Dynamic Performance Analysis and Optimization Design of Machine

Mechanism Based on Advanced Algorithms

Xiaona Cai

Guangdong University of Science and Technology, Dongguan City, Guangdong Province 523083, China

Keywords: Advanced Algorithms, Machine Mechanism, Indicators.

Abstract: In order to effectively operate the application mechanism system and reduce the application risk of dynamic

performance monitoring of machine mechanism, this study deeply explores the application characteristics of

the dynamic performance of machine mechanism, and uses advanced algorithmsCreate a dynamic

performance monitoring model of the machine mechanism. In this study, the operability of dynamic

performance monitoring of machine mechanism is indexed through the application of practical cases, and the

dynamic performance analysis and optimization design effect of machine mechanism are compared with

advanced algorithms, so as to clarify the effectiveness of advanced algorithms. Obviously, if the operation of

dynamic performance monitoring of some machine mechanisms can be reasonably applied, the development

loopholes of dynamic performance monitoring of machine mechanisms can be significantly reduced.

1 INTRODUCTION

In the dynamic performance analysis and

optimization design of the machine mechanism, the

application of the index system is mainly used to

realize the field form of the dynamic performance

monitoring of the machine mechanism with advanced

algorithms (Behroz, and Baseri, et al. 2024).

Combined with the traditional machine mechanism

requirements, a single operation and application

mode is adopted, which leads to a serious waste of

machine mechanism design resources (Chen, and

Chen, et al. 2023). The dynamic performance

monitoring system of machine mechanism has the

characteristics of fast operation and high index

efficiency, and at the same time, the advanced

algorithm also shows the advantages of sustainable

upgrading in the dynamic performance analysis and

optimization design of machine mechanism (Fan, and

Li, et al. 2024). Therefore, it has become an inevitable

trend in the development of modern machinery to

promote the optimization and upgrading of the field

of machine mechanism and vigorously promote the

operation of the dynamic performance monitoring

system of machine mechanism (Li, and Yang, et al.

2023).

2 RELATED WORKS

Nowadays, the field of machine mechanism started

relatively late, and in its development, it is restricted

by various factors such as dynamic performance

analysis and optimization design environment of

machine mechanism, resulting in its overall

technology upgrade and optimization progress is

relatively slow (Meng, and Hao, et al. 2024).

However, in recent years, with the support of national

policies, the development of the field of machinery

has once again ushered in new opportunities

(Nematov and Berdiev, et al. 2023). Up to now, many

studies on the application of machine mechanism

mainly focus on the dynamic performance monitoring

and evaluation of machine mechanism, the

application of indicators and the integration of

machine mechanism (Ran, and Song, et al. 2024). For

example, scholars have made scientific analysis and

accurate evaluation of the application of dynamic

performance monitoring of machine mechanisms

(Tabakovic and Zeljkovic, et al. 2024). Scholars have

conducted in-depth research on the impact of

dynamic performance monitoring, further discussed

the driving force of dynamic performance monitoring

of machine mechanisms, and also gave some specific

dynamic performance analysis and design schemes of

machine mechanisms.

Cai, X.

Dynamic Performance Analysis and Optimization Design of Machine Mechanism Based on Advanced Algorithms.

DOI: 10.5220/0013539900004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 1, pages 277-282

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

277

The team of scholars conducted an in-depth

discussion on the influencing factors in the

application process of dynamic performance analysis

and optimization design of machine mechanism in the

aspects of dynamic performance monitoring, fusion

and application of machine mechanism (Yamazaki,

and Seki, 2023). Scholars have deeply analyzed the

basic differences between the dynamic performance

monitoring of machine mechanisms and the

traditional model. From another point of view, the

research on the development of the field of machine

mechanism mainly focuses on the analysis of

development and the evaluation of development

influencing factors, for example, scholars analyze the

influencing factors of the dynamic performance

monitoring operation of machine mechanism from

the aspects of operation application and optimization

design (Zhu, and Zhao, et al. 2024). Scholars study

the influence of advanced algorithm technology on

the development of dynamic performance monitoring

of machine mechanism, so as to accurately analyze

the development of machine mechanism field.

In order to solve the problem of the operation and

development of the dynamic performance monitoring

application of the machine mechanism, this study

uses an advanced algorithm to solve the problem of

the dynamic performance monitoring model of the

machine mechanism, firstly uses the basic advanced

algorithm to analyze the constructed operation model,

and then on this basis, effectively improves the

application scope and depth of the advanced

algorithm to ensure the construction and application

effect of the dynamic performance monitoring system

of the machine mechanism.

Therefore, taking the application scheme of a

machine mechanism as an example, considering that

the problem handling mode of the advanced

algorithm is continuous, the specific operation

method is to arrange the dynamic performance

monitoring application links in ascending order, so as

to promote the follow-up task of dynamic

performance monitoring of the machine mechanism.

Therefore, this study needs to focus on the

development of dynamic performance monitoring of

machine mechanisms, and construct a mathematical

calculation model with the goal of dynamic

performance analysis and optimization design of

machine mechanisms, so as to ensure the accurate

calculation of the operation indicators of dynamic

performance monitoring of machine mechanisms, so

as to effectively promote the application and

operation development of machine mechanisms.

3 METHODS

3.1 Dynamic Performance Analysis

and Optimization Design Analysis

of Machine Mechanism

Combined with the actual dynamic performance

monitoring requirements of the machine mechanism,

it is necessary to construct the dynamic performance

analysis and optimization design model of the

machine mechanism to form a complete and

comprehensive dynamic performance monitoring

system, so as to clarify the dynamic performance

monitoring model of the machine mechanism as

shown in equation (1).

1

1

F

n

n

F

ϕϕ

=

=

(1

)

In equation (1), the 𝐹operation data representing

the dynamic performance analysis and optimization

design of the machine mechanism represent the

𝜑

control index of the dynamic performance

monitoring of the machine mechanism; The

1

F

n

n

ϕ

=

is completion time of the index representing

the dynamic performance analysis and optimization

design of the machine mechanism represents the basic

control index of the dynamic performance monitoring

of the machine mechanism, 𝜑 as shown in equation

(2).

1

1

j

L

jn

n

j

WV

C

=

=

(2

)

In equation (2), the

is index development and

total resources of the advanced algorithm are

represented. The 𝑉

is time limit of the standard index

representing the dynamic performance analysis and

optimization design of the machine mechanism, the

index index representing the dynamic performance

monitoring of the machine mechanism, and the

operating conditions of the dynamic performance

monitoring of the machine mechanism (3𝑊

𝐿

). are

shown in equation

𝑓

=𝐷

𝐶𝑜𝑛𝑣

𝐶

𝐵𝑅𝑏

(3

)

In the formula, the 𝐷

is index completion time

representing the dynamic performance analysis and

INCOFT 2025 - International Conference on Futuristic Technology

278

optimization design of the machine mechanism, 𝑣

is

the operation data representing the dynamic

performance monitoring of the machine mechanism,

the 𝐶

is index time representing the dynamic

performance analysis and optimization design of the

machine mechanism, and the 𝐵𝑅𝑏

operation

requirements for completing the dynamic

performance monitoring link of the machine

mechanism, as shown in equation (4).

𝑓

∈𝑅

×

=𝐺𝐴𝑃

𝑓

∈𝑅

×ℎ×

(4)

In the formula, 𝑅

×

represents the operating

deviation of the dynamic performance analysis and

optimization design of the machine mechanism,

the𝑓

is operation time of the dynamic performance

monitoring of the machine mechanism, and the

𝑅

×ℎ×

is comprehensive operation effect of the

dynamic performance analysis and optimization

design of the machine mechanism, as shown in

equation (5).

𝑓

=𝑤

⊗

𝑓

+𝑏

(5)

In the formula, 𝑤

represents the start time limit of

the dynamic performance analysis and optimization

design of the machine mechanism,𝑓

is the time

limit for the completion of the dynamic performance

monitoring of the machine mechanism, and𝑏

is the

time limit for the end of the dynamic performance

analysis and optimization design of the machine

mechanism.

3.2 Application Analysis Based on

Advanced Algorithms in Dynamic

Performance Analysis and

Optimization Design of Machine

Mechanism

Through the analysis of the operation and application

of the machine mechanism system, and then the index

operation based on the advanced algorithm, the

dynamic performance monitoring of the machine

mechanism with high technology can be obtained in

this study, and the comprehensive index model is

shown in equation (6).

𝑓

′

=𝜁

𝑇𝑌𝐶𝑜𝑛𝑣

𝑓

(6)

In the formula, 𝜁 represents the constraints of

dynamic performance analysis and optimization

design of the machine mechanism, the 𝑇is index time

of the dynamic performance monitoring of the

machine mechanism, the𝑣

application time index of

the dynamic performance monitoring of the machine

mechanism, the 𝐶𝑜𝑛𝑣

𝑓

is application

environmental conditions of the dynamic

performance monitoring of the machine mechanism,

and 𝑌 is the operation index of the dynamic

performance monitoring of the machine mechanism.

As shown in equation (7):

𝑚𝑖𝑛𝐹 =

𝑓

+

𝑓

+

𝑓

(7

)

In the formula, 𝑓

is the constraints of dynamic

performance analys and𝑓

is optimization design of

the machine mechanism are represented, the

application duration index of the dynamic

performance monitoring of the machine mechanism

is defined, the 𝑓

is application environmental

conditions of the dynamic performance monitoring of

the machine mechanism are represented, and

𝑚𝑖𝑛𝐹the operation data of the dynamic performance

monitoring of the machine mechanism is based on the

advanced algorithm, and the comprehensive model is

obtained as shown in equation (8). 。

𝑇

=

(8

)

In the formula, 𝑉 represents the operation

deviation of the dynamic performance analysis and

optimization design of the machine mechanism, the𝑐

is operation time on the dynamic performance

monitoring of the machine mechanism, the 𝑢

is

comprehensive operation effect of the dynamic

performance monitoring of the machine

mechanism,𝐶

is the operation time on the dynamic

performance monitoring of the machine mechanism,

and 𝑇

is the start time limit of the dynamic

performance monitoring of the machine mechanism.

In order to effectively improve the operation

efficiency of the dynamic performance monitoring of

the machine mechanism, the operation index of the

dynamic performance monitoring of the machine

mechanism is constructed.

4 RESULTS AND DISCUSSION

4.1 Case Study on the Kinetic

Performance of Machine

Mechanisms

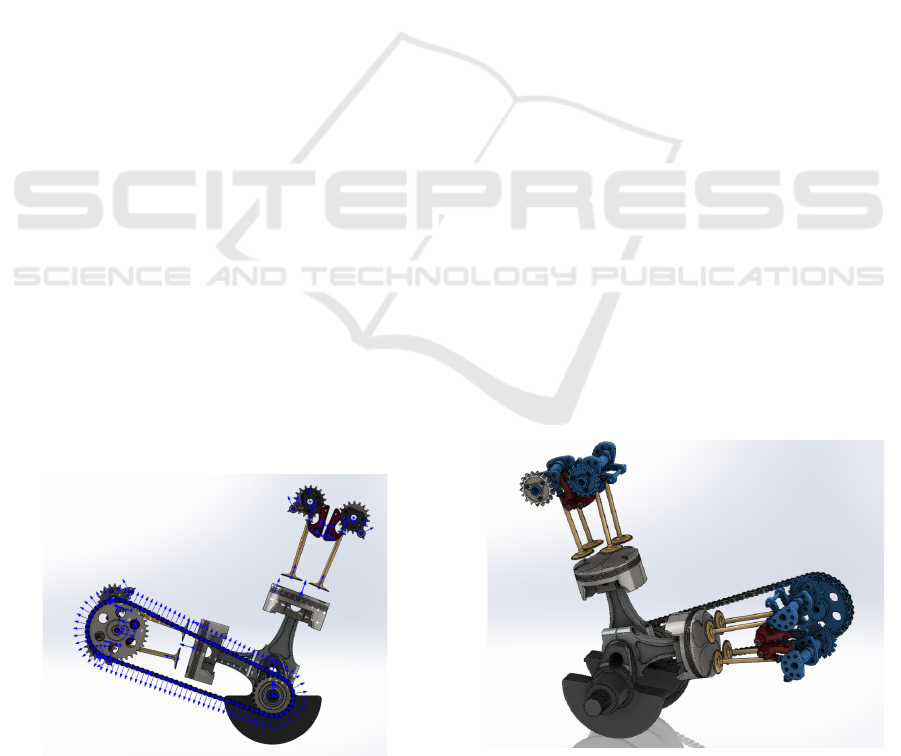

The performance of the mechanical kinetic energy

composition of the engine is analyzed as the research

Dynamic Performance Analysis and Optimization Design of Machine Mechanism Based on Advanced Algorithms

279

object, and the performance of the piston, combustion

chamber, and bearings of the engine is judged. The

friction coefficient, friction force, transmission force,

transmission shaft, and overall transmission structure

and transmission effect are comprehensively judged

and analyzed to improve the effectiveness of the

analysis results. The performance is continuously

tested for 30-40 times, and the average value of the

performance is analyzed and studied, including the

force distribution, transmission force and

transmission effect during the transmission process.

4.2 Advanced Algorithm Analysis of

Machine Performance

According to the dynamic performance analysis and

optimization design of the existing machine

mechanism, the operation direction of the machine

mechanism that needs to be used is further clarified,

and it can be seen that the development of dynamic

performance monitoring of machine mechanism is

relatively higher than that of the traditional model.

Although this method can effectively optimize the

resource allocation of the machine mechanism, the

operation data of the dynamic performance

monitoring part of the machine mechanism increases

more than the traditional index model, so that the

overall development of the machine mechanism field

has been at a high level, which seriously affects the

development of the dynamic performance monitoring

of the machine mechanism. In the development of

dynamic performance analysis and optimization

design of all machine mechanisms, this has an

important impact on the overall dynamic performance

monitoring operation data of machine mechanisms.

Therefore, the development of dynamic performance

monitoring and application of machine mechanism

will help reduce the occurrence of machine design

loopholes, as shown in Figure 1.

Fig 1: Application evaluation and analysis of dynamic

performance analysis and optimized design of machine

mechanism

According to Figure 1, the dynamic performance

analysis and optimization design of the machine

mechanism based on advanced algorithms are

relatively stable. Therefore, by improving the

dynamic performance analysis and optimization

design of the machine mechanism, the application

scheme and the upgrade process, this study can

gradually upgrade based on the dynamic performance

analysis and optimization design of the machine

mechanism, improve the efficiency of the use of

advanced algorithms, thereby reducing the

development risk of the advanced algorithms, and

finally achieve the overall goal of upgrading and

developing the dynamic performance monitoring of

the machine mechanism. Therefore, in this study, it is

necessary to appropriately upgrade the operation

process of applying dynamic performance monitoring

of machine mechanisms, so as to reduce the operation

loopholes of dynamic performance monitoring of

machine mechanisms.

4.3 Application Inspection and

Analysis Based on Advanced

Algorithms in the Dynamic

Performance Analysis and

Optimization Design of Machine

Mechanism

Based on the above analysis, it can be seen that this

study deeply explores the advantages of advanced

algorithms in dynamic performance analysis and

optimization design of machine mechanisms by

improving the advanced algorithms, and forms a flow

chart for improving the advanced algorithms

according to the application process of dynamic

performance monitoring of machine mechanisms, as

shown in Figure 2.

Figure 2: Comparison of the application conditions of

advanced algorithms in the dynamic performance analysis

and optimization design of machine mechanisms

INCOFT 2025 - International Conference on Futuristic Technology

280

As shown in Figure 3, this study combines the

dynamic performance analysis of the machine

mechanism and the operation development of the

optimization design to upgrade the application to

index the practical value and stable efficiency of the

advanced algorithm.

Figure 3: Analysis of the dynamic performance of the

machine mechanism and the application effect of the

optimized design

The application process of dynamic performance

monitoring of machine mechanism can be

summarized as the application and operation

development problem of advanced algorithm, and

then the corresponding dynamic performance

monitoring task processing of machine mechanism is

completed, and there is a clear processing sequence

between different links of dynamic performance

analysis and optimization design of machine

mechanism.

4.4 Summary of Analysis Results on

Positive Performance Dynamics

the time taken of each operation link of the dynamic

performance monitoring of the machine mechanism

is relatively different, which leads to the basic change

of the dynamic performance monitoring of the

machine mechanism, as shown in Table 1.

Table 1: Application inspection and analysis of dynamic

performance analysis and optimized design of machine

mechanism

Classification of

indicators for dynamic

performance

monitoring of machine

mechanisms

Apply inspection analysis

Advanced

algorithms

Controlled

analysis

I. Class Subsystem 311.253.26 216.523.65

II. Class of

subsystems

320.562.37 220.356.62

Class III. Subsystems 306.562.39 235.162.34

Based on the above data analysis, the dynamic

performance monitoring of the machine mechanism

has obvious operation index requirements in the

operation analysis based on the dynamic performance

analysis and optimization design of the machine

mechanism, as shown in Table 2.

Table 2: Dynamic performance analysis and optimization

design of machine mechanism operation index

requirements

Classification of

indicators for

dynamic performance

monitoring of

machine mechanisms

Operational metric

requirements

Advanced

algorithms

Controlled

analysis

Natural frequency 29.56 11.23

Damped response 30.57 12.35

modality 31.56 12.95

As can be seen from Table 2, based on the

operation requirements of dynamic performance

indicators such as natural frequency, damping

response, and modality, the effectiveness of the

advanced algorithm is the effectiveness of the

advanced algorithm, and the advanced algorithm is

now applied to the machine mechanism system.

According to the data analysis of relevant operating

indicators, through the application of advanced

algorithms, the application problems of dynamic

performance analysis and optimization design of

machine mechanism are effectively solved, and it is

concluded that the application of dynamic

performance monitoring of machine mechanism is

more practical, so the advanced algorithm has a

positive impact on the dynamic performance

monitoring of machine mechanism.

5 CONCLUSIONS

In summary, this study effectively promotes the

development of dynamic performance monitoring

and application of machine mechanism by upgrading

the dynamic performance analysis and optimization

design and application operation process of machine

mechanism. With the help of the development

structure of dynamic performance monitoring of

machine mechanism, this study builds a dynamic

performance monitoring model based on advanced

algorithms, and effectively realizes the operation goal

of dynamic performance monitoring of machine

mechanism with the support of advanced algorithms,

Dynamic Performance Analysis and Optimization Design of Machine Mechanism Based on Advanced Algorithms

281

and finally proves that the advanced algorithm has a

positive effect on machine mechanism.

ACKNOWLEDGEMENTS

Guangdong University of Science and Technology

Mechanical Design, Manufacturing and Automation

Course Ideological and Political Demonstration

Major. (GKZLGC2021248).

REFERENCES

Behroz, H., H. Baseri, and H. Nourmohammadi. (2024). A

Two-degree-of-freedom Tool-holder Mechanism for

Real-time Adjustment of Tool Angles in Turning

Process. International Journal of Engineering, 37(11),

2162-2170.

Chen, S., Z. T. Chen, C. H. Cui, C. R. Si, and H. Ye. (2023).

Hierarchical design, dimensional synthesis, and

prototype validation of a novel multi-spindle 5-axis

machine tool for blisk machining. International Journal

of Advanced Manufacturing Technology, 126(9-10),

4213-4224.

Fan, J. W., Z. Li, R. Pan, K. Sun, and S. L. Liu. (2024).

Mechanism analysis and accuracy prediction for

kinematic errors of machine tool. Journal of the

Brazilian Society of Mechanical Sciences and

Engineering, 46(7).

Li, J., G. D. Yang, and J. L. Liu. (2023). Quantitative

Analysis of Electromagnetic Torque Generation

Mechanism in Axial-Flux Permanent Magnet Machine

Based on the Air-Gap Field Modulation Theory.

Journal of Electrical Engineering & Technology, 19(1),

453-462.

Meng, Z., Z. C. Hao, Z. J. Sun, and C. K. Ming. (2024).

Kinematics analysis and optimization of the lower hook

mechanism in netting machine. Journal of Mechanical

Science and Technology, 38(5), 2563-2577.

Nematov, E., A. Berdiev, and P. Wang. (2023). Kinematic

Parameters of the Biplanetary Mechanism (Intermittent

Mixing Machines). Manufacturing Technology, 23(5),

685-690.

Ran, J. H., Z. P. Song, Q. Zhang, W. S. Guo, and X. F.

Wang. (2024). Design of a New Drip Irrigation Belt

Recovery Machine with Anti Breakage Function.

Agriculture-Basel, 14(3).

Tabakovic, S., M. Zeljkovic, S. Zivanovic, A. Budimir, Z.

Dimic, and A. Kosarac. (2024). Calibration of a Hybrid

Machine Tool from the Point of View of Positioning

Accuracy. Applied Sciences-Basel, 14(12).

Yamazaki, K., and Y. Seki. (2023). Zeroization of Cogging

Torque of Permanent Magnet Machines by Optimizing

Rotor Surface Shape: Comparison Between Surface

and Interior Types. Ieee Transactions on Magnetics,

59(5).

Zhu, F. T., X. K. Zhao, C. S. Wang, C. B. Li, C. Lu, and C.

Zhang. (2024). A data and mechanism hybrid driven

cutting parameter optimization method considering the

machine tool and coolant condition flexibility.

International Journal of Advanced Manufacturing

Technology, 133(3-4), 1349-1363.

INCOFT 2025 - International Conference on Futuristic Technology

282