Smart Separator: Optimizing Conveyor Belt, Vibration Feed, and Drum

Speeds of Barrier Eddy Current Separator

Shohreh Kia

a

and Benjamin Leiding

b

Institute for Software and System Engineering, Technische Universit

¨

at Clausthal, Arnold-Sommerfeld-Straße 1,

Clausthal-Zellerfeld, Germany

Keywords:

Data Processing, Machine Learning, Industrial Optimization, Data Analysis, Energy Consumption Reduction,

Sustainable Recycling Practices, Barrier Eddy Current Separator.

Abstract:

Efficient separation of metals and plastics in recycling is crucial for improving material purity and reducing

costs. This paper optimizes the performance of a Barrier Eddy Current Separator (BECS) for sorting alu-

minium, copper, plastic, and brass. The BECS consists of a conveyor belt, vibration feeder, and magnetic

drum. Current methods rely on operator experience for speed and angle settings, often leading to suboptimal

performance. This research applies a data-driven approach to determine optimal operational parameters. The

study examines how varying conveyor belt speed (6.80 Hz to 87.70 Hz), vibration feeder amplitude (low,

medium, high), and magnetic drum angle (20°, 30°, 40°) affect separation accuracy and energy consumption.

Eighty-two experiments measured separation errors and energy use, with machine learning models identifying

optimal settings. Experimental validation showed significant error reduction, achieving the lowest separa-

tion errors and energy consumption. Minimizing errors also eliminated rework, improving efficiency. Unlike

conventional trial-and-error methods, this systematic approach enhances BECS calibration, demonstrating its

effectiveness in improving recycling separation accuracy and energy efficiency.

1 INTRODUCTION

The increasing demand for sustainable recycling solu-

tions has significantly emphasized improving the effi-

ciency and accuracy of material separation processes

in the recycling industry. Barrier eddy current separa-

tors (BECS) are widely used to separate non-ferrous

metals like aluminium, copper, and brass from other

materials like plastic. However, achieving optimal

separation quality remains a challenge due to the dy-

namic interaction between the three primary compo-

nents of the separator: the conveyor belt, vibration

feeder, and magnetic drum. Each component operates

at variable speeds, directly impacting the separation

process (Rem et al., 1997). As they have been shown

in Figure. 1

The conveyor belt transports materials to the mag-

netic drum, while the vibration feeder regulates the

flow and distribution of materials on the conveyor.

The magnetic drum generates high-intensity mag-

netic fields to separate non-ferrous metals from non-

magnetic materials. Finding the optimal speed config-

a

https://orcid.org/0009-0001-4046-5289

b

https://orcid.org/0000-0002-9191-7548

Figure 1: [1]Magnetic drum, [2]Vibration feed, [3]Con-

veyor belt.

uration for these components is critical to minimizing

separation errors and ensuring the purity of recovered

materials. Furthermore, operational efficiency must

balance energy consumption and machine durability.

Excessive speeds may increase energy costs and wear

on mechanical components, while insufficient speeds

can lead to poor material separation and the need for

reprocessing. Traditional manual adjustments to com-

ponent speeds often lead to suboptimal performance,

304

Kia, S., Leiding and B.

Smart Separator: Optimizing Conveyor Belt, Vibration Feed, and Drum Speeds of Barrier Eddy Current Separator.

DOI: 10.5220/0013558500003964

In Proceedings of the 20th International Conference on Software Technologies (ICSOFT 2025), pages 304-318

ISBN: 978-989-758-757-3; ISSN: 2184-2833

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

making the process time-consuming and error-prone.

This study optimizes the BECS system parameters

to maximize material throughput while maintaining

a sorting accuracy of 90%. The goal is to ensure ef-

ficient separation with minimal energy consumption.

Experimental data, including separation error rates

and energy consumption, were collected for various

conveyor belts and vibration feeder speed combina-

tions to achieve this. In contrast, the magnetic drum

speed on the control panel was fixed at level 6, corre-

sponding to 67.40 Hz as displayed on the PLC moni-

tor, to ensure consistent operation and maintain safety

across all experiments. A machine learning model

analyses the data and identifies the optimal speed con-

figuration that minimizes separation errors and energy

consumption. By integrating advanced data analy-

sis and optimization techniques, this study provides a

framework for enhancing the quality of recycled ma-

terials while reducing operational costs and environ-

mental impact (Wang et al., 2020; Nagel et al., 2020;

Smith et al., 2019; Rem et al., 1997).

Note: All speed values are reported in Hertz (Hz),

as used by the machine’s frequency converters and

PLC interface. The drives operate within a 0–50 Hz

range (equivalent to 0–100% capacity). Conversion

to meters per second (m/s) was not possible due to a

lack of access to mechanical specifications. For the

magnetic drum, Hz refers to revolutions per second.

Each test separated fine particles (1–4 mm) of alu-

minium, copper, brass, and plastic. After separation,

the misclassified materials were weighed to quantify

the error for each category. Due to space constraints,

only a selection of representative charts is shown be-

low. These were chosen based on their closeness to

machine-learning model predictions to support later

evaluation. The full dataset, including all 81 scenar-

ios and visual outputs, is publicly available on our

GitHub repository.

1.1 Background

The BECS process is one of the most important in-

dustrial techniques for recycling non-ferrous metals

from industrial and electronic waste. This method is

based on the induction of eddy currents in non-ferrous

metals, which generate Lorentz forces that separate

them from other materials when exposed to the rotat-

ing magnetic drum (Roy et al., 2010). Aluminium,

copper, and brass are among the most commonly re-

cycled metals.

They are widely used in various industries, from

electronics manufacturing to industrial packaging.

With technological advancements and the increas-

ing demand for high-quality recycling and energy-

efficient processes, various research efforts have been

made to improve BECS performance (Ahmed Nour

El Islam and Youcef, 2016). Most of these studies

have either focused on optimizing the physical design

of the magnetic drum or using numerical modelling to

analyze magnetic forces. However, simultaneous op-

timization of the operating speeds of different BECS

components to enhance separation efficiency and re-

duce energy consumption has received less attention.

1.2 Problem

Achieving optimal and precise separation of non-

ferrous metals has always been a significant challenge

in the recycling industry. Improper speed adjustments

of the conveyor belt, vibration feeder, and magnetic

drum can lead to reduced separation efficiency, caus-

ing misclassification of materials and the need for re-

processing, which increases operational costs. Fur-

thermore, a lack of precise control over component

speeds can result in excessive energy consumption

and higher electricity costs for recycling facilities.

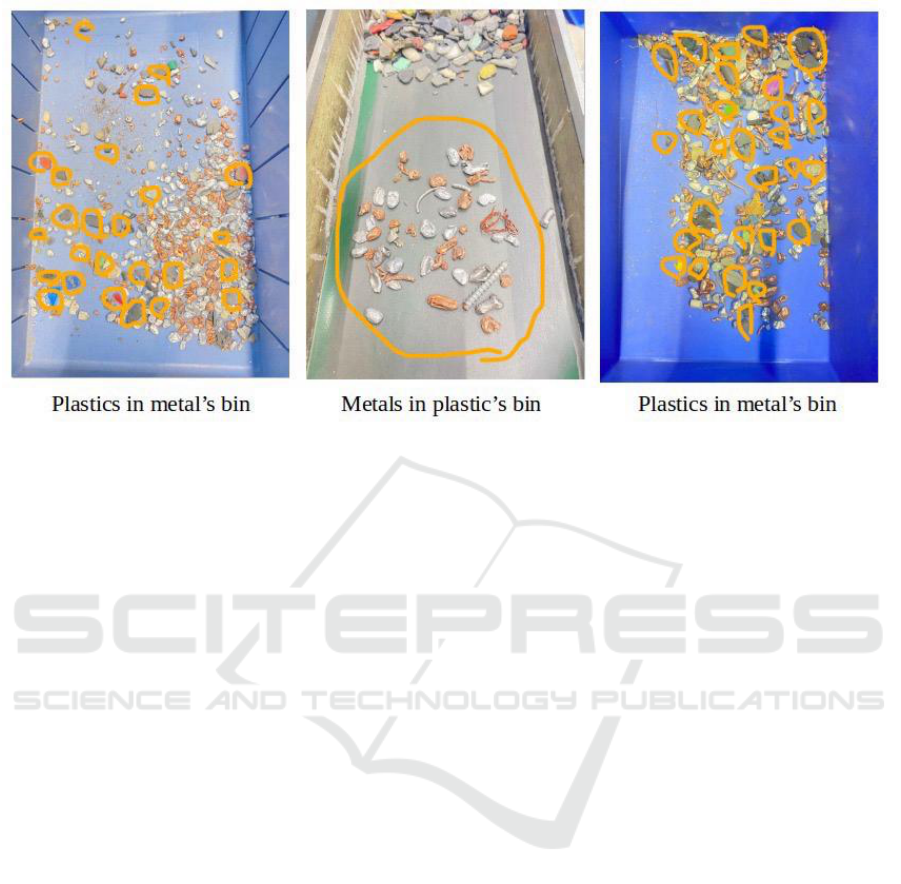

Figure. 2 shows separation challenges in a BECS sys-

tem, where incorrect material sorting has occurred

during the recycling process.

The major challenge is the absence of a data-

driven model to determine the optimal speed con-

figuration for BECS components. In many exist-

ing systems, speed adjustments are performed man-

ually based on operator experience, which is time-

consuming, prone to errors, and inefficient. Addi-

tionally, most previous studies have relied primarily

on numerical simulations, with limited experimental

validation under industrial conditions. Therefore, an

approach to simultaneously optimizing the operating

speeds of BECS components using real-world data

and machine learning methods is essential. Such an

approach can enhance material purity, reduce separa-

tion errors, lower energy consumption, and improve

system safety, making BECS more reliable and effi-

cient for industrial applications.

1.3 Existing Body of Knowledge and

State of the Art

Various studies have been conducted on eddy cur-

rent separators (ECS) to recover non-ferrous metals.

Some studies (Yi et al., 2022; Bin et al., 2022) have

focused on the effect of a single variable, such as

temperature and particle size, on separation perfor-

mance. Article (Yi et al., 2022) utilized liquid nitro-

gen to lower the material temperature, increasing its

electrical conductivity and generating a more potent

Lorentz force. In contrast, Article (Bin et al., 2022)

Smart Separator: Optimizing Conveyor Belt, Vibration Feed, and Drum Speeds of Barrier Eddy Current Separator

305

Figure 2: Errors collections.

investigated the effect of particle size on ECS perfor-

mance, showing that reducing particle size increases

particle rotation and alters the Lorentz force, making

separation more challenging. Other studies (Smith

et al., 2019; Shan et al., 2024b) have focused on op-

timizing the physical design of ECS devices, partic-

ularly the magnetic drum and magnetic pole arrange-

ments. Article (Smith et al., 2019) demonstrated that

increasing the drum speed or modifying the magnetic

pole configuration can enhance the Lorentz force and

improve separation efficiency. Article (Shan et al.,

2024b)optimized the magnetic drum design, showing

that a Halbach array configuration can increase mag-

netic field density by up to 75%. Several other studies

(Bin et al., 2021; Huang et al., 2021) have utilized

numerical simulations to predict ECS performance.

They used numerical modelling to simulate particle

trajectories in ECS separation, while Article (Li et al.,

2018) li2018preliminary analyzed magnetic flux den-

sity and its impact on separation efficiency. Some

studies (Shan et al., 2024a; Shan et al., 2025) have

examined particle interactions and their influence on

ECS performance. Article (Shan et al., 2024a) found

that eddy current induction between particles can al-

ter their movement trajectories, reducing separation

efficiency. Article (Shan et al., 2025) explored the

feasibility of vertical eddy current separation (VECS)

and identified slight differences in electrical conduc-

tivity among metals, such as Ag/Cu and Pt/Pb, which

make their separation challenging. Increasing the

drum speed and magnet thickness was proposed to ad-

dress this issue. Other studies (Ye et al., 2020; Huang

et al., 2024) have focused on ECS applications for re-

cycling specific waste materials, such as printed cir-

cuit boards (PCBs) and aluminum-contaminated plas-

tics. Article (Ye et al., 2020) showed that optimizing

magnetic drum design can enhance metal separation

from PCBs, but challenges such as particle interac-

tions and magnetic flux density effects remain. Ar-

ticle (Huang et al., 2024) used finite element anal-

ysis (FEA) to investigate magnetic field distribution

and Lorentz forces to address aluminium contami-

nants in HDPE plastics. Finally, Articles (Ruan and

Xu, 2012; Bai et al., 2023) focus on mathematical

modelling and experimental testing to optimize BECS

performance. Article (Ruan and Xu, 2012) developed

a mathematical model to predict eddy current forces

and showed that particle size and AC frequency sig-

nificantly impact separation efficiency. Article (Bai

et al., 2023), which focused on metal separation from

lithium-ion batteries, proposed a novel combination

of ball milling and BECS to achieve more energy-

efficient metal recovery.

1.4 Gap Detection

A review of prior studies on ECS for non-ferrous

metal recovery highlights several overlooked aspects.

Most research has examined isolated variables, such

as temperature, particle size, or magnetic drum speed,

without considering their combined effects. However,

in industrial settings, separation efficiency depends

on multiple interrelated factors, including conveyor

belt speed, vibration feeder speed, and magnetic drum

speed. Optimizing a single parameter without ac-

counting for system interactions often results in lim-

ICSOFT 2025 - 20th International Conference on Software Technologies

306

ited and unstable improvements.

Many studies (Ruan and Xu, 2012; Bai et al.,

2023) rely heavily on numerical simulations with-

out industrial experimental validation, reducing real-

world applicability. While simulations provide valu-

able insights, industrial data is essential for practi-

cal optimization, as real-world conditions often differ

from theoretical models. Additionally, most research

(Ruan and Xu, 2012; Bai et al., 2023) prioritizes sepa-

ration performance over energy efficiency, neglecting

the impact of parameter adjustments on power con-

sumption. Increasing component speeds without con-

sidering energy usage can lead to higher costs and re-

duced system performance.

Some studies (Smith et al., 2019; Shan et al.,

2024b) propose physical modifications to the mag-

netic drum or field distribution but overlook safety

concerns. Strong high-speed magnetic fields can gen-

erate excessive heat, shorten equipment lifespan, and

pose fire hazards if ferrous particles become trapped.

Despite its critical role, safety remains underexplored

in prior research. Furthermore, solutions like new

drum shell designs (Huang et al., 2024) enhance

separation efficiency but lack adaptability, requiring

costly modifications when material composition or

size changes. This study introduces a data-driven

approach to BECS optimization, evaluating key op-

erational parameters—conveyor belt speed, vibration

feeder speed, and magnetic drum speed—using ma-

chine learning to identify optimal configurations that

minimize separation errors and maximize purity. Un-

like previous studies that rely predominantly on sim-

ulations, this research incorporates real-world indus-

trial data, ensuring practical applicability. Analyzing

energy consumption at different speed settings opti-

mizes separation efficiency and power usage, reduc-

ing operational costs. Magnetic drum speed is fixed

at level 6 on the control panel, to enhance safety, pre-

vent overheating, and mitigate fire hazards, ensuring

stable and efficient separation while minimizing mis-

classification errors.

1.5 Research Questions

RQ: How can the optimal combination of component

speeds in a BECS and the magnetic drum angle be

determined using experimental data analysis and sta-

tistical modelling to minimize separation errors while

optimizing energy consumption?

RQ1: What are the key factors to consider when

developing a comprehensive and standardized dataset

for optimizing the BECS process, considering com-

ponent speeds, magnetic drum angle, and energy con-

sumption?

RQ2: What technologies and approaches can be

applied to analyze experimental data and optimize the

operational settings of the BECS to enhance separa-

tion accuracy and reduce energy consumption?

2 SUPPLEMENTARY

LITERATURE AND RELATED

WORK

Many previous studies have focused on optimizing

the performance of ECS. In some of these studies

(Yi et al., 2022; Bin et al., 2022), the investigation

was limited to the effect of a single variable, such

as temperature or particle size, on the separation per-

formance. However, in real-world industrial applica-

tions, multiple operational parameters, including con-

veyor belt speed, vibration feeder speed, and mag-

netic drum speed, play a crucial role in determining

separation efficiency.

The present study addresses this limitation by

analyzing the combined influence of multiple vari-

ables on separation efficiency and energy consump-

tion rather than focusing on a single factor. More-

over, in Article (Yi et al., 2022), liquid nitrogen was

used to lower the material temperature to improve

separation efficiency. However, this method is im-

practical in large-scale industrial applications due to

its high operational cost and process complexity. In

contrast, the present study achieves separation opti-

mization without needing expensive technologies, re-

lying solely on the intelligent adjustment of compo-

nent speeds to enhance system performance. Several

studies (Smith et al., 2019; Shan et al., 2024b) primar-

ily focused on the physical optimization of the mag-

netic drum design. These works demonstrated that in-

creasing drum speed or altering magnetic pole config-

urations could enhance Lorentz’s force and improve

separation efficiency. However, such approaches have

significant challenges, including high costs, increased

maintenance requirements, and potential safety haz-

ards. The present study proposes a software-based op-

timization approach rather than implementing expen-

sive hardware modifications. This eliminates the need

for costly physical redesigns of the magnetic drum or

stronger magnets, which require continuous monitor-

ing. Additionally, by keeping the drum speed within

a safe range (60 - 70 Hz), the risks associated with

overheating, which were overlooked in previous stud-

ies, have been effectively mitigated. Most previous

research (Bin et al., 2021; Huang et al., 2021; Shan

et al., 2024a; Shan et al., 2025) relied on numeri-

cal simulations to predict ECS performance. While

Smart Separator: Optimizing Conveyor Belt, Vibration Feed, and Drum Speeds of Barrier Eddy Current Separator

307

3D simulations can provide valuable insights, their

accuracy in industrial settings is often compromised

due to variations in real-world material properties and

environmental factors. These studies used simulated

numerical data instead of actual experimental results,

which may lack the reliability for real-world imple-

mentation. The present study overcomes this limi-

tation by conducting all experiments in a real indus-

trial environment, where operational data were col-

lected and analyzed. This approach enhances the re-

liability of the results compared to purely simulated

models, ensuring the proposed optimization strate-

gies can be directly applied in industrial settings. An-

other major limitation of previous studies (Bin et al.,

2021; Huang et al., 2021) and (Ye et al., 2020) is

their failure to account for energy consumption in

ECS operations. These works focused on enhanc-

ing separation efficiency without considering that spe-

cific optimizations—such as increasing drum speed

or magnetic field intensity—can significantly esca-

late energy consumption. The present study addresses

this issue by accurately measuring energy consump-

tion across various speed configurations. As a result,

both separation efficiency and energy consumption

have been optimized, leading to a reduction in opera-

tional costs. While Article (Bin et al., 2021) claimed

that a redesigned magnetic drum could reduce en-

ergy consumption, no documented experimental data

were provided to support this claim. In contrast, the

present study leverages real-world data to quantify en-

ergy usage and integrates it as a key variable in the

regression-based optimization model. Furthermore,

none of the reviewed studies (Yi et al., 2022; Bin

et al., 2022; Smith et al., 2019; Shan et al., 2024b; Bin

et al., 2021; Huang et al., 2021; Shan et al., 2024a;

Shan et al., 2025; Ye et al., 2020; Huang et al., 2024;

Ruan and Xu, 2012; Bai et al., 2023) considered the

safety implications of ECS operation. Hazards such

as drum overheating, fire risks due to unintended iron

particle presence, and the need for constant operator

supervision at high speeds were ignored entirely. Ad-

ditionally, all these studies focused on ECS technol-

ogy, which does not apply to BECS due to differences

in drum angles and their impact on the separation pro-

cess. The present study meticulously addresses these

critical aspects. Additionally, the impact of various

operational parameters was systematically analyzed

to ensure long-term machine stability and reduced

operator intervention requirements. Some previous

studies (Shan et al., 2024a) explored new casing de-

signs for the magnetic drum, which were customized

for a specific particle size range (e.g., 3–5 mm). How-

ever, this approach lacks adaptability since a com-

pletely new casing design would be required if the in-

put material size varies, adding significant costs and

complexity. Reviewing related works shows that most

prior research either focused on isolated variables, re-

lied solely on numerical simulations, or failed to con-

sider energy efficiency and safety concerns. None of

these studies addressed ECS adaptability for differ-

ent material types and sizes in a practical industrial

setting. In contrast, the present study provides a com-

prehensive optimization framework based on accurate

experimental data. It simultaneously analyzes the im-

pact of multiple operational parameters while ensur-

ing energy efficiency and machine safety. By stabi-

lizing drum speed, fire hazards and overheating risks

are minimized, making the system more reliable for

industrial applications.

Rather than introducing costly physical modifica-

tions, the present study utilizes a software-driven ap-

proach to adjust component speeds dynamically. This

allows for greater adaptability across various material

types without expensive hardware alterations. This

methodology enhances flexibility, reduces operational

costs to almost zero, and improves overall system ef-

ficiency, making it a practical and scalable solution.

3 CONSTRUCTING A RELIABLE

DATASET FOR MACHINE

LEARNING-BASED BECS

OPTIMIZATION

The Barrier Eddy Current Separator (BECS) sys-

tem is designed to recover non-ferrous metals such

as aluminium, copper, and brass from mixed waste

streams (Gomathi and Sridevi, 2015). Due to the sys-

tem’s complex physical dynamics and sensitivity to

mechanical settings, achieving high separation qual-

ity requires precise tuning of operational parameters.

This project optimizes separation efficiency and en-

ergy usage by experimentally analyzing the effects of

conveyor belt speed, vibration feeder speed, and mag-

netic drum angle. A comprehensive dataset was de-

veloped through 81 experimental scenarios, system-

atically varying key operational parameters to support

this. The magnetic drum speed was fixed at 67.40 Hz

in all tests to maintain system stability and safety. The

conveyor belt speed ranged from 6.80 Hz to 87.70 Hz,

while the drum angle was set at 20°, 30°, and 40°. The

vibration feeder was tested at low, medium, and high

levels to assess its effect on material distribution and

separation outcomes.

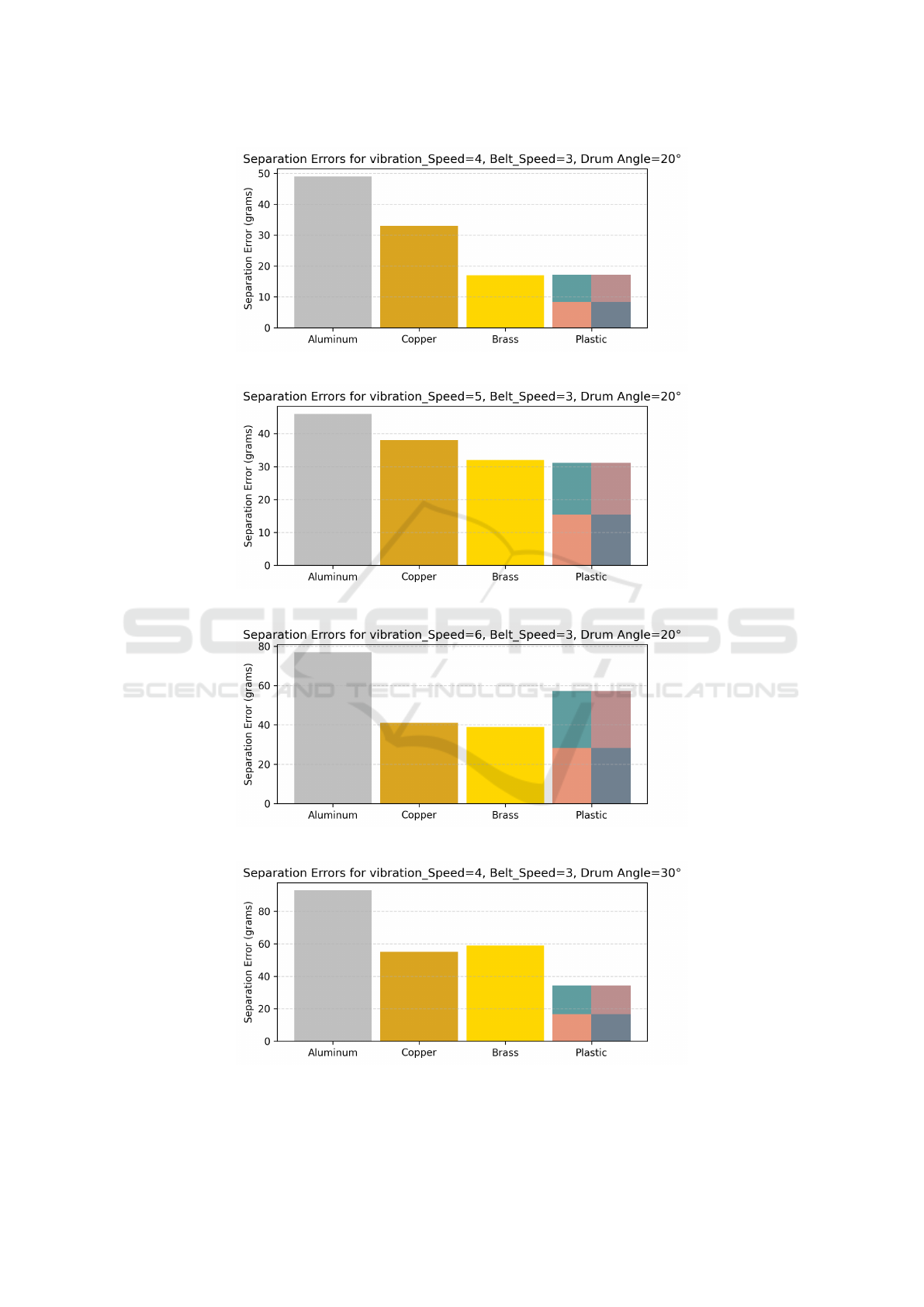

Figure. 3 to Figure. 11 illustrate these scenar-

ios, showcasing representative vibration combina-

tions, belt speed, and drum angle combinations. The

ICSOFT 2025 - 20th International Conference on Software Technologies

308

complete dataset and the remaining experimental vi-

sualizations from all 81 test scenarios are available in

the project’s GitHub repository.

Each chart illustrates the separation errors (in

grams) for the four target material classes. For vi-

sualization clarity, plastic errors are visualized using

segmented stacked colors representing mixed mate-

rial residues.

After each experiment, separation errors were

quantified by measuring the weight of incorrectly

classified materials within each category.

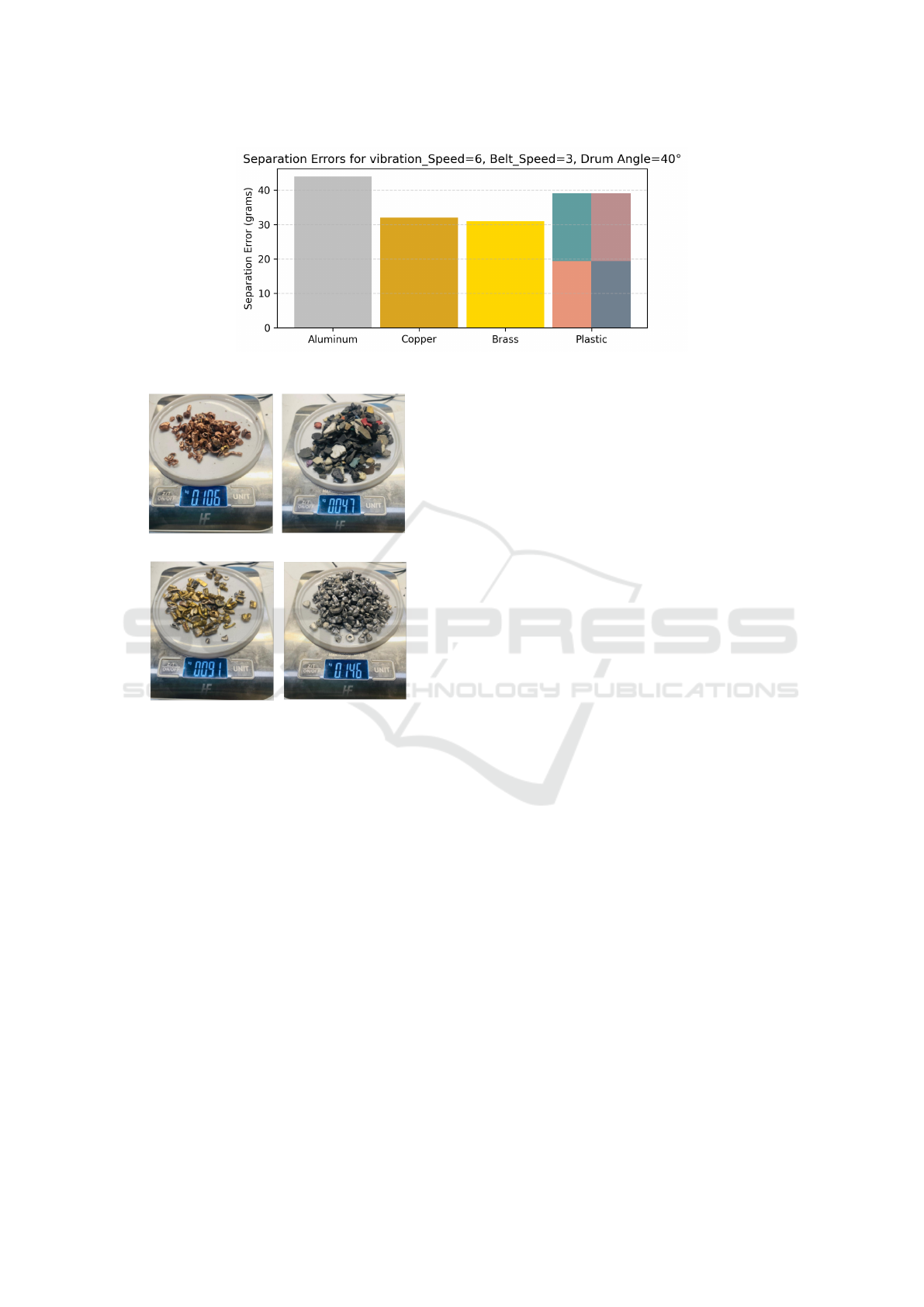

Figure. 12 shows the weight measurement of col-

lected errors in wrong bins.

The errors recorded included:

• The amount of copper misclassified into the plas-

tic fraction.

• The amount of plastic misclassified into the metal

fraction.

• The amount of brass misclassified into the plastic

fraction.

• The amount of aluminum misclassified into the

plastic fraction.

Additionally, the device’s electrical energy con-

sumption was measured in each scenario using an En-

ergy Logger (Sen, 2021; Nunn, 2013; Hirst et al.,

2013) to assess the impact of different speed settings

on power usage. Measurements were taken system-

atically across varying belt speeds, drum speeds, and

vibration levels to capture the complete energy profile

under different operational conditions. All collected

data—including detailed records of separation errors,

power consumption, and their corresponding speed

settings—was carefully documented for each tested

configuration. This ensured a structured dataset that

allowed for precise analysis. The dataset underwent

comprehensive analysis following the experimental

phase to examine the interdependencies between op-

erational parameters and energy efficiency. The goal

was to identify optimal speed and drum angle com-

binations that minimize separation errors while opti-

mizing power consumption, ultimately enhancing the

system’s overall efficiency.

4 MACHINE LEARNING-BASED

OPTIMIZATION OF BARRIER

EDDY CURRENT SEPARATION

Our approach focused on analyzing experimental data

and optimizing the BECS operational settings using

machine learning techniques to address the second re-

search question. These settings include conveyor belt

speed, drum speed, vibration speed, and drum angle,

all of which directly impact the accuracy of material

separation. To achieve this, a Multi-Output Regres-

sion machine learning model was implemented to pre-

dict the optimal operational settings, enhancing sep-

aration accuracy while minimizing operational costs.

This chapter outlines the dataset and data Preparation,

model implementation, and optimization process. It

explains how the model processed and analyzed the

collected data and how the results improved separa-

tion accuracy and reduced energy consumption.

4.1 Dataset and Data Preparation

The dataset used in this study was collected from a

real-world industrial BECS system containing opera-

tional parameters and material separation error rates.

The data is categorized into two main groups:

Input Features (X):

• Vibration Speed(low, medium, high)

• Magnetic Drum Speed (Hz)

• Conveyor Belt Speed (Hz)

• Separation Error for – aluminum, copper, brass,

and plastic (grams)

• Drum Angle (degrees)

Output Variables (y):

• Optimized Vibration Speed

• Optimized Magnetic Drum Speed

• Optimized Conveyor Belt Speed

• Optimized Drum Angle

During preprocessing, missing values were identified

and handled. To enhance the model’s accuracy, Min-

MaxScaler normalized the input features, ensuring

all variables were scaled within a standardized range.

The dataset was split into 80% training data and 20%

test data for model evaluation.

4.2 Model Development and Machine

Learning Implementation

A Multi-Output Regression model (Peng et al., 2023)

was implemented using the Scikit-learn library (Gar-

reta and Moncecchi, 2013) to predict the optimal

Smart Separator: Optimizing Conveyor Belt, Vibration Feed, and Drum Speeds of Barrier Eddy Current Separator

309

Figure 3: Vibration=4, Belt=3, Drum Angle=20°.

Figure 4: Vibration=5, Belt=3, Drum Angle=20°.

Figure 5: Vibration=6, Belt=3, Drum Angle=20°.

Figure 6: Vibration=4, Belt=3, Drum Angle=30°.

ICSOFT 2025 - 20th International Conference on Software Technologies

310

Figure 7: Vibration=5, Belt=3, Drum Angle=30°.

Figure 8: Vibration=6, Belt=3, Drum Angle=30°.

Figure 9: Vibration=4, Belt=3, Drum Angle=40°.

Figure 10: Vibration=5, Belt=3, Drum Angle=40°.

Smart Separator: Optimizing Conveyor Belt, Vibration Feed, and Drum Speeds of Barrier Eddy Current Separator

311

Figure 11: Vibration=6, Belt=3, Drum Angle=40°.

Figure 12: Errors weight measurement.

BECS settings. This approach allows for the simul-

taneous prediction of multiple target variables, mak-

ing it well-suited for optimizing interdependent pa-

rameters. The Random Forest Regressor (Rodriguez-

Galiano et al., 2015) was selected as the base model

due to its ability to capture complex nonlinear rela-

tionships between input and output variables. This

model leverages multiple decision trees to enhance

predictive accuracy compared to simpler regression

models. Multi-Output Regression with Random For-

est Regressor:

y

j

= f

j

(X) + ε

j

, j = 1, 2, ..., m (1)

where:

• X = (x

1

, x

2

, ..., x

n

) is the vector of input features,

consisting of:

– x

1

: Vibration Speed (low, medium, high)

– x

2

: Magnetic Drum Speed (Hz)

– x

3

: Conveyor Belt Speed (Hz)

– x

4

: Separation Error for Aluminum in Plastics

(grams)

– x

5

: Separation Error for Copper in Plastics

(grams)

– x

6

: Separation Error for Brass in Plastics

(grams)

– x

7

: Separation Error for Plastics in Metals

(grams)

– x

8

: Drum Angle (degrees)

• y

j

represents the predicted optimized operational

settings, including:

– y

1

: Optimized Vibration Speed (low, medium,

high)

– y

2

: Optimized Magnetic Drum Speed (Hz)

– y

3

: Optimized Conveyor Belt Speed (Hz)

– y

4

: Optimized Drum Angle (degrees)

• f

j

(X) is a nonlinear function approximated by the

Random Forest model, trained to find the optimal

settings for the BECS system.

• ε

j

represents the model error, accounting for the

discrepancy between the predicted and actual op-

timal operational settings.

After selecting the model, it was trained using the

prepared dataset, learning the relationships between

operational settings and separation accuracy. Once

trained, the model was tested on unseen data to eval-

uate its predictive performance. The model’s primary

function is to take initial operational values and out-

put the most effective configuration for maximizing

separation efficiency.

5 EVALUATION AND

DISCUSSION

The MultiOutputRegressor was selected as the ma-

chine learning framework due to its capacity to si-

multaneously predict multiple output parameters crit-

ical to optimising the BECS system. These param-

eters—vibration speed, drum speed, conveyor belt

ICSOFT 2025 - 20th International Conference on Software Technologies

312

Figure 13: Separation errors using model-predicted parameters.

speed, drum angle, and energy usage—are interde-

pendent, and a change in one often affects the oth-

ers. The chosen model architecture enables the train-

ing of dedicated regressors (Borchani et al., 2015) for

each output while maintaining cross-dependencies.

Random Forest Regressor (Rodriguez-Galiano et al.,

2015), employed as the base estimator, is well-suited

for detecting complex nonlinear patterns and provides

accurate results even with relatively small datasets. It

is also lightweight enough to run on standard CPUs or

embedded systems with limited memory (e.g., 2–4GB

RAM), making it an ideal solution for industrial set-

tings with constrained computational resources. Deep

learning models (e.g., neural networks) were deemed

unsuitable due to limited data availability and overfit-

ting risks. Classical models (Cook et al., 2022), like

linear regression, also fail to capture complex nonlin-

ear relationships between inputs and outputs.

Figure. 13 presents the separation error results

obtained by applying the optimized parameter val-

ues predicted by the trained model. This model was

trained on 81 real industrial test scenarios using actual

material and equipment in an operational recycling fa-

cility. The recommended values for vibration speed,

belt speed, and drum angle were tested in a real ex-

periment. The results showed a noticeable reduction

in misclassification errors—especially for aluminium,

copper, and brass—compared to those observed in the

original experimental dataset.

This performance demonstrates the effectiveness

of using machine learning for parameter optimiza-

tion. Lower error rates mean materials need not be

routed back into the separation process, saving signif-

icant energy and labour. In contrast, arbitrary or un-

balanced parameter combinations can lead to severe

issues. For example, if the drum speed is fixed at 6,

but the vibration feeder is set too high (e.g., 7) and

the conveyor belt too low (e.g., 3), excessive material

accumulates on the belt. As shown in Figure. 14, this

buildup creates a bulk that overwhelms the magnetic

drum, which ends up ejecting the entire load instead

of separating it. The resulting mess disrupts separa-

tion quality and spills material around the device, re-

quiring human intervention for cleanup.

Figure 14: Material buildup caused by high vibration speed

and low belt speed.

Similarly, very little material lands on the belt

when the conveyor belt is too high relative to the

vibration feeder (e.g., belt at 8 and vibration at 4).

This situation, depicted in Figure. 15, leads to mostly

empty belt operation. Even if a few particles reach

the magnetic field zone, they pass too quickly to be

separated correctly. This causes poor separation and

unnecessary energy usage while accelerating mechan-

ical wear due to underloaded operation.

By contrast, when the vibration feeder and belt

speeds are well-balanced, the material spreads uni-

formly across the conveyor, enabling stable and ef-

ficient separation. An example of this can be seen

in Figure. 16, where the material flow from the feeder

onto the belt appears evenly distributed, a prerequisite

for effective downstream separation. Hence, finding

optimal and compatible speed combinations is essen-

tial for achieving high separation accuracy, improving

energy efficiency and reducing the need for reruns.

Smart Separator: Optimizing Conveyor Belt, Vibration Feed, and Drum Speeds of Barrier Eddy Current Separator

313

Figure 15: Sparse material flow due to high belt speed and

low vibration feed.

The model suggested in this work achieved this by

learning directly from real industrial data. The chart

in Figure. 13 reflects a scenario selected by the trained

regressor as optimal, and the result confirms its su-

perior performance. These findings underscore the

potential of intelligent systems in enhancing the sus-

tainability and reliability of industrial recycling pro-

cesses.

Figure 16: Proper material flow with balanced vibration and

belt speeds.

5.1 Post-Model Training Steps

Real-world industrial data from a BECS system was

used for training. Initial material quantities included:

• 500 grams of aluminum

• 500 grams of copper

• 500 grams of brass

• 500 grams of plastics

uniformly mixed and processed. Separation errors

under varying operational parameters were recorded.

For example at:

• medium- vibration

• 47.30 Hz conveyor speed

• 30 degrees drum’s angle

47 grams of aluminium were misplaced into the

plastic bin. Similar copper, brass, and plastic errors

were logged under different conditions. These error

values and operational parameters served as input for

model training. After training, the model proposed

optimized parameters (e.g., vibration speed, conveyor

speed, drum angle) to minimize separation errors.

The Table 1 shows suggested optimized speeds.

To validate the model’s results, we tested its rec-

ommendations under industrial conditions. During

this phase, we reran the separation process, but this

time, we used the machine learning model’s sug-

gested settings. The results showed a significant re-

duction in separation errors. Table 2 presents the

recorded errors and the separation process’s accuracy.

Additionally, energy consumption was measured

throughout the process, revealing that the average en-

ergy consumption reached its lowest recorded level

compared to all previous measurements. Power con-

sumption data was measured before and after model

implementation using an energy logger to evaluate the

impact of the machine learning model on energy con-

sumption. The two images, Figures. 17 and 18, repre-

sent the system’s power consumption under different

conditions, which are analyzed and compared below.

• The total power consumption fluctuates between

1.2 kW and 1.4 kW.

• Power at Cursor 1 (09:58:38): 0.494 kW

• Power at Cursor 2 (10:05:26): 0.490 kW

• Delta (Power Difference): 0.041 kW

• The system’s power consumption is relatively

high and exhibits significant fluctuations.

• The total power consumption is now within 1.1

kW to 1.2 kW, which is lower than in the previous

graph.

ICSOFT 2025 - 20th International Conference on Software Technologies

314

Table 1: Optimized Table with Merged Cells.

Final Model’s Output

Machine Components Model Evaluation (Mean Absolute Error) Predicted Output

Vibration Speed 0.0 medium

Drum Speed 0.0 67.40

Belt Speed 0.0547 36.60

Drum Angle 0.0 20.0

Table 2: Recorded Errors and Accuracy of the Separation.

Material Recorded Errors (gram) Accuracy of Separation (%)

Aluminum 19 96.2

Copper 9 98.2

Brass 15 97.0

Plastic 26 94.8

Figure 17: Energy Consumption Before Machine Learning Optimization.

• Power at Cursor 1 (14:45:05): 0.430 kW

• Power at Cursor 2 (14:46:37): 0.418 kW

• Delta (Power Difference): 0.012 kW

• Energy consumption is lower, and fluctuations are

significantly reduced.

Table 3 compares the machine’s energy consump-

tion in two scenarios: one during data collection while

measuring all 82 cases and the other with the sug-

gested optimized speeds applied to all three machine

components.

The reduction in energy consumption is approxi-

mately 0.2 kW – 0.25 kW, representing a 15% – 18%

decrease in total energy usage. This reduction in en-

ergy consumption directly impacts operational cost

savings and enhances system sustainability, which

can be highly valuable in industrial environments.

This model is not limited to a specific type of bar-

rier eddy current separator but can also be applied

to other recycling machines. For instance, it works

for both a barrier eddy current separator and a simple

eddy current separator. This flexibility allows differ-

ent industries to customize the model based on their

needs by adding new input variables or removing un-

necessary ones. Recycling industries can modify the

model according to their machine’s conditions and

obtain customized results.

One of the key factors contributing to the success

of this project was the use of accurate industrial data.

Unlike similar studies (Bin et al., 2021; Huang et al.,

2021; Shan et al., 2024a; Shan et al., 2025) that rely

on simulated data, our proposed model was trained on

real-world industrial data. This makes its predictions

far more reliable for practical applications. Previous

Smart Separator: Optimizing Conveyor Belt, Vibration Feed, and Drum Speeds of Barrier Eddy Current Separator

315

Figure 18: Energy Consumption After Machine Learning Optimization.

Table 3: Comparison of Energy Consumption Before and After ML Optimization.

Comparison Before ML Optimization After ML Optimization

System Condition Higher power consumption with instability Lower power consumption with increased stability

Average Total Power Consumption 1.2 kW – 1.4 kW 1.1 kW – 1.2 kW

Power Usage Variations Significant fluctuations observed Reduced variations, more stable operation

studies often suffered from low accuracy because sim-

ulated data failed to capture unpredictable variables in

real industrial environments.

Additionally, one major factor overlooked in pre-

vious studies (Yi et al., 2022; Bin et al., 2022; Smith

et al., 2019; Shan et al., 2024b; Bin et al., 2021;

Huang et al., 2021; Shan et al., 2024a; Shan et al.,

2025; Ye et al., 2020; Huang et al., 2024; Ruan and

Xu, 2012; Bai et al., 2023) was measuring energy

consumption during the separation process. In our

project, we recorded power consumption in all test

scenarios. This is a key advantage for industries be-

cause lower energy consumption translates into lower

operational costs on a large scale. This project was

not financially expensive and was executed with al-

most zero financial cost. However, it was quite time-

consuming.

The reason for this was the collection of accurate

industrial data, which required running over 82 differ-

ent test scenarios, meticulously recording errors, and

processing experimental data. No similar research

study has been conducted with such a large volume

of real-world data because conducting industrial ma-

chine experiments, logging data, and accurately re-

peating each scenario is exceptionally tedious, time-

consuming, and exhausting.

5.2 Limitations

The data collected in this study corresponds to ma-

terials that have undergone industrial pre-processing

before entering the BECS. These materials passed

through milling and screening stages before separa-

tion. As a result, all tested samples had particle

sizes between 1 and 4 millimetres and were rounded

without sharp edges. This characteristic facilitated

magnetic drum calculations for detection and sepa-

ration, improving separation quality compared to ir-

regular or sharp-edged materials. Additionally, ex-

periments demonstrated that the optimal drum angle

decreases as particle size decreases. However, since

this study focused solely on materials within the 1

to 4-millimeter range, its findings are limited to this

size range. The model’s performance for finer pow-

ders (less than 1mm) remains unexplored. Industries

intending to adopt this approach should first analyze

their materials’ composition, shape, and size distribu-

tion. The model’s effectiveness is highly dependent

on the characteristics of the input materials, and its

performance may vary when applied to materials out-

side the studied range. However, if the input materi-

als align with the conditions examined in this study,

the proposed optimization method can deliver highly

accurate and reliable results. Moreover, experimen-

ICSOFT 2025 - 20th International Conference on Software Technologies

316

tal results indicated that particle size. Decreases, the

optimal angle of the magnetic drum should also be

reduced. This is because smaller particles are more

sensitive to magnetic and gravitational forces, and at

steeper angles, they may deviate from their intended

separation trajectory. However, it is important to note

that the scope of this study was limited to materi-

als ranging from 1 to 4 millimetres in size. There-

fore, the findings can only be generalized within this

size range, and the model’s performance on signif-

icantly finer materials—especially powders smaller

than 1 millimetre—has not been evaluated. During

this research, access to powder samples and parti-

cles smaller than 1 millimetre was extremely limited.

Even if a more significant quantity had been avail-

able, conducting accurate experiments on such mate-

rials would have presented significant challenges. Un-

like particles in the 1–4 mm range, where misclassi-

fied items could be visually identified and manually

separated for weighing, powders made this process

unfeasible. The naked eye could not easily distin-

guish ultra-fine particles, and manual separation was

practically impossible. This limitation made it impos-

sible to evaluate the model’s accuracy on powdered

inputs, as there was no practical method for reliably

identifying or quantifying separation errors in those

cases. Therefore, the proposed model’s effectiveness

has only been validated for materials within a spe-

cific particle size range. Extending its applicability to

other material types—particularly powders—will re-

quire more precise detection and measurement tools

to support future studies.

6 CONCLUSION AND FUTURE

WORK

This study successfully optimized the operational

parameters of the Barrier Eddy Current Separator

(BECS) using machine learning techniques. Imple-

menting the MultiOutputRegressor with a Random

Forest base model identified optimal settings for key

system components, significantly improving separa-

tion accuracy and reducing energy consumption. The

optimized parameters determined by the model were:

• Vibration speed: medium

• Drum speed: 67.40 Hz

• Belt speed: 36.30 Hz

• Drum angle: 20.0°

Applying these optimized settings in actual industrial

conditions resulted in a significant reduction in sepa-

ration errors. The accuracy rates achieved for differ-

ent materials were as follows:

• Aluminum: 96.2%

• Copper: 98.2%

• Brass: 97.0%

• Plastic: 94.8%

In addition to improving separation accuracy, the

optimization also enhanced energy efficiency. The

system’s power consumption decreased from an ini-

tial range of 1.2 kW—1.4 kW to a more stable 1.1

kW—1.2 kW, leading to a 15%—18% reduction in

total energy usage. This translates into lower opera-

tional costs and increased system sustainability, mak-

ing the solution highly practical for industrial appli-

cations. Future research will enhance the system’s

adaptability by incorporating predictive mechanisms

for detecting unwanted materials (e.g., sharp-edged

or ferromagnetic contaminants) and expanding the

dataset to cover a broader range of particle sizes.

These improvements will further strengthen the op-

timized BECS system’s applicability and robustness

in diverse industrial settings. All the codes, recorded

datasets, and other related needed information are

available in GitHub (Kia, 2025).

ACKNOWLEDGEMENTS

I sincerely thank Professor Daniel Goldmann for al-

lowing us to use the barrier eddy current separator

machine. Special thanks to Jean-Marie Dornbusch,

Olaf Tschenscher and Alexander Gaun, whose con-

tinuous support greatly benefited our team.

REFERENCES

Ahmed Nour El Islam, A. and Youcef, R. (2016). Simula-

tion of eddy current separation of gold particles from

sands. International Journal of Engineering and Man-

ufacturing, 6:30–37.

Bai, Y., Zhu, H., Zu, L., and Bi, H. (2023). Eddy current

separation of broken lithium battery products in con-

sideration of the shape factor. Journal of Material Cy-

cles and Waste Management, 25(4):2262–2275.

Bin, C., Yi, Y., Yerbol, A., Lei, F., Zongqiang, Z., Tian-

sheng, W., and Qiang, W. (2021). Optimization of hal-

bach magnetic roller for eddy current separation based

on the response surface method and multi-objective

genetic algorithm. Journal of Cleaner Production,

278:123531.

Bin, C., Yi, Y., Zhicheng, S., Qiang, W., Abdelkader, A.,

Kamali, A. R., and Montalvao, D. (2022). Effects of

particle size on the separation efficiency in a rotary-

drum eddy current separator. Powder Technology,

410:117870.

Smart Separator: Optimizing Conveyor Belt, Vibration Feed, and Drum Speeds of Barrier Eddy Current Separator

317

Borchani, H., Varando, G., Bielza, C., and Larranaga, P.

(2015). A survey on multi-output regression. Wiley

Interdisciplinary Reviews: Data Mining and Knowl-

edge Discovery, 5(5):216–233.

Cook, R. J., Lee, K.-A., Lo, B. W., and Macdonald, R. L.

(2022). Classical regression and predictive modeling.

World Neurosurgery, 161:251–264.

Garreta, R. and Moncecchi, G. (2013). Learning scikit-

learn: machine learning in python, volume 2013.

Packt Publishing Birmingham.

Gomathi, N. and Sridevi, I. (2015). Recovery of noble

metal from e-waste using leaching, electro deposition

and electro generative process. Der Pharma Chemica,

7(4):219–224.

Hirst, J. M., Miller, J. R., Kaplan, B. A., and Reed, D. D.

(2013). Watts up? pro ac power meter for automated

energy recording: A product review. Behavior Analy-

sis in Practice, 6:82–95.

Huang, Z., Lin, K., Dong, L., Jiang, C., Li, K., Niu, Y., Qin,

Y., Xu, K., and Ruan, J. (2024). Mechanism study of

removing sealing aluminum contaminates from waste

packaging high-density polyethylene by eddy current

separation. ACS Sustainable Chemistry & Engineer-

ing, 12(37):13861–13872.

Huang, Z., Zhu, J., Wu, X., Qiu, R., Xu, Z., and Ruan, J.

(2021). Eddy current separation can be used in sep-

aration of non-ferrous particles from crushed waste

printed circuit boards. Journal of Cleaner Production,

312:127755.

Kia, S. (2025). Smart-separator. https://github.com/Obscu

raKrypta/Smart-Separator. Accessed: 2024-07-10.

Li, W., Han, Y., Xu, R., and Gong, E. (2018). A prelim-

inary investigation into separating performance and

magnetic field characteristic analysis based on a novel

matrix. Minerals, 8(3):94.

Nagel, J. R., Cohrs, D., Salgado, J., and Rajamani, R. K.

(2020). Electrodynamic sorting of industrial scrap

metal. KONA Powder and Particle Journal, 37:258–

264.

Nunn, J. (2013). Educational electrical appliance power me-

ter and logger. Physics Education, 48(5):570.

Peng, T., Sellami, S., Boucelma, O., and Chbeir, R. (2023).

Multi-output regression for imbalanced data stream.

Expert Systems, 40(10):e13417.

Rem, P., Leest, P., and Van den Akker, A. (1997). A model

for eddy current separation. International journal of

mineral processing, 49(3-4):193–200.

Rodriguez-Galiano, V., Sanchez-Castillo, M., Chica-Olmo,

M., and Chica-Rivas, M. (2015). Machine learning

predictive models for mineral prospectivity: An eval-

uation of neural networks, random forest, regression

trees and support vector machines. Ore geology re-

views, 71:804–818.

Roy, S., Ari, V., Dey, S., and Das, A. (2010). Optimization

of eddy current separation technology for the recovery

of valuables from waste printed circuit boards.

Ruan, J. and Xu, Z. (2012). Approaches to improve sepa-

ration efficiency of eddy current separation for recov-

ering aluminum from waste toner cartridges. Environ-

mental science & technology, 46(11):6214–6221.

Sen, P. C. (2021). Principles of Electric Machines and

Power Electronics, International Adaptation. John

Wiley & Sons.

Shan, Z., Yuan, Y., Cao, B., Miao, S., Li, G., and Wang, Q.

(2024a). The effect of interaction between particles on

eddy current separation. Separation and Purification

Technology, 346:127382.

Shan, Z., Yuan, Y., Yang, L., Cao, B., Li, G., and Wang,

Q. (2025). Possibilities and difficulty levels for ver-

tical eddy current separation between different non-

ferrous metals. Separation and Purification Technol-

ogy, 356:129933.

Shan, Z., Yuan, Y., Zhou, Z., Feng, L., Cao, B., Li, G., and

Wang, Q. (2024b). The effects of the separator struc-

tures and magnetic roller arrangements on eddy cur-

rent separation. Minerals Engineering, 214:108793.

Smith, Y. R., Nagel, J. R., and Rajamani, R. K. (2019).

Eddy current separation for recovery of non-ferrous

metallic particles: A comprehensive review. Minerals

Engineering, 133:149–159.

Wang, Q., Zhang, B., Yu, S., Xiong, J., Yao, Z., Hu, B.,

and Yan, J. (2020). Waste-printed circuit board recy-

cling: focusing on preparing polymer composites and

geopolymers. ACS omega, 5(29):17850–17856.

Ye, F., Ren, X., Liao, G., Xiong, T., and Xu, J. (2020).

Mathematical model and experimental investigation

for eddy current separation of nonferrous metals. Re-

sults in Physics, 17:103170.

Yi, Y., Bin, C., Xuemei, Z., Lei, F., Tiansheng, W., and

Qiang, W. (2022). Effects of material temperature on

the separation efficiency in a rotary-drum type eddy

current separator. Powder Technology, 404:117449.

ICSOFT 2025 - 20th International Conference on Software Technologies

318