Research on Optimization of Cold Chain Logistics Network of Fresh

Agricultural Products Based on Genetic Algorithm

Xudong Xing, Huihui Li, Hui Yao, Na Liu and Chen Du

Shandong Institute of Commerce and Technology, Jinan, Shandong, China

Keywords: Natural Evolution Theory, Genetic Algorithm, Logistics Network Optimization Problems, Cold Chain,

Logistics, Fresh Produce.

Abstract: The problem of logistics network optimization plays an important role in the cold chain logistics network of

fresh agricultural products, but there is the problem of inaccurate optimization positioning. The traditional

particle swarm algorithm cannot solve the network optimization problem in the cold chain logistics network

of fresh agricultural products, and the effect is not satisfactory. In today's globalized trade, the circulation of

fresh agricultural products is no longer limited to the local market. As consumer demand for fresh, healthy

food increases, it becomes even more important to ensure the freshness and safety of these products during

transportation. As an important means to ensure food quality, the optimization of cold chain logistics is of

great significance to reduce energy consumption, reduce costs and improve customer satisfaction. The

purpose of this paper is to explore how to use advanced genetic algorithm (GA) to optimize the cold chain

logistics network of fresh agricultural products, in order to achieve a win-win situation of logistics efficiency

and economic benefits.

1 INTRODUCTION

Genetic algorithm is a search heuristic that simulates

the principles of natural selection and genetics, which

solves optimization problems by simulating the

process of biological evolution in nature (Shen,

2023). In the optimization of the cold chain logistics

network for fresh agricultural products, we are faced

with a series of complex decision variables, such as

the location of the warehouse, the choice of

transportation routes (Lin, 2021), and the strategy of

goods distribution. Genetic algorithms continuously

evolve to obtain approximate optimal solutions by

randomly generating initial populations (solution

sets) and then generating new generation populations

through selection (replication), crossover

(recombination), and mutation (random change)

operations (Wang, 2021).

2 RELATED CONCEPTS

2.1 Mathematical Description of the

Genetic Algorithm

Specific to the optimization of cold chain logistics

network, genetic algorithm can be applied to the

following aspects: Route optimization: use GA to

determine the shortest or most economical

distribution route, reducing transit time and costs

while maintaining product freshness (Cao and Wang,

2021);

1

lim( ) max( 2)

2

iij ij ij

x

yt y t

→∞

⋅= ≥ ÷

(1

)

Among them, the judgment of outliers is shown in

Equation (2).

2

max( ) ( 2 ) ( 4)

ij ij ij ij

tttmeant=Γ + ⋅ +

M

(2

)

Xing, X., Li, H., Yao, H., Liu, N. and Du, C.

Research on Optimization of Cold Chain Logistics Network of Fresh Agricultural Products Based on Genetic Algorithm.

DOI: 10.5220/0013537600004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 1, pages 171-176

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

171

Vehicle scheduling: use GA for vehicle

scheduling, reasonably arrange the use of

transportation vehicles, reduce the empty driving rate

and improve transportation efficiency (Zeng and

Wang, et al. 2021).

The strength of the genetic algorithm lies in its

flexibility and global search capabilities. It is not

limited by the size of the problem and can handle

nonlinear, multi-objective, and high-dimensional

optimization problems (Zhang Nan, 2023). In a cold

chain logistics network for fresh produce, this means

that we are able to consider multiple objectives at the

same time, such as minimising costs, maximizing

customer satisfaction and minimising environmental

impact (Pan and Li, et al. 2023).

() 2 7

ii i

Fd t y

ξ

=Ο ⋅ → ⋅

(3)

2.2 Selection of Logistics Network

Optimization Problem Scheme

There are still some challenges in the application of

genetic algorithms in practice, such as parameter

setting, determination of algorithm termination

conditions, and stability of the solution process.

()= ( )

ii i i

dy

gt x z Fd w

dx

⋅−Ε

∏

(4)

Based on assumptions I and II, the comprehensive

function of the logistics network optimization

problem can be obtained, and the result is shown in

Equation (5).

lim ( ) ( ) max( )

ii ij

x

gt Fd t

→∞

+≤

(5)

Inventory management: Optimize inventory

levels through GA, reduce the risk of over-storage or

stock-outs, and ensure the efficient operation of the

supply chain (Jia and Sun, 2022); Facility layout: GA

is applied to determine the optimal location of

warehouses and distribution centers, as well as how

they are connected to each other, thereby improving

the efficiency of the entire logistics network;.

() ( ) ( 4)

ii ij

gt Fd mean t+↔ +

(6

)

2.3 Analysis of Logistics Network

Optimization Problem Scheme

However, in order to realize the potential of genetic

algorithms, we need precise mathematical models to

describe the behavior of cold chain logistics systems

(Wei and Zhang, 2023). This includes understanding

every step of the product from field to fork: post-

harvest handling, refrigerated storage, temperature

control during transit, distribution center operations,

final retail display, etc (Qi and Tai, 2021). In addition,

a large amount of data needs to be collected for

algorithm analysis, such as shipping time, cost,

temperature change, product loss rate, etc.

()

() ( )

!

()

(4)!!

ii

i

ij

gt Fd

n

No t

mean t r n r

+

=

+−

(7

)

The choice of parameters such as crossover rate

and mutation rate will directly affect the performance

of the algorithm, and the termination condition should

ensure that the algorithm can find a good solution and

avoid unnecessary computational waste (Zhan and

Zhang, 2022). Stability is about the consistency of the

results produced by the algorithm in different runs.

() [ () ( )]

iii

Z

ht gt F d=+

(8

)

In summary, genetic algorithms provide a

powerful tool for solving complex problems of cold

chain logistics network optimization of fresh

agricultural products. By simulating biological

evolution, it is able to find an effective approximate

optimal solution in a large solution space (Li and Wu,

2021). Although detailed modeling, accurate data,

and appropriate parameter setting are required in the

application, the potential of genetic algorithms is

huge, and it is worthy of further exploration and

application in the industry (Chen and Li, et al. 2022).

With the improvement of computing power and the

advancement of intelligent algorithms, we can expect

that genetic algorithms will help us find more

economical, green and efficient solutions in the field

of fresh agricultural product logistics in the future.

min[ ( ) ( )]

()

() ( )

ii

i

ii

gt Fd

accur t

gt Fd

+

=Λ

+

(9

)

Consumers are paying more and more attention to

the quality of fresh agricultural products, and cold

INCOFT 2025 - International Conference on Futuristic Technology

172

chain logistics to ensure the freshness of food from

the field to the table is particularly important.

Algorithmic optimization plays a pivotal role in this

process, not only to improve logistics efficiency, but

also to ensure the freshness and safety of agricultural

products. In this article, we will take a closer look at

how algorithmic optimization can improve the

performance of cold chain logistics and analyze its

indispensable value in the modern fresh produce

supply chain.

min[ ( ) ( )]

()

() ( )

ii

i

ii

gt Fd

accur t

gt Fd

+

=Φ

+

(10)

First and foremost, it is crucial to understand the

core of cold chain logistics. Cold chain logistics refers

to a service system that continuously provides a low-

temperature environment in the whole process of

production, storage, transportation, sales and

consumption. In the case of fresh produce, this

process must be temperature-controlled to prevent

food spoilage and bacterial growth. Therefore,

precise temperature control and real-time monitoring

are essential.

3 OPTIMIZATION STRATEGY

FOR LOGISTICS NETWORK

OPTIMIZATION PROBLEMS

Algorithmic optimization plays an important role

here. By collecting data from each node of

agricultural products from the origin to the consumer,

a comprehensive logistics information network can

be built. In this network, advanced algorithms, such

as machine learning and artificial intelligence, can be

used to optimize the configuration of logistics routes,

transportation methods, and storage conditions.

These algorithms can predict traffic conditions, avoid

congested road sections, calculate optimal loading

scenarios to reduce transportation costs, and even

adjust transportation plans to harsh weather

conditions based on weather forecasts.

3.1 Introduction to Logistics Network

Optimization Issues

In addition to route and transportation optimization,

algorithms can also automate inventory management

without sacrificing food safety. For example, by

monitoring the condition of agricultural products in

real time and predicting their shelf life, the system can

notify retailers in time to reduce losses and prevent

expired products, allowing for accurate inventory

allocation and renewal.

Table 1: Logistics network optimization problem

requirements

Scope of

application

Grade Accura

cy

Logistics

network

optimization

issues

Cargo flow

time

I 85.00 78.86

II 81.97 78.45

Cargo I 83.81 81.31

II 83.34 78.19

Sustainable

development

I 79.56 81.99

II 79.10 80.11

The logistics network optimization problem

process in Table 1 is shown in Figure 1,

Logistics

network

Analysis

Fresh agricultural

products

Genetic

algorithm

Cold chain

Natural

evolution

Logistics

Figure 1: The analysis process of logistics network

optimization problems

In practical applications, algorithm optimization

has achieved remarkable results. Taking a large

supermarket chain as an example, the company has

realized real-time monitoring and management of the

temperature of the whole chain of agricultural

products by deploying an advanced cold chain

monitoring system and intelligent algorithms. The

results are impressive: a significant reduction in

attrition rates and a significant increase in customer

satisfaction, all thanks to algorithms' accurate

interpretation of data and immediate responses.

3.2 Logistics Network Optimization

Problems

Of course, to fully realize the potential of algorithm

optimization in cold chain logistics, all parties in the

industry need to work together. From farms to

Research on Optimization of Cold Chain Logistics Network of Fresh Agricultural Products Based on Genetic Algorithm

173

wholesalers to retailers, every step of the way requires

contributing data, sharing information, and

leveraging algorithmic tools to make quick decisions.

At the same time, technological progress and

innovation are also key drivers driving the

development of this field.

Table 2: Overall picture of the logistics network

optimization problem scenario

Category Random

data

Reliability Analysis

rate

Cargo flow

time

85.32 85.90 83.95

Car

g

o 86.36 82.51 84.29

Sustainable

develo

p

ment

84.16 84.92 83.68

Mean 86.84 84.85 84.40

X6 83.04 86.03 84.32

P=1.249

3.3 Logistics Network Optimization

Problems and Stability

With the continuous advancement of technology,

algorithms have quietly become an indispensable part

of our daily life and work.

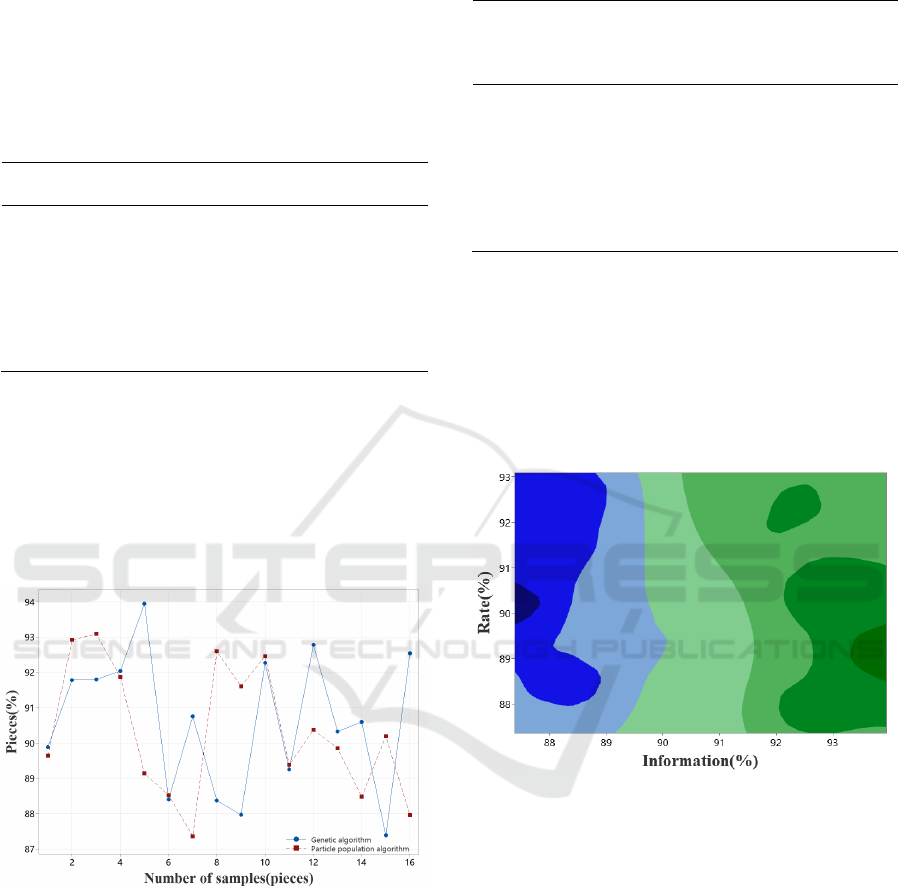

Figure 2: Logistics network optimization problem with

different algorithms

Sum up, algorithm optimization has brought

revolutionary changes to cold chain logistics. It not

only improves logistics efficiency and reduces

operating costs, but also ensures the high quality and

safety of food. In the future, with the continuous

development and innovation of technology, algorithm

optimization will continue to play a key role in the

cold chain logistics of fresh agricultural products,

bringing more efficient, reliable and intelligent

solutions to global food supply chain management.

Table 3: Comparison of accuracy of logistics network

optimization problems of different methods

Algorith

m

Surve

y data

Logistics

network

optimizatio

n issues

Magnitud

e of

change

Error

Genetic

algorith

m

85.33 85.15 82.88 84.9

5

Particle

swarm

arithmeti

c

85.20 83.41 86.01 85.7

5

P 87.17 87.62 84.48 86.9

7

Especially in the field of cold chain logistics of

agricultural products, algorithm optimization not only

improves efficiency, but also ensures the safety and

quality of food. This article will deeply analyze the

key role of algorithm optimization in the cold chain

logistics of agricultural products, and discuss its

future development direction.

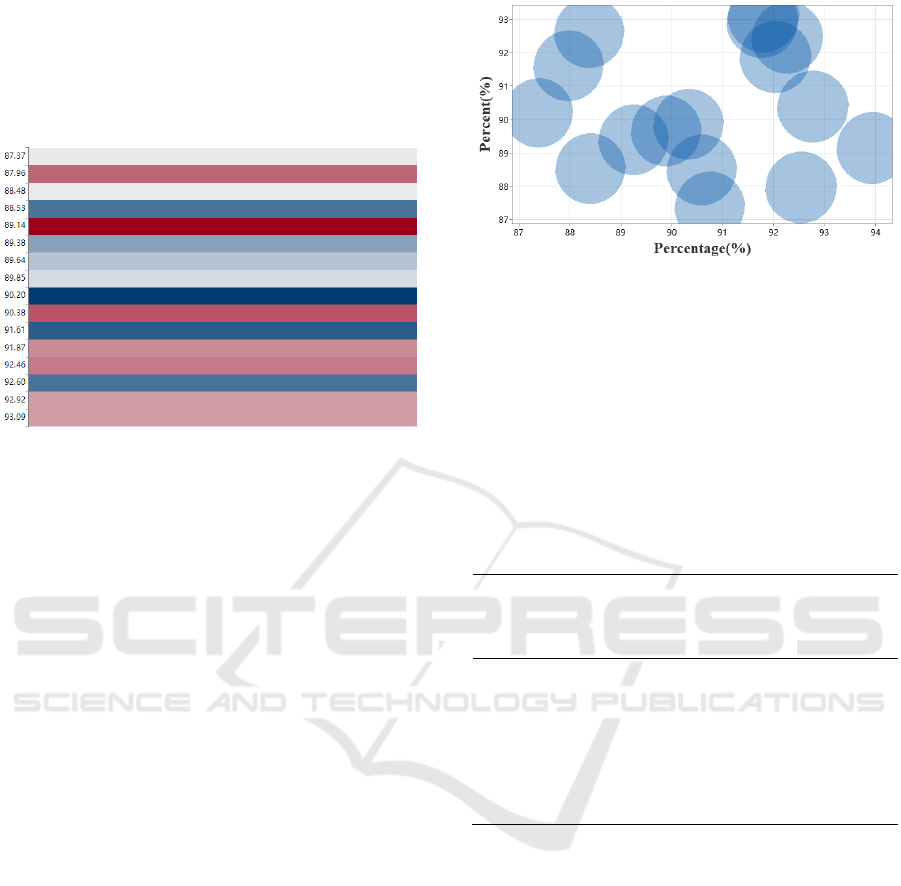

Figure 3: Logistics network optimization problem of

genetic algorithm

First of all, we must understand what "cold chain

logistics" is. To put it simply, cold chain logistics

refers to the temperature-controlled transportation

and storage of temperature-sensitive products such as

fresh agricultural products and frozen foods

throughout the supply chain. This process is essential

to ensure food safety and reduce wastage. However,

traditional cold chain logistics management often has

problems such as information lag and low efficiency.

Algorithm optimization technology is the key to

solving these problems.

INCOFT 2025 - International Conference on Futuristic Technology

174

3.4 Rationality of Logistics Network

Optimization Problems

The role of algorithm optimization in the cold chain

logistics of agricultural products is mainly reflected

in the following aspects.

Figure 4: Logistics network optimization problem with

different algorithms

Route optimization: By analyzing the optimal

distribution route through algorithms, transportation

time can be reduced, energy consumption can be

reduced, and the freshness of agricultural products

can be ensured. This is especially important for

geographically dispersed farms and markets.

Inventory management: Algorithms can predict

market demand based on historical data, helping

enterprises to plan inventory reasonably, avoid excess

or shortage, and reduce waste. Real-time monitoring:

Intelligent algorithms combined with Internet of

Things (IoT) technology can monitor the temperature

and humidity of agricultural products in real time, and

adjust environmental conditions in time to ensure

product quality.

3.5 Effectiveness of Logistics Network

Optimization Problems

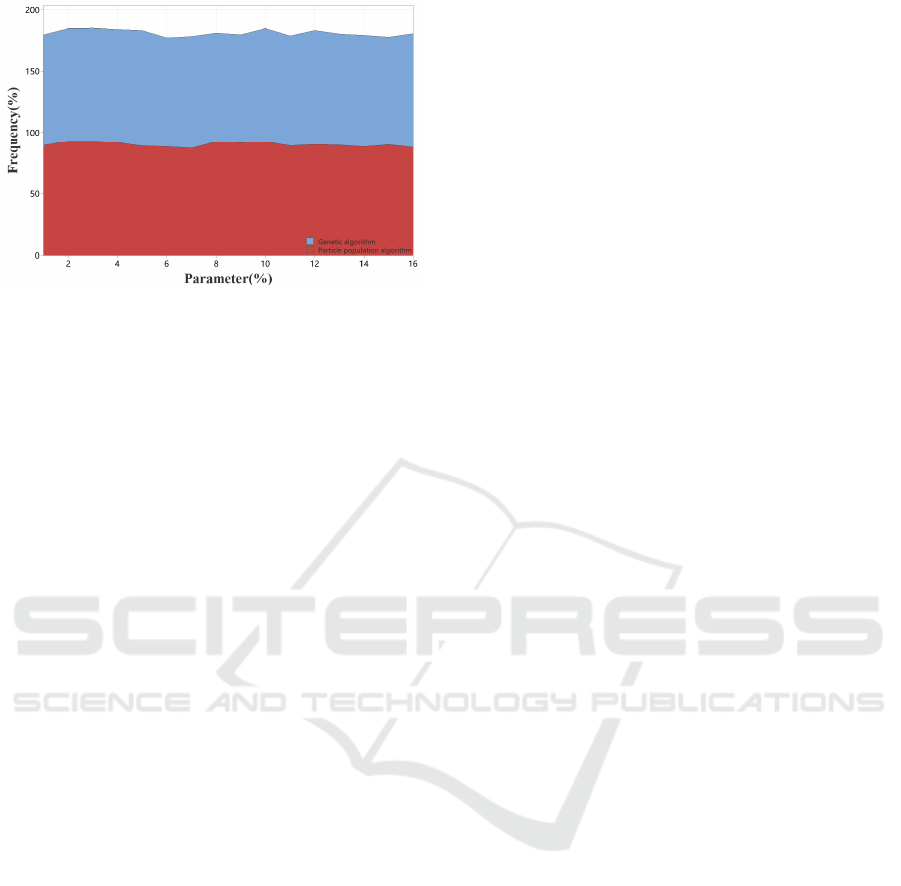

In order to verify the effectiveness of the genetic

algorithm, the logistics network optimization

problem scheme is comprised with the particle swarm

algorithm, and the logistics network optimization

problem scheme is shown in Figure 5 shown.

Figure 5: Logistics network optimization problems with

different algorithms

Risk management: Using big data analysis and

prediction algorithms, potential risk factors, such as

weather changes, traffic delays, etc., can be assessed

and coping strategies can be formulated. Cost

savings: By optimizing transportation, storage and

other links, algorithms can help enterprises

effectively control costs and improve profit margins.

Table 4: Comparison of the effectiveness of logistics

network optimization problems of different methods

Algorith

m

Surve

y data

Logistics

network

optimizatio

n issues

Magnitud

e of

change

Error

Genetic

al

g

orith

m

82.21 85.92 84.59 82.8

5

Particle

swarm

arithmeti

c

83.73 84.23 84.41 83.5

5

P 84.20 87.39 84.76 83.9

0

For example, an agricultural products company

introduced a machine learning-based forecasting

model that accurately predicted seasonal demand

fluctuations and achieved precise control of inventory,

thereby significantly reducing wastage while

maintaining high customer satisfaction.

Research on Optimization of Cold Chain Logistics Network of Fresh Agricultural Products Based on Genetic Algorithm

175

Figure 6: Genetic algorithm logistics network optimization

problem

In the future, with the continuous development of

artificial intelligence and big data technology, the

application of algorithm optimization in the cold

chain logistics of agricultural products will be more

extensive. For example, deep learning technology can

further improve the accuracy of predictive models,

blockchain technology can enhance the transparency

and traceability of supply chains, and drones and

autonomous vehicles can be combined to achieve

more efficient logistics and distribution.

4 CONCLUSIONS

In short, algorithm optimization has become a force

to be reckoned with in the field of cold chain logistics

of agricultural products. It not only improves logistics

efficiency and ensures food safety, but also brings

considerable economic benefits to enterprises. With

the continuous advancement of technology, the cold

chain logistics of agricultural products will become

more intelligent and automated in the future, bringing

consumers higher quality food enjoyment.

In this data-driven era, mastering algorithm

optimization technology is equivalent to mastering

the future of the industry. Therefore, whether it is the

government, enterprises or scientific research

institutions, they should increase investment to

promote the in-depth research and extensive

application of algorithm optimization technology in

the cold chain logistics of agricultural products. Only

in this way can we find the perfect balance between

food safety and supply chain efficiency to create

greater value for society.

REFERENCES

Shen Jiaming. (2023). Research on intelligent scheduling

mode of fresh agricultural products cold chain logistics

in high-speed service isas under digitalization. Jiangsu

Business Review(1), 35-39.

Lin Diansheng. (2021). Research on optimization of low-

carbon cold chain logistics network for fresh

agricultural products. (Doctoral dissertation, South

China University of Technology).

Wang Hong. (2021). Research on the development

problems of fresh agricultural products cold chain

logistics in Henan Province based on SWOT analysis.

Journal of Hebei Softwis Vocational and Technical

College, 23(2), 4.

Cao Wenbin, Wang Ting. (2021). Research on optimization

of fresh cold chain distribution path considering

freshness constraint. Logistics Technology, 44(7), 7.

Zeng Mingang, Wang Xiuhui, Li Jianyu. (2021). Research

on cold chain logistics network planning considering

node interruption and carbon emissions. Journal of

South China University of Technology: Social Sciences

Edition, 23(4), 12.

Zhang Nan. (2023). Multi-objective optimization method

for location selection of cold chain logistics distribution

sharing wishouse under low-carbon constraint.

Automation and Instrumentation.

Pan Weiqiang, Li Beihua, Lu Yiqin, Qin Jiancheng, Wang

Meng, Wang Haihan. (2023). A multi-objective

optimization scheduling method for hybrid

transmission in time-sensitive networks.

CN116389289A.

Jia Xin, Sun Tongtong. (2022). Research hotspots and

frontier evolution of cold chain logistics based on

scientific knowledge graph. Science and Technology

and Industry, 22(9), 26-34.

Wei Ziqiu, Zhang Xin. (2023). Optimization of cold chain

distribution path considering soft time window.

Logistics Technology, 42(1), 69-73.

Qi Yuxuan, Tai Qiuyue. (2021). Research on demand

forecasting of fresh agricultural products cold chain

logistics based on grey neural network. Commercial

Modernization(16), 3.

Zhan Chenlin, Zhang Yanfu. (2022). Optimization research

on individual business farmer's market cold chain

logistics under green concept. Value Engineering,

41(21), 56-59.

Li Kang, Wu Daqing. (2021). Research on evolution and

integrated optimization of fresh agricultural products

cold chain logistics system. Lixin Accounting Press.

Chen Xinying, Li Yilin, Xiao Siyi. (2022). Optimization of

fresh agricultural products logistics distribution path

based on improved genetic algorithm. Journal of Dalian

Jiaotong University, 43(5), 97-102.

INCOFT 2025 - International Conference on Futuristic Technology

176