Research on Location Perception of Fault Points in Railway Tunnel

Operation Inspection Based on Beidou Positioning Fusion UWB

Ruiqiang Shao

Shuohuang Railway Development Co., Ltd. Original Ping Branch, Hebei, 062350, China

Keywords: UWB Technology, Beidou Positioning, Fusion, Railway Tunnel Operation and Maintenance Fault Points,

Location Awareness.

Abstract: The purpose of this paper is to research and develop a fault point location perception system for railway tunnel

operation and inspection based on Beidou positioning fusion UWB, and ensure that the system has the

characteristics of high precision and strong robustness, and can provide real-time monitoring and early

warning functions, so as to solve the problem of difficult fault point location in railway speed transportation

inspection. Firstly, this paper designs a system architecture of Beidou positioning fusion UWB. Then, select

and integrate the relevant hardware devices, and carry out system testing and optimization. Based on the

optimization of system configuration and algorithm, the system shows obvious performance advantages in

many aspects in the test. The results of this paper show that the average positioning accuracy of the optimized

system is 0.6 meters, which is 33% higher than the original. In addition, the problem of signal loss has been

eliminated. In terms of real-time warning response time, it was shortened to 0.5 seconds, and the improvement

rate reached 37.5%. In addition, the detection time of the system from the railway speed to the location of the

fault point of the operation inspection is only 9 minutes, which is 40% shorter than the original design, and

can quickly identify and respond to faults. Based on this, it can be seen that the system can maintain efficient

operation in complex railway tunnels and improve the reliability and safety of railway operation and

inspection.

1 INTRODUCTION

As a key component of railway transportation, it is

difficult to achieve fast and effective operation and

maintenance inspection due to the complex

environment and difficult positioning of railway

tunnels (Badran, Rizk, et al. 2024), (Cui, Yang, et al.

2023). Traditional manual O&M methods have the

problem of poor accuracy in the face of complex

environments and other practical factors (Guo,

Huang, et al. 2023), (Liu, Kang, et al. 2024), and

have great security risks. This paper proposes an

efficient, accurate and reliable fault point location

perception system for railway tunnel operation and

maintenance, which is of great practical significance.

The system integrates BDS and UWB technologies,

which can effectively solve the problem of fault point

location perception in railway tunnel operation and

maintenance inspection. The research method in this

paper is to design the architecture of the system and

integrate Beidou and UWB positioning technologies

to better ensure the efficient operation of the system.

Then, the hardware selection and integration are

carried out. For example, select Beidou and UWB

equipment with high precision, and then realize

system integration. This is followed by system testing

and validation, i.e. a comprehensive test in the

laboratory and an evaluation of the system's

performance. Subsequently, the performance of the

system was optimized in many aspects. After

optimization, the positioning accuracy of the system

has been improved from the original average of 0.9

meters to the subsequent 0.6 meters, an improvement

rate of 33%. At the same time, it also improves the

real-time warning response time by 37.5%, and

finally only needs 0.5 seconds to respond quickly.

Based on this, it can be seen that the system

developed in this research can operate efficiently in

the complex railway tunnel inspection environment,

which can provide certain technical support for the

safety guarantee of related operation and inspection

work.

164

Shao, R.

Research on Location Perception of Fault Points in Railway Tunnel Operation Inspection Based on Beidou Positioning Fusion UWB.

DOI: 10.5220/0013537500004664

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Futuristic Technology (INCOFT 2025) - Volume 1, pages 164-170

ISBN: 978-989-758-763-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

2 RELATED WORKS

2.1 Application of Beidou Navigation

System (BDS).

The abbreviation of the Beidou Navigation System is

BDS (Badran, Rizk, et al. 2024), which is a set of

global satellite navigation systems independently

developed by China (Luo, Shang, et al. 2024), (Lv,

Yuan, et al. 2024). At present, it has been widely used

in many fields. In recent years, BDS has been well

used in transportation. Studies have shown that it can

be well used in railway transportation positioning,

navigation and timing services, and greatly improve

its traffic safety and operational efficiency.

2.2 The Development of UWB

Technology

UWB technology is characterized by high accuracy,

low power consumption, and good penetration. These

characteristics make it a great advantage in short-

distance positioning. UWB technology has been

maturely applied in many fields, such as indoor

positioning and robot navigation, industrial

monitoring, etc. (Qiao, Yin, et al. 2023), (Sun, Chen,

et al. 2023). Relevant studies have shown that UWB

technology can achieve high positioning accuracy at

the centimeter level, which can provide the possibility

for further high-precision positioning in various

complex environments such as railway tunnels.

2.3 Beidou and UWB Fusion

Positioning Technology

In recent years, the integration of multiple positioning

technologies to improve the positioning accuracy and

robustness in complex environment positioning has

become a new research hotspot. By integrating

Beidou positioning with UWB technology, the

system can greatly improve the location perception

performance of the system at fault points in complex

environments (Wang, Lu, et al. 2023), (Zhang, and

Li, 2023). At present, a new system of multi-sensor

fusion algorithm, orbit constraint model and

cooperative positioning technology has been

proposed to improve the service quality of fault point

location perception and positioning.

3 METHODS

3.1 System Architecture Design

First, the components of the system architecture. The

overall architecture of the fault point location

perception system for railway tunnel operation and

maintenance based on Beidou positioning fusion

UWB is very important. Its design part should

include: (1) Beidou positioning module, referred to as

BDS. BDS is mainly responsible for providing global

satellite navigation signals for the system's position

perception to achieve the initial location of the fault

points of railway tunnel operation and maintenance

with wide coverage. (2) UWB positioning module. It

is mainly used for high-precision and short-distance

positioning in the process of internal inspection of

railway tunnels; (3) Fusion positioning algorithm

module. Combined with the data of Beidou and

UWB, it can provide high-precision positioning

function of the location of fault points in railway

tunnel operation and maintenance [3]. (4) Data

processing and monitoring system. With this system,

the data of the system can be processed and monitored

in real time, and the location of the fault point can be

perceived.

Second, the Beidou positioning module. The main

principle of this module is to use the satellite to

transmit a given pseudo-distance signal to carry out

the location calculation of the fault point of railway

tunnel operation and maintenance. The formula for

calculating it is shown in equation (1).

222

()( )()

ii ii

P

xx yy zz c t

δ

=−+−+−+⋅

(1

)

In Eq. (1),

i

P

it is the receiver and the first

i

satellite

pseudodistances from each other;

, ,

x

yz

is the

position coordinates of the receiver;

, ,

iii

x

yz

is the

i

position coordinates of the first satellite;

c

is the

speed of light;

t

δ

is the constant deviation of the

receiver.

t

δ

is the clock skew of the receiver.

Thirdly, the UWB positioning module. The

module is based on the measurement of the time

difference in the arrival of the signal for high-

precision positioning, as shown in equation (2).

()/

ij i j

Tddc=−

(2

)

Research on Location Perception of Fault Points in Railway Tunnel Operation Inspection Based on Beidou Positioning Fusion UWB

165

In Eq. (2),

ij

T

is

i

j

the time difference between

the signal received by the first and first reference

nodes;

,

ij

dd

In turn, the distance between the signal

from the transmitter to the first

i

and first

j

reference

nodes;

c

It's the speed of light.

Fourth, fusion positioning algorithm. Specifically,

the Kalman filter should be used to fuse the data of

Beidou and UWB to improve the positioning

accuracy and robustness. The calculation process will

be discussed later in the text, but it will be omitted

here.

Fifth, schematic diagram of system architecture. It

demonstrates the interrelationships between the

various modules of the system [4]. The Beidou fusion

UWB positioning data can be processed by the fusion

positioning algorithm module to finally achieve

effective and high-precision positioning of fault

points in the railway tunnel, and can be monitored in

real time.

3.2 Hardware Selection and

Integration

First, hardware selection. For example, for the Beidou

positioning module, a high-precision and low-power

Beidou-dual-band receiver, such as the BGI HBD-2

Beidou receiver [5], should be selected, and at the

same time, equipped with a high-gain antenna to

enhance signal reception. These devices can greatly

improve the positioning accuracy and reliability of

the system; For example, UWB modules. In this

regard, you should choose a centimeter-level UWB

module, such as a DWM1001, and match it with an

omnidirectional antenna, so that the signal coverage

is guaranteed. This step is very important, and the key

reason for this is that it can have an impact on the

positioning capability within the railway tunnel.

Another example is data processing and monitoring

systems. For this, choose a high-performance

embedded processor, such as the NVIDIA Jetson

series, with high-capacity SSD storage. At the same

time, it is necessary to ensure that a variety of

interfaces can be supported to ensure that the system

has a high degree of compatibility.

Second, integration and installation. The first is

module integration. To this end, it is necessary to

rationally arrange the Beidou receiver, UWB module

and data processing platform to ensure the stability of

signal transmission. When integrating, it is also

necessary to pay attention to the specific

circumstances of each component, such as power

management and thermal design [6]. In short, the

effective integration of the components is very

important, it needs to ensure the interoperability

between the devices, and ensure that their fault point

detection is fast and effective. The second is system

debugging. For this purpose, initial commissioning

should be carried out in the laboratory and the

performance of the individual modules, such as

communication and data processing, should be tested

to ensure that the system functions properly. During

debugging, multiple iterative optimizations are

carried out to solve or occur hardware and software

problems. Then, install the fix. To this end, it is

necessary to select the appropriate installation

location based on the specific situation of the railway

tunnel, and at the same time, adopt a stable fixing

method, such as adding mounting brackets on the wall

and beside the track [7]. In the process of installation,

the part of the equipment protection should also be

considered, so that its installation can achieve a

certain degree of safety. Finally, a test of

environmental adaptability is conducted. For

example, comprehensive tests are carried out in the

actual railway tunnel environment and the operational

stability and reliability of the system in different

environments are checked.

3.3 Development of Fusion

Localization Algorithms

In this system, the fundamental reason for UWB

based on Beidou positioning fusion is to improve the

accuracy and robustness of the location perception

and positioning of railway track operation and

maintenance fault points. To this end, it is necessary

to develop a fusion positioning algorithm, so that the

data of Beidou positioning can be effectively fused

with UWB data, and the data of each sensor can be

integrated to achieve high-precision positioning.

First, data preprocessing is performed. Before data

fusion, the data of Beidou and UWB should be

preprocessed, and the steps include noise filtering,

data smoothing, and error correction [8]. Specifically,

noise filtering is to use the bandpass filtering method

to remove high-frequency noise from the signal. Data

smoothing is the use of moving average processing to

smooth the data, so that mutations can be reduced [9].

Error correction needs to be done based on the error

model of the known fault point perception system of

railway track operation and inspection. Secondly,

algorithm design. In order to fuse the data of the two

devices, an algorithm is designed to fuse the data of

Beidou positioning and UWB, and to ensure that it

can be suitable for state estimation of linear dynamic

systems. In this process, the algorithm should be

INCOFT 2025 - International Conference on Futuristic Technology

166

guaranteed to run based on the prediction and update

steps. For the prediction step, see Eq. (3).

|1 1|1

k

kk k k−= − −+xFx Bu

(3)

In Eq. (3), is the estimated

|1kk−

x

value of the state

at the moment

k

;

F

is the state transition matrix;

1| 1kk−−

x

is the

1k −

estimated value of the state at the

moment;

B

is the control input matrix;

k

u

is

k

the

control vector of the moment.

For details on the status update step, see Eq. (4)

and

||1( |1

)

k

kk kk k kk=−+ − −xx KzHx

(4

)

|kk

x

is the updated state estimate;

k

K

is the

Kalman gain matrix;

k

z

is

k

the measurement vector

of the moment, as in Eq. (5);

|1( |1

)

TT

kkk kk=− −+KP HHP HR

(5)

In Eq. (5),

|1kk−

P

is the co-square matrix of the

prediction error;

R

is the covariance matrix of

measurement errors.

Secondly, in view of the above analysis, this paper

needs to make targeted optimization, and the main

optimization measures include: (1) optimizing the

positioning accuracy of the system. Specifically,

increase the number of UWB base stations to cover

all dead zones in railway tunnels and reduce the

impact of signal occlusion and multipath effects; (2)

The optimized algorithm is used to improve its

positioning accuracy in complex environments, and

the optimization formula is referred to Equation (6).

optimized BB UU SS

PWPWPWP=⋅+⋅+⋅

(6

)

in equation (6),

optimized

P

is the positioning

accuracy of the system after the optimization is

completed;

B

W is the weight coefficient of the data of

the Beidou system;

B

P It is the positioning data given

by the Beidou system;

U

W is the weight coefficient

of the UWB data;

u

P is the positioning data provided

by UWB;

S

W is the weight coefficient corresponding

to the data of the sensor;

S

P It is the positioning data

given by the sensor; (3) Improve robustness. Signal

boosters and relay devices are introduced to enhance

signal strength and reduce signal loss. In addition, the

antenna layout needs to be optimized to improve the

propagation path of the signal to minimize the

multipath effect; (4) Optimize the real-time

monitoring and early warning function. In this regard,

it is necessary to optimize the data processing

algorithm of the system, reduce the data processing

delay, and improve the overall response speed of the

system. See Eq. (7) for details

In order to optimize the real-time monitoring and

early warning function of the system, it is necessary

to improve the data processing algorithm and reduce

the data processing delay, so as to improve the overall

response speed of the system, as shown in Eq. (7).

oi p c

TT T T=−Δ−Δ

(7

)

In Eq. (7),

o

T is the response time after the

optimization of the data processing algorithm;

i

T is

the response time of the system before optimization;

p

TΔ

is the latency of data processing minus from this

optimization;

c

TΔ is the reduced delay time of fault

point detection after this optimization; (5) Increase

the tunnel search design to ensure that the system can

still operate stably in high load and extreme

environments, see formula (8) for details

1

1(1)

n

s

i

i

R

R

=

=− −

∏

(8

)

In Eq. (8),

s

R

the overall reliability of the system;

i

R

is

i

the reliability of the first redundant

component;

n

is the number of redundant

components

4 RESULTS AND DISCUSSION

4.1 Introduction to the Test

To test the functionality of the component. For

example, detect whether the functions of various

hardware components in the system, such as the

Beidou positioning module and the UWB positioning

module, are normal, and ensure the stability and

Research on Location Perception of Fault Points in Railway Tunnel Operation Inspection Based on Beidou Positioning Fusion UWB

167

normal state of the data processing platform. It is

important to ensure that all components can

communicate smoothly and that there are no fault

points to detect delays and packet loss [10]. The

environment of a railway tunnel should be simulated

in a laboratory environment, and separate positioning

accuracy tests should be carried out on Beidou and

UWB systems. The overall positioning accuracy of

the design algorithm of the system is tested to ensure

that it is consistent with the expected sub-meter level,

and the simple composition of the positioning system

is shown in Figure 1.

Figure 1: Data transmission for Beidou positioning

4.2 Experiments and Analysis

After the specific functional and system

integration tests of the system, Tables I and II are

derived.

Table 1: Various data of the system after initial experiments

Test Item Test Metric Test

Result

Deficiencies

Component

Function

Test

Normal

Operation

Passe

d

None

Positioning

Accuracy

Test

Accuracy <

1m

Avg.

0.9m

Inadequate

accuracy in

some areas

Robustness

Test

Signal

Interference

Partia

l

Signal

Loss

Insufficient

adaptability

to complex

environment

s

Real-time

Monitoring

and

Warning

Function

Warning

Timeliness <

1s

Avg.

0.8s

Delays

under

extreme

conditions

System

Integration

Test

Normal

Communicatio

n

Passe

d

None

Stability

Test

Long-term

Stable

O

p

eration

Passe

d

None

Power

Consumptio

n Test

Power < 10W Avg.

9.5W

None

First of all, based on Table I, data analysis needs

to be carried out. Specifically, it includes,

The average positioning accuracy is 0.9 meters,

and in some areas of the railway tunnel, the

positioning accuracy is reduced to 1.2 meters. This

may be due to the effects of signal occlusion and

multipath effects, as shown in Figure 2.

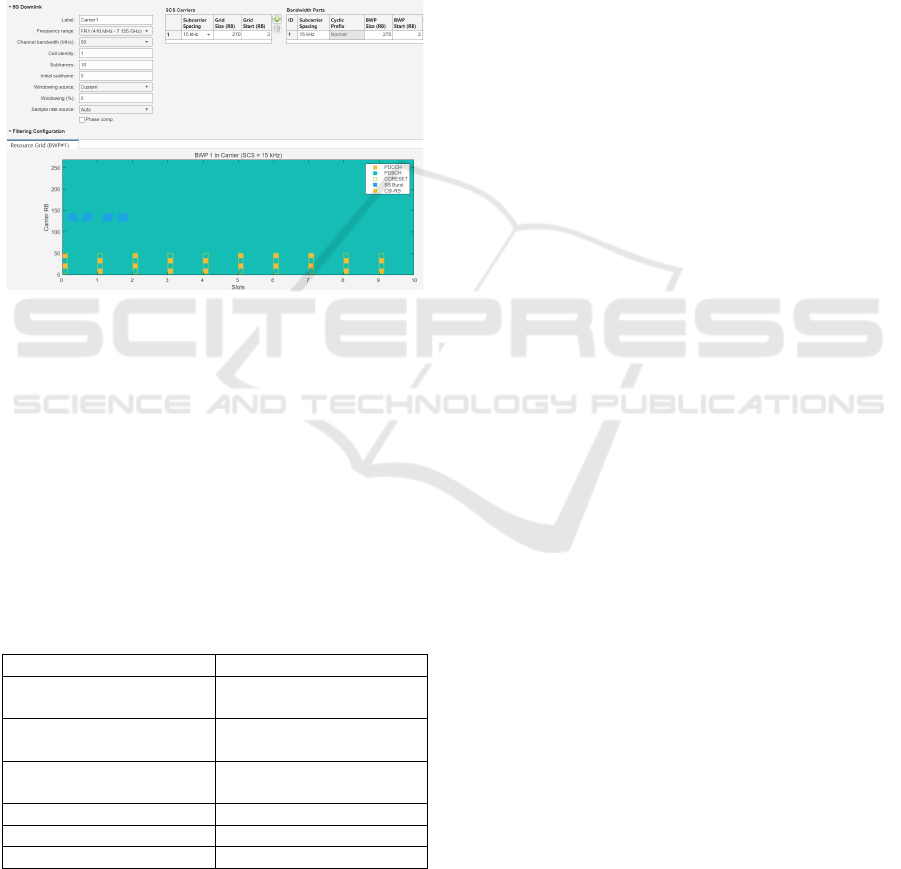

Figure 2: Analysis of Beidou RF signals

As can be seen from Figure 2, in some areas of the

railway tunnel that are greatly affected by signal

occlusion and multipath effect, some signals are lost,

which makes the positioning data of the system very

unstable. It can be seen that the system is not able to

achieve high enough adaptability in complex

environments;

In the vast majority of cases, the system's alert

timeliness is 0.8 seconds, and in some extreme cases,

this value increases to 1.5 seconds. This indicates that

the system needs to be optimized to improve its

performance under high loads and extreme

environmental conditions.

Based on these optimization measures, the system

is tested again and new test data are obtained, as

shown in Table 2.

Table 2: Various data of the optimized system

Test Item Pre-

Optimizatio

n Result

Post-

Optimizatio

n Result

Improveme

nt

Positionin

g

Accuracy

Test

Avg. 0.9m Avg. 0.6m 33%

Improveme

nt

Robustnes

s Test

Partial

Signal Loss

Stable

Signal

Signal Loss

Eliminate

d

Real-time

Monitorin

g and

Warning

Function

Avg. 0.8s Avg. 0.5s 37.5%

Improveme

nt

Specifically, complex environmental conditions

in railway tunnels, such as signal occlusion and

INCOFT 2025 - International Conference on Futuristic Technology

168

multipath effects, need to be simulated. The

robustness of the system under these conditions was

tested. It is necessary to verify the real-time data

processing capability of this part, and verify that it has

the fault warning function to ensure that the system

can find and report the fault points in the operation

and maintenance of railway tunnels in a timely

manner. Second, integration testing. The integration

test of the system requires the integration of various

hardware components and software modules, and the

overall system test is carried out to ensure seamless

collaboration between the various parts, as shown in

Figure 3.

Figure 3: Location detection of faults in the tunnel

According to the Beidou test, the location test of

the fault point in the tunnel is relatively stable. Also,

run UWB technology for a long time and test the

stability of the system to see if there are any memory

leaks or crashes in the system. Second, conduct a

power consumption test. The overall power

consumption of the system is tested to ensure that its

power supply is sufficient during the long period of

operation in the tunnel. Table 3 can be obtained by

comparing the data before and after.

Table 3: The improvement of various data in the optimized

system compared to before

Metric Improvement

Average Positioning

Accurac

y

(

m

)

33%

Fault Detection Time

(

mins

)

40%

Real-time Warning

Response (s)

37.5%

Si

g

nal Stabilit

y

Eliminate

d

Power Consum

p

tion

(

W

)

-

S

y

stem U

p

time 10%

Based on the above three tables, experimental

conclusions can be drawn. That is to say, based on the

optimization of the hardware configuration and

algorithm of the system, the system has been

significantly improved in terms of positioning

accuracy and robustness, real-time monitoring and

early warning functions. After optimization, the

positioning accuracy of the system has been improved

by 33%, and the robustness has been greatly

enhanced, and the problem of signal loss has been

basically eliminated. In addition, the system's

monitoring and early warning function has been

improved, and its response speed has increased by

37.5%. It can be seen that the optimization effect is

very obvious, and these optimization work allows the

system to operate efficiently in the complex railway

tunnel environment, and then improve the safety and

reliability of its railway tunnel operation and

inspection.

5 CONCLUSIONS

From the research in this paper, a number of

conclusions can be drawn. First, the system can

achieve high-precision positioning of the fault points

of railway track operation and maintenance. It is clear

that after a certain amount of testing and optimization,

the average positioning accuracy of the system has

been significantly improved, with an improvement

rate of 33%. This fully shows that after the

optimization of the system, it can provide people with

accurate operation and maintenance fault point

perception and positioning services in the complex

railway tunnel environment, reduce errors, and

improve the overall operation and inspection

efficiency. Second, the system is highly robust. The

system has been optimized for robust performance in

complex railway tunnel inspection environments, and

signal dropouts have been eliminated. This shows that

the system can maintain a certain stability and

reliability in the process of railway tunnel operation

and inspection, and improve the safety and continuity

of its operation and inspection work. Third, the

system has certain comprehensive advantages. For

example, it combines the advantages of Beidou and

UWB technology, which not only has strong

capabilities in the perception of the location of fault

points in railway tunnel operation inspection, but also

has excellent real-time performance. Moreover,

through data fusion and algorithm optimization, it can

better adapt to complex environments such as railway

tunnels, and improve the safety and efficiency of

operation and maintenance work. There are

limitations in this study, mainly the dataset of Beidou

positioning fusion and the incomplete collection of

Research on Location Perception of Fault Points in Railway Tunnel Operation Inspection Based on Beidou Positioning Fusion UWB

169

fault point selection of railway tunnels, which will be

analyzed in the future.

REFERENCES

Badran, O., Rizk, M. E. M., Hu, W. H., & Abulanwar, S.

(2024). Gaussian Process Regression-Based Predictive

Fault Location Algorithm For Three-Terminal Lines

Using Two-Terminal Pmus. Ieee Transactions On

Power Systems, 39(4), 5829-5853.

Cui, H. A., Yang, Q., Sun, J., & Zhou, T. (2023). Effect Of

Stray Capacitance In A Distribution Network On The

Accuracy Of Fault Location Based On Electromagnetic

Time Reversal Method. Ieee Transactions On

Electromagnetic Compatibility, 65(4), 1256-1265.

Guo, Z. Q., Huang, W. T., Yu, M. D., & Li, R. (2023). An

Active Pole-To-Ground Fault Location Scheme For Fb-

Mmc-Mtdc System Using The Short-Time Blocking Of

Sub-Modules. International Journal Of Electrical

Power & Energy Systems,2(2),154.

Liu, L., Kang, X. N., Ma, X. W., Chen, X. M., Li, S. C., Li,

X. Y., Et Al. (2024). Mplm Algorithm Based Fault

Location Method For Mtdc Systems Using Backward

Voltage Traveling Waves. Electric Power Systems

Research,2(3),235.

Luo, G. M., Shang, B. Y., Wang, X. J., Liu, Z., Liu, C. Y.,

& He, J. H. (2024). Intelligent Location Method With

Limited Measurement Information For Multibranch

Distribution Networks. Ieee Transactions On

Instrumentation And Measurement,3(2), 73.

Lv, X. D., Yuan, L. F., Cheng, Z., He, Y. G., Yin, B. Q., &

Ding, C. W. (2024). Sparse Bayesian Learning-Based

Topology Reconstruction Under Measurement

Perturbation For Fault Location. Ieee Transactions On

Instrumentation And Measurement,3(3), 73.

Qiao, J., Yin, X., Wang, Y. K., Yin, X. G., Lu, Q. H., Zhu,

L. J., Et Al. (2023). Faulty Phase Selection And

Location Method Of Rotor Ground Fault For Variable

Speed Pumped Storage Generator-Motor. Ieee

Transactions On Power Delivery, 38(6), 4253-4262.

Sun, G. Q., Chen, R. S., Han, Z. Y., Liu, H. G., Liu, M. Y.,

Zhang, K., Et Al. (2023). Accurate Fault Location

Method Based On Time-Domain Information

Estimation For Medium-Voltage Distribution Network.

Electronics, 12(23),18.

Wang, H., Lu, Y., Li, S. Q., Yu, H. A., & Bian, J. (2023).

A Pole-To-Ground Fault Location Method For Dc

Distribution Network Based On High-Frequency Zero-

Mode Current Sparsity. Electric Power Systems

Research,3(3), 225.

Zhang, Y. X., & Li, T. (2023). Fault Location For Overhead

And Cable Hybrid Dc Line Based On The Energy

Transmission Characteristics. Electric Power Systems

Research,11(3), 221.

INCOFT 2025 - International Conference on Futuristic Technology

170