Application of Electromechanical Automation Technology Based on

Computer Virtualization in Coal Mine

Lijun Sun

Yantai Vocational College , Yantai, Shandong, China

Keywords: Electromechanical Automation, Computer Virtualization, Automation System, Coal Mine Operation

Abstract: As we all know, the environment of coal mines is a complex time-varying environment that is intertwined

due to many factors such as human, environment and machinery, and the various data of each coal mine will

show heterogeneous, unstructured and multi-source characteristics. Furthermore, the underground

environment is often semi-closed, so many traditional coal mine technology cannot be effectively applied.

This paper studies the application of electromechanical automation technology based on computer

virtualization in coal mines. First, design the automation system, and introduce the virtualization technology

into the automation control system, and then conduct experimental testing on the designed system. The

experimental results show that the design of this article the status monitoring of the downhole by the system

is not much different from the actual situation, and the error is controlled within 20%.

1 INTRODUCTIONS

Coal is the main source of energy in our country.

Supporting our country's industrialization process

and supporting our country's national economy are

the foundation of social development (Wang and Shi,

et al. 2018). Although the country is also committed

to the development of new energy sources, there are

few results (Li and Sun, et al. 2020). In the absence

of cheaper and more environmentally friendly

alternative energy sources, coal will remain the main

energy source in our country for a long time to come

(Wang and Li, et al. 2018). In the process of coal

mining, the underground environment is complex and

various factors are interrelated. The basement is a

semi-enclosed environment (Liu and Wu, et al. 2020).

There are not many traditional technologies that can

be applied. Therefore, some researchers have

proposed to introduce modern technologies in coal

mining (Willand and Mccravy, et al. 2018).

Aiming at the application research of

electromechanical automation technology in coal

mines, some researchers took large-scale

electromechanical equipment in coal mines as the

research object, and design a set of scene simulation

of roaming system using virtual technology, and

realized the equipment virtualized assembly and

maintain, and apply virtual technology to the virtual

simulation of coal mining face (Li and Ji, et al. 2017).

Experiments have proved that the virtual system

improves equipment and maintenance efficiency

(Tizado and NúEz-Pérez, et al. 2016). There are also

researchers who use the principle of Voronoi diagram

in geometry to analyze the relationship between coal

mine tunnel nodes and Voronoi, and propose a new

method of node layout of coal mine tunnels (Craig, et

al, 2016). Without increasing network costs, the use

of virtual technology increases a large number of

virtual anchor nodes communicate with sensor nodes

through anchor nodes, and combined with range-free

DV-Hop algorithm, the location of roadways is

proposed (Roy and Gautam, et al, 2016). There are

also researchers who use the Internet of Things

technology to establish a coal mine dynamic

information platform, which can monitor and record

the underground equipment of the coal mine

production system and the location of the miners

(Adiansyah and Haque, et al, 2017).

This article researches the application of

electromechanical automation technology in coal

mines based on computer virtualization, and

summarizes the application research of

electromechanical automation technology in coal

mines on the basis of reference to relevant literature

materials (Strong, 2020). Then put forward the

application of virtualization technology to the coal

mine automation system, then design the coal mine

Sun, L.

Application of Electromechanical Automation Technology Based on Computer Virtualization in Coal Mine.

DOI: 10.5220/0013538900004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 1, pages 239-243

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

239

automation system, and test the designed system

through experiments, and draw relevant conclusions.

2 RESEARCH ON THE

APPLICATION OF

ELECTROMECHANICAL

AUTOMATION TECHNOLOGY

IN COAL MINES

2.1 Application of Electromechanical

Automation Technology in Coal

Mines

(1) Caving mining is a special coal mining

technology. Workface automation has the same

control functions and controls as general workflow

automation. Only in the coal placement part, the

control and return machine control are added. In

summary, the control of the carbon leveling surface

mainly includes the following procedures: coal

cutting control, front conveyor movement, coal

loading hydraulic support movement, coal loading

lowering and rear conveyor traction (Daniels and

Zipper, et al, 2016). Coal output consists of two parts:

coal shearer cutting coal and top coal caving. In order

to increase the rate of coal adoption and increase the

efficiency of coal mining face in caving coal, the

principle of maximum parallel operation of the coal

mining process has been improved, and the impact

time of the process on the coal processing process has

been minimized to ensure that the system and coal

mining equipment compatible with production

capacity.

(2) If various types of underground sensors (gas

concentration sensors, temperature sensors, wind

speed sensors, etc) can be used, multi-sensor data

fusion technology can be used before the occurrence

of dangerous gas accidents in coal mines to timely

and accurately detect different types of coal mine gas

accidents. Comprehensive monitoring, analysis and

analysis evaluation factor indicators (gas

concentration, temperature, wind speed, etc) and

early warning of possible gas disasters will be more

conducive to coal safety production and the

occurrence of disaster accidents. Therefore, the

establishment of a sound early warning system for

coal mine safety and the implementation of coal mine

gas environmental assessment and early warning are

of great significance for reducing the incidence of

coal mine accidents.

(3) The system performs overall comprehensive

control of the mine to achieve the best operation of

the entire mine. It not only involves each process, but

also involves the processing of production

management information. In the production process,

the system can automatically collect specific data,

which can be geology, work site or a large amount of

production condition information, which is processed

and analyzed by the computer in order to receive

decisions in time. Through the implementation of the

mine automation central control system, the social

prospects of the mining industry will be changed.

2.2 Introduction of Virtual Technology

Virtual technology is mainly used to show a model

that is the same as the real situation. Virtual

technology can be used to demonstrate the mining

process in the mining process of coal mines. Through

virtual mining demonstrations, the mining plan can be

better displayed and the mining scheduling more

effective.

2.3 PCL Control Algorithm for

Electromechanical Automation

2.3.1 Traditional Control Algorithm

Although the research of various intelligent control

algorithms by experts and researchers in the control

field has become more and more mature in recent

years, due to their application in actual production

control, due to the following reasons, they cannot

successfully get from the laboratory the stages are

separated various complications. At present, the most

widely used in the process control field is still the

simple PID control algorithm. The PID control rules

are shown in the following formula:(1)

)]()(

1

)([)( te

dt

d

d

Tte

i

T

te

p

Ktu +

+=

(1

)

In the formula: K p --- proportional coefficient;

Ti --- integral time constant; Td --- differential time

constant

2.3.2 PID Parameter Optimization Method

Based on Ant Colony Algorithm

2.3.2.1 Problem Description

Assume that the effective values of the three

parameters Kp, Ti and Td are all 5 bits. According to

experience, among the 5 significant figures of Kp,

INCOFT 2025 - International Conference on Futuristic Technology

240

there are 2 digits before the decimal point and 3 digits

after the decimal point; among the 5 significant digits

of Ti and Td, there are 1 digit before the decimal point

and 4 digits after the decimal point. Therefore, a set

of parameters (Kp, Ti, Td) corresponds to a sequence

of 15 digits.

2.3.2.2 Define the Objective Function

Reasonable selection of target operations can ensure

that the system runs well. The main performance

indicators of the system include stability, accuracy

and speed. In order to obtain better system control

results, we also consider the restrictions on the system

control amount, control error and increase time.

Therefore, use the following performance indicator

function (target function).As shown in the(2).

∞

=

++=

1

)(

2

2

)(

1

(

i

u

t

a

wiuwiewJ

(2

)

2.3.2.3 Build the Path.

This step is the main step of the entire ant colony

algorithm. First, assume that each artificial ant is at

the starting point 0; then each ant at (xi-1, yj') climbs

to the next node (xi, Yj), until each ant reaches (15,

yj) , we assume that the time for each ant to climb

from the previous node to the next node is equal to

the previous two nodes, and the distance between the

two points does not matter. In addition, each ant in

(xi-1, yj') enters according to The next node of the

random ratio rule (xi, yj)

2.3.2.4 Update of Pheromone

All ants start from the initial point, after 15 time units,

climb to the end and complete a cycle, the amount of

information on the node (xi, yj) will change

3 DESIGN OF COAL MINE

AUTOMATION SYSTEM

BASED ON VIRTUAL

TECHNOLOGY

3.1 The overall Structure of the System

Function

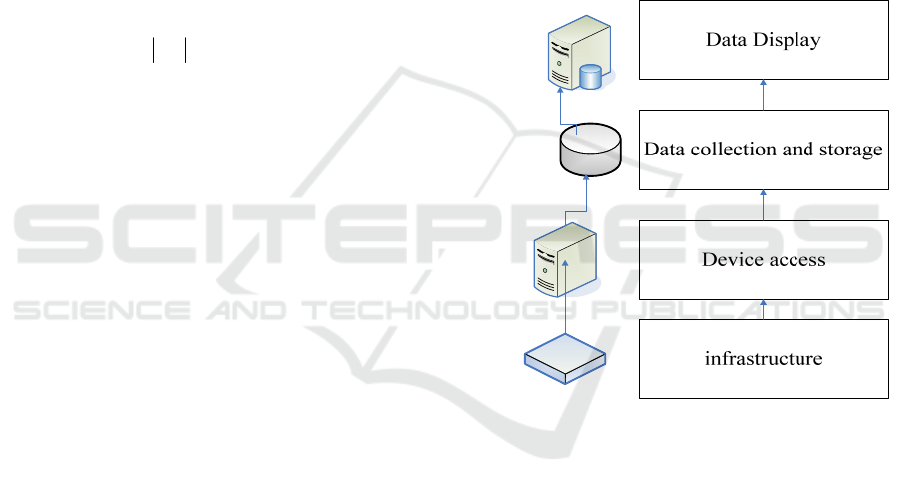

The built-in automation software system is a

complete data operation software that integrates data

communication, processing, acquisition, control,

setting, integrated intelligent judgment and graphic

display, as shown in Figure 1. According to different

environmental changes, timely processing and

normal system operation, it can adapt quickly and

efficiently, and play a real-time monitoring role. The

integrated automation system adopted this time is

easy to use and can be integrated monitoring and

management. At the same time, based on system

software upgrades, the system can maintain stable

and efficient operation through multiple links such as

technology, design, development, and maintenance to

meet the needs of current mine management and

development. Therefore, the overall structure of the

coal mine system includes data display, data

collection and storage, equipment access,

infrastructure, and users log in.

Figure 1: System function overall architecture

3.2 Data Display

This module is mainly for the display of some

equipment status data and virtualized on-site display.

The equipment status and downhole data are mainly

collected by sensors. In the virtualized site, it is made

according to the 1:1 ratio based on the camera

collection and modeling software, can be used to

demonstrate underground mining experiments.

3.3 Data Collection and Storage

3.3.1 Spindle Lifting System

In the process of completing the coal mining

automation system, the spindle lifting system is an

important production subsystem. The data must be

Application of Electromechanical Automation Technology Based on Computer Virtualization in Coal Mine

241

true, accurate and reliable. In the data collection

process, it is mainly the elevator speed and the

missing position. The elevator is in normal operation

or correction mode, and the operation mode is

monitored, such as start, stop, fault, etc. Finally, these

data are displayed on the operator's work interface

through the configuration interface.

3.3.2 System Modeling

The use of system template modeling can be quickly

developed through multiplexing. System modeling is

based on the variable table provided by the

underlying equipment supplier and rearranged in

accordance with the OPC communication standard

into monitoring points that comply with the OPC data

collection standard.

3.4 User Login

The system divides users into different work groups

according to the data requirements of different users.

Different working groups have different rights. The

server confirms that it is a legitimate user according

to the authentication and password entered by the

user, and then opens the relevant subsystem

according to its authority. In this way, it can prevent

illegal users from "invading" the system.

3.5 Device Access

3.5.1 Hardware Device Access

1) Server access method

For an automated system, it is relatively simple. It

does not have an Ethernet interface, but only has one

host. It can be added to the host in the Ethernet

communication card to physically connect to a nearby

switch.

2) PLC access method

For an automation system that uses a plc for

control, you can consider adding an Ethernet module

to the plc to connect it naturally with the switch.

3) Subnet access method

The automation system is very mature, has its own

network, integrates an external Ethernet interface,

and can be physically connected to the switch through

this RJ45 port.

3.5.2 Software Access

Since each automation system will be connected to

the built-in Gigabit Ethernet for automation, the next

job is to solve the data communication problem

through this software. Each enterprise's automation

system can choose to use the following four

communication modes: opc communication,

movement mode and development model, dde /

netdde mode and independent development model,

but it is best to use the opc communication mode, and

the original factory must provide it with opc interface.

4 SYSTEM DETECTION

4.1 System Testing Design

Since the system designed in this paper is a highly

comprehensive system, including field equipment

monitoring and communication structure layout, the

actual field test of the system is a bit large and

difficult to implement, so the test is only for one of

them. The experiment is to monitor the gas

concentration underground, and the experiment site is

in a well-known coal company in this city.

4.2 Analysis of Experimental Results

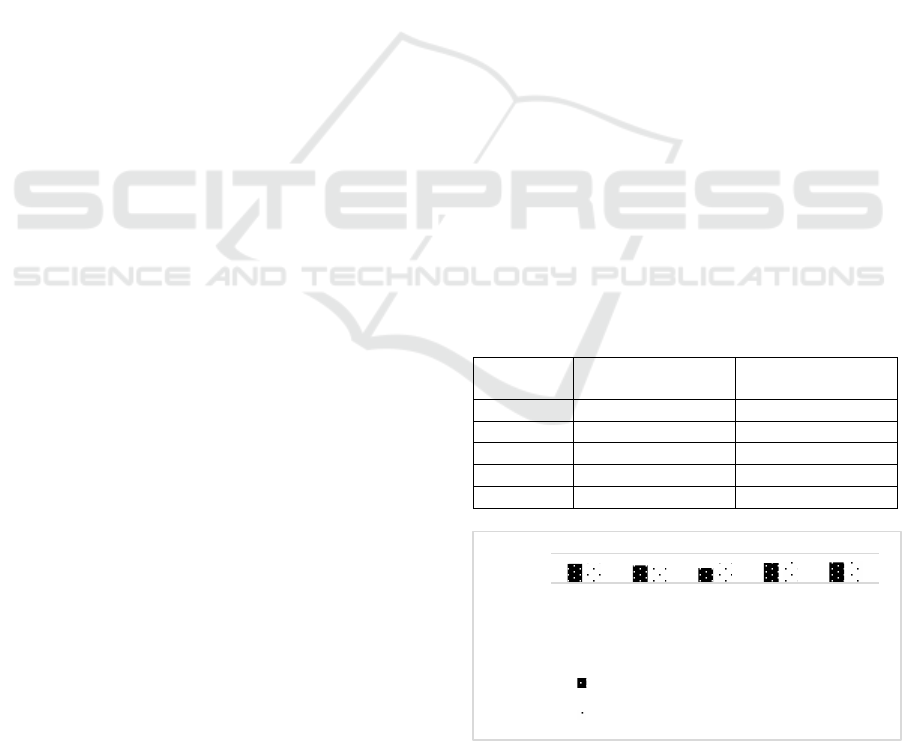

In this paper, the results of the downhole gas

concentration detected by the system are compared

with the actual gas concentration results, and the gas

concentration at 5 moments is randomly selected for

experiments to verify the accuracy of the system's

monitoring. The relevant data results are shown in

Table 1:

Table 1: Analysis of results

Actual gas

concentration

Monitoring gas

concentration

t1 0.65 0.643

t2 0.6 0.567

t3 0.5 0.67

t4 0.675 0.71

t5 0.7 0.74

Figure 2: Analysis of results

0

1

t1 t2 t3 t4 t5

concentration

time

Actual gas concentration

Monitoring gas concentration

INCOFT 2025 - International Conference on Futuristic Technology

242

It can be seen from Figure 2 that the coal mine gas

concentration monitored by the system is not much

different from the actual gas concentration. By

calculating the maximum error value of 0.17, it can

be seen that the monitoring accuracy of the system is

relatively high.

5 CONCLUSIONS

This paper aims at the application research of

electromechanical automation technology based on

computer virtual technology in coal mines. Through

the design of coal mine automation integrated control

system, and virtual technology modules are added to

the system, the automation system can better realize

the comprehensive control and dispatch of coal

mines. In the research process of this article, due to

the lack of literature on the introduction of virtual

technology into coal mine automation, the relevant

conclusions presented in this article may be biased.

REFERENCES

Wang F , Shi L , Fan W , et al. Application of

computational geometry in coal mine roadway 3D

localization[J]. The international arab journal of

information technology, 2018, 15(4):668-674.

Li M , Sun Z , Jiang Z , et al. A Virtual Reality Platform

for Safety Training in Coal Mines with AI and Cloud

Computing[J]. Discrete Dynamics in Nature and

Society, 2020, 2020(3):1-7.

Wang S , Li X . Bauxite orebody demarcating and virtual

mining for mining optimization within an underground

bauxite seam, Southwest China[J]. Environmental earth

sciences, 2018, 77(6):221.1-221.14.

Liu G , Wu C , He Z , et al. Data model for geological

spatiotemporal big data expression and storage

management[J]. Dizhi Keji Qingbao/Geological

Science and Technology Information, 2020, 39(1):164-

174.

Willand J E , Mccravy K W . Variation in diel activity of

ground beetles (Coleoptera: Carabidae) associated with

a soybean field and coal mine remnant[J]. Great Lakes

Entomologist, 2018, 39(3):141-148.

Li H , Ji H , Shi C , et al. Distribution of heavy metals and

metalloids in bulk and particle size fractions of soils

from coal-mine brownfield and implications on human

health[J]. Chemosphere, 2017, 172(APR.):505-515.

Tizado E J , E Nú?Ez-Pérez. Terrestrial Arthropods in the

Initial Restoration Stages of Anthracite Coal Mine

Spoil Heaps in Northwestern Spain: Potential

Usefulness of Higher Taxa as Restoration Indicators[J].

Land Degradation & Development, 2016, 27(4):1131-

1140.

P, Craig, S, et al. Investigations into the corrosive

environments contributing to premature failure of

Australian coal mine rock bolts - ScienceDirect[J].

International Journal of Mining Science and

Technology, 2016, 26(1):59-64.

Roy D , Gautam S , Singh P , et al. Carbonaceous species

and physicochemical characteristics of PM10 in coal

mine fire area—a case study[J]. Air Quality

Atmosphere & Health, 2016, 9(4):429-437.

Adiansyah J S , Haque N , Rosano M , et al. Application

of a life cycle assessment to compare environmental

performance in coal mine tailings management[J].

Journal of Environmental Management, 2017,

199(sep.1):181-191.

Strong, D. F . Rare Earth Elements and Yttrium (REY) in

coal mine drainage from the Illinois Basin, USA[J].

Canadian Journal of Earth ences, 2020, 21(7):775-780.

Daniels W L , Zipper C E , Orndorff Z W , et al. Predicting

total dissolved solids release from central Appalachian

coal mine spoils[J]. Environmental Pollution, 2016,

216(sep.):371-379.

Application of Electromechanical Automation Technology Based on Computer Virtualization in Coal Mine

243