Research on Self Adjustment Technology of Data Mining Algorithm

in Control Engineering

Chunxiang Huang, Nenjun Ben

*

and Guojun Yan

Institute of Intelligent Manufacturing, Yancheng Polytechnic College, Yancheng, Jiangsu,224005, China

Keyword: Data Mining Algorithm, Control Engineering, Automatic Adjustment.

Abstract: The research direction is the self-tuning technology of data mining algorithm in control engineering. The main

purpose of this research is to develop a new technology of automatic fault identification and diagnosis in

various industrial systems based on nonlinear models. The proposed method will be used to optimize such

systems through neural networks. The results obtained in the implementation stage show that the neural

network with a large number of hidden units (up to 500) can be used as an effective tool to solve nonlinear

model problems. The research on self-tuning technology of data mining algorithm in control engineering is

to find the best method of using data mining algorithm to control the process. It is also called intelligent

system or artificial intelligence (AI). The main goal of this research is to develop an intelligent system that

can perform better than human operators in the control process. Self tuning technology refers to the ability of

computer systems to learn from past experience and improve performance by using these experiences without

any human intervention.

1 INTRODUCTION

Now the numerical solution of the computer is so

simple and fast. From the aspect of solution alone (or

from the aspect of publishing papers), the frequency

domain method seems to have no need to exist (Wang

and Shen, et al. 2019). Just like the Routh criterion, it

has completed the historical task and can quit the

historical dance stage with honor (unfortunately, it is

still teaching the Routh criterion now). Moreover, the

frequency domain method will eventually be

transformed into the time domain algorithm (Xu and

Miao, 2018). However, the real engineering of

control system, LTI system, still depends on Bode

diagram (signal or system) most of the time (Bi and

Meng, et al. 2021). Many of the top international

companies and engineers I have learned will look at

Bode diagram when designing control system, at least

before the actual operation of the system (Hong,

2021). And it is not only the control system, but also

in the field of signal processing (digital signal

processing), even more obvious (Sun and Zhijian, et

al. 2019).

Personally, I think the more important reason is

physical intuition. This word is actually not rigorous.

In fact, the frequency domain method is often not

rigorous, but it is useful (Luo and Zheng, et al. 2019).

For example, the cut-off frequency / bandwidth, if

spectrum peak, low-frequency gain, high-frequency

gain, these key points can be seen by experience,

roughly (pay attention to roughly) the response curve,

robustness, high and low if interference suppression,

stability, accuracy, etc., and really can be seen by

simple calculation in your mind. More importantly, if

you want to change a certain characteristic (response

curve, robustness, high and low if interference

suppression, stability, accuracy, etc.), you can also

directly know which parameters to adjust and what

impact this characteristic will have on other

characteristics (Chen and Xu, et al. 2021).

In contrast, given a differential equation, even if

you can calculate some performance indicators

through the computer, if you want to change this

indicator to meet a specific requirement, you can

almost only try (Tung-and WU, et al. 2019); And

most of the time, one performance is good, and the

other performance is not good, because there are

interactions (Bai and Xiong, et al. 2019). Based on

this, this paper studies the self-tuning technology of

data mining algorithm in control engineering.

Huang, C., Ben, N. and Yan, G.

Research on Self Adjustment Technology of Data Mining Algorithm in Control Engineering.

DOI: 10.5220/0013545400004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 1, pages 453-456

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

453

2 RELATED WORKS

2.1 Data Mining Algorithm

Data mining is the process of discovering useful

patterns in data. The purpose of data mining session

is to determine the trend and pattern of data. Data

mining emphasizes the processing of a large number

of observed databases. It is a frontier discipline

involving database management, artificial

intelligence, machine learning, pattern recognition,

and data visualization. From a statistical point of

view, it can be seen as the automatic exploratory

analysis of a large number of complex data sets

through computers. Data source: it is the foundation

of data warehouse system and the data source of the

whole system. It usually includes internal and

external information of the enterprise. Internal

information includes various business processing

data and various document data stored in RDBMS.

External information includes various laws and

regulations, market information and competitor

information, etc (Liang, 2018).

Data storage and management: it is the core of the

whole data warehouse system. The real key of data

warehouse is data storage and management. The

organization and management mode of data

warehouse determines that it is different from

traditional database, and also determines its

manifestation of external data. To decide what

products and technologies to adopt to establish the

core of data warehouse, we need to analyze the

technical characteristics of data warehouse. The data

of existing business systems are extracted, cleaned

up, effectively integrated, and organized according to

the theme. Data warehouse can be divided into

enterprise level data warehouse and department level

data warehouse (usually called data mart) according

to the coverage of data. Figure 1 below shows the data

mining process.

Figure 1: Data mining process

OLAP server: effectively integrate the data

required for analysis and organize it according to the

multidimensional model, so as to conduct multi angle

and multi-level analysis and find trends. Its specific

implementation can be divided into ROLAP,

MOLAP and HoLap. ROLAP basic data and

aggregate data are stored in RDBMS; MOLAP basic

data and aggregate data are stored in

multidimensional database; HoLap basic data is

stored in RDBMS, and aggregated data is stored in

multidimensional database.

Front end tools: mainly including various report

tools, query tools, data analysis tools, data mining

tools and various application development tools

based on data warehouse or data mart. Among them,

data analysis tools are mainly for OLAP servers,

while report tools and data mining tools are mainly

for data warehouses.

2.2 Control Engineering Technology

As for master control engineering, first of all, we need

to mention the basic theory of control engineering

system control process, that is, control engineering

cybernetics. Its main research contents are

information, state and control engineering topology.

Usually, this theory is the reference basis for building

master control engineering. The main function of the

master control project is to input control commands

and parameters, and display the operation and

feedback information of the controlled equipment. In

addition, from the perspective of the basic framework

of the master control of control engineering, it is

divided into three control structures: centralized,

decentralized and hierarchical. Each control structure

has the advantages and disadvantages of dichotomy.

Second, the centralized control structure is relatively

simple in structure and control, which makes the

management and network construction easier, and the

delay time is small, reducing the error in the

transmission process. However, the installation

workload is large and the cost is high, which is not

conducive to resource sharing. The advantage of

decentralized control structure is its high reliability.

Even if the controller fails, the control engineering

system will not be completely paralyzed. Therefore,

when the system scale meta method is centralized

control, the communication is more convenient, or the

user requires the use of decentralized control

structure, the decentralized control structure can be

used. However, the decentralized control structure

also has some defects. If the state of the control

engineering system cannot be controlled and

observed, the hierarchical control structure combines

INCOFT 2025 - International Conference on Futuristic Technology

454

the centralized and decentralized control structure,

which can realize both local control and global

coordinated control.

𝑃

1

1𝑝

𝑝

𝑝

𝑝1

𝑝

𝑃

(1

)

𝑆𝑖𝑚

𝑑

,𝑑

∑

𝑊

𝑊

∑

𝑊

∙

∑

𝑊

(2)

The controlled control engineering system is

mainly based on the cybernetics of control

engineering. The control mechanism can be

implemented through software or hardware to

provide certain control services. Generally, the

controlled control engineering system can be

understood as a data resource, or it can be a control

system centered on computer, which combines field

control with management and data acquisition. In

terms of structure, it mainly includes control

engineering control center, acquisition node user

interface and intermediate control node. During the

design process, certain principles should be followed,

that is, the planning of safety detection, safety

protection and emergency recovery reflects the

principle of integrity, and the classification of safety

levels and levels of controlled control projects reflects

the principle of hierarchy. The introduction of

variable factors in controlled control engineering

reflects the principle of dynamic, and the restriction

of authority reflects the principle of minimization.

Only by ensuring the application of design principles

can the safety and controllability of control

engineering system be guaranteed.

3 RESEARCH ON SELF-TUNING

TECHNOLOGY OF DATA

MINING ALGORITHM IN

CONTROL ENGINEERING

System analysis refers to the analysis of system

performance with known system structure and

parameters System design refers to the performance

indicators that the control object and the control

system are known to achieve. It is required to design

a system to achieve these indicators.

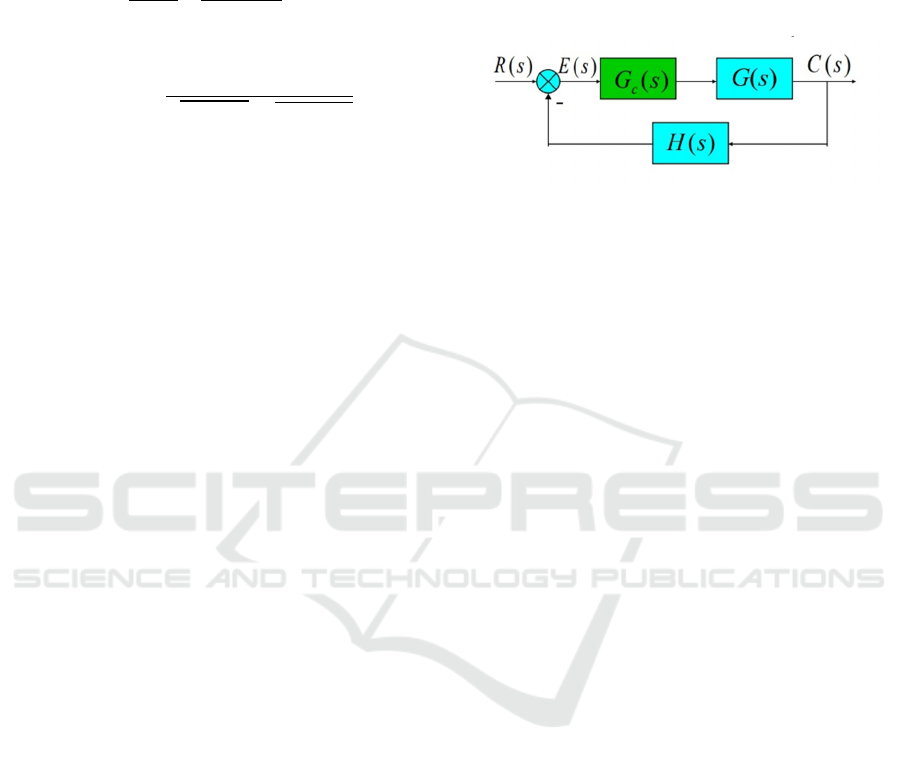

If the parameters of the control system cannot

fully meet the performance index of the design

requirements by adjusting its own parameters, it is

necessary to add some devices in the system whose

parameters and characteristics can be changed as

needed to make the system performance fully meet

the design requirements, which is system correction

(correction), and the corresponding correction device

is also called compensator As shown in Figure 2

below, series correction in automatic adjustment.

Figure 2: Series correction in automatic adjustment

It infers future data from historical and current

data according to time series data, and it can also be

considered as related knowledge with time as the key

attribute. At present, time series prediction methods

include classical statistical methods, neural networks

and machine learning. In 1968, box and Jenkins put

forward a set of relatively perfect time series

modeling theory and analysis methods. These

classical mathematical methods predict time series by

establishing random models, such as autoregressive

model, autoregressive moving average model,

summation autoregressive moving average model

and seasonal adjustment model. Because a large

number of time series are non-stationary, their

characteristic parameters and data distribution change

with the passage of time. Therefore, only through the

training of some historical data, the establishment of

a single neural network prediction model can not

complete the accurate prediction task. Therefore,

people put forward retraining methods based on

statistics and accuracy. When it is found that the

existing prediction model is no longer suitable for the

current data, retrain the model to obtain new weight

parameters and establish a new model. Many systems

also use the computational advantages of parallel

algorithms to predict time series.

In addition, other types of knowledge can be

found, such as deviation, which is a description of

differences and extreme special cases, and reveals the

abnormal phenomena of things that deviate from the

Convention, such as special cases outside the

standard category, outliers outside the data clustering,

etc. All these knowledge can be found at different

conceptual levels, and with the improvement of

conceptual levels, from micro to meso to macro, to

meet the needs of different users at different levels of

decision-making.

Research on Self Adjustment Technology of Data Mining Algorithm in Control Engineering

455

It reflects the characteristic knowledge of the

common nature of similar things and the different

characteristic knowledge between different things.

The most typical classification method is based on

decision tree. It constructs a decision tree from the set

of examples, which is a guided learning method. This

method first forms a decision tree according to the

training subset (also known as window). If the tree

cannot give the correct classification of all objects,

select some exceptions to add to the window, and

repeat the process until the correct decision set is

formed. The final result is a tree, whose leaf node is

the class name, and the intermediate node is an

attribute with branches, which corresponds to a

possible value of the attribute Data classification also

includes statistics, rough set and other methods.

Linear regression and linear discriminant analysis are

typical statistical models. In order to reduce the cost

of decision tree generation, an interval classifier is

also proposed. Recently, some people have also

studied the use of neural network methods for

classification and rule extraction in databases.

4 CONCLUSIONS

The self-tuning technology of data mining algorithm

is the most important part of control engineering. Self

adjustment technology is to adjust the feedback

signal, which is generated by data mining algorithm

to achieve a stable and reliable control system. This

paper studies the self-tuning technology of data

mining algorithm in control engineering. First, there

are two types of algorithms used to adjust the

feedback signal: independent algorithm and

dependent algorithm. Secondly, there are three

methods to adjust the feedback signal: direct method,

indirect method and mixed method. In general, it can

be said that the focus of these studies is to develop

intelligent systems based on the use of AI technology.

ACKNOWLEDGEMENT

2021 Jiangsu Province Policy Guidance Plan (Special

for Introducing Foreign Talents) Fund Project:Key

technology research and development of wall-

climbing robots for large ferromagnetic surfaces such

as ships(BX2021051)

REFERENCES

Wang X , Shen Y , Yang H . Exploration of Data Mining

Technology in Data of Food Control[J]. Chinese

Pharmaceutical Affairs, 2019.

Xu Y , Miao Z . Application of data mining technology in

quality control of building material equipment

manufacturing process[J]. China Building Materials

Science & Technology, 2018.

Bi B , Meng J , Cheng B . A Study on the Dynamic

Adjustment of Pressure Relief Gas Drainage Drilling in

Mined-Out Areas[J]. 2021, 9(2):9.

Hong X . Application of Data Mining Technology in

Software Engineering[J]. Journal of Physics:

Conference Series, 2021, 2066(1):012013-.

Sun W , Zhijian W U , Zhang F , et al. Self-Adjustment

Algorithm of Self-Regulating Grounding Fault in

Distributed Microgrid[J]. Computer & Digital

Engineering, 2019.

Luo Q F , Zheng H J , Zhang S C . Preliminary Study on

Analysis Technology of Normal Water Storage Level

Adjustment for Constructed Reservoir-Taking

Hangzhou City Qingshan Reservoir as an Example[J].

Zhejiang Hydrotechnics, 2019.

Chen Z , Xu P , Feng F , et al. Data mining algorithm and

framework for identifying HVAC control strategies in

large commercial buildings[J]. 2021.

Tung-sheng, WU, Ying-sing, et al. The Control Technology

of Medical Expenses: A Combination of Data Mining

and Quality Control Chart[C]// 2019.

Bai Y , Xiong Y , Jiang L . Application of Data Mining

Technology in College Student Management[J].

Journal of Hubei Open Vocational College, 2019.

Liang J . Microblog community data mining algorithm

based on chaotic stability sub-control mechanism[J].

Foreign Electronic Measurement Technology, 2018.

INCOFT 2025 - International Conference on Futuristic Technology

456