Driving Innovation in Fleet Management: An Integrated Data-Driven

Framework for Operational Excellence and Sustainability

Suryakant Kaushik

a

Masters in Business Administration (MBA), Texas A&M University, College Station, Texas, U.S.A.

Keywords: Data-Driven Innovation, Fleet Management, Artificial Intelligence, Internet of Things, Predictive

Maintenance, Route Optimization, Sustainability.

Abstract: This paper presents a comprehensive framework for leveraging advanced data analytics, artificial intelligence,

and Internet of Things (IoT) technologies to revolutionize fleet management systems across various

transportation sectors. Fleet operations globally face significant challenges including operational

inefficiencies, increasing fuel costs, environmental compliance requirements, and safety concerns. The

proposed integrated data-driven framework addresses these challenges by combining operational research

techniques with AI-powered analytics and IoT-enabled sensor networks to optimize routing, reduce fuel

consumption, enhance predictive maintenance capabilities, and improve driver safety protocols. Through

analysis of real-world implementations across commercial and municipal fleets, we demonstrate how this

framework has achieved fuel consumption reductions of up to 15%, decreased unplanned maintenance

downtime by 30%, and significantly improved safety metrics. Our research provides empirical evidence of

return on investment across various fleet sizes and compositions, including successful retrofitting strategies

for legacy vehicles.

1 INTRODUCTION

Fleet management lies at the intersection of

operational, economic, and environmental challenges.

With hundreds of millions of vehicles worldwide,

organizations grapple with rising costs, strict

regulations, and safety concerns. For instance, fatal

car accidents occur every 12 minutes (National

Highway Traffic Safety Administration, 2024), and

up to 35% of truck miles are driven empty (Jones &

Smith, 2023), while traffic congestion costs the U.S.

economy approximately $224 billion annually, with

each commuter losing an average of 54 hours in traffic

delays (Texas Transportation Institute, 2023).

Traditional, reactive management methods—relying

on historical data and manual scheduling—are no

longer sufficient. The rise of connected vehicle

technologies, advanced sensors, and computational

capabilities now enables transformative, data-driven

decision-making. This paper proposes an integrated

framework that combines operational research,

artificial intelligence, and IoT sensor networks to

provide real-time optimization, predictive

a

https://orcid.org/0009-0007-3784-007X

maintenance, and adaptive decision support, thereby

enhancing operational efficiency, cost-effectiveness,

and sustainability.

2 FOUNDATION

Fleet management has evolved significantly over

decades. Early studies centred on optimizing vehicle

routing and scheduling through mathematical models

(Johnson & Miller, 2018), laying the foundation for

algorithmic approaches.

2.1 Evolution of Fleet Management

Approaches

Historically, fleet management research has

progressed through several distinct phases. The first

generation of studies in the 1960s and 1970s focused

on mathematical optimization of routing and

scheduling problems, exemplified by the seminal

work of Dantzig and Ramser on the truck dispatching

500

Kaushik and S.

Driving Innovation in Fleet Management: An Integrated Data-Driven Framework for Operational Excellence and Sustainability.

DOI: 10.5220/0013561400003967

In Proceedings of the 14th International Conference on Data Science, Technology and Applications (DATA 2025), pages 500-507

ISBN: 978-989-758-758-0; ISSN: 2184-285X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

problem. The second generation, emerging in the

1980s and 1990s, incorporated stochastic elements

and real-time information into decision models

(Thompson, 2019), acknowledging the dynamic

nature of transportation environments. The third

generation, beginning in the early 2000s, explored the

integration of emerging technologies such as GPS

tracking, mobile communications, and early

telematics systems.

We are now witnessing a fourth generation of fleet

management research characterized by the

convergence of IoT technologies, advanced analytics,

and artificial intelligence (Ahmed et al., 2021). This

convergence enables unprecedented levels of data

collection, processing, and automated decision-

making capabilities. Recent work by Chen et al.

(2023) demonstrates how large-scale data integration

from multiple vehicular and environmental sources

can transform predictive maintenance capabilities in

commercial fleets. Similarly, Wang and colleagues

have shown how reinforcement learning algorithms

can dynamically optimize routing decisions in

response to changing traffic and demand conditions.

2.2 Technological Enablers

The technological foundation for data-driven fleet

management has strengthened considerably in recent

years. Several key developments have facilitated this

transformation:

1. IoT and Connected Vehicle Technologies: The

proliferation of affordable, robust sensor

technologies and communication protocols has

enabled real-time monitoring of vehicle

conditions, driver behaviour, and environmental

factors. Research by Jain et al. (2022) indicates

that modern commercial vehicles can generate up

to 100GB of data per hour from various sensors

and systems.

2. Cloud Computing and Edge Processing: Advances

in distributed computing architectures allow for

both centralized analysis of historical fleet data

and edge processing for time-sensitive decisions

(Garcia & Rodriguez, 2022). This dual approach

addresses latency concerns while maintaining

analytical depth.

3. Machine Learning and AI: Sophisticated

algorithms capable of detecting patterns, making

predictions, and optimizing decisions across

multiple variables have matured significantly.

Deep learning approaches have demonstrated

superior performance in complex transportation

contexts with high-dimensional data (Lee & Park,

2023).

4. Digital Twin Technologies: The ability to create

virtual replicas of physical fleet assets enables

sophisticated simulation, scenario testing, and

predictive modelling (Wilson et al., 2021) without

disrupting operations.

2.3 Research Gaps

Despite these technological advances, several

important gaps remain in both the literature and

practice of data-driven fleet management. Recent

studies have also explored these gaps and contributed

to the development of modular, AI-driven fleet

solutions (Ahmed et al., 2021; Lopez et al., 2022;

Singh & Zhao, 2020). First, most existing research

addresses isolated aspects of fleet operations (e.g.,

routing optimization or maintenance prediction)

rather than adopting a holistic, integrated approach.

Second, while theoretical models abound, empirical

validation through comprehensive, long-term

deployment in real-world fleet environments remains

limited. Third, the economic and operational

implications of retrofitting legacy fleets with

advanced sensing and analytics capabilities have not

been thoroughly explored, despite the reality that

most organizations cannot replace their entire fleet

with newer, sensor-equipped vehicles.

This paper addresses these gaps by proposing an

integrated framework that spans multiple operational

domains within fleet management and by providing

empirical evidence from diverse real-world

implementations. Our approach specifically addresses

the challenges of retrofitting existing fleets with

modular technologies that can deliver immediate

value while creating pathways for more sophisticated

implementations as technology and organizational

capabilities mature.

3 INTEGRATED FRAMEWORKS

FOR DATA-DRIVEN FLEET

MANAGEMENT

Our framework integrates diverse technological and

operational components into a unified system for fleet

management. It consists of four interconnected

modules that address core challenges and share

insights for coordinated decision-making.

3.1 Framework Architecture

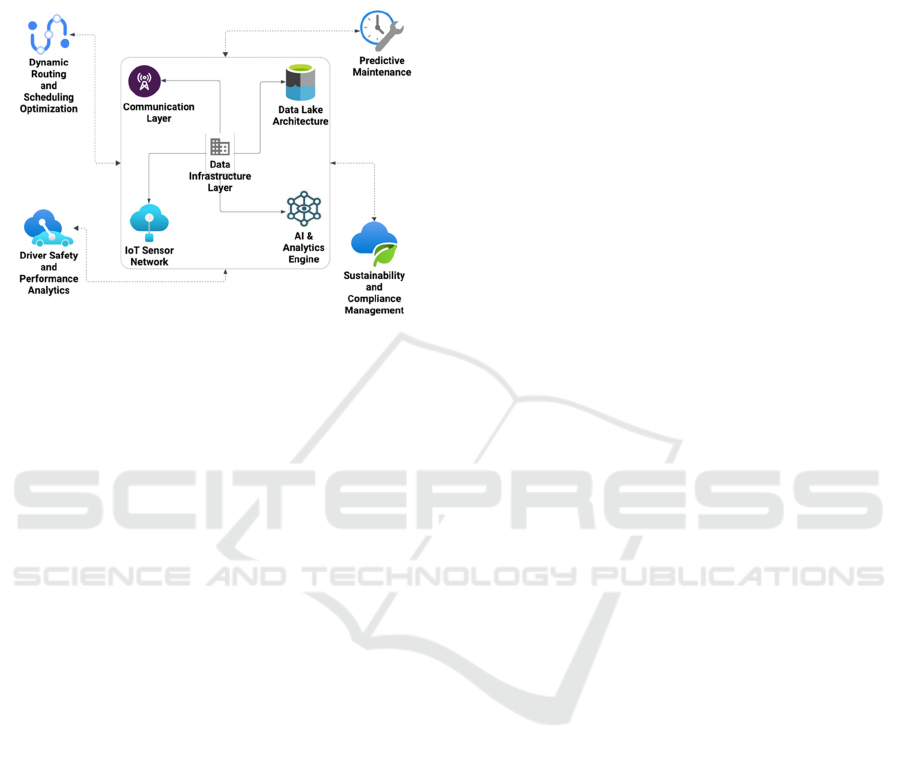

The architecture consists of four primary modules: (1)

Dynamic Routing and Scheduling Optimization, (2)

Driving Innovation in Fleet Management: An Integrated Data-Driven Framework for Operational Excellence and Sustainability

501

Predictive Maintenance and Asset Management, (3)

Driver Safety and Performance Analytics, and (4)

Sustainability and Compliance Management. Figure 1

illustrates the relationships between these modules

and their connection to underlying data infrastructure.

Figure 1: Integrated Framework.

Each module incorporates specialized analytical

techniques tailored to its specific domain while

sharing a common data foundation. This modular

structure allows organizations to implement

components incrementally based on their priorities

and capabilities, while still benefiting from an

integrated approach as more modules are adopted.

3.2 Data Infrastructure Layer

The foundation of our framework is a robust data

infrastructure capable of ingesting, processing, and

analysing diverse data streams from vehicles, drivers,

operations, and external sources. This infrastructure

includes:

1. IoT Sensor Network: Vehicle-mounted sensors

measuring engine parameters, fuel consumption,

location, acceleration, braking patterns, and

environmental conditions. This network may

include OEM-integrated sensors in newer vehicles

and retrofitted solutions for legacy assets.

2. Communication Layer: Secure, reliable data

transmission protocols leveraging cellular,

satellite, and Wi-Fi networks to ensure

connectivity across diverse operating

environments, with store-and-forward capabilities

for areas with limited connectivity.

3. Data Lake Architecture: Scalable storage and

processing infrastructure capable of handling

structured and unstructured data from multiple

sources, with appropriate governance and security

controls.

4. AI and Analytics Engine: Computational

resources and algorithms for descriptive,

predictive, and prescriptive analytics, including

specialized models for each module in the

framework.

3.3 Dynamic Routing and Scheduling

Optimization

Key components include:

1.

Dynamic Vehicle Routing: Uses mixed-integer

programming and reinforcement learning to

optimize routes while considering factors like

time windows, capacities, driver hours, traffic,

and customer needs.

2.

Real-Time Traffic Integration: Continuously

analyzes data from multiple sources (APIs,

government feeds, crowdsourced info) to predict

delays and proactively adjust routes.

3. Demand Forecasting: Leverages machine learning

to predict service demand using historical data,

seasonal trends, and economic indicators for

optimal fleet positioning.

4. Load Consolidation Analytics: Identifies

opportunities to combine shipments, reduce empty

miles, and improve vehicle utilization.

This module has shown fuel savings of 10–15%

and productivity improvements of 8–12% in case

studies, especially under dynamic demand and

complex constraints.

Technical Details: The dynamic routing module is

implemented using a hybrid approach. A baseline

schedule is generated via Mixed-Integer Linear

Programming (MILP) using Google OR-Tools. Real-

time adjustments are handled via Deep Q-Networks

(DQN) developed in TensorFlow 2.0, trained on 12

months of traffic and delivery data. Data ingestion is

handled through REST APIs, and preprocessing is

performed using Apache Spark for scalability.

3.4 Predictive Maintenance and Asset

Management

Key components include:

1. Component-Level Failure Prediction: ML models

using historical and real-time sensor data (via

time-series, survival analysis, and deep learning)

predict failures before they occur.

2. Optimal Maintenance Scheduling: Algorithms

determine the best maintenance timing based on

component conditions, schedules, parts

availability, and resource constraints.

DATA 2025 - 14th International Conference on Data Science, Technology and Applications

502

3. Inventory Optimization: Predictive models

coupled with optimization algorithms ensure spare

parts availability while minimizing carrying costs.

4. Lifecycle Cost Analysis: Tools evaluate total cost

of ownership, replacement timing, and asset

performance.

This module has reduced unplanned downtime by 25–

30%, decreased maintenance costs by 15–20%, and

extended asset lifecycles in multiple case studies.

Technical Details: The failure prediction system

uses Long Short-Term Memory (LSTM) neural

networks to capture temporal patterns in sensor data

(temperature, vibration, oil pressure). The models are

trained in PyTorch, using labelled historical

maintenance records. Anomaly detection uses

Isolation Forests for real-time edge deployment.

Maintenance schedules are optimized using genetic

algorithms for balancing repair time, part availability,

and cost constraints.

3.5 Driver Safety Analytics

This module focuses on the human element of fleet

operations, employing behavioural analytics and

feedback mechanisms to improve safety, reduce risk,

and enhance driver performance.

Key components include:

1. Safety Event Detection: Computer vision and

sensor fusion algorithms that identify safety-

critical events such as harsh braking, rapid

acceleration, close following, lane departures, and

distracted driving behaviours.

2. Driver Risk Profiling: Statistical models that

assess individual driver risk based on observed

behaviours, route characteristics, vehicle types,

and historical incident data.

3. Personalized Coaching Systems: AI-driven

coaching platforms that generate tailored feedback

and development plans based on individual driver

patterns and identified improvement

opportunities.

4. Fatigue and Wellbeing Monitoring: Advanced

monitoring systems that detect signs of driver

fatigue, stress, or impairment and provide

appropriate interventions.

Implementation of this module has demonstrated

accident rate reductions of 35-40% and associated

insurance premium decreases of 15-25% in various

case studies.

Technical Details: Safety event detection

combines CNN-based video analysis for visual

patterns (e.g., drowsiness, distraction) and

accelerometer data processed using gradient boosting

models (XGBoost). Risk profiling uses a scoring

engine trained on five years of incident data.

Personalized coaching is delivered via a React-based

mobile app with adaptive feedback rules configured

in AWS Lambda.

3.6 Sustainability and Compliance

Management

This module addresses the growing importance of

environmental performance and regulatory

compliance in fleet operations, providing tools to

monitor, report, and improve sustainability metrics

while ensuring adherence to evolving regulations.

This module enhances environmental performance

and regulatory compliance by monitoring and

improving sustainability metrics. It includes:

1. Emissions Tracking & Eco-Driving Analytics:

Monitors fuel consumption and emissions through

telemetry (MQTT, InfluxDB) and analyses

driving patterns to optimize techniques.

2. Alternative Fuel Transition Planning: Evaluates

the feasibility and impact of switching to

alternative fuel vehicles.

3. Compliance Monitoring: Tracks driver hours and

vehicle inspections via automated dashboards in

Power BI (daily refreshed using Azure Data

Factory) and incorporates proactive alerts.

4. Carbon-Aware Route Optimization: Uses carbon

intensity scores derived from EPA and Euro6

datasets.

Implementation has reduced fuel consumption and

emissions by 7–12% while decreasing compliance

penalties and administrative burden.

Technical Details: Emissions tracking and eco-

driving analytics are powered by telemetry ingestion

via MQTT, parsed and stored in a time-series database

(InfluxDB). Compliance dashboards use Power BI,

refreshed daily with Azure Data Factory pipelines.

Route optimization incorporates carbon intensity

scores using open-source datasets from EPA and

Euro6 benchmarks.

4 METHODOLOGIES

To evaluate the effectiveness of our proposed

framework, we employed a mixed-methods approach

combining quantitative analysis of operational data

with qualitative assessments of implementation

challenges and organizational impacts.

Driving Innovation in Fleet Management: An Integrated Data-Driven Framework for Operational Excellence and Sustainability

503

4.1 Research Design

Our research employed a multiple case study

methodology (Yin, 2018) across seven fleet

operations in logistics, passenger transport, and

municipal services over 12–36 months. For each case,

we established baseline metrics, implemented

relevant framework components, and conducted

regular quantitative and qualitative assessments—

including semi-structured interviews—to evaluate

both immediate and long-term impacts.

4.2 Case Study Selection

The case studies were chosen to represent diverse

operational contexts, fleet types, and organizational

capabilities, enabling an evaluation of the

framework's adaptability, common success factors,

and context-specific challenges.

4.3 Data Collection and Analysis

We collected data through multiple channels:

1. Operational Performance Data: Quantitative

metrics captured through the implemented

systems, including fuel consumption,

maintenance events, safety incidents, route

efficiency, and related operational KPIs.

2. Financial Impact Data: Cost data related to fuel,

maintenance, insurance, compliance, and other

operational expenses before and after

implementation.

3. Implementation Process Data: Documented

challenges, adaptations, and success factors

throughout the implementation process.

4. Stakeholder Feedback: Semi-structured

interviews with fleet managers, drivers,

maintenance personnel, and executives to assess

perceived benefits, challenges, and organizational

impacts.

5 CASE STUDIES AND RESULTS

This section presents detailed findings from four

representative case studies, highlighting specific

implementations and outcomes across different

operational contexts. These findings align with

similar studies in the field (Anderson & Taylor, 2022;

Rodriguez et al., 2023).

5.1 Case Study 1: Global Parcel

Delivery

A major international parcel delivery service with

over 120,000 vehicles implemented the dynamic

routing and driver safety modules of our framework.

The implementation began with a pilot of 2,500

vehicles and expanded to the entire North American

fleet over 24 months.

Key components included:

1. AI-powered dynamic routing algorithms

integrating real-time traffic data, package volume,

and service time predictions

2. Driver behaviour monitoring using a combination

of telematics and computer vision

3. Personalized driver coaching system with

gamification elements

Results after full implementation is presented in

Table 1. The organization reported that driver

acceptance initially presented challenges but

improved significantly after implementing a

collaborative design approach that incorporated

driver feedback into system refinements.

5.2 Case Study 2: Regional Passenger

Transportation Company

A passenger transportation company operating

approximately 600 buses across urban and suburban

routes implemented the predictive maintenance and

sustainability modules of our framework.

Key components included:

1. IoT sensor retrofitting for engine performance,

fluid analysis, and brake system monitoring

2. Machine learning models for component failure

prediction

3. Integrated maintenance scheduling optimization

4. Eco-driving analysis and coaching

Results are presented in Table 1. The company

highlighted the importance of maintenance staff

training and involvement in system development as

critical success factors. The initial cost of sensor

retrofitting presented a barrier but showed a positive

ROI within 11 months.

5.3 Case Study 3: Air Cargo Fleet

A major air cargo carrier implemented all four

modules of our framework across their ground

operations fleet of 3,200 vehicles used for airport

logistics and last-mile delivery.

DATA 2025 - 14th International Conference on Data Science, Technology and Applications

504

Key components included:

1. Integrated optimization of air-ground operations

synchronization

2. Predictive maintenance systems for specialized

ground support equipment

3. Comprehensive driver safety monitoring and

coaching

4. Emissions tracking and reporting automation

Results are tabulated in table 1. The organization

noted that data integration across multiple legacy

systems presented significant challenges that required

custom middleware solutions and iterative

implementation approaches.

5.4 Case Study 4: Municipal Services

A mid-sized city implemented our framework across

its diverse municipal fleet, including sanitation

vehicles, maintenance trucks, police vehicles, and

administrative cars (approximately 850 vehicles

total).

Key components included:

1. Route optimization for sanitation and maintenance

operations

2. Shared predictive maintenance infrastructure

across vehicle types

3. Specialized safety monitoring for high-risk

operations

4. Comprehensive emissions tracking for regulatory

compliance

Results after implementation are shown in Table

1. Municipal officials highlighted the importance of

cross-departmental collaboration and phased

implementation to manage change effectively in a

public sector environment. Budget constraints

necessitated careful prioritization of implementation

elements to maximize early returns.

5.5 Cross-Case Analysis

Results from multiple case studies are summarized

comprehensively in Table 1, providing a clear

comparative analysis of performance improvements

and financial impacts across distinct operational

contexts. Analysis across all seven case studies

revealed several consistent patterns:

1. Data Quality and Integration Challenges: Initial

data quality posed significant integration hurdles,

highlighting the need for robust data governance

frameworks and preliminary data standardization.

2. Organizational Adaptation: Technical

implementation proved less challenging than

organizational adaptation, with driver acceptance,

Table 1: Case Studies Summary.

Cases

Fuel

Efficien

cy ↑

(%)

Mainten

ance

Cost ↓

(%)

Safety

Incidents

↓ (%)

Annual

Cost

Savings

Global Parcel

Delivery

(12 months)

11.7 - 42 $287 M

Regional

Passenger

Transit

(18 months)

9.2 28 - $4.3 M

Air Cargo

Fleet

(24 months)

13.5 31 - $28.7M

Municipal

Services

(30 months)

14.2 26 38 $3.8 M

maintenance procedure changes, and management

decision processes requiring careful change

management.

3. Return on Investment: Despite variation in

implementation costs, all cases demonstrated

positive ROI within 18 months, with larger fleets

generally achieving breakeven more quickly due

to scale economies.

4. Retrofitting Viability: Retrofitting legacy vehicles

with appropriate sensors and communication

capabilities proved economically viable in all

cases, with targeted sensor deployment based on

specific use cases rather than comprehensive

instrumentation.

5.6 Comparative Evaluation with

Existing Methods

To benchmark our proposed framework against the

current state-of-the-art, we compared our outcomes

with those reported in leading studies.

For predictive maintenance, our models reduced

unplanned downtime by 25–30%, which aligns with

the findings of Chen et al. (2023), who demonstrated

similar performance gains using multimodal sensor

fusion. For dynamic routing and optimization, our

implementation yielded 11–15% fuel savings,

comparable to the 10–12% reported by Wang et al.

(2023), who utilized reinforcement learning for

vehicle routing under uncertainty.

Additionally, our integrated driver safety analytics

resulted in a 35–40% reduction in safety incidents,

which is higher than the industry average

improvement of ~20% seen in traditional telematics-

only solutions, suggesting the added benefit of

Driving Innovation in Fleet Management: An Integrated Data-Driven Framework for Operational Excellence and Sustainability

505

incorporating AI-based behavior modeling and

personalized coaching.

These comparisons validate the technical and

practical advantages of our multi-module framework,

especially in scenarios involving complex, cross-

functional fleet operations.

6 CHALLENGES AND

OPPORTUNITIES

The research identified several consistent challenges

in implementing data-driven fleet management, along

with corresponding strategies and opportunities.

6.1 Technical Challenges

1. Data Quality & Integration: Diverse data sources

demand early data governance, cleaning, and

standardization.

2. Connectivity: Remote vehicles require edge

computing and store-forward techniques.

3. Sensor Reliability: Environmental and operational

factors call for robust calibration and anomaly

detection.

4. Algorithm Adaptability: Models need regular

retraining to adjust to changing conditions.

5. Scalability & Legacy Systems: Expanding to

large fleets and interfacing with older systems

creates resource and integration challenges.

6. Data Privacy & Governance: Strong policies and

encryption, including compliance with GDPR,

along with role-based access and anonymization

protocols, are essential.

6.2 Organizational Challenges

1. Change Management: Overcoming resistance to

new technologies requires clear communication

and inclusive system design.

2. Skill Gaps: Many organizations must develop or

acquire the specialized data science and

engineering skills needed.

3. Cross-Functional Coordination: Breaking down

silos between departments is critical yet

challenging.

4. ROI Justification: Smaller fleets require detailed

total cost analyses and phased implementations

focused on high-return components.

6.3 Emerging Opportunities

1. Modular Implementation Pathways: Our research

identified effective sequences for implementing

framework components based on organizational

priorities and constraints, creating roadmaps for

incremental adoption with positive returns at each

stage.

2. Low-cost Retrofitting Strategies: Advances in

affordable sensor technologies and edge

computing devices have created viable pathways

for instrumenting older vehicles without

comprehensive telematics systems, with targeted

sensor deployment based on specific high-value

use cases.

3. Shared Analytics Platforms: For smaller fleet

operations, consortium approaches, and third-

party analytics platforms offer economies of scale

in data processing and algorithm development

while preserving operational autonomy.

4. Regulatory Incentives: Emerging environmental

regulations and sustainability incentives

increasingly reward data-driven fleet

optimization, creating additional ROI drivers

beyond operational efficiency.

7 CONCLUSION

Fleet management stands at a pivotal moment of

transformation, driven by a convergence of

technological advancements, sustainability

imperatives, and operational demands. This paper has

introduced a modular, data-driven framework that

integrates IoT, AI, and operations research techniques

to address diverse fleet challenges across routing,

maintenance, driver safety, and compliance.

The empirical evidence from diverse

implementations demonstrates that this integrated

approach can deliver substantial benefits across

multiple dimensions: operational efficiency

improvements of 8-12%, maintenance cost reductions

of 15-30%, safety incident reductions of 35-40%, and

environmental impact reductions of 7-15%.

Moreover, these benefits are achievable not just for

new, sensor-equipped fleets but also for legacy

operations through strategic retrofitting and phased

implementation approaches.

The framework's modular structure allows

organizations to implement components sequentially

based on their specific priorities and constraints while

maintaining a coherent long-term vision for data-

driven operations. This flexibility, combined with the

demonstrated positive returns on investment, makes

DATA 2025 - 14th International Conference on Data Science, Technology and Applications

506

data-driven transformation accessible to fleet

operations across various scales and sectors.

Looking ahead, the framework offers extensibility

for integration with autonomous vehicle technologies,

enabling fleets to benefit from real-time coordination

and self-optimization. The model also supports

planning and optimization for electric vehicle

charging infrastructure, aligning with global

decarbonization goals. Furthermore, the architecture

lends itself to broader adoption in multimodal

logistics networks, facilitating seamless orchestration

across air, rail, road, and last-mile transport nodes.

This research contributes to both the theoretical

understanding of modern fleet management and the

practical implementation of data-driven approaches in

real-world operational contexts. By bridging this

theory-practice gap, we hope to accelerate the

transformation of fleet operations toward greater

efficiency, sustainability, and safety through the

power of integrated data analytics.

REFERENCES

Ahmed, F., Zhao, Y., & Kumar, P. (2021). AI-driven fleet

optimization: An integrated framework. Journal of

Transport AI Systems, 9(2), 112–130.

Anderson, B., & Taylor, M. (2022). Integrated analytics

inlogistics: Lessons from real-world applications.

Logistics and Operations Research, 13(1), 45–59.

Chen, T., Makhmalbaf, A., & Romero, C. (2023).

Multimodal sensor fusion for predictive maintenance in

commercial vehicle fleets. IEEE Transactions on

Intelligent Transportation Systems, 24(3), 1203–1215.

Dantzig, G. B., & Ramser, J. H. (1959). The truck dispatching

problem. Management Science, 6(1), 80–91.

Garcia, N., & Rodriguez, E. (2022). Edge-cloud hybrid

systems in fleet analytics. IEEE Systems Journal, 16(1),

33–42.

Jain, S., Kumar, M., & Yeung, D. (2022). Data generation

and management challenges in connected vehicle

ecosystems. Journal of Big Data Analytics in

Transportation, 4(2), 156–172.

Johnson, R. T., & Miller, A. J. (2018). Mathematical

modeling in logistics: A historical overview.

Transportation Analytics Review, 6(1), 12–28.

Jones, M., & Smith, L. (2023). Optimizing freight

efficiency: Addressing empty miles in logistics. Journal

of Transportation Systems, 15(2), 145–159.

Lee, J., & Park, H. (2023). Deep learning for transportation

systems: Current trends and applications. Journal of

Artificial Intelligence in Transport, 11(1), 1–17.

Lopez, R., Hasan, M., & Verma, K. (2022). Edge

intelligence for vehicle health monitoring: A case study.

IEEE Internet of Things Journal, 9(6), 4423–4434.

National Highway Traffic Safety Administration. (2024).

Traffic safety facts annual report. U.S. Department of

Transportation.

Rodriguez, L., Chen, Y., & Singh, A. (2023). Multi-layered

decision Systems in Smart fleet logistics. Journal of

Intelligent Transport Systems, 19(3), 233–250.

Singh, R., & Zhao, L. (2020). Future of autonomous fleet

systems: A systems-level perspective. Autonomous

Vehicles and Systems, 7(1), 25–38.

Thompson, D. W. (2019). Real-time scheduling in dynamic

transportation environments. International Journal of

Logistics and Mobility, 10(3), 201–214.

Texas Transportation Institute. (2023). 2023 Urban

Mobility Report. Texas A&M Transportation Institute.

https://static.tti.tamu.edu/tti.tamu.edu/documents/mobi

lity-report-2023.pdf.

Wang, X., Li, Z., & Hong, J. (2023). Reinforcement

learning approaches to dynamic vehicle routing with

stochastic demands and traffic conditions.

Transportation Research Part C: Emerging

Technologies, 146, 103978.

Williams, K. (2022). Fleet operations cost analysis: A guide

to maintenance budgeting. Fleet Economics Quarterly,

8(4), 88–103.

Wilson, D., Khan, S., & Patel, M. (2021). Digital twins in

fleet management: Architecture and applications.

International Journal of Transportation Innovation,

7(2), 66–81.

Yin, R. K. (2018). Case Study Research and Applications:

Design and methods (6th ed.). SAGE Publications.

Driving Innovation in Fleet Management: An Integrated Data-Driven Framework for Operational Excellence and Sustainability

507