needs. These

products find extensive application in : Rubber

compounding, Pharmaceuticals, Food industry,

Agriculture, Industrial packaging, Auto

component/spares packing, Other industrial

packaging applications The company’s

manufacturing facility is located in the picturesque

area of ‘Pirangut’, near Pune, India. Their clientele

spans across India, including cities such as Roorkee,

Mumbai, Jammu, Bangalore, and Hyderabad. Hence

work to present in this seminar was to test the

algorithms with real time data. This sample data file

contains 3 main groups of data as:

1. Total Number of Sensors: 04

2. Data Recorded: 3 Months per minute [Dec.2022–

Feb.2023]

3. Total count: 50302

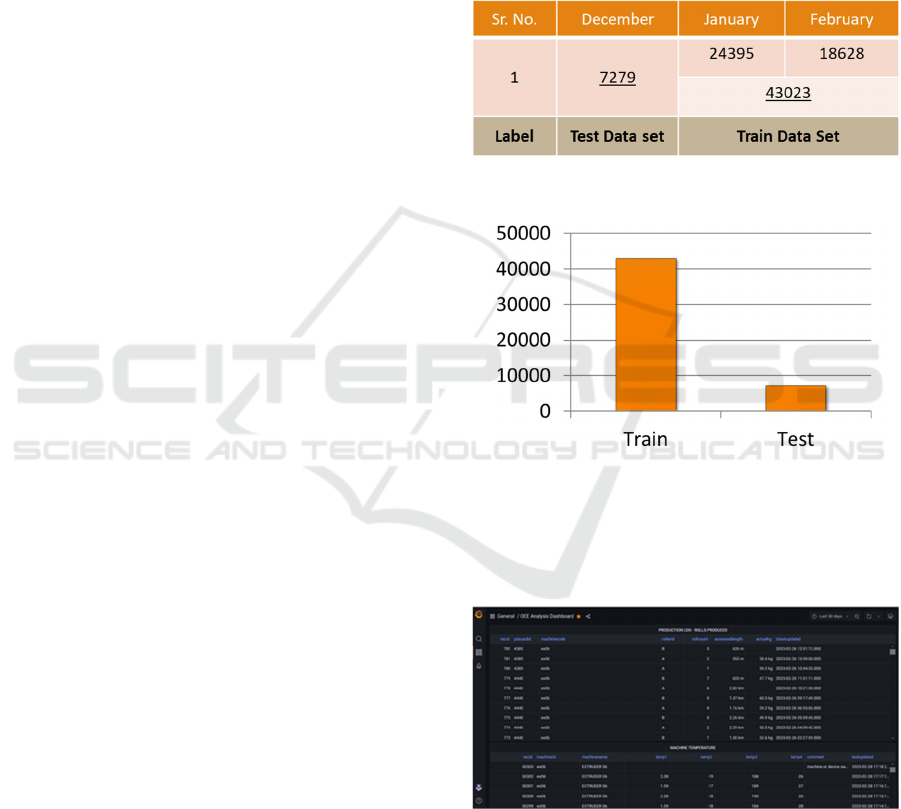

Figure 1: Category as per Machine Status

Figure 2: Distribution of Data Set

Here, three months of data utilised. With the help of

time-based splitting, the data divided into train and

test, where 2 months of data used as train dataset and

rest used as test dataset.

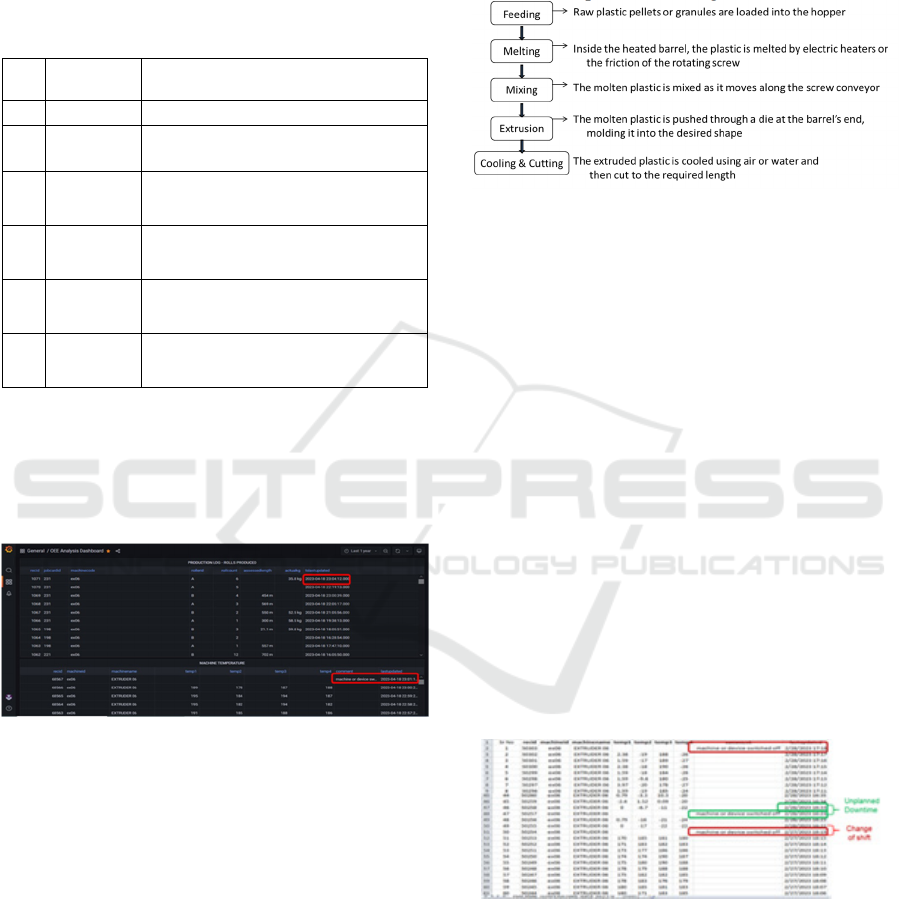

Figure 3: Dashboard of Data set

The above figure shows the dashboard. Dataset is

categorized as Production Log and Machine

Temperature. The upper part “Production Log” used

for OEE calculation. Bottom part, Machine

Temperature, with tracking these 4 sensors predicts

the failures.

INCOFT 2025 - International Conference on Futuristic Technology

766

Bottom side machine temperature dashboard with

recid, machine id, machine name, with 4 temperature

sensors. They named as temp1, temp2, temp3, temp4.

Automatic comment gets generated whenever

machine gets switched off [Reasons are unknown], to

identify these reasons PdM is needed.

Table I: Machine Tags With Description

Sr.

No.

Tags Description

01 ex06 Extruder Machine Name

02 recid

The serial number, updated at new

entry

03 Roller id

It can be either A or B, each has

different features

04 Roller count

Number of rolls produced for the job

card during the shift

05

Assessed

length

Roll length [ranges from 10 m to 9.53

km]

06 Actual kg

Weight of the roll [range is 10 kg to

92.1 kg]

Here, the dataset is shown for complete 1 year for

OEE as well as PdM Calculations. The figure is

showing data recorded for 18th April. Last entry of

18th April is at 11 PM of 35.8 kg at that time message

popped up as machine is switched off.

Figure 4: Dashboard of Data set of 1 Year

The data for this study considered from ‘Radhan

Plastics’ online platform known as the “OEE

Analysis Dashboard”. This dashboard provided real-

time data in .csv format, which can be downloaded

for further analysis. The dataset includes information

from four temperature sensors used to monitor the

temperature of a plastic extruder machine. Plastic

Extruder Machine: It is used in manufacturing to melt

and shape plastic materials into continuous profiles or

shapes by forcing them through a die. It plays a

crucial role in industries such as packaging,

construction, and automotive, producing items like

pipes, sheets, and filaments.

Next figure shows csv file data recorded for 28th

February. Range of temperature sensor is [-1 to 240

degree Celsius]. Maximum limit is 240 degree

Celsius, for this particular reading machine should

provide an alert before any failure occurs. Through

the timestamp data, information extracted as start of

shift and of shift and unplanned downtime during the

shift. This helps in calculating various loses at field.

Figure 5: Working Principle of Plastic Extruder Machine

Deep learning, a subset of machine learning

derived from artificial neural networks, is

characterized by multiple non- linear processing

layers. Its goal is to learn hierarchical representations

of data. The field is rapidly evolving, with new

models being developed frequently. The deep

learning community is highly collaborative, offering

numerous high- quality tutorials and books. Thus, this

text provides only a brief overview of key deep

learning techniques used in machine health

monitoring. The review covers four major deep

architectures—Auto-encoders, CNNs, RNNs, and

their variants. Researchers have developed predictive

maintenance algorithms using both machine learning

and deep learning. Initially, two machine learning

algorithms were created for testing purposes to

compare their results with those of deep learning

algorithms. These algorithms are now being tested

with real-time data. The selected machine learning

and deep learning algorithms include BPNN, CNN,

SVM, Bi-LSTM, LSTM, and PNN.

Figure 6: Dataset CSV File

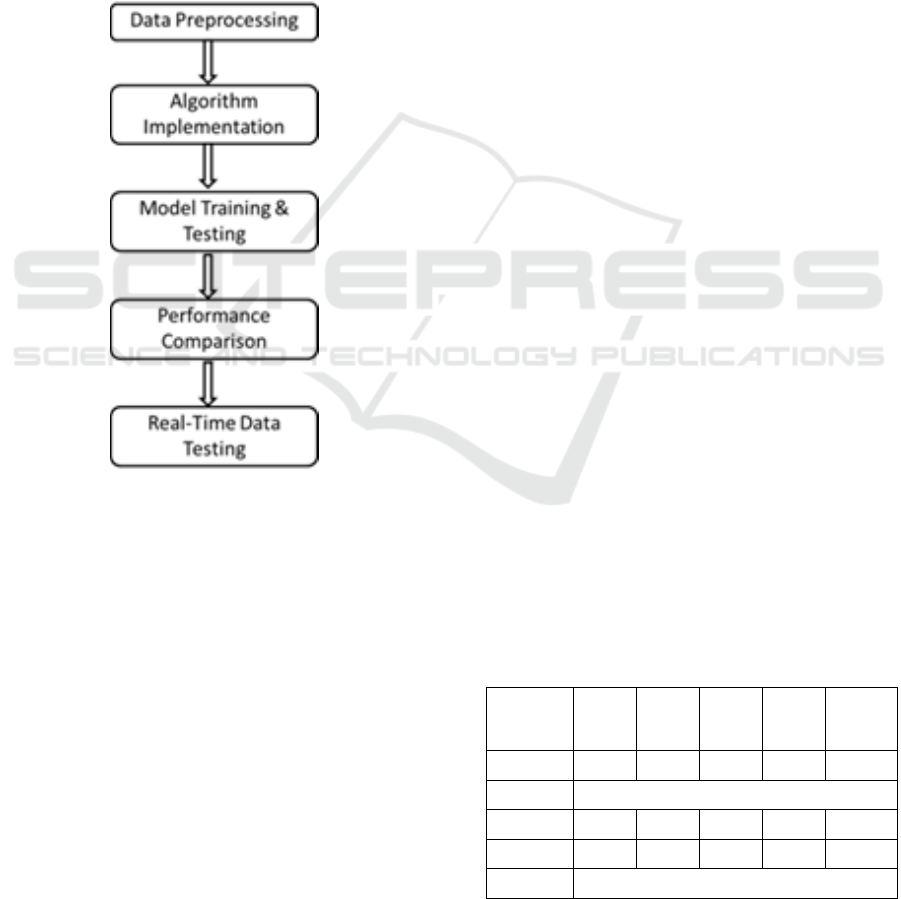

4 METHODOLOGY

In this research, MATLAB R2023b software will be

utilized to test all the selected algorithms. The dataset

comprises 19,679 rows, each containing data from

Analysing ML, DL Approaches for Real-Time Maintenance Forecasting in Industrial Scenarios

767

four temperature sensors. Initial testing indicates that

the Probabilistic Neural Network (PNN) performs

better for this specific dataset. The research will

involve the following steps:

4.1 Data Pre-Processing

Data pre-processing involved cleaning and

normalizing the dataset to ensure consistency and

accuracy. This step included handling any missing or

anomalous values, which could have otherwise

skewed the results. The dataset was then split into

training and testing subsets to allow for model

validation and performance assessment.

Figure 7: Methodology

4.2 Algorithm Implementation

The implementation phase involved setting up the

chosen machine learning and deep learning

algorithms: BPNN, CNN, SVM, Bi-LSTM, LSTM,

and PNN. Each algorithm was configured with

appropriate parameters and hyper-parameters tailored

to the specific characteristics of the dataset.

MATLAB 2023b was used to code and run these

algorithms.

4.3 Model Training & Testing

During model training, each algorithm was trained on

the training subset of the data to learn the underlying

patterns. After the training, the models were sending

for testing subset to estimate their predictive

accuracy. We do have various performance matrices

to test the model accuracy. Performance metrics like

accuracy, precision, recall, and F1-score were used to

assess the models.

4.4 Performance Comparison

The performance of each and every algorithm got

compared with each other. The comparison is

performed to determine which model is best. This

comparison involved analysing various performance

metrics and identifying strengths and weaknesses of

each algorithm. The goal was to find the most

effective model for predictive maintenance.

4.5 Real-Time Data Testing

In the final phase, the best-performing algorithms

were applied to real-time data to validate their

effectiveness in a live environment. This testing

helped ensure that the models could handle real-world

conditions and provide reliable predictions for

machine health monitoring. The performance in this

phase confirmed the practical applicability of the

models.

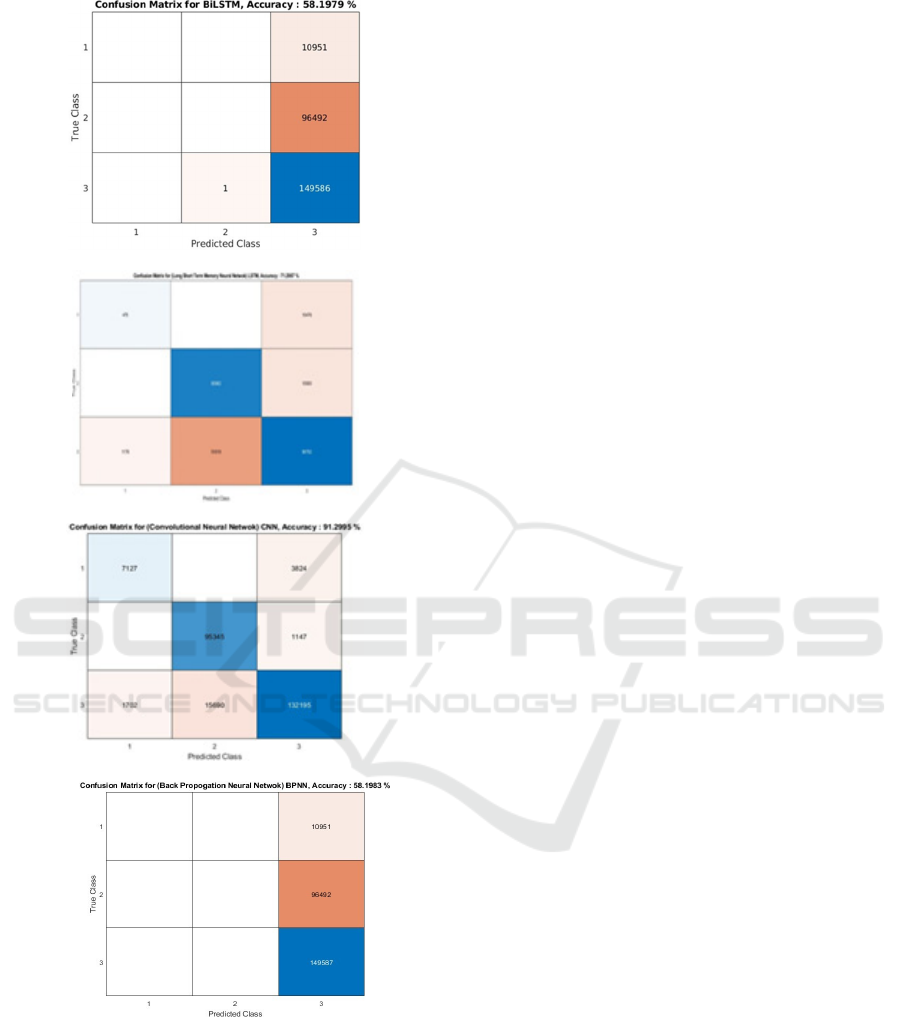

5 RESULTS & DISCUSSION

The following table shows the results of various

algorithms, where each was run five times with a

learning rate of 0.001 and a maximum epoch size of

1000. The table highlights that the Probabilistic

Neural Network (PNN) achieved the highest accuracy

at 99.70%. Thus, for the applied real-time dataset

consisting of 19,679 rows of 4 temperature sensors

from a plastic extruder machine, PNN was observed

to be the best- performing model.

Table 2:: Model Performance Comparison

(Learning Rate: 0.001, Epoch: 1000)

Models /

Max

E

p

ochs

1

2

3

4

5

BILSTM 58.20 49.26 58.20 58.20 58.20

BPNN 58.20

LSTM 71.29 77.18 73.32 79.91 65.39

CNN 91.30 92.13 91.19 91.74 91.30

PNN 99.70

INCOFT 2025 - International Conference on Futuristic Technology

768

Figure 8: Confusion Matrix o f BILSTM, LSTM, CNN,

BPNN.

6 CONCLUSIONS

The Predictive maintenance is very much essential. It

ensures optimal performance as well as prevents

costly down-times. The costly downtimes

considering machines like extruder machines are very

crucial as it requires a consistent product quality. This

study is purposely focused on use of real-time data.

The data is from four temperature sensors fitted in a

plastic extruder machine. The temperature sensor

ensures precise temperature control and high-quality

output. The dataset analysed comprised 19,679 rows

of data. A range of machine learning (ML) and deep

learning (DL) algorithms were tested. Tested

algorithms are as follows:

Probabilistic Neural Network (PNN),

Backpropagation Neural Network (BPNN),

Convolutional Neural Network (CNN), Support

Vector Machine (SVM), Long Short Term Memory

(LSTM), and Bidirectional LSTM (BiLSTM). Each

algorithm tested for the five consecutive times with a

learning rate of 0.001 and a maximum epoch size of

1000.

The results proved that PNN, ML algorithm

achieved the remarkable accuracy of 99.70%. This

makes it the best- performing model for the applied

real-time dataset. PNN’s ability to handle noisy data

and its robustness against outliers contributed to its

superior performance. Additionally, PNN’s

architecture allowed for efficient processing of large

datasets and required minimal parameter tuning

compared to more complex algorithms like LSTM

and BiLSTM.

REFERENCES

Wang, Yanyu & Qiu, Peng & Liu, Yang & Guo, Yishen &

Peng, Cheng. 2024. IGSA-PNN-based Methods for

Power Transformer Fault Diagnosis, Journal of

Physics: Conference Series.

Niazi, Sajawal Gul & Nawaz, Ali & Huang, Tudi & Bai,

Song & Huang, Hong-Zhong, 2023. Prediction of

Remaining Useful Life of Bearings using a Parallel

Neural Network, Proceedings of the 33rd European

Safety and Reliability Conference (ESREL 2023),

1792-1799.

Sergii Voronov, Mattias Krysander and Erik Frisk, 2023,

Predictive Maintenance of Lead-Acid Batteries with

Sparse Vehicle Operational Data, International

Journal of Prognostics and Health Management, ISSN

2153-2648, 2020 008

Chen, Hong-Ming, et al., Hot-Pressing Furnace Current

Monitoring and Predictive Maintenance System in

AEROSPACE APPLICATIONS.” Sensors 23.

Converso, Giuseppe, et al. Predicting failure probability in

Industry 4.0 production systems: A workload-based

prognostic model for maintenance planning, Applied

Sciences 13.3,1938.

Jovani Dalzochio, Rafael Kunst, Jorge Luis Victoria

Barbosa, Pedro Clarindo da Silva Neto, Edison

Analysing ML, DL Approaches for Real-Time Maintenance Forecasting in Industrial Scenarios

769

Pignaton, Carla Schwengber ten Caten, and Alex de

Lima Teodoro da Penha,V2023. Predictive

Maintenance in the Military Domain: A Systematic

Review of the Literature, ACM Comput. Surv. 55, 13s,

Article 267 (December 2023), 30 pages, 2023.

Zhang, Bin, and Yung C. Shin, A probabilistic neural

network for uncertainty prediction with applications to

manufacturing process monitoring, Applied Soft

Computing 124 (2022): 108995,2022.

Seyed Mostafa Hallaji, Yihai Fang, Brandon K. Winfrey,

Predictive maintenance of pumps in civil

infrastructure: State-of-the-art, challenges and future

directions, Automation in Construction, Volume 134,

104049, ISSN 0926-5805,2022.

Nashed, Mohamad Shadi, Renno, Jamil, Mohamed, M.

Shadi, Mod- elling fatigue uncertainty by means of

nonconstant variance neural networks, Fatigue &

Fracture of Engineering Materials & Structures, 45,

9, ISSN - 8756-758X, 2468, 24802022, 2022.

Drakaki, Maria & Karnavas, Yannis & Tziafettas, Ioannis

& Linardos, Vasilis & Tzionas, Panagiotis,Machine

Learning and Deep Learning Based Methods Toward

Industry 4.0 Predictive Maintenance in Induction

Motors: State of the Art Survey. Journal of Industrial

Engineering and Management, 2022.

Kane, Archit P., et al.Predictive maintenance using

machine learning.” arXiv preprint arrive: 2205.

09402, 2022.

Zdravkovic´, M., Panetto, H., & Weichhart, G. 2021, AI-

enabled Enterprise Information Systems for

Manufacturing, Enterprise Information Systems,

16(4), 668–720, 2021.

H. Zhu, S. A. Z. Ahmed, M. A. Alfakih, M. A. Abdelbaky,

A. R. Sayed and M. A. A. Saif, Photovoltaic Failure

Diagnosis Using Sequential Probabilistic Neural

Network Model, in IEEE Access, vol. 8, pp. 220507-

220522, 2020.

Tyagi, Vinayak, et al. A survey: Predictive maintenance

modeling using machine learning techniques,

Proceedings of the International Conference on

Innovative Computing & Communications

(ICICC),2020.

Dalzochio, Jovani & Kunst, Rafael & Pignaton de Freitas,

Edison & Binotto, Alecio & Sanyal, Srijnan & Favilla,

Jose & Barbosa, Jorge, 2020 Machine learning and

reasoning for predictive maintenance in Industry 4.0:

Current status and challenges. Computers in Industry,

2020.

Li, A.; Yang, X.; Dong, H.; Xie, Z.; Yang, C. Machine

Learning-Based Sensor Data Modeling Methods for

Power Transformer PHM. Sensors 2018, 18, 4430,

2018.

Chuan-Jun Su, Shi-Feng Huang, Real-time big data

analytics for hard disk drive predictive maintenance,

Computers & Electrical Engineering, Volume 71,

2018, Pages 93-101, ISSN 0045-7906, 2018.

S. Mishra et al., Classification of power system faults using

voltage Concordia pattern feature aided PNN. 2016

IEEE 6th International Conference on Power Systems

(ICPS) (2016): 1-6, 2016.

Yi J-H, Wang J, Wang G-G. Improved probabilistic neural

networks with self-adaptive strategies for transformer

fault diagnosis problem. Advances in Mechanical

Engineering. 2016;8(1),2016.

Devendiran, S., and K. Manivannan, Vibration signal based

multi-fault diagnosis of gears using roughset

integrated PCA and neural networks, Int. J. Mech.

Mechatron. Eng 15.01,2015.

Hameed, Shameer V., and K. M. Shameer, Proactive

Condition Monitoring Systems for Power Plants,

International Journal of Scientific and Research

Publications 3.11 (2013): 1-5,2013.

Mellit, Adel & Drif, Mahmoud & Ali, Malek, 2010, EPNN-

based prediction of meteorological data for renewable

energy systems. Revue des Energies Renouvelables.

13. 25-47. 10. 54966 / jreen . v13 i1. 176 ,2010.

Crupi, Vincenzo, Eugenio Guglielmino, and G. Milazzo,

Neural- network-based system for novel fault

detection in rotating machinery, Journal of Vibration

and Control 10.8 (2004): 1137-1150, 2004.

Mohammad Azam, Fang Tu, and Krishna R. Pattipati,

Condition- based predictive maintenance of industrial

power systems, Proc. SPIE 4733, Component and

Systems Diagnostics, Prognostics, and Health

Management II, 16 July 2002.

INCOFT 2025 - International Conference on Futuristic Technology

770