Research on the Performance of Air Source Heat Pump Auxiliary

Heating Solar Drying System

Dong Huang and Qihang Zheng

Shantou Polytechnic, Shantou, Guangdong Province, 515041, China

Keywords: Energy-Saving Theory, Big Data Algorithms, Drying System, Solar Energy, Eco-Friendly.

Abstract: Solar drying system is an energy-saving and environmentally friendly drying system, but a single solar drying

system cannot solve the defect problem that is easily affected by climatic factors during drying operations,

and the evaluation is unreasonable. Therefore, this paper proposes a big data algorithm, combined with an air-

source heat pump to assist a solar drying system, and conducts innovative performance evaluation and analysis

of the system. First of all, the energy-saving theory is used to evaluate the drying operation, and the indicators

are divided according to the performance evaluation requirements to reduce the performance evaluation in the

interfering factor. Then, the performance evaluation of the innovative solar drying system is formed by the

energy-saving theory, and the performance evaluation results are carried out Comprehensive analysis.

MATLAB simulation shows that under the condition of certain evaluation criteria, the thermal performance,

drying energy efficiency and energy saving of the air-source heat pump assisted heating solar drying system

of big data algorithm are better than those of conventional drying system .

1 INTRODUCTION

Solar drying technology is an effective grain

preservation and drying technology (Bai, Jia, et al.

2023), which has the advantages of low cost, easy

installation and operation, and environmental

protection, and is widely used in rural and agricultural

production. However, traditional solar drying

systems have seasonal and weather limitations

(Ballerini, Di et al. 2023) in order to solve this

problem, this paper will discuss the design and

analysis of auxiliary heating solar drying systems

based on air source heat pump technology.

1.1 Basis of Air Source Heat Pump

Technology

Air source heat pump technology is a new type of

clean energy technology, the principle of which is to

generate high-grade heat through the low-grade heat

in the air (Bellos, Tsimpoukis, et al. 2023), which is

converted through the compression and expansion

process. Specifically, the air-source heat pump

system passes low-temperature air through an

evaporator to obtain low-grade heat; Then through the

compressor, the low-temperature, low-pressure

refrigerant is compressed into high-temperature,

high-pressure gas; The high-temperature gas is then

passed through the condenser to release high-grade

heat, and finally the refrigerant is returned to the

evaporator through the expansion valve to complete a

cycle (Buday, and Buday-Bodi, 2023).

Air-source heat pump technology offers a variety

of advantages, including high energy efficiency,

environmental protection, safety, and ease of

operation. At the same time, it is suitable for many

different application scenarios, including heating, air

conditioning, hot water, etc (Capone, Guelpa, et al.

2023).

1.2 Solar Drying System Design Based

on Air Source Heat Pump

1.2.1 System Structure

Based on air source heat pump technology, the

designed auxiliary heating solar drying system

includes the following main parts:

(1) Solar collector panel: Solar collector panel is

the core component of the solar drying system, and its

function is to convert solar energy into heat energy

and supply the drying system for use [(Chen, Li, et al.

2023).

188

Huang, D. and Zheng, Q.

Research on the Performance of Air Source Heat Pump Auxiliary Heating Solar Drying System.

DOI: 10.5220/0013538100004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 1, pages 188-193

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

(2) Air source heat pump system: The air source

heat pump system includes compressors, evaporators,

condensers, expansion valves and other main

components, which are converted into high-grade

heat through low-grade heat in the air to provide

auxiliary heating for the drying system (Cui, Geng, et

al. 2023).

(3) Thermal energy storage device: The thermal

energy storage device is used to store the heat energy

generated by the air source heat pump so that the

drying system can be used when needed (Duc, Kien,

et al. 2023).

(4) Fan and duct system: The fan and duct system

are used to circulate and transmit the air in the drying

system to ensure the normal operation and effect of

the drying system.

1.2.2 System Performance

The auxiliary heating solar drying system based on air

source heat pump has the following main properties:

(1) High energy efficiency: Air source heat pump

technology has the characteristics of high energy

efficiency, which provides auxiliary heating for the

drying system by converting low-grade heat in the air

into high-grade heat, and greatly improves the energy

efficiency of the system (Fan, Jiang, et al. 2023.

(2) All-weather: The auxiliary heating solar

drying system based on the air source heat pump has

all-weather and can operate under various climatic

conditions, regardless of the season and weather.

(3) Environmental protection: Air source heat

pump technology belongs to clean energy technology,

which has the characteristics of environmental

protection and will not cause pollution to the

environment (Fu, Shi, et al. 2023).

(4) Easy to operate: Air source heat pump

technology has the characteristics of simple operation

and easy maintenance, which can reduce the

operating cost and operation difficulty of the system

(Hasrat, Jensen, et al. 2023).

1.2.3 System Optimization

In order to further improve the performance and

effect of the auxiliary heating solar drying system

based on air source heat pump, the following

optimization measures can be taken:

(1) Optimize the system structure: The energy

efficiency and performance of the system can be

further improved by improving the material and

structure of the solar collector panel, improving the

compressor and refrigerant of the air source heat

pump system (Hou, Zheng, et al. 2023).

(2) Adjust system parameters: Parameters such as

temperature, humidity and air flow of the system can

be adjusted according to the characteristics of dry

materials and climatic conditions to better meet the

drying needs (Hou, Quan, Kim, 2023).

(3) Application of intelligent control technology:

through the application of intelligent control

technology, the system operation process can be

finely controlled and optimized, and the automation

degree and efficiency of the system can be improved

(Hou, Guo, et al. 2023).

The auxiliary heating solar drying system based

on air source heat pump technology has broad

application prospects and market demand, which can

meet the needs of drying technology in rural and

agricultural production fields. Through continuous

optimization and innovation, it is hoped that the

system can be more widely used and promoted, and

contribute to the construction of a resource-saving

society and sustainable development.

Conventional drying operations of heat sources

mainly based on coal and electricity have high energy

consumption and environmental pollution problems.

In order to reduce the energy consumption of drying

operations, clean and efficient drying technology and

equipment are sought. Based on this, some scholars

believe that the big data algorithm combined with the

air-source heat pump auxiliary heat supply is applied

to the analysis of solar drying system. It can

effectively analyze the performance evaluation

scheme and provide corresponding support for

performance evaluation. On this basis, this paper

proposes a big data algorithm to optimize the

performance evaluation scheme and verify the

effectiveness of the model.

2 RELATED CONCEPTS

2.1 Mathematical Description of Big

Data Algorithms

The big data algorithm uses data theory to

optimize the performance evaluation scheme is

i

x

,

and finds the unqualified values in the solar drying

system according to the index parameters in the

performance evaluation In order to and integrate the

performance evaluation scheme is

i

y

, the parameters

is finally judged to the feasibility of the solar drying

system is

() ()

ii

Tx Fd+ , and the calculation is

shown in Equation (1).

Research on the Performance of Air Source Heat Pump Auxiliary Heating Solar Drying System

189

1

() () (, )

n

ii ijii

i

Tx Fd x y

τ

=

+= +

(1)

Among them, the judgment of outliers is shown in

Equation (2).

() ()(1 )

i

x

p

xpxp

∈ℵ

=−

(2

)

Big data algorithms combine the advantages of

data theory and use solar drying systems for

quantification, which can improve the performance of

solar drying systems.

Suppose I. The performance evaluation

requirements is

i

x

, the performance evaluation

scheme is

F

, the satisfaction of the performance

evaluation scheme is

γ

, and the performance

evaluation scheme judgment function is

()

i

p

d ,As

shown in Equation (3).

()

ii

p

dxF

τ

γ

→

=

(3

)

2.2 Selection of Solar Drying System

Scheme

Hypothesis II The solar drying system function is

(, )

ii

Gx y ,and the weight coefficient is

i

d , then, the

performance evaluation requires an unqualified solar

drying system as shown in Equation (4).

1

(, )=w ()

n

ii i i

i

Gx y d u

τ

=

−

(4

)

Using assumptions, I and II, a comprehensive

function of system performance can be obtained, as

shown in Equation (5).

1

() (,) (,)

n

iii ijii

i

p

d Gxy xy

τ

=

+≤+

(5)

In order to improve the effectiveness of

performance evaluation, all data needs to be

standardized and the results are shown in Equation

(6).

() (,) ()(1 )

iii

x

p

dGxy px p

∈ℵ

+↔ −

(6

)

2.3 Analysis of Performance

Evaluation Schemes

Before the big data algorithm, the performance

evaluation scheme should be analyzed in multiple

dimensions, and the performance evaluation

requirements should be mapped to the solar drying

system data database, and the unqualified

performance evaluation scheme should be eliminated

is

()

i

TP y

, According to Equation (6), the anomaly

evaluation scheme can be proposed, and the results

are shown in Equation (7).

() (,)

()

()(1 )

iii

i

x

p

dGxy

TP y

p

xp

∈ℵ

+

=

−

(7

)

Among them, the parameter is to explain the

scheme is

() (,)

1

()(1 )

iii

x

pd Gx y

px p

∈ℵ

+

≤

−

,needs to be

proposed, otherwise the scheme needs to be

integrated The parameter is

()

i

Th x

, and the result is

shown in Equation (8).

() () (, )

iiii

Th x p d G x y=+

(8

)

The solar drying system conducts comprehensive

analysis and sets the threshold and index weight of

the performance evaluation scheme to ensure the

accuracy of the big data algorithm. Solar drying

system is a system test performance evaluation

scheme, which needs to be innovatively analyzed. If

the solar drying system is in a non-normal

distribution, its parameters is

()

i

unno j , its

performance evaluation scheme will be affected,

reducing the accuracy of the overall performance

evaluation , whose argument is

ax b

τ

+

, the

calculation result is shown in Equation (9).

INCOFT 2025 - International Conference on Futuristic Technology

190

min[ ( ) ( , )]

100%

() (,)

iii

iii

pd Gx y

ax b

pd Gx y

τ

+

+= ×

+

(9

)

The survey performance evaluation scheme

shows that the solar drying system scheme presents a

multi-dimensional distribution, which is in line with

the objective facts. The solar drying system is not

directional, indicating that the solar drying system

scheme has strong randomness, so it is regarded as a

high analytical study. If the stochastic function of the

solar drying system is

()

i

randon j , then the

calculation of equation (9) can be expressed as

formula (10).

min[ ( ) ( , )]

100% ( )

() (, )

iii

i

iii

pd Gx y

a x b randon j

pd Gx y

τ

+

+= × +

+

(10)

Among them, the solar drying system meets the

normal requirements, mainly because the data theory

adjusts the solar drying system, removes duplicate

and irrelevant schemes, and supplements the default

scheme, so that the dynamic correlation of the whole

performance evaluation scheme is strong.

3 OPTIMIZATION STRATEGY

OF AUXILIARY HEATING

SUPPLY OF AIR SOURCE HEAT

PUMP

The big data algorithm adopts the random

optimization strategy for the auxiliary heating supply

of the air source heat pump and adjusts the drying

operation parameters to realize the optimization of the

auxiliary heating supply of the air source heat pump.

The big data algorithm divides the auxiliary heat

supply of air source heat pump into different

performance evaluation levels, and randomly selects

different schemes. In the iterative process, the

performance evaluation schemes with different

performance evaluation levels are optimized and

analyzed. After the optimization analysis is

completed, the performance evaluation level of

different schemes is compared, and the optimal air

source heat pump auxiliary heating solar drying

system is recorded.

4 PRACTICAL CASE OF

AUXILIARY HEATING SUPPLY

OF AIR SOURCE HEAT PUMP

4.1 Performance Evaluation

Presentation

In order to facilitate performance evaluation, this

paper takes the air-source heat pump auxiliary heating

solar drying system under complex conditions as the

research object, with 12 paths and a test time of 12h,

and the performance evaluation of the specific solar

drying system The scheme is shown in Table 1.

Table 1: System Performance Evaluation Requirements

Scope of

application

grade Energy

saving

effect

Innovative

effect

Air collectors I 90.82 89.00

II 89.63 89.90

Centrifugal

fan

I 90.02 90.75

II 91.24 91.60

Air volume

regulating

valve

I 88.84 89.53

II 89.94 89.15

The performance evaluation process in Table 1 is

shown in Figure 1.

Solar collector

Centrifugal

fan

Drying chamber

Air-cooled

condenser

Main engine of air

heat source pump

Centrifugal

fan

Figure 1: Analysis process of auxiliary heat supply by air

source heat pump

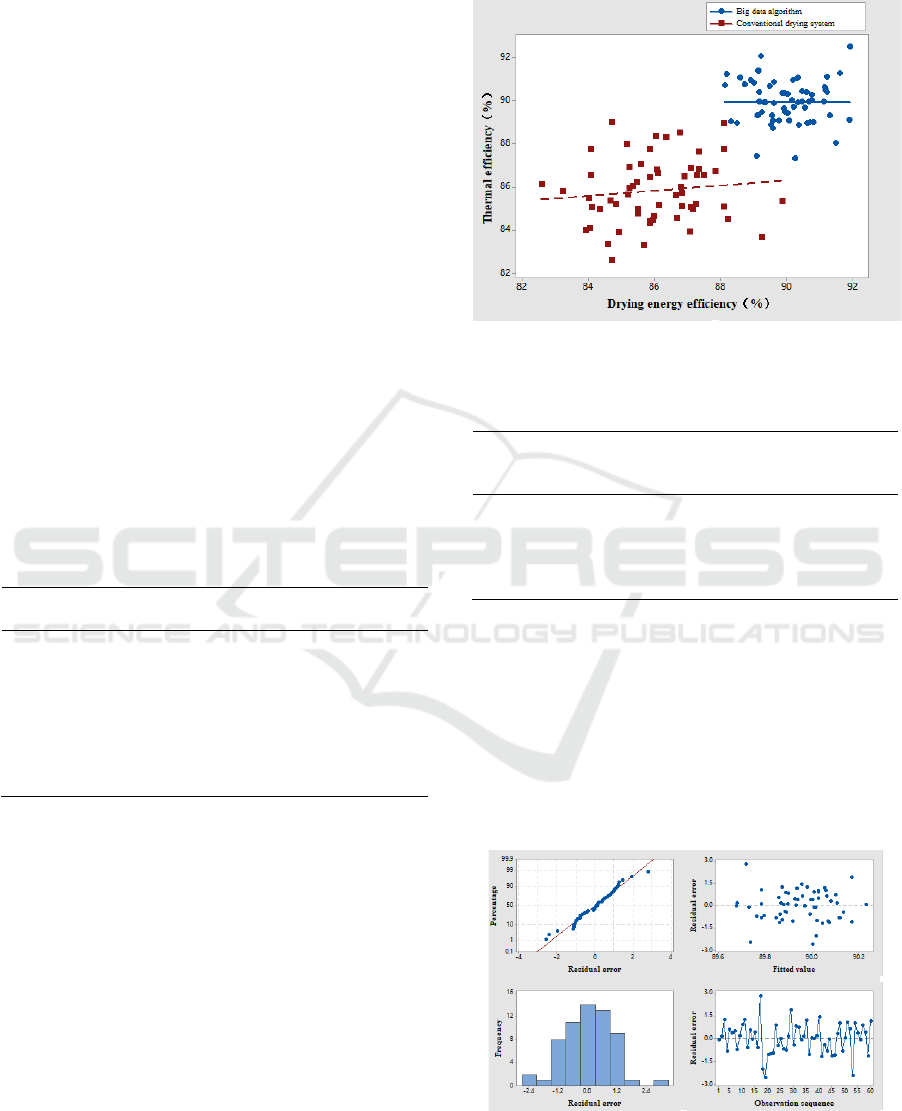

Compared with conventional drying systems, the

performance evaluation scheme of big data algorithm

is closer to the actual performance evaluation

requirements. In terms of the rationality and

fluctuation range of the air-source heat pump

auxiliary heating solar drying system, the big data

algorithm is better than the conventional drying

system. Through the change of performance

evaluation scheme in Figure 2, it can be seen that the

Research on the Performance of Air Source Heat Pump Auxiliary Heating Solar Drying System

191

stability of the big data algorithm is better, and the

energy-saving effect is better. Therefore, the

performance evaluation scheme of big data algorithm

has better thermal performance, drying energy

efficiency, energy-saving effect, and summation

stability.

4.2 Auxiliary Heating Situation of Air

Source Heat Pump

The performance evaluation scheme of auxiliary

heating of air source heat pump includes non-

structural information, semi-structural information

and structural information. After the pre-selection of

big data algorithm, a preliminary performance

evaluation scheme of auxiliary heating supply of air

source heat pump is obtained, and the auxiliary

heating of air source heat pump is obtained the

feasibility of the performance evaluation scheme is

analyzed. In order to more accurately verify the

innovative effect of the air-source heat pump

auxiliary heating solar drying system, the solar drying

system with different performance evaluation levels

was selected, and the performance evaluation scheme

is shown in Table 2 shown.

Table 2: The overall situation of the solar drying system

solution

Category Drying energy

efficienc

y

Analysis rate

Solar hot air

subs

y

stem

89.92 90.67

Air source heat

p

um

p

subs

y

ste

m

88.93 88.49

Drying roo

m

89.08 89.57

mean 90.39 90.58

X

6

38.62 37.59

P=3.98

4.3 Energy Saving and Stability of

solar Drying System for

Performance Evaluation

In order to verify the accuracy of the big data

algorithm, the performance evaluation scheme is

compared with the conventional drying system, and

the performance evaluation scheme is shown in

Figure 2.

It can be seen from Figure 2 that the solar drying

system of the big data algorithm is higher than that of

the conventional drying system, but the error rate is

lower, indicating that the performance evaluation of

the big data algorithm is relatively stable the

performance evaluation of conventional drying

systems is uneven. The average performance

evaluation scheme of the above two methods is

shown in Table 3.

Figure 2: Solar drying systems of different methods

Table 3: Comparison of performance evaluation accuracy

of different methods

Algorithm Solar

drying

s

y

stem

Magnitude

of change

Error

Big data

algorithms

88.97 90.68 1.69

Conventional

drying syste

m

82.79 86.94 4.15

P 37.06 38.26 36.73

By Table 3, it can be seen that the conventional

drying system has deficiencies in thermal efficiency

and drying temperature in terms of drying energy

efficiency, and the drying system has undergone

significant changes. High error rate. The general

result of the big data algorithm is higher for solar

drying systems, which are better than conventional

drying systems. At the same time, the solar drying

system of the big data algorithm is greater than 88%,

and the accuracy has not changed significantly. In

Figure 3: Solar drying system for performance evaluation

of big data algorithm

INCOFT 2025 - International Conference on Futuristic Technology

192

order to further verify the superiority and

effectiveness of the big data algorithm, the general

analysis of the big data algorithm is carried out by

different methods, Figure 3 shown.

By Figure 3, it can be seen that the solar drying

system of the big data algorithm is significantly better

than the conventional drying system, and the reason

is that the big data algorithm combines the air source

heat pump to assist the heating and set up the drying

operation thresholds to reject non-compliant

performance evaluation schemes.

5 CONCLUSIONS

Aiming at the problem that a single solar drying

system is not ideal; this paper proposes a big data

algorithm and optimizes the solar drying system by

combining the auxiliary heat supply of air source heat

pump. At the same time, the performance evaluation

innovation and threshold innovation are analyzed in

depth to construct the drying operation set. The

research shows that compared with the traditional

drying system, the air source heat pump auxiliary

heating solar drying system with big data algorithm

has the advantages of energy saving and

environmental protection and has the characteristics

of high thermal efficiency and low drying

temperature.

ACKNOWLEDGEMENTS

This paper was supported by Shantou Polytechnic and

the project of The Optimization Design of Roller

Dryer Assisted with Solar Heating.2018 Guangdong

Provincial College Youth Innovative Talents Project

"Optimization Design of Solar Energy Auxiliary

Heating to Drum Dryer"

REFERENCES

Bai, J., Jia, Y. F., Cui, S. Q., Zhang, C., Feng, S. W., Xu,

C., & Fan, H. F.(2023) EXPERIMENTAL STUDY ON

HIGH TEMPERATURE HEAT PUMP SYSTEM

WITH A DOUBLE HEAT SOURCE CASCADE.

Thermal Science, 27(3A): 1845-1853.

Ballerini, V., di Schio, E. R., Valdiserri, P., Naldi, C., &

Dongellini, M.(2023) A Long-Term Dynamic Analysis

of Heat Pumps Coupled to Ground Heated by Solar

Collectors. Applied Sciences-Basel, 13(13).

Bellos, E., Tsimpoukis, D., Lykas, P., Kitsopoulou, A.,

Korres, D. N., Vrachopoulos, M. G., & Tzivanidis,

C.(2023) Investigation of a High-Temperature Heat

Pump for Heating Purposes. Applied Sciences-Basel,

13(4).

Buday, T., & Buday-Bodi, E.(2023) Reduction in CO2

Emissions with Bivalent Heat Pump Systems. Energies,

16(7).

Capone, M., Guelpa, E., & Verda, V.(2023) Optimal

Installation of Heat Pumps in Large District Heating

Networks. Energies, 16(3).

Chen, X. Y., Li, Z. Q., Dai, L. K., Zeng, W. M., & Liu,

M.(2023) Occupant Heating Patterns of Low-

Temperature Air-to-Air Heat Pumps in Rural Areas

during Different Heating Periods. Buildings, 13(3).

Cui, S. Q., Geng, S. W., Bai, J., Zhang, Y., Guan, S. Z., &

Yang, H. F.(2023) HIGH TEMPERATURE

CASCADE HEAT PUMP SYSTEM WITH DOUBLE

MEDIUM AND LOW TEMPERATURE HEAT

SOURCES. Thermal Science, 27(3A): 1835-1843.

Duc, L., Kien, P. V., Tan, N. T., Son, D. T., Nguyen, N. V.,

& Nguyen, N. X.(2023) HEAT AND MASS

TRANSFER IN DRYING OF CARROT BY RADIO

FREQUENCY ASSISTED HEAT PUMP DRYING.

Frontiers in Heat and Mass Transfer, 20.

Fan, Y., Jiang, L., Zhang, X., Xu, X., & Frazzica, A.(2023)

Heat pump assisted open three-phase sorption thermal

battery for efficient heat storage. Energy Conversion

and Management, 277.

Fu, H. L., Shi, J., Yuan, J. Q., Zhang, X. Y., & Sun,

L.(2023) Heat recovery scheme design and

thermodynamic analysis of closed-cycle heat pump

drying system. Energy Conversion and Management,

286.

Hasrat, I. R., Jensen, P. G., Larsen, K. G., & Srba, J.(2023)

A toolchain for domestic heat-pump control using

UPPAAL STRATEGO. Science of Computer

Programming, 230.

Hou, B. Z., Zheng, Y. H., Xing, L. Y., & Song, Q. L.(2023)

Performance of a thermoelectric heat pump with

recirculation and regenerative heat recovery. Applied

Thermal Engineering, 223.

Hou, L. S., Quan, Z. H., Du, B. Y., & Zhao, Y. H.(2023)

Performance of a novel dual-heat-source heat pump

system. Applied Thermal Engineering, 230.

Hou, S. J., Guo, J. X., Yu, Z. C., Zhang, L. Y., & Sun, J.

F.(2023) Optimization of biomass energy coupled

multi-source heat pumps cooperative heating system: A

case study. Energy Sources Part a-Recovery Utilization

and Environmental Effects, 45(3): 8153-8166.

Research on the Performance of Air Source Heat Pump Auxiliary Heating Solar Drying System

193