Application of Block Chain Technology in Cross Border Food

Information Tracing

Jing Sun

*

and Xueling Zheng

Health and Elderly Caring Industry School, Shandong Institute of Commerce and Technology,

Jinan 250103, Shandong, China

Keywords: Block Chain, Information Traceability, Cross-Border Food, PBFT Algorithm

Abstract: In recent years, blockchain technology has swept the world, because of its complete integration of encryption

algorithm, chain storage, consensus mechanism and other technologies, which makes it a transaction

mechanism that can conduct business communication when distributed nodes are not familiar with each other.

It breaks the traditional trading mechanism of centralized management, high cost, opacity and other problems.

This paper mainly studies the application of blockchain technology in cross-border food information

traceability. This paper proposes an improved PBFT algorithm based on node partitioning, introduces

partitioning and credit mechanism into the PBFT algorithm, and describes the algorithm improvement process

in detail. According to the consensus algorithm of improved Ethereum blockchain, a traceability design

scheme of food supply chain based on improved Ethereum blockchain is designed. Firstly, the traceability

process of supply chain is analyzed and a traceability process scheme based on blockchain is designed. Then,

a traceability system architecture based on blockchain technology is established and the specific

implementation method of the traceability system architecture is explained.

1 INTRODUCTION

With the improvement of people's living standards,

consumers pay more attention to the quality and

safety of products than to the basic needs such as price

and variety. In recent years, food, medicine and other

industries that are directly related to people's life and

health have repeatedly experienced quality problems,

which have significantly increased consumers' doubts

about product quality and safety and their sensitivity

to it (Tsang and Choy, et al. 2019). In recent years,

such as "melamine", "inferior gelatin event",

"longevity vaccine event" and so on product quality

and safety incidents after exposure, these bad

products not only harm the health of body and mind

of the consumer, more sharply reduces the consumer's

trust in the food and drug quality and safety, but also

make the enterprise suffered huge economic losses

(Tan and Gligor, et al. 2020). Therefore, it is

imperative to establish an effective food traceability

system. Using modern information management

technology to assign a unique identification code to

each product, the identification code records the

relevant process information, which can realize the

tracking and traceability of the product (Sharma and

Jhamb, et al. 2020). Once quality problems are found

after the products are marketed, they can be quickly

traced out and recalled to reduce food safety risks

(Pendrous, 2017). In addition to the food field,

traceability technology has also been applied in the

fields of medicine, tobacco, daily chemical industry

and so on (Sander and Semeijn, et al. 2018). Based on

the technological progress and the need of market

competition, consumers can scan the QR code pasted

on the goods through mobile phones to obtain the

business unit, customs declaration number, entry time

and other information of the goods, which has

become a supplementary means for consumers to

obtain information and government departments to

master data (Mengjia and ZENG, et al. 2019).

The application of blockchain in the field of

traceability has its unique advantages and is currently

a hot research direction (Kamath, 2018). The

retroactive application of blockchain technology also

appeared in the world one after another (Deng and

Feng, 2020). The European Union has established a

series of food control systems to address food safety

issues, and proposed for the first time that food can

be traced back to the source of raw materials from the

table (Gao and T-PBFT, 2019). The United States has

532

Sun, J. and Zheng, X.

Application of Block Chain Technology in Cross Border Food Information Tracing.

DOI: 10.5220/0013548500004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 1, pages 532-536

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

issued a series of bills on food safety guarantee and

risk control, elevating food quality management to

the national level (Zheng and Feng, et al. 2021). The

French government also proposed to establish a food

safety traceability system, and the traceability

information should cover the operation of each node

of the food supply chain. India has also established a

food traceability system, requiring enterprises

responsible for production and processing to record

the operation information of the whole process of

food from raw materials to finished products (Han-

Back and Moo-Sub , et al. 2018). Meanwhile, the

processing company's own information should be

prepared and recorded in the traceability label, so as

to ensure that food can be traced back to the source of

food production when consumers buy it (Zhao and

Wu, et al. 2020).

Based on the blockchain technology and in

combination with the cross-border food traceability

project, the research of this paper aims at the

problems in the cross-border food traceability system,

and makes improvements on the consensus of the

application of blockchain and the additional

difficulties in nodes, so as to build an efficient and

accurate traceability food production chain.

2 APPLICATION OF

BLOCKCHAIN TECHNOLOGY

IN FOOD TRACEABILITY

2.1 Blockchain - Based Traceability

Architecture

Blockchain-based food traceability system

architecture design, the architecture from bottom to

top is divided into operation layer, data acquisition

layer, network layer, data layer, display layer and user

layer, a total of 6 layers, each layer corresponds to

different technical applications and entity objects.

Through iot equipment operation process of each link

of the supply chain data, and through the wireless

network transmission to the supply chain of each

node, and then through the supply chain elected

master node data information for the deal and food

packaged into data information blocks, the entire

network to reach consensus, chain block, block chain

data will be stored in the block chain network, each

node. The information on the chain can not be

tampered with and is true and reliable. Users can trace

the source of consumer food and inquire the

production process of products through the

development platform.

2.1.1 Operation Layer

Each link of the supply chain includes the selection

and purchase of raw materials, food processing,

processed food inspection, food warehouse storage,

processed food packaging and packaged food sales.

The raw material supplier shall purchase raw

materials from the place of production in accordance

with national regulations and company rules, and

input the variety, quantity and source of raw materials

into the system.

2.1.2 Data Acquisition Layer

When the whole supply chain is running, each stage

chooses its own collection method according to its

own characteristics. In the raw material procurement

link of the supply chain, raw material information can

be input through a handheld terminal and generate a

two-dimensional code. Processing manufacturers can

scan the two-dimensional code to check the detailed

information of raw materials and verify the

authenticity of the information when purchasing raw

materials. Raw materials in the production line for

processing, through the intelligent sensor raw

material processing production environment in the

process of information into the system, and generate

the corresponding qr code information, quality

inspection personnel on the inspection of qualified

products to the food with food quality inspection

information, such as processed foods after complete

quality inspection and packaging will complete qr

code information on the package. In the process of

logistics transportation, an RFID tag is assigned to

each package to facilitate the query of package

information in transportation and transit warehouses.

Consumers using mobile terminals can scan the QR

code on the food package to understand the detailed

operation of the food.

2.1.3 Network Layer

The network layer mainly uses wireless transmission

technology. GPRS can provide users with long

distance data transmission, and can realize the

transparent transmission of collected data. ZigBee

and WiFi signal frequencies are the same, but

implementation standards are different. ZigBee has

good stability, small data transmission and low power

consumption, and is suitable for use in the production

stage of raw materials. WiFi has poor stability, short

transmission distance but large data volume, which is

convenient and practical for consumers to query the

detailed information of goods.

Application of Block Chain Technology in Cross Border Food Information Tracing

533

2.1.4 Data Layer

Each node of the supply chain detects data through

Internet of Things devices and transmits it to its own

platform via wireless network. After receiving the

data, the platform will broadcast it to other nodes of

the supply chain. Each node of the supply chain first

selects the master node, and then the master node

sorts the data information received according to the

time stamp and packages a certain amount of data to

generate blocks. Then the blocks are broadcast to

other nodes of the supply chain, and consensus is

reached on the generated blocks through DPOA and

PBFT consensus mechanism and the blocks are

linked up.

2.1.5 Display Layer

This layer designs the relationship between user

authentication and data access rights and defines the

block chain data access interface. For qualified users,

they can query the information collected in the whole

link of the supply chain through the data access

interface and display the information to users in

accordance with certain specifications.

2.1.6 User Layer

The user layer reflects the division of each link of the

supply chain into suppliers, processing

manufacturers, carriers, retailers, etc., as well as

regulatory authorities according to their different

functions.

2.2 PBFT Algorithm and its

Improvement

2.2.1 PBFT Algorithm

PBFT is a distributed consistency algorithm based on

state machine copy replication. To ensure the normal

operation of the algorithm, a view replacement

protocol, a checkpoint protocol and a consistency

protocol are designed in PBFT.

2.2.1.1 View Replacement Protocol

In the PBFT consensus process, all node states must

be consistent, that is, in the same view. A view

contains a primary node and several other backups,

all of which have the same view number V. The

master node receives requests from clients in order of

time, and initiates consensus protocol to broadcast

requests to the slave nodes. View changes are

triggered by a timeout mechanism that prevents the

slave node from waiting indefinitely for the request to

execute. If the slave node I does not receive the

request sent by the master node in view v over

timeout, the slave node will start the view

replacement protocol and change the system view

number v to v+1 to elect a new master node. In PBFT,

assume that the set of all nodes is S and the node

numbers are {0,1,2... , | S | - 1}, when from the node

execution view change agreement, view code v + 1,

the new master node number calculated as follows:(1)

||mod Svp =

(1

)

2.2.1.2 Checkpoint Protocol

The information of the PBFT consensus process is

kept in the replica log, occupying the node memory,

and the checkpoint protocol can be used to clean up

the information and free the node memory. In the

PBFT, when the sequence number of the execution

request is divisible by some constant, a checkpoint S

is generated from the node. Once the stability of the

checkpoint S is proved, the slave node will discard all

pre-prepare, prepare, and commit messages in its log

with a sequence number less than or equal to S, as

well as previous checkpoints and checkpoint

messages. At the same time, the checkpoint protocol

is used to set the next sequence number range: (2)

khH +=

(1

)

h is the sequence number of the last stable

checkpoint, and K is the fixed value set.

2.2.1.3 Conformance Protocol

Consistency protocol is the core protocol of PBFT

algorithm, which uses a three-stage protocol to

broadcast requests to slave nodes, including pre-

prepare, prepare and commit.

2.2.2 Improve the Model

In a large-scale distributed system, layering

technology and agent technology are the basic

technologies of large-scale computing and complex

communication. The I-PBFT model proposed in this

chapter is based on the concepts of layering

technology and agent technology. In the i-PBFT

algorithm, the consensus model is divided into two

layers: the upper layer is the agent node region, and

the lower layer is the consensus node partition. Each

agent node in the upper layer of the consensus model

INCOFT 2025 - International Conference on Futuristic Technology

534

is the local master node of a partition in the lower

layer, and there is a global master node in the agent

node. The PBFT conformance algorithm is performed

within each partition, while the partitioning level is

dynamic and the number of partitions can be changed

as needed.

In the i-PBFT algorithm, the nodes in the whole

network are divided into four categories: client,

global master node, agent node and consensus node.

In the algorithm, the nodes are partitioned first. In the

process of node partitioning, the view replacement

protocol of the original PBFT algorithm is changed in

this paper, and the master node and agent node are

selected according to the node credit value. One

master node and several agent nodes are selected. Set

the number of agent nodes as K. After the agent nodes

are selected, the remaining nodes are merged into the

partition where K agent nodes are located to form a

PBFT consensus network with K partitions. In

addition, the number of nodes of each type is variable

throughout the network, and the total number of

nodes is constantly changing.

3 MODEL SIMULATION

EXPERIMENT

This paper uses Python language to implement a

small multi-node blockchain experimental system,

PBFT algorithm and I-PBFT algorithm proposed in

this paper are simulated. The algorithms are

compared and analyzed in four aspects:

communication overhead, fault tolerance, transaction

delay and throughput.

3.1 Transaction Delay

In order to test the trading delay of the algorithm, the

client constantly initiates trading requests in the

experiment and records the time of completion of

each consensus. For the accuracy of the experiment,

the average value of 100 transaction delays is taken

as the algorithm's transaction delays, and the test is

carried out in the case of different number of nodes to

get the final results.

3.2 Throughput

In order to test the throughput of the algorithm in the

same environment, the client was set to send 200

Transaction requests in the experiment, record the

Transaction completion time, and then calculate the

number of transactions completed Per unit time,

namely TPS(Transaction Per Second), according to

the data obtained from the experiment.

4 SIMULATION EXPERIMENT

RESULTS

4.1 Transaction Delay Test

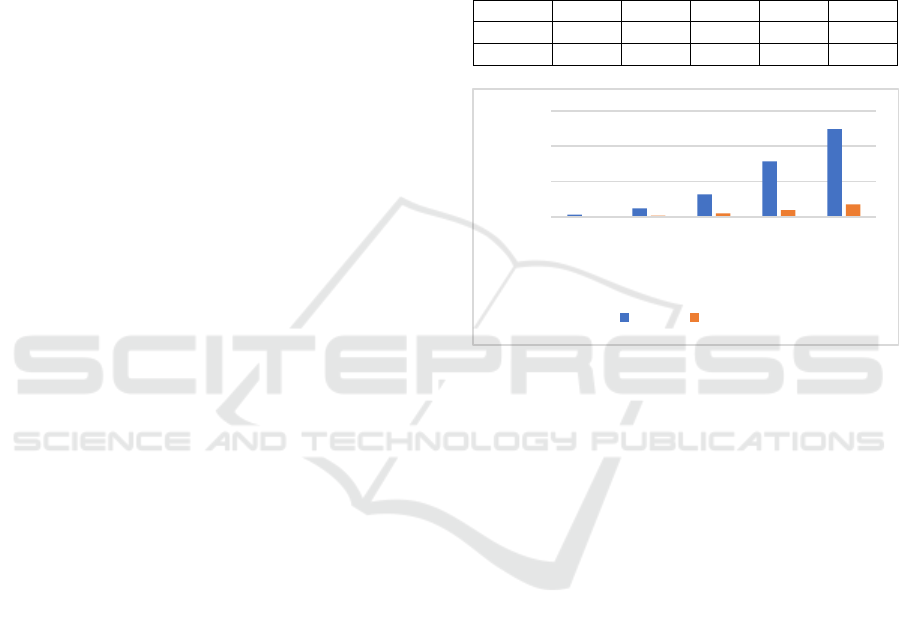

Table 1: Node delay comparison

5 10 20 30 40

PBFT 0.12 0.47 1.27 3.14 4.96

I-PBFT 0.03 0.07 0.19 0.38 0.71

Figure 1: Node delay comparison

As shown in Table 1 and Figure 1, the transaction

delay of the PBFT algorithm increases significantly

with the increase of nodes, and the delay of the I-

PBFT algorithm is far less than that of the PBFT

algorithm. The average delay of PBFT is 1.99s, and

the average delay of I-PBFT algorithm is reduced to

0.27s. With the increase of the number of nodes, the

communication overhead of PBFT algorithm

increases exponentially in the consensus process. In

this paper, the node partition method is adopted to

reduce the communication overhead of the node to

about 1/4. Meanwhile, the four partitions

synchronously carry out consensus, and the

transaction delay is nearly 8 times lower than that of

PBFT.

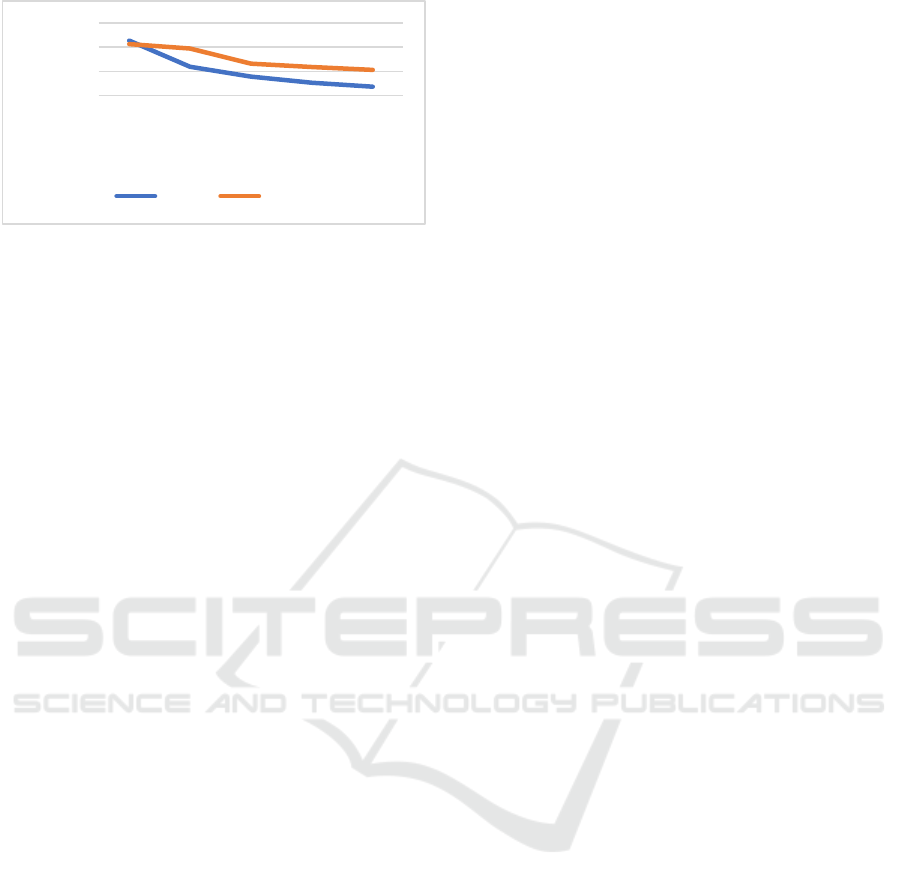

4.2 Throughput Test

As shown in Figure 2, the throughput comparison

between i-PBFT and PBFT algorithm in the number

of nodes from 15 to 50 is shown. The throughput of

the I-PBFT algorithm is higher than that of the PBFT

algorithm. The average throughput of the PBFT is

102TPS, and the average throughput of the i-PBFT is

increased to 152TPS.

0

2

4

6

5 10203040

Time delay(s)

Number of nodes

PBFT I-PBFT

Application of Block Chain Technology in Cross Border Food Information Tracing

535

Figure 2: Throughput comparison

Compared with PBFT algorithm, I-PBFT

algorithm reduces the communication times of nodes

in the consensus process, effectively reduces the

network communication overhead, and reduces the

generation of malicious nodes through the node credit

mechanism. Experimental results show that I-PBFT

algorithm performs well when there are more nodes,

and its delay and throughput are better than PBFT

algorithm.

5 CONCLUSIONS

The main work of this paper is to solve the problem

of cross-border food safety traceability. Due to the

problems of centralization and information tampering

in the cross-border food traceability system, the

authenticity of food information in the whole

traceability process cannot be guaranteed. Therefore,

combining with modern blockchain technology to

solve the problem of data centralization, food

information is not controlled by a certain node or link

of the supply chain. Through the analysis of the

current food supply chain data acquisition mode and

other industry data acquisition mode, this paper puts

forward a comprehensive combining qr code and

RFID solutions to solve the problem of food

information collection, in combination with manual

input of food processing environment parameters,

such as planting, so that greatly reduces the

traceability platform of supply chain operating costs.

This paper designs an improved consensus algorithm

based on PBFT, optimizes the consistency protocol,

and proposes an improved PBFT algorithm for node

partitioning based on credit, I-PBFT. The experiment

proves that the consensus efficiency of the optimized

consensus algorithm is improved, and the

consumption of network communication is reduced,

which proves the feasibility of the algorithm.

REFERENCES

Tsang Y P , Choy K L , Wu C H , et al. Blockchain-driven

IoT for Food Traceability with an Integrated Consensus

Mechanism[J]. IEEE Access, 2019, 7(1):129000-

129017.

Tan A , Gligor D , Ngah A . Applying Blockchain for Halal

food traceability[J]. International Journal of Logistics,

2020(103):1-18.

Sharma A , Jhamb D , Mittal A . Food Supply Chain

Traceability by Using Blockchain Technology[J].

Journal of Computational and Theoretical Nanoscience,

2020, 17(6):2630-2636.

Pendrous R . Blockchain takes off in food and drink[J].

Food Manufacture, 2017, 92(10):27-27.

F Sander, Semeijn J , Mahr D . The acceptance of

blockchain technology in meat traceability and

transparency[J]. British Food Journal, 2018,

120(9):2066-2079.

Mengjia, ZENG, Xu, et al. Process Monitoring of Harmless

Disposal for Dead or Sick Livestock Based on

Blockchain[J]. Agricultural Biotechnology, 2019,

v.8(03):184-190.

Kamath R . Food Traceability on Blockchain: Walmart's

Pork and Mango Pilots with IBM[J]. The Journal of

British Blockchain Association, 2018, 1(1):1-12.

Deng M , Feng P . A Food Traceability System Based on

Blockchain and Radio Frequency Identification

Technologies[J]. Journal of Computer and

Communications, 2020, 08(9):17-27.

Gao S . T-PBFT: An EigenTrust-Based Practical Byzantine

Fault Tolerance Consensus Algorithm[J]. China

Communications, 2019, 16(12):111-123.

Zheng X , Feng W , Huang M , et al. Optimization of PBFT

Algorithm Based on Improved C4.5[J]. Mathematical

Problems in Engineering, 2021, 2021(2):1-7.

Han-Back S , Moo-Sub K , Sunmi K , et al. Quantitative

analysis of prompt gamma ray imaging during proton

boron fusion therapy according to boron

concentration[J]. Oncotarget, 2018, 9(3):3089-3096.

N Zhao, Wu H , Zhao X . Consortium Blockchain-Based

Secure Software Defined Vehicular Network[J].

Mobile networks & applications, 2020, 25(1):314-327.

0

100

200

300

15 20 30 40 50

TPS

Number of nodes

PBFT I-PBFT

INCOFT 2025 - International Conference on Futuristic Technology

536