Research on Power Plant Production Data Mining Technology Based

on Association Rules

Hao Zhang, Chao Wen, Zengtao Zhao, Tao Peng and Zihang Liang

China Southern Power Grid Energy Storage Co.,Ltd, China

Keywords: Association Rules, Power Plant Production Data Mining Technology, Power Plants, Pow

Abstract: In the production process, the power plant will generate a huge and important data asset, and if the knowledge

and rules can be effectively mined and utilized, it will certainly provide important support for the operation

efficiency and production cost reduction of the power plant. This paper systematically expounds the research

on power plant production excavation technology based on association rules and makes a detailed study of

each link in it. Based on the combination of theoretical analysis, qualitative analysis and case verification

methods, it can be found that this technology can effectively explore the value rules existing in the production

data of power plants and provide certain support for the intelligent management of power plants. The research

results of this paper can provide a strong reference for the digital transformation and practice of electric power.

1 INTRODUCTION

As an important supporting industry in the national

economy, the production and operation of the power

industry has always been a topic of concern in the

industry (Ben, 2010). The power plant is a core unit

in the power system, and its production process will

generate a huge amount of data content, which

contains extremely rich knowledge and laws, and if it

can be effectively mined and utilized, it will

inevitably improve the operation efficiency of the

power plant (Chen. and Lai, et al. 2003). Based on

this, data mining technology based on association

rules will become a key means in the intelligent

transformation of the power industry (Han, 2006).

Therefore, this paper will describe the research

process of this technology from the aspects of data

preprocessing and association rule mining, and

combine it with case analysis to explain its

application value in the power industry (Intan, 2006).

It is hoped that the writing of this article can provide

a strong reference for the further digital

transformation and practice of power enterprises.

2 RESEARCH METHODS

First, Theoretical Analysis Method. In the key part of

the paper, the working mechanism of the Apriori

algorithm and the key points in the parameter design

are discussed in detail, so as to provide a theoretical

basis for the subsequent practical application

(Kryszkiewicz, 1998). In the process of discussing the

evaluation and selection of rules, this paper starts with

a qualitative analysis of various aspects such as

support and confidence, and how to mine correlation

rules based on these indicators, and carry out effective

evaluation and screening, so as to ensure the quality

and value of rule mining (Lee, 2001). This qualitative

analysis can provide an effective basis for the

subsequent application of the rules (Tan, 2012);

Finally, based on a specific application case of power

plant production data mining technology, this paper

illustrates the application effect of the selected high-

quality rules in actual production decision-making

and equipment condition monitoring (Yamada. and

Funayama,, et al. 2015). This method of case analysis

will show the practical application value of

association rule technology in power production data

mining (Ye and Liu et al. 2011).

3 THE RESEARCH PROCESS

Will generate a very large amount of operating data

in the process of power plant production, including

equipment parameters and operating status. The

knowledge contained in these data is very rich and has

Zhang, H., Wen, C., Zhao, Z., Peng, T. and Liang, Z.

Research on Power Plant Production Data Mining Technology Based on Association Rules.

DOI: 10.5220/0013545300004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 1, pages 447-452

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

447

many rules, and if it can be effectively mined and

utilized, it can greatly improve the production

efficiency of power plants, reduce their operating

costs and optimize production planning, providing

important support for this (Zhao, and Zhang, 2007).

The basic idea is to discover the implicit value

patterns and rules based on the correlation between

events and projects in the power plant production

data, so as to provide an important basis for the

production decision-making of power plants. The

research process includes: data preprocessing and

association rule mining, rule evaluation and

screening, rule application, etc. First, data

preprocessing. In this step, people need to collect all

kinds of data in the production of power plants, and

carry out various pre-processing operations such as

cleaning, integration, and transformation, to prepare

for data mining in the future. Second, association rule

mining. The Apriori algorithm is used to mine

association rules and find frequent item sets and

association rules contained in the data. The focus of

this step is to design reasonable and reliable support

and confidence thresholds to uncover the rules that

are truly valuable, and thirdly, to evaluate and screen

the rules. Evaluate the associated rules that have been

excavated, and eliminate some of the useless and

redundant rules, and retain those rules that can

provide guidance value for the power plant's

production decisions. The evaluation indicators

include utilization, lift, and coverage, and fourth, rule

application. The selected association rules are applied

to various scenarios of the power plant, such as the

formulation of production plans, the monitoring of

equipment status, fault diagnosis, etc., so as to

provide strong support for the intelligent management

of the power plant. As shown in Equation 1.

()

01 1

jΔ

0

0

01

2

e

kn

n

Tx E

nn

ε

→=⋅

+

(1)

3.1 Data Preprocessing

first, data collection. In the production process of the

power plant, a lot of heterogeneous data will be

generated, such as equipment operating parameters

and production indicators, maintenance records,

environmental monitoring data, etc. People need to

collect relevant raw data from various systems and

data sources to lay the foundation for future analysis

and mining; Collected raw data often has a lot of

missing values, outliers, and noise, so it needs to be

carefully cleaned. As shown in Equation 2.

()

0

01

2n

fXx

nn

⋅=

+

(2

)

For example, to identify and deal with missing

values, this can be done by interpolation and average

substitution. For example, detecting them and

weeding out outliers can be done through statistical

analysis and machine learning. For example, it is

necessary to eliminate noise interference in the data

and improve the signal-to-noise ratio of the data, and

thirdly, data integration. As shown in Equation 3.

1

12

2

()

n

fxn

nn

⋅=

+

(3

)

Because the major subsystems and their data

sources in the power plant are scattered, people need

to integrate these heterogeneous data and then

establish a unified data warehouse. This requires

standardizing the processing of data and eliminating

the semantic differences between different systems to

ensure data consistency and comparability.

Sometimes the form of raw data may be difficult to

be directly used in data mining, so it is necessary to

make appropriate transformations to it. For example,

time series data can be discretized, and continuous

numerical variables can be discretized into

categorical variables, and derivative features can be

constructed to extract hidden information. As shown

in Equation 4.

1

12

2

()

n

f

yk

nn

≡⋅

+

(4

)

Based on the above data pre-processing process,

people can obtain a high-quality data set, which can

lay a solid foundation for subsequent association rule

mining. This process should be integrated with the

actual power plant and give full play to the

advantages of domain experts to ensure that the data

is highly representative and that the data mining

results are fully reliable.

3.2 Mining of Association Rules

First, the basic principle of the Apriori algorithm.

Apriori algorithm is an association rule mining

algorithm based on prior knowledge. The basic idea

is to first find the frequent itemset in the dataset, and

then use the frequent itemset to form specific

association rules. Based on the iterative method, the

algorithm is constantly reducing the size of its

candidate set, and finally finds the frequent itemset

INCOFT 2025 - International Conference on Futuristic Technology

448

and association rules that can satisfy the minimum

support and minimum confidence thresholds. The

algorithm process includes: first, scan the dataset and

count the support degree of each item, and then form

a candidate 1-item set. Secondly, pruning is

performed for the candidate K-itemset, and a new

candidate (k+1)-itemset is formed. As shown in

Equation 5.

1

1

2

()

m

mm

n

fxy

nn

−

−

≈

+

(5

)

Then, repeat. Then, until no new candidate set is

generated. Then, the support and confidence

calculation activities are carried out for the final

candidate set, and the itemset that satisfies the

threshold is determined as the frequent itemset.

Finally, the frequent item set is used to generate

association rules, and thirdly, the parameter design.

With the Apriori algorithm, the key is how to set the

required support and confidence thresholds. This is a

trade-off that needs to be made against the realities of

power plant production.

First, if the threshold of support is too high, some

valuable rules may be missed, and if it is too low,

there may be many useless rules. Second, if the

confidence threshold is too high, then the confidence

level of the rule will be high, but the coverage may be

small. If it's too low, it may contain a lot of rules that

are not very credible. As shown in Equation 6.

0

jΔ

lo e() g

mm

kn

f

xz

ε

′

=⋅

(6

)

Table 1: Test results

Data

sourc

es

Sam

pling

perio

d

Accu

racy

ratin

gs

Descri

ption

of

accura

c

y

Improv

ements

Gener

ation

SCA

DA

syste

m

real

time

A

No

anomali

es

Heat

loss

rate

Man

ual

entr

y

daily B-

Occasio

nal data

loss

Fuel

flow

sens

or

per

minu

te

A-

Slight

deviatio

ns

Based on this, it can be seen that people should do

a good job of repeated experiments to find out the

applicable threshold parameters and dig out the

correlation rules that are beneficial to the production

decisions of the power plant. Finally, the excavated

correlation rules should be analyzed and explained in

combination with the actual production of the power

plant, so as to discover the knowledge content and

laws contained therein. In conclusion, association

rule-based mining methods (such as the Apriori

algorithm) can play an important role in the mining

and analysis of power plant production data. The

focus is on the rational design of relevant parameters

and the in-depth interpretation of the mining results

in combination with domain knowledge.

3.3 Rule Evaluation and Screening

First, rule evaluation indicators. First of all, support.

It indicates how often a rule occurs in the entire

dataset, that is, the degree of co-occurrence of the

rule. If the support is relatively high, it means that the

rule is generally well represented. Second,

confidence. Confidence indicates how reliable the

rule itself is, that is, the probability that the outcome

will occur when the condition occurs. If the

Table 2: Test height and accuracy

Online

monito

ring

per

hour

A+

Highl

y

consi

stent

Keep

it up

Device

status

Fault

diagno

sis

system

real

time

C+

Freq

uent

false

alar

ms

Repair

records

Mainte

nance

logs

Ever

y

repa

ir

B

Som

e

recor

ds

are

missi

ng

Mainte

nance

costs

Financi

al

system

s

mon

thly

A

The

data

is

accur

ate

and

com

p

lete

Research on Power Plant Production Data Mining Technology Based on Association Rules

449

confidence level of a rule is high, it means that there

is a strong correlation between the condition and the

result. Then, the lift. The degree of lift indicates the

degree to which the rule is improved, that is, whether

the result is improved because of the occurrence of

the condition.

A lift greater than 1 indicates a positive

correlation between the condition and the result, a lift

less than 1 indicates a negative correlation, and a lift

equal to 1 indicates no relevance. Finally, coverage.

Coverage indicates the proportion of data samples

covered by the rule, that is, the comprehensive

coverage of the data by the rule. First, the degree of

support and the degree of confidence are filtered. Set

the appropriate support level and confidence

threshold, and eliminate the rules that do not meet the

support and confidence thresholds, so as to ensure the

quality of the rules. Secondly, the screening of lift.

According to the relevance of the lift evaluation rules,

the rules with a lift greater than 1 are retained, so as

to exclude irrelevant and negative correlation rules.

Then, the coverage is filtered. In this regard, it is

necessary to consider the coverage of the rules, and

retain the rules with a relatively high coverage, so that

the rules have higher universality and

representativeness. Finally, the combination of

domain knowledge is screened. Combined with the

professional knowledge in the field of power plant

production, and manually review and interpret the

excavated rules, the rules that are inconsistent with

the actual situation and have no guiding value are

eliminated, and thirdly, the rule evaluation and

selection process. First, calculate the support and

confidence levels corresponding to each rule. Then,

according to the set threshold, the preliminary

screening is done, and the rules that do not meet the

support and confidence standards are eliminated.

Then, evaluate the improvement and coverage of

those remaining rules, and combine domain

knowledge to do a good job of manual review.

Finally, high-quality rules are identified that

correspond to the requirements to support subsequent

plant production decisions. D. Rules are applied in

this link, and people should apply the screened high-

quality rules to the production decision-making and

equipment status monitoring of power plants, so as to

provide important support for the intelligent

management of power plants. In addition, it is

necessary to constantly monitor and update its rule

base, and to maintain the applicability and

effectiveness of the rules.

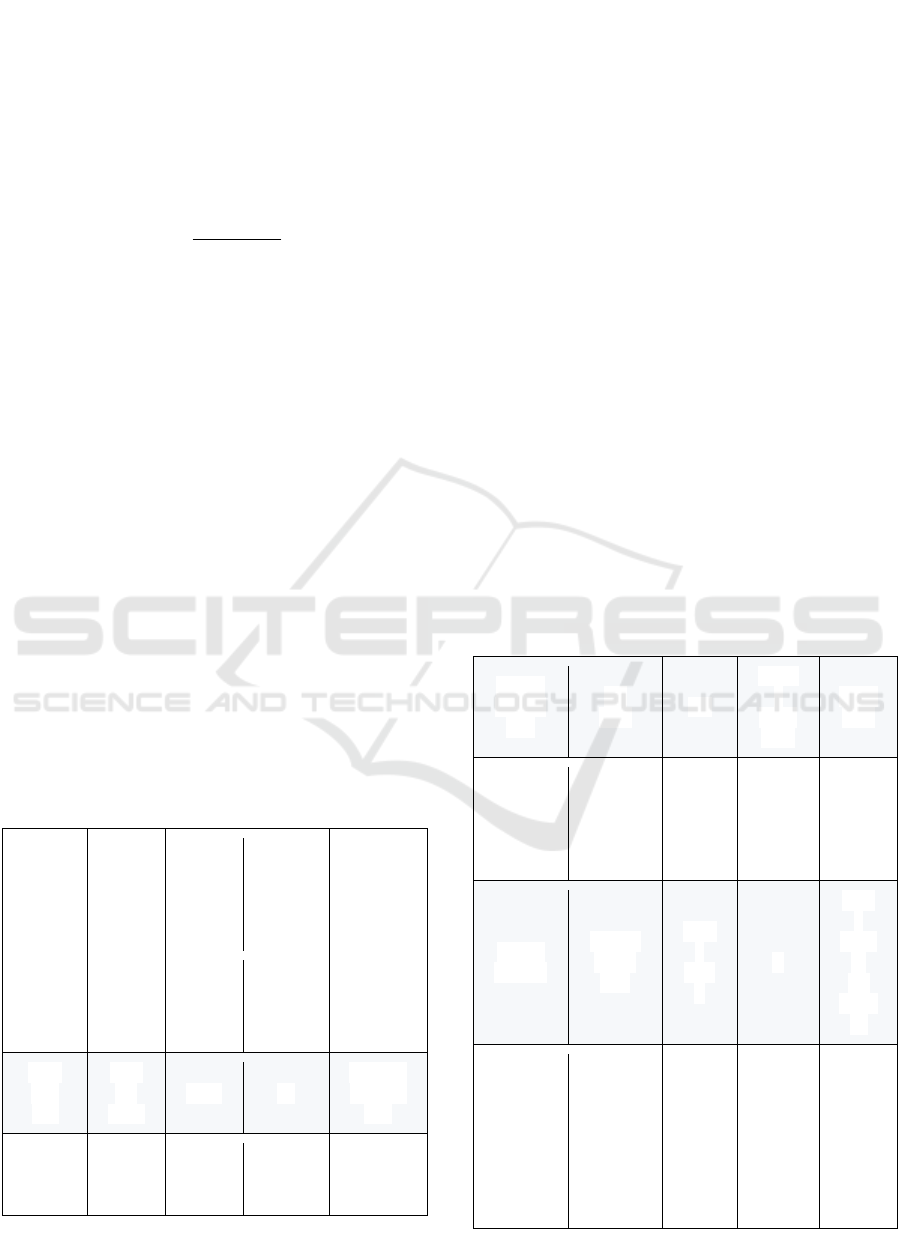

Figure 1: Data mining depth

Case background: A thermal power plant has

accumulated a lot of equipment operation data in its

daily production process, based on these data, through

the application of association rule mining technology,

to mine some valuable rules for it, and apply them to

the intelligent management of the power plant. First,

it should be used in the formulation of production

decisions in power plants. It can be found that there is

a clear correlation between some equipment

parameters and equipment parameters, such as the

boiler inlet temperature and the positive correlation

between the steam turbine speed and the generator

output.

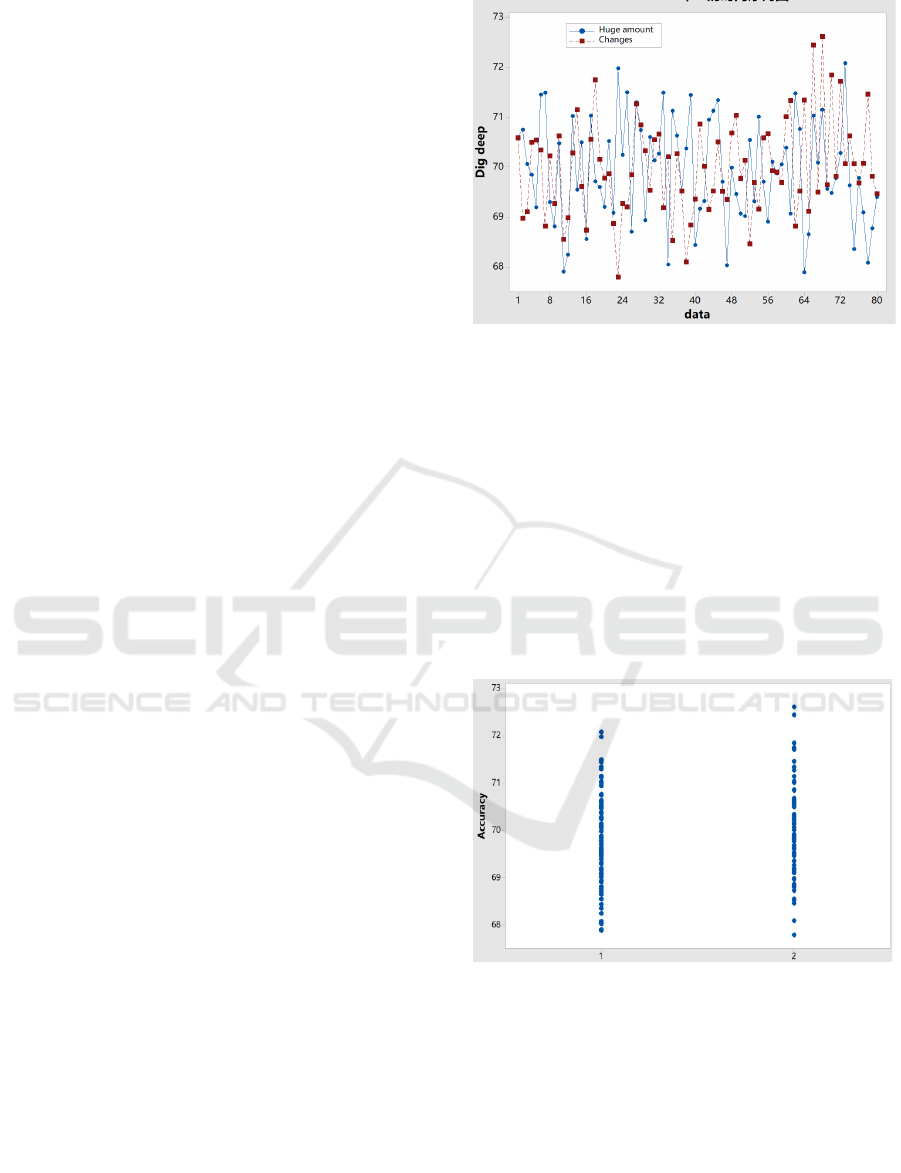

Figure 2: Accuracy of mining

The rule can be applied to the formulation of the

power plant production plan, and the electrical load

can be adjusted according to the parameters of the

real-time monitoring equipment, so as to improve the

operation efficiency and economy of the unit, and

secondly, it can be applied to the equipment condition

monitoring. Based on the data mining technology of

association rules, this paper finds that some devices

will find abnormal combinations of specific

parameters in an abnormal state. These rules are

INCOFT 2025 - International Conference on Futuristic Technology

450

directly applied to the real-time monitoring of power

plant equipment, and once some abnormal patterns

are detected, they can be warned in time, which can

provide an effective basis for the status diagnosis and

fault prevention of the equipment; In this paper, it is

found that some equipment failures are generally

accompanied by a certain parameter change pattern.

By integrating these fault diagnosis rules into the

power plant's professional intelligent diagnosis

system, if the system detects these specific fault

characteristics, it can quickly locate the cause of the

failure, which will provide strong support for the

decision-making of maintenance personnel.

4 CONCLUSIONS

Results Based on the research in this paper, it can be

seen that the power production data mining

technology based on association rules has the

following advantages:

First, discover the hidden value rules. In the

production process of the power plant, a large amount

of data content will be accumulated, and these data

generally have many different, valuable association

patterns and rules, and it is difficult to find these rules

through manual means, but the use of data mining

technology based on association rules can

automatically mine these hidden rules, so as to

provide strong support for the subsequent intelligent

management of the power plant; The key rules

excavated through this method can provide an

effective reference for the formulation of production

plans of power plants, the monitoring of equipment

status, and the diagnosis of faults. Implicit in these

rules is the intrinsic relationship between equipment

operation status and production indicators, which can

provide a scientific basis for further decision-making

by power plant managers, and improve the accuracy

and effectiveness of their decision-making. The

application of this technology is typical, and it can

make full use of the massive production data in the

power plant to mine valuable content for it. This

method is conducive to the enhancement of the data

application capability of power enterprises, and

promotes the production of power plants to move

from experience-driven to data-driven. The power

production data mining technology based on

association rules can maintain a certain degree of

dynamics, and its rules will be continuously updated

and optimized with the continuous change of the

power plant production environment. Based on

continuous monitoring and updating of the rule base,

the plant will be able to dynamically adjust its

production decisions, which will support the

improvement of its management flexibility and

adaptability, and fifthly, improve the level of

intelligent management of the plant. By applying the

excavated high-quality association rules to the

intelligent production management system of the

power plant, the real-time and effective monitoring of

equipment status, intelligent fault diagnosis, and

intelligent production plan optimization can be

achieved, which greatly improves the intelligent

management level of the power plant.

REFERENCES

Ben Ahmed, E. (2010, Sep 01-03). Incremental update of

cyclic association rules. Paper presented at the 11th

International Conference on Intelligent Data

Engineering and Automated Learning, Univ W

Scotland, Paisley, SCOTLAND.

Chen, X. H., Lai, B. C., & Luo, D. (2003). Mining

association rule efficiently based on data warehouse.

Journal of Central South University of Technology,

10(4), 375-380.

Han, J. C., & Ieee. (2006, Jul 16-21). Learning fuzzy

association rules and associative classification rules.

Paper presented at the IEEE International Conference

on Fuzzy Systems, Vancouver, CANADA.

Intan, R. (2006, Jun 20-22). Generating multidimensional

association rules implying fuzzy value. Paper presented

at the International Multiconference of Engineers and

Computer Scientists, Kowloon, PEOPLES R CHINA.

Kryszkiewicz, M. (1998). Representative association rules.

In X. D. Wu, R. Kotagiri & K. B. Korb (Eds.), Research

and development in knowledge discovery and data

mining (Vol. 1394, pp. 198-209).

Lee, K. M. (2001, Jul 25-28). Mining generalized fuzzy

quantitative association rules with fuzzy generalization

hierarchies. Paper presented at the 9th International-

Fuzzy-Systems-Association World Congress/20th

North-American-Fuzzy-Information-Processing-

Society, International Conference, Vancouver, Canada.

Tan, J. (2012, Sep 15-16). Different types of association

rules mining review. Paper presented at the

International Conference on Measurement,

Instrumentation and Automation (ICMIA 2012),

Guangzhou, PEOPLES R CHINA.

Yamada, S., Funayama, T., Yamamoto, Y., & Ieee. (2015,

Nov 18-20). Visualization of relations of stores by

using association rule mining. Paper presented at the

13th International Conference on ICT and Knowledge

Engineering, Bangkok, THAILAND.

Ye, F. Y., Liu, J. X., Qian, J., & Shi, Y. X. (2011, Sep 23-

25). Discovering association rules change from large

databases. Paper presented at the 3rd International

Conference on Artificial Intelligence and

Computational Intelligence (AICI 2011), Taiyuan,

PEOPLES R CHINA.

Research on Power Plant Production Data Mining Technology Based on Association Rules

451

Zhao, Q., & Zhang, S. (2007, Oct 19-21). Association rules

lattice and association rules compressed lattice. Paper

presented at the Conference on Systems Science,

Management Science and System Dynamics, Shanghai,

PEOPLES R CHINA.

INCOFT 2025 - International Conference on Futuristic Technology

452