A Decision Framework for AI/MLOps Toolchain Selection in

Manufacturing

Martin Bischof

a

and Florian Wahl

b

Faculty of Applied Computer Science, Deggendorf Institute of Technology, Dieter-G

¨

orlitz-Platz 1,

94469 Deggendorf, Germany

fl

Keywords:

Computer Vision, Quality Assurance, Industrial Implementation, Deep Learning, Defect Detection, Platform

Selection.

Abstract:

This paper addresses the growing challenge of implementing and selecting appropriate Machine Learning

Operations toolchains in manufacturing environments, where computer vision applications are becoming in-

creasingly prevalent. We introduce a comprehensive framework that uniquely combines MLOps platform

evaluation criteria with a practical workflow methodology tailored for manufacturing settings. To validate

our framework, we conducted experiments using the MVTec Anomaly Detection dataset, achieving 77.78 %

accuracy in granular defect-type classification when deployed through a commercial MLOps platform. Our

framework effectively bridges the gap between theoretical principles and real-world manufacturing constraints

by emphasizing both technical requirements and workflow considerations. This research advances indus-

trial AI implementation by providing a systematic methodology that transcends conventional data mining

approaches while specifically addressing manufacturing-sector challenges. Our findings demonstrate that suc-

cessful MLOps toolchain selection necessitates a balanced evaluation of both functional capabilities and im-

plementation workflows.

1 INTRODUCTION

The manufacturing sector is at a pivotal junc-

ture, where traditional industrial processes intersect

with modern artificial intelligence (AI) capabilities.

Since the breakthrough in deep learning architec-

tures (Krizhevsky et al., 2012), computer vision appli-

cations have become increasingly viable in manufac-

turing environments, driven by the widespread avail-

ability of high-resolution cameras and enhanced com-

putational resources. However, the practical deploy-

ment of these systems remains challenging. Studies

indicate that 75–85 % of machine learning projects

fail to meet sponsor expectations (Studer et al., 2021),

often due to difficulties in scaling from proof-of-

concept to sustained operational implementation.

While traditional methodologies, such as the

Cross-Industry Standard Process for Data Mining

(CRISP-DM) framework (Wirth and Hipp, 2000),

have served as foundational guidelines for data min-

ing projects, they were not explicitly designed to ad-

dress the complexities of modern Machine Learn-

a

https://orcid.org/0009-0005-1819-3976

b

https://orcid.org/0000-0002-1163-1399

ing (ML) applications within manufacturing envi-

ronments. Manufacturers encounter numerous chal-

lenges in operationalizing ML systems, including

the need to ensure high-quality data, monitor model

performance in dynamic and evolving settings, and

integrate these systems with legacy industrial con-

trol infrastructures. Additionally, standardizing in-

terfaces across diverse sensor manufacturers and sus-

taining model reliability amidst fluctuating produc-

tion conditions remain persistent obstacles. The

advent of specialized Machine Learning Operations

(MLOps) platforms presents promising solutions to

these challenges. However, manufacturers often

struggle with selecting and implementing the most

suitable toolchains for their unique requirements.

This difficulty is compounded by the absence of a

systematic decision-making framework tailored to the

nuanced operational demands of manufacturing con-

texts.

In response to these challenges, this paper pro-

vides two key contributions:

1. A comprehensive requirements for evaluating

MLOps platforms in manufacturing environments

2. A practical workflow methodology for computer

Bischof, M., Wahl and F.

A Decision Framework for AI/MLOps Toolchain Selection in Manufacturing.

DOI: 10.5220/0013523400003967

In Proceedings of the 14th International Conference on Data Science, Technology and Applications (DATA 2025), pages 439-446

ISBN: 978-989-758-758-0; ISSN: 2184-285X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

439

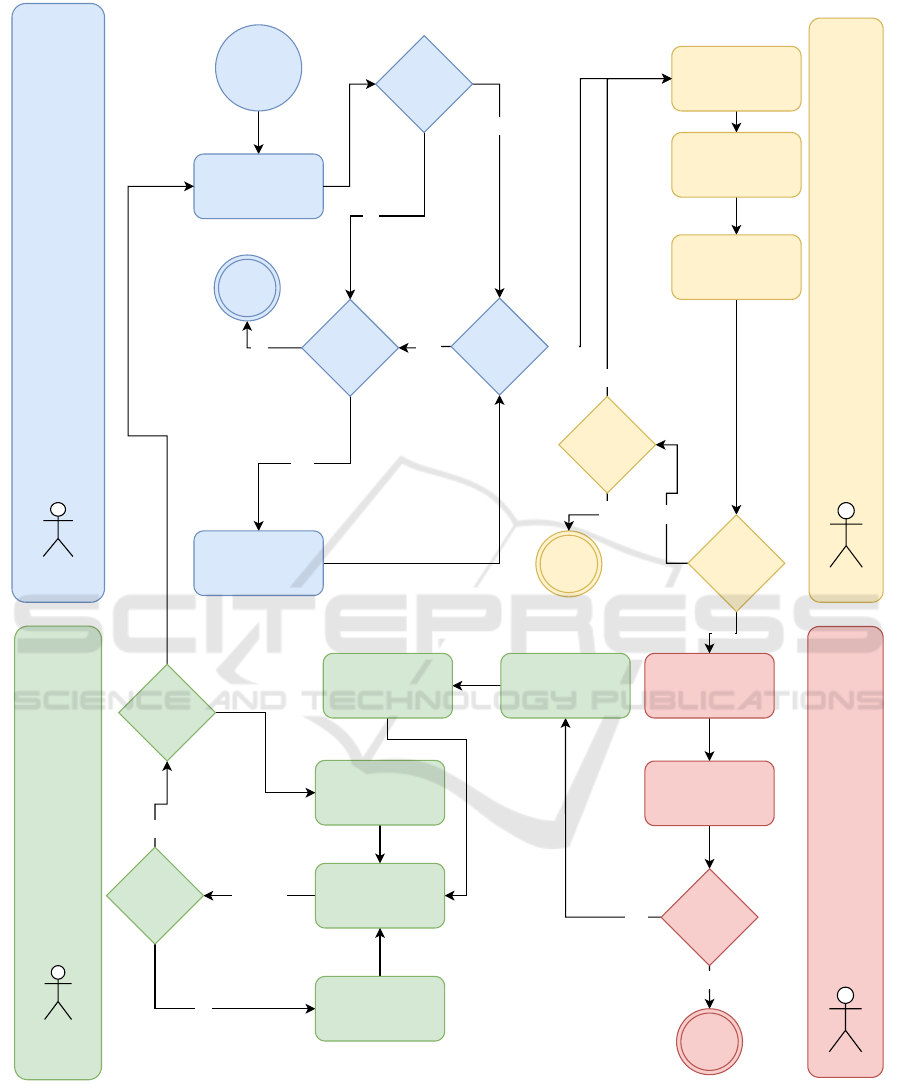

Bussines and Data understing (Planning Phase + Collection Phase)

Idea

or

Demand

Planning

yes

no

Images

Available?

Development for Production (Integration Phase)

Modeling and Evaluation (Aproach Phase)

Development and Production (System Phase)

yes

no

Collect?

Collect

bad

goodQuality?

Define Approach

Develop

Approach

Train/Eval/Test

no

yes

Did it work?

End

End

yes

no

Continue?

Design the

Integration

Implement the

Integration

no

yes

System

Working?

End

RolloutUSE IT

problem Monitor

no

yes

Model

related?

Retrain

Standard

Procedure

no

System

Changed?

Management

Engineers

Engineers

Management

Engineers

IT

Engineers

Figure 1: Our proposed workflow for computer vision projects in manufacturing environments. The workflow consists of

five sequential phases: Planning, Collection, Approach, Integration, and System. Each phase incorporates specific decision

points, documentation requirements, and stakeholder roles to ensure systematic progression and quality control throughout

the implementation process.

vision implementation that bridges theoretical

foundations with manufacturing constraints

Through these contributions, we aim to provide

manufacturers with a structured approach to MLOps

toolchain selection and implementation, specifically

DATA 2025 - 14th International Conference on Data Science, Technology and Applications

440

tailored to computer vision applications in industrial

settings.

2 RELATED WORK

Our analysis focuses on three key research do-

mains: Computer Vision methodologies, manufac-

turing AI integration, and MLOps. The field of AI

has established foundational concepts and method-

ologies, as fully documented in the standard refer-

ence work (Russell and Norvig, 2020). Similarly,

the domains of data mining and ML have under-

gone a significant evolution since the introduction of

standardized methodologies. The CRISP-DM frame-

work (Wirth and Hipp, 2000), for instance, emerged

as a hierarchical process model structured across four

levels of abstraction, ranging from general phases to

specific process instances. This methodology pro-

vided a robust and comprehensive approach for ex-

ecuting data mining projects, remaining independent

of both industry sectors and the technologies em-

ployed. However, recent research has highlighted

limitations in the original CRISP-DM framework,

particularly in its applicability to modern ML use

cases. The traditional model lacks explicit guidance

on quality assurance methodologies and does not ad-

equately address scenarios where ML models must

make real-time decisions over extended periods. To

overcome these deficiencies, Cross-Industry Standard

Process for Machine Learning with Quality Assur-

ance (CRISP-ML(Q)) (Studer et al., 2021) was in-

troduced, incorporating quality assurance practices

across six well-defined phases while preserving its

neutrality with respect to industries and applications.

This evolution has proven critical, as surveys indicate

that 75-85 % of practical ML projects fail to meet

sponsor expectations. In manufacturing contexts,

the adoption of data-driven approaches presents dis-

tinct challenges. For example, (Tripathi et al., 2020)

demonstrated that applying robust, industry-specific

knowledge discovery models often encounters numer-

ous obstacles related to data and model development.

These challenges include experimental design con-

siderations, managing model complexity, addressing

class imbalance issues, and mitigating concerns re-

lated to data dimensionality. Moreover, the manufac-

turing sector requires systematic and efficient coordi-

nation between different phases of the knowledge dis-

covery process to ensure success. The emergence of

MLOps as a discipline has introduced new paradigms

for implementing ML systems in manufacturing en-

vironments. For instance, (Beck et al., 2020) exam-

ines processes for developing, integrating, and oper-

ating ML systems effectively. In addition, (Faubel and

Schmid, 2024) conducted multiple case studies on

implementing MLOps within Industry 4.0 contexts,

emphasizing the processes, tools, and organizational

structures necessary for reliable model deployment.

Recent advancements (Jon Bokrantz and Skoogh,

2024) have further extended the CRISP-DM frame-

work specifically for manufacturing applications by

introducing an “Operation and Maintenance” phase.

This extension underscores the importance of man-

aging AI drift while ensuring that domain expertise,

data science proficiency, and data engineering com-

petency are maintained throughout all process phases.

In particular, it highlights the critical role of data en-

gineering, a component often overlooked in conven-

tional AI workflows. In the realm of computer vision,

significant progress has been made since (Krizhevsky

et al., 2012) demonstrated breakthrough performance

in image classification using deep convolutional neu-

ral networks. Current industrial implementations fo-

cus on practical considerations such as build versus

buy decisions for vision-based AI software in man-

ufacturing environments (Robovision, 2024). Addi-

tionally, (Schneider et al., 2024) explored integration

challenges within Industry 4.0 ecosystems, identify-

ing four key areas: system integration, data-related

issues, workforce adaptation concerns, and ensuring

trustworthy AI implementation.

3 PROPOSED WORKFLOW

We introduce a structured framework designed to

guide computer vision projects in manufacturing en-

vironments. Divided into five distinct phases, the

workflow addresses critical aspects of project devel-

opment and implementation.

3.1 The Five Phases

Our proposed workflow is structured in five phases as

follows:

Phase 1: Planning Phase The foundational plan-

ning phase establishes the groundwork necessary for

achieving project success. During this stage, stake-

holders engage in comprehensive requirements en-

gineering to clearly define the scope and objectives.

Collaborative sessions facilitate the creation of de-

tailed documentation outlining resource allocation,

timeline constraints, and key success factors. Quan-

tifiable quality metrics and well-defined acceptance

criteria are developed to serve as benchmarks for sub-

sequent phases.

A Decision Framework for AI/MLOps Toolchain Selection in Manufacturing

441

Phase 2: Collection Phase Building on the plan-

ning stage, the collection phase emphasizes system-

atic data acquisition and preparation activities. Rigor-

ous protocols ensure consistency and reliability in im-

age acquisition processes. To maintain high data qual-

ity throughout the project life cycle, standardized and

robust validation procedures are implemented. Spe-

cial focus is placed on verifying image quality param-

eters and ensuring dataset completeness before ad-

vancing to later stages.

Phase 3: Approach The approach phase focuses

on designing technical solutions and crafting an im-

plementation strategy tailored to manufacturing con-

straints. This pivotal stage involves algorithm selec-

tion and architectural decisions aligned with produc-

tion requirements. Model development proceeds it-

eratively, with each cycle incorporating optimization

strategies informed by manufacturing-specific perfor-

mance metrics. Validation processes are carefully de-

signed to address metrics relevant to industrial appli-

cations.

Phase 4: Integration Phase Integration serves as

a critical link between development and production

deployment. Seamless compatibility with existing

manufacturing infrastructure is prioritized to ensure

system performance under real-world conditions. In-

terfaces are developed alongside comprehensive test-

ing protocols to guarantee system reliability. Deploy-

ment documentation becomes increasingly detailed,

incorporating practical insights from the manufactur-

ing environment to streamline implementation efforts.

Phase 5: System Phase A final system phase ad-

dresses challenges associated with production deploy-

ment and long-term operation. Continuous assess-

ment of system health is enabled through sophisti-

cated monitoring mechanisms. Clear guidelines for

system upkeep are established through maintenance

protocols, while iterative improvement mechanisms

drive ongoing optimization efforts. Performance in

dynamic manufacturing environments remains a cen-

tral focus during this phase.

3.2 Implementation

The effectiveness comes from the structured pro-

gression of the workflows through clearly defined

transitions between phases. Each transition is val-

idated against predefined criteria, ensuring system-

atic advancement while upholding quality standards

throughout the process. Empirical observations have

informed specific cycle limitations that prevent ex-

cessive iteration while maintaining thorough develop-

ment practices. This balanced approach ensures re-

finement without compromising practical constraints,

resulting in a robust framework that effectively guides

computer vision projects from initial conception to

full-scale production deployment.

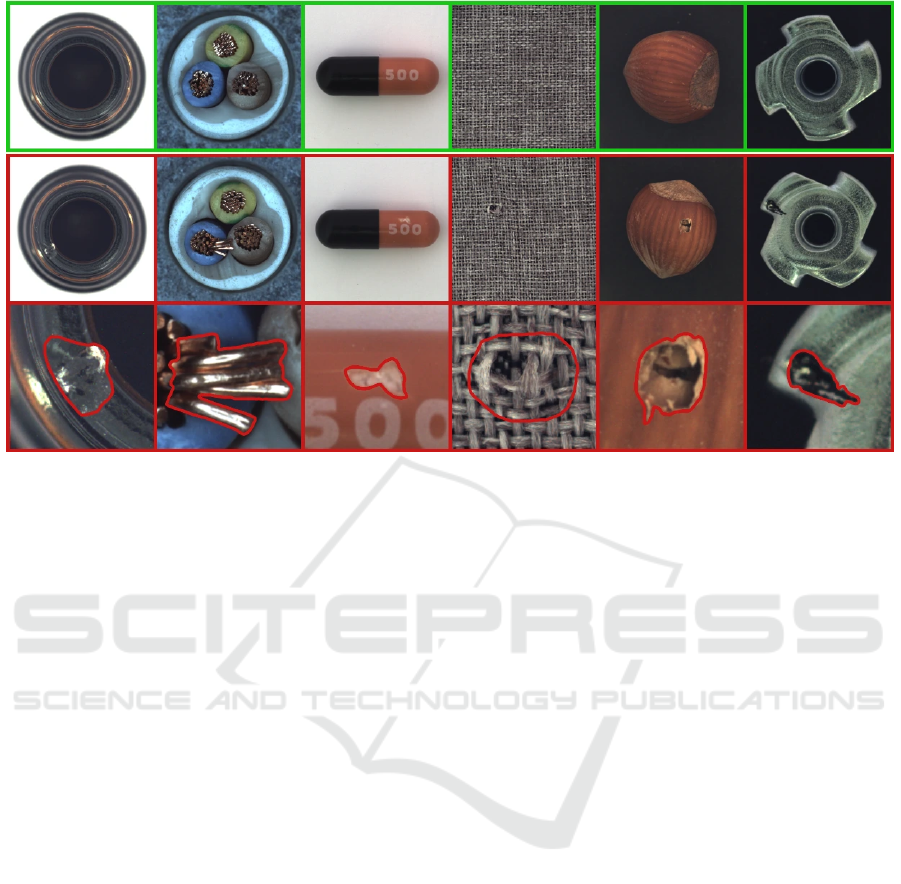

4 EXPERIMENT

To validate our proposed workflow and derive plat-

form requirements, we utilized the MVTec Anomaly

Detection (MVTec AD) dataset (Bergmann et al.,

2019) of which some examples can be seen in Fig-

ure 2. Chosen for its extensive coverage of industrial

defect scenarios and established relevance in manu-

facturing computer vision applications, this data set

proved particularly well suited for workflow valida-

tion, because of its real world comparability.

4.1 Dataset Structure and Preparation

Comprising 15 distinct object categories, the MVTec

AD dataset represents a diverse array of industrial

products and textures. Each category includes defect-

free samples alongside various defect manifestations,

offering a robust foundation for validation efforts. To

align with our objectives, manual reorganization of

the dataset resulted in two distinct classification con-

figurations. The first configuration consolidated all

the defect variants within each product category into

a unified defect class. For example, images depicting

contamination, broken seals, and surface scratches in

the bottle category were aggregated into a single com-

prehensive defect class. This approach facilitated val-

idation focused on broad-spectrum defect detection

capabilities. In contrast, the second configuration re-

tained the granular classifications, preserving the de-

tailed structure of the original MVTec dataset. This

arrangement enabled validation of fine-grained defect

discrimination capabilities. Original image distribu-

tion patterns were maintained during preparation; for

example, the bottle category contained 209 defects-

free images and 63 defective samples spanning vari-

ous types of anomaly.

4.2 Validation Process

Validation involved a comprehensive implementation

of each phase using an ML Ops platform. The sys-

tematicatic data ingestion and preparation procedures

established processingssing pipelines for both dataset

configurations. Subsequent phases included model

development and training, with hyper-parameter set-

tings and training protocols meticulously documented

through platform support.

DATA 2025 - 14th International Conference on Data Science, Technology and Applications

442

Figure 2: The used dataset example. The figure shows examples from the MVTec Anomaly Detection dataset, displaying

normal samples (top row), defective samples (middle row), and ground truth defect annotations (bottom row). From left to

right: metal nut, cable, capsule, fabric, hazelnut, and metal part categories (Bergmann et al., 2019).

4.2.1 Workflow Implementation

A full execution cycle of the proposed workflow was

carried out during this phase. Data preparation and

ingestion procedures initiated the process, followed

by iterative model development stages. Rigorous in-

tegration testing and production environment simu-

lations validated real-world applicability. Through-

out this cycle, emerging requirements were systemat-

ically documented as part of practical workflow exe-

cution.

4.2.2 Requirements Documentation

Functional and non-functional requirements were

identified and documented during systematic imple-

mentation. These requirements spanned technical

specifications, integration prerequisites, and opera-

tional constraints essential for successful deployment

in manufacturing environment. Special attention was

given to requirements critical for production-grade

computer vision implementations in industrial con-

texts. Concrete evidence of both the workflow’s prac-

tical applicability and the platform’s ability to support

advanced manufacturing computer vision workflows

emerged from this experimental approach. Findings

from this validation process formed the basis for a

comprehensive analysis of platform requirements and

an assessment of its effectiveness.

5 CONTRIBUTIONS

Two key contributions were developed to aid manu-

facturers in selecting and implementing MLOps plat-

forms. These contributions underwent validation

through practical application using the MVTec AD

dataset (Bergmann et al., 2019). First, a set of essen-

tial requirements was compiled for evaluating MLOps

platforms in manufacturing environments. Second, a

practical workflow was created to guide organizations

through computer vision implementation from start to

finish.

Experimental validation delivered compelling re-

sults across both dataset configurations. Training uti-

lized 1132 samples for training and 126 samples for

validation, maintaining a consistent 90/10 split ra-

tio because of the limited data. Defect-specific clas-

sification models (MV TEC defect types) exhibited

promising yet more nuanced performance. Efficient-

Net implementations achieved validation accuracies

of 77.78 % and 78.57 %, reflecting the increased com-

plexity of distinguishing specific defect types. These

models were trained using the same data distribution

of 1132 training samples and 126 validation samples,

ensuring consistency across experiments.

Both contributions, the requirements and practical

workflow, are intrinsically linked; neither can func-

tion effectively without the other. Requirements facil-

itate platform selection, while the workflow optimizes

utilization.

A Decision Framework for AI/MLOps Toolchain Selection in Manufacturing

443

5.1 Software Tool Requirements

Analysis revealed that distinguishing between func-

tional and non-functional requirements is crucial for

MLOps platform selection. Operational needs di-

verge from systemic constraints in industrial com-

puter vision deployments, empowering manufacturers

to evaluate toolchain capabilities against both techni-

cal specifications and quality attributes.

5.2 Functional Requirements

5.2.1 Must Haves

Operations on Data: Systematic processes are es-

sential for managing visual data throughout the com-

puter vision lifecycle. Image data ingestion into cen-

tralized repositories like data lake architectures, con-

figured to store raw images while maintaining meta-

data, serves as a successful starting point. Criti-

cal sub-operations include automated data prepara-

tion pipelines, annotation tools, and domain-specific

augmentation strategies. Rigorous quality assurance

protocols leverage automated analysis and outlier de-

tection to ensure dataset integrity. Annotation work-

flows perform optimally when integrating human-in-

the-loop validation and active learning mechanisms.

Dataset management requires splitting methodologies

aligned with data science standards to prevent model

overfitting.

Model Development and Training Capabili-

ties: Structured methodologies are vital for creating

industrial-grade computer vision models. Develop-

ment pipelines must implement multi-stage training

protocols, combining transfer learning from domain-

specific pretrained models with automated hyper-

parameter optimization. Modern validation require

stratified evaluation across manufacturing edge cases,

supported by explainability techniques such as Grad-

CAM heatmaps to audit model decisions. Version-

controlled experimentation tracking ensures repro-

ducibility of architecture variants and training config-

urations.

Deployment Capabilities: Practical deployment

is a critical functional requirement for MLOps plat-

forms in manufacturing environments. Models must

be seamlessly deployed on local servers or in the

cloud, with version tracking enabling precise iden-

tification of model versions in use across facilities.

Flexibility is essential, some factories require simul-

taneous updates across systems, while others prefer

gradual rollouts. Container support ensures consis-

tent model performance across diverse systems, while

rollback capabilities minimize downtime during fail-

ures. Integration with existing factory systems elim-

inates isolated solutions, aligning deployments with

modern manufacturing practices.

5.2.2 Should Haves

Hyperparameter Tuning and Comparability:

Systematic optimization of model configurations

is critical for efficient experimentation workflows.

Automated hyperparameter search capabilities

eliminate manual trial-and-error processes, while

concurrent experiments on distributed compute

resources accelerate development timelines.

Extensibility: Adapting AI/MLOps platforms to

unique workflows requires structured plugin architec-

tures and SDKs with well-defined extension points.

Extensibility preserves institutional knowledge by al-

lowing engineers to embed custom scripts that reflect

factory-specific expertise.

5.3 Nonfunctional Requirements

5.3.1 Must Haves

Usability: Intuitive UI/UX design is essential for

manufacturing environments where operators may

lack specialized expertise in machine learning work-

flows. Interfaces must abstract complex operations

into domain-specific workflows that facilitate rapid

execution by manufacturing engineers.

Deployment Monitoring: Robust monitoring ca-

pabilities are necessary to maintain smooth operation

of computer vision systems over time. Engineers re-

quire clear insights into prediction accuracy, response

times, and model confidence levels, with alerts trig-

gered when metrics deviate from acceptable ranges.

5.3.2 Should Haves

Standard Algorithm Library: Foundational li-

braries offering pre-implemented algorithms save sig-

nificant development time for common tasks such as

classification, anomaly detection, segmentation, and

optical character recognition (OCR). These out-of-

the-box solutions reduce initial development over-

head while enabling engineers to focus on task-

specific fine-tuning.

User Management Integration: Native

LDAP/AD compatibility simplifies deployment

by integrating seamlessly with existing user au-

thentication systems prevalent in manufacturing

IT environments. When unavailable, built-in user

management systems provide secure access control

without requiring extensive custom coding or external

dependencies.

DATA 2025 - 14th International Conference on Data Science, Technology and Applications

444

6 DISCUSSION

Experimental results reveal both strengths and limi-

tations of the proposed framework. Performance on

defect-specific classifications (77.78 % and 78.57 %)

underscores the inherent complexity of fine-grained

defect categorization in manufacturing environments.

Distinguishing between similar defect types remains a

significant challenge, particularly when working with

limited data diversity and class imbalance.

These findings offer valuable insights into MLOps

platform selection for manufacturing applications.

First, successful implementation of both classifica-

tion approaches using MLOps platforms validates the

requirements ability to identify appropriate toolchain

capabilities. Supporting workflows from data prepa-

ration to model deployment, the platform demon-

strates practical utility as part of an integrated man-

agement process approach.

Certain limitations in the validation approach

must be acknowledged. Relying on a 90/10 split ra-

tio, while practical for initial validation, limits the

robustness of performance evaluation compared to a

three-way split (training/validation/test). This limita-

tion stems from platform constraints, as Robovision

currently lacks native support for advanced dataset

splitting strategies. Additionally, exclusive reliance

on the MVTec AD dataset restricts validation to a nar-

row subset of manufacturing defect scenarios, leaving

broader applicability unexplored.

Conducted through February 2025, the experi-

mental timeline illustrates the relevance with current

MLOps platforms and modern deep learning architec-

tures. Using a consistent training set of 1132 images

and validation set of 126 samples across all experi-

ments ensured stable comparisons between category-

level and defect-specific classification tasks. Despite

these constraints, results demonstrate the framework’s

potential for guiding effective MLOps platform selec-

tion and implementation in manufacturing contexts.

7 CONCLUSION

This paper presents two significant contributions to

manufacturing AI implementation: a comprehensive

requirements for MLOps platform selection and a

practical workflow for computer vision deployment.

Experimental validation using the MVTec AD dataset

demonstrates the effectiveness in guiding both plat-

form selection and implementation decisions.

Findings suggest that successful MLOps toolchain

selection in manufacturing requires careful consider-

ation of functional and non-functional requirements

alongside a structured implementation approach. The

ability to support both broad category-level classifica-

tion and fine-grained defect-type discrimination high-

lights its flexibility in addressing diverse manufactur-

ing needs. Achieving perfect accuracy in category-

level classification while maintaining reasonable per-

formance in more complex tasks validates its practical

utility for real-world applications.

Future research could expand this work by explor-

ing applicability across other manufacturing domains

beyond computer vision and testing its effectiveness

with alternative MLOps platforms. Extending valida-

tion to real-time production environments and incor-

porating more diverse defect scenarios would further

strengthen practical relevance.

ACKNOWLEDGEMENTS

This research was supported by the Hightech Agenda

Bavaria.

REFERENCES

Beck, N., Martens, C., Sylla, K.-H., Wegener, D., and

Zimmermann, A. (2020). Machine learning opera-

tions (MLOps): Prozesse f

¨

ur entwicklung, integra-

tion und betrieb. Whitepaper, Fraunhofer-Institut

f

¨

ur Intelligente Analyse- und Informationssysteme

IAIS, Sankt Augustin. Zukunftssichere L

¨

osungen f

¨

ur

Maschinelles Lernen.

Bergmann, P., Fauser, M., Sattlegger, D., and Steger, C.

(2019). Mvtec ad–a comprehensive real-world dataset

for unsupervised anomaly detection. Proceedings of

the IEEE/CVF Conference on Computer Vision and

Pattern Recognition, pages 9592–9600.

Faubel, F. and Schmid, U. (2024). MLOps: A multiple case

study in Industry 4.0. In IEEE ETFA. IEEE. To appear.

Jon Bokrantz, M. S. and Skoogh, A. (2024). Realising the

promises of artificial intelligence in manufacturing by

enhancing crisp-dm. Production Planning & Control,

35(16):2234–2254.

Krizhevsky, A., Sutskever, I., and Hinton, G. E. (2012). Im-

agenet classification with deep convolutional neural

networks. In Advances in Neural Information Pro-

cessing Systems, volume 25, pages 1097–1105.

Robovision (2024). Build vs. buy: Choosing between

in-house development and off-the-shelf vision AI.

Whitepaper, Robovision. Includes McKinsey AI im-

plementation archetypes and PackCheck case study.

Russell, S. and Norvig, P. (2020). Artificial Intelligence:

A Modern Approach. Pearson, 4th edition. Global

Edition equivalent to 2021 US Edition (ISBN 978-0-

13-461099-3).

Schneider, J., Fischer, L., and Voelter, M. (2024). Artificial

intelligence in industry 4.0: A review of integration

A Decision Framework for AI/MLOps Toolchain Selection in Manufacturing

445

challenges. arXiv preprint arXiv:2405.18580. intro +

motivation.

Studer, S., Bui, T. B., Drescher, C., Hanuschkin, A., Win-

kler, L., Peters, S., and M

¨

uller, K.-R. (2021). Towards

crisp-ml(q): A machine learning process model with

quality assurance methodology. Machine Learning

and Knowledge Extraction, 3(2):392–413.

Tripathi, S., Muhr, D., Brunner, M., Emmert-Streib, F.,

Jodlbauer, H., and Dehmer, M. (2020). Ensuring the

robustness and reliability of data-driven knowledge

discovery models in production and manufacturing.

CoRR, abs/2007.14791.

Wirth, R. and Hipp, J. (2000). Crisp-dm: Towards a stan-

dard process model for data mining. 4th International

Conference on the Practical Application of Knowl-

edge Discovery and Data Mining (PAKDD 2000).

DATA 2025 - 14th International Conference on Data Science, Technology and Applications

446