Enhancing Accuracy and Efficiency in Physical Count Processes:

Leveraging AI, IoT, and Automation for Real-Time Inventory

Management in Supply Chain

Prabhakaran Rajendran

1

, Nirmal Kumar Balaraman

2

and Hareesh Viswanathan

3

1

CSCS LLC, Alpharetta, Georgia, U.S.A.

2

Inframark LLC, Norcross, Georgia, U.SA.

3

prabhu@cscs.io, nbalaraman@inframark.com, hareesh.viswanathan@bsci.com

Keywords: AI, IoT, Automation, Inventory Management, Real-Time Tracking.

Abstract: This paper aims at studying how much AI, IoT, and automation play a crucial role in improving the calibration

and effectiveness of physical inventory count exercises. As supply chain networks become enhanced,

companies are using these technologies to counter issues that come with the use of enhanced inventory control

including but not limited to errors, slowness among others. About this, the present paper examines two

different case studies one, based on a well-known logistics company in Finland, and the other, Amazon’s

fulfillment centers exploring how the application of AI, IoT and automation enhance real-time inventory

management. The study informs that the adoption of these technologies greatly improves both the integrity

and efficiency of inventory data, accurate real-time monitoring, and less reliance on manual adjustments, and

streamlines warehouse logistics. This paper fills the existing literature gap in understanding technological

advancements in inventory management and provides valuable recommendations to companies that wish to

transform in the context of the Fourth Industrial Revolution.

1 INTRODUCTION

1.1 Overview

In today’s dynamic business world, inventory control

has emerged as one of the key aspects in determining

business effectiveness in delivering timely goods and

services that meet the customer’s expectations . Such

manual ways of conducting physical inventory counts

as a basic approach is a bit slow and can have a high

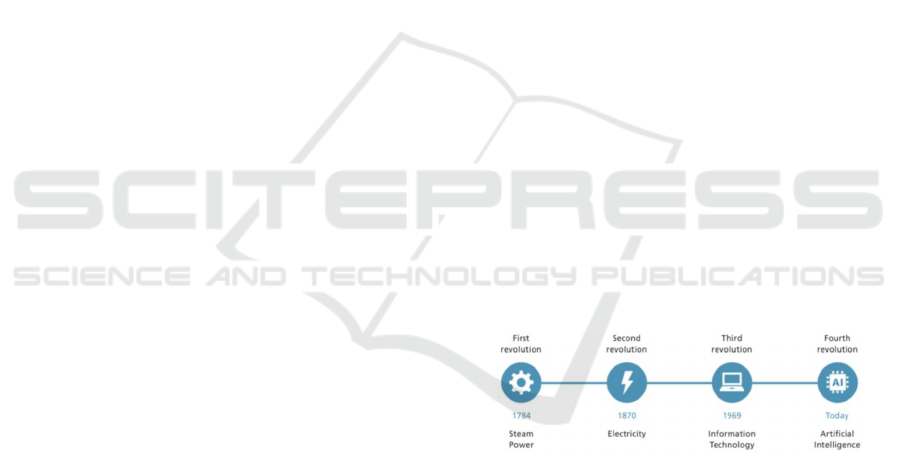

incidence of errors (Mermi, 2024). Below figure 1

illustrates the four industrial revolutions. The first

revolution (1784) was powered by steam engines,

revolutionizing manufacturing and transportation. The

second (1870) harnessed electricity, enabling mass

production. The third (1969) introduced information

technology, transforming communication and data

processing. The ongoing fourth revolution is driven by

artificial intelligence, shaping the future of

automation, innovation, and decision-making.

When organizations grow and there is a demand

for rapid data flow, the continuous utilization of

manual handling of inventory records is

counterproductive (Ugbebor, 2024). To deal with

these challenges

Figure 1: The industrial revolution (Dinh,2020).

Companies are seeking innovative solutions that are

AI, IoT and automation. All these technologies are

likely to bring about enhanced accuracy of the

inventory management processes coupled with

efficiency gains (Ayoola, 2024). The current research

aims at establishing how physical inventory count can

be improved using AI, IoT and automation to provide

real-time inventory updates thus minimizing costs

and improving the supply chain.

1.2 Background

Conventional physical inventory taking procedures

involve tasks such as estimating quantities via stock

Rajendran, P., Balaraman, N. K. and Viswanathan, H.

Enhancing Accuracy and Efficiency in Physical Count Processes: Leveraging AI, IoT, and Automation for Real-Time Inventory Management in Supply Chain.

DOI: 10.5220/0013506000003944

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 10th International Conference on Internet of Things, Big Data and Security (IoTBDS 2025), pages 493-500

ISBN: 978-989-758-750-4; ISSN: 2184-4976

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

493

counts which are done by employees; this is

unproductive, cumbersome and may lead to

inaccuracies. These manual techniques cause

inconsistencies in stock data thus causing stock out,

overstocking or incorrect records in the financial

accounts. In addition, the increasing scale of business

operational hampers the accuracy of inventories

records and the extent of its update. Hence, companies

are looking for ways of increasing accuracy of the

inventory and enhance the effectiveness of such a

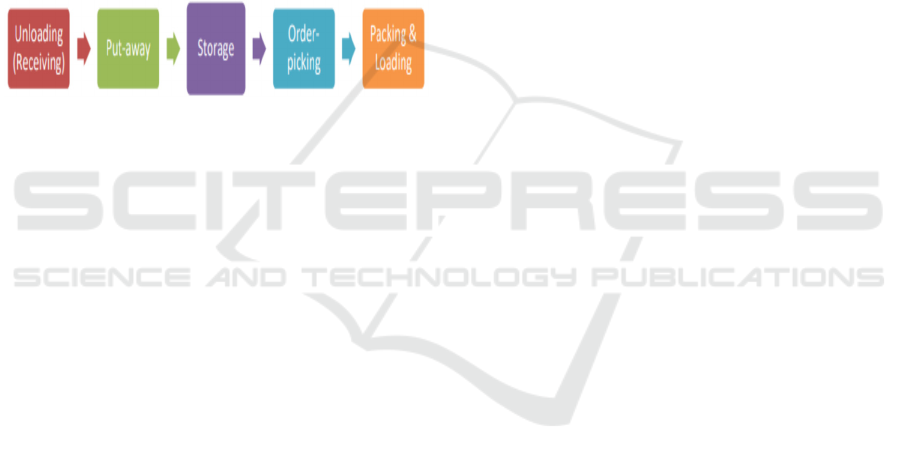

procedure. Below figure 2 represents the key stages of

warehouse operations. It begins with unloading and

receiving goods, followed by the put-away process,

where items are stored in designated locations. Next,

goods are organized in storage until needed. When an

order is placed, the order-picking stage retrieves the

required items. Finally, products are packed and

loaded for shipment to their destination.

Figure 2: Warehouse operation process .

1.3 Significance of the Study

Effective resource management is essential to meeting

consumer needs without overstocking or incurring

high operating costs (Kumar, 2024). Real-time

inventory tracking allows businesses to make

informed decisions on restocking, supply chain

management, and demand forecasting (Vinolyn

Vijaykumar, 2024). Inventory mismanagement can

directly impact customers, particularly in industries

reliant on tendering of products (Vaka, 2024).

Integrating AI, IoT, and automation presents a viable

solution for improving inventory accuracy and overall

business performance(Dash, 2019).

This study explores how these technologies

enhance traditional inventory management, offering

valuable insights into their impact on efficiency,

decision-making, and operational effectiveness in

modern supply chain processes.

1.4 Technological Context

Artificial Intelligence (AI), the Internet of Things

(IoT), and automation are at the forefront of

technological advancements in inventory

management. AI uses machine learning algorithms to

analyze inventory data, predict demand, optimize

stock levels, and detect anomalies in real-time (Khan,

2024). IoT enables businesses to track inventory using

smart sensors and RFID (Radio Frequency

Identification) tags, allowing for seamless and real-

time updates on inventory levels (None Shivam,

2024). Automation, such as the use of drones or

robotic systems for physical counting, reduces human

intervention, increases speed, and minimizes the

chances of errors. These technologies work in tandem

to provide a more accurate, efficient, and automated

approach to managing inventory, making them crucial

for modern businesses looking to streamline their

operations (Vigneshwaran Gowrishankar, 2024).

1.5 Research Questions

• How can AI, IoT, and automation enhance the

accuracy of physical inventory count

processes?

• What efficiency improvements can be

achieved through real-time inventory

management using these technologies?

2 LITERATURE REVIEW

Inventory control has long been a crucial aspect of

supply chain and operations management,

emphasizing the importance of maintaining optimal

stock levels to meet customer demand efficiently and

cost-effectively. Traditionally, businesses relied on

manual processes such as Excel spreadsheets or

periodic stock counts, which proved error-prone and

inefficient (N. Kargah-Ostadi, 2020). Over time,

models like Economic Order Quantity (EOQ) and

Just-in-Time (JIT) have been introduced to optimize

inventory while minimizing holding and ordering

costs. However, many industries still rely on manual

procedures. Today, advanced technologies such as AI,

IoT, and automation are beginning to transform

inventory management, enhancing accuracy and

efficiency (Soori, 2023).

AI, IoT, and automation have revolutionized

inventory management. Machine learning and

predictive analytics enhance demand forecasting by

identifying stock patterns. IoT enables real-time

inventory tracking through RFID tags and sensors,

providing instant stock updates (Mukherjee, 2021).

Automation technologies like drones and robotics are

increasingly adopted for stocktaking, reducing errors

and speeding up inventory counting processes

2.1 Technological Integration

Numerous studies highlight how AI, IoT, and

automation enhance inventory control. AI-driven

AI4EIoT 2025 - Special Session on Artificial Intelligence for Emerging IoT Systems: Open Challenges and Novel Perspectives

494

predictive models analyze demand fluctuations,

optimizing inventory replenishment timing and

storage allocation (Kumar, 2024). For instance,

machine learning can process past sales data to

forecast future demand accurately, minimizing

stockouts and overstocking. IoT enables real-time

inventory tracking, offering a more efficient approach

to inventory and supply chain management. Research

indicates that RFID-based IoT systems provide

systematic, real-time stock updates while reducing

human errors in inventory control. These

technologies collectively improve accuracy,

efficiency, and decision-making, making them

essential for modern inventory management and

supply chain optimization (Dash, 2019).

Automation has significantly improved efficiency

in large-scale warehouses. Drones and robots

streamline stocktaking, reducing labor reliance while

enhancing speed and accuracy (Vigneshwaran

Gowrishankar, 2024). Research indicates that

automated systems improve inventory counting

accuracy by 40% over manual methods. These

technologies provide real-time inventory insights,

enabling better decision-making, optimizing

operations, and ultimately enhancing customer

satisfaction.

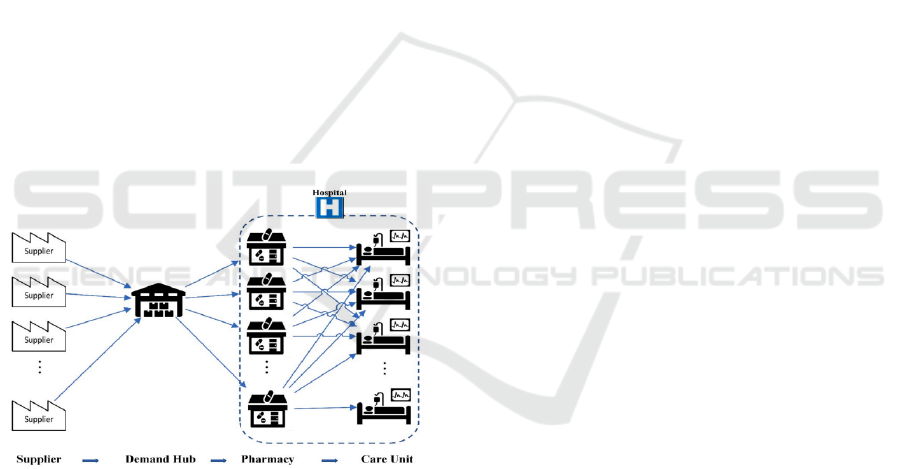

Figure 3: Flow of medical supplies (Mermi, 2024).

2.2 Gaps in Literature

Currently, there is a vast amount of literature that

discusses the individual technologies – AI, IoT, and

automation; however, theoretical research and case

studies on the application of these technologies are

abundant (Vaka, 2024). However, there is a lack of

published work presenting combined effects of both

on the physical inventory count processes, more so

from the perspective of real-time inventory count

(Ayoola, 2024). More literature reviews are confined

to single technology or existing sectors where

technological processes have been undertaken, while

a research gap exists regarding how these

technologies operate simultaneously to mitigate the

issues that arise with physical inventory counts

(Olugbenga Madamidola, 2024).

In addition, many studies examine IoT and

automation in manufacturing efficiency, few focus on

their impact on physical stock counting in inventory

management (Mukherjee, 2021). Existing literature

lacks insights into how these technologies enhance

accuracy and efficiency in near-real time, leaving

gaps in understanding their full potential for

inventory optimization.

Existing literature extensively examines AI, IoT,

and automation individually, with numerous

theoretical studies and case analyses on their

applications. However, there is a significant research

gap regarding their combined impact on real-time

physical inventory counting. Most studies focus on

single technologies or specific industries, offering

limited insights into their integrated potential. While

some research explores IoT and automation in

operational efficiency, few analyze their direct role in

improving stock counting accuracy. Additionally, the

absence of a proposed novel approach for real-time

inventory tracking restricts practical advancements.

These gaps hinder the development of actionable

insights needed to optimize inventory management

practices.

3 METHODOLOGY

Case Study (Dinh, 2020): AI in Inventory

Management at Finnish Logistics Company

This paper examines a Finnish logistics company that

has implemented AI in warehouse inventory

management, integrating Machine Learning (ML)

and Deep Learning (DL) to optimize supply chain

processes. AI has improved real-time inventory

tracking, replenishment accuracy, and efficiency.

Using a quantitative approach, data was collected

through employee interviews. The study evaluates

AI’s impact on inventory accuracy, efficiency, and

employee awareness while analyzing its strengths,

weaknesses, opportunities, threats, and future

prospects in inventory management.

Case Study

(Mermi, 2024): AI and Robotics in

Amazon’s Fulfilment Centres

Amazon’s use of AI in its fulfillment centers

exemplifies how technology can revolutionize

inventory management. The company employs

robotics, automated guided vehicles (AGVs), and

advanced automation for movement control, order

picking, restocking, and inventory tracking. By

Enhancing Accuracy and Efficiency in Physical Count Processes: Leveraging AI, IoT, and Automation for Real-Time Inventory

Management in Supply Chain

495

maximizing operational capacity, Amazon has

achieved exceptional accuracy in handling vast

inventories, setting international supply chain

management standards. This case study, based on

secondary research from online databases, press

releases, industry reports, and academic journals,

highlights AI’s role in enhancing warehouse

efficiency. The study focuses on how robotics and

automation streamline inventory processes,

improving speed, accuracy, and real-time stock

control while reducing human dependency.

Additionally, it explores how other firms can

replicate Amazon’s AI-driven strategies to optimize

their own inventory management systems.

3.1 Comparison of Case Studies

The two case studies present different but

complementary perspectives on the integration of AI

into inventory management. While both companies

utilize AI, IoT, and automation, their approaches and

implementations vary significantly due to the

differences in scale, industry, and technological

infrastructure.

1. Technological Scope:

• Finnish Logistics Company: The focus is

primarily on AI-driven solutions like machine

learning and deep learning to enhance

inventory control. The case highlights the

challenges of adopting AI in a more traditional

logistics environment.

• Amazon: In contrast, Amazon has a much

broader implementation of AI, integrating

robotics, AGVs, and AI algorithms in its

fulfillment centers. This allows for more

advanced automation, enabling higher levels

of real-time tracking and inventory accuracy.

2. Impact on Inventory Management:

• Finnish Logistics Company: The integration

of AI has led to notable improvements in

inventory accuracy and operational efficiency.

However, challenges remain in the form of

employee adaptation to AI-driven changes,

which will likely improve over time.

• Amazon: AI has been successfully applied to

virtually all aspects of inventory management,

with a strong emphasis on robotics and

automation. The company’s fulfillment

centers represent a highly efficient and

scalable model for real-time inventory

management.

3. Scalability and Application:

• Finnish Logistics Company: While the

company’s adoption of AI is impressive, its

scale is smaller compared to Amazon, and

the focus is on improving efficiency and

accuracy within a single logistics operation.

• Amazon: Amazon’s global scale and use of

cutting-edge robotics and AI technologies

set it apart, with the company continuously

innovating in warehouse automation and

inventory management.

By comparing these cases highlights AI’s diverse

impact across companies. Both demonstrate AI’s role

in enhancing inventory precision and productivity,

but Amazon represents large-scale automation with

advanced robotics, a model difficult to replicate on a

smaller scale. In contrast, the Finnish logistics

company offers a more practical example of AI

integration, showcasing challenges in adoption.

Together, these cases illustrate how AI, IoT, and

automation are transforming inventory management,

improving accuracy, efficiency, and real-time

tracking across different business scales.

3.2 Potential Challenges in Adopting

IoT for Big Warehouses

Implementing IoT in large warehouses presents

several challenges affecting efficiency and

scalability. Latency and Connectivity Issues arise

from weak signal coverage and network congestion,

delaying inventory tracking. Scalability Constraints

occur when integrating thousands of sensors and

RFID tags across multiple warehouses, requiring

infrastructure upgrades. Data Overload demands

advanced cloud solutions and edge computing to

manage vast real-time inventory data. Cybersecurity

Risks increase with more IoT entry points,

necessitating robust security. Integration with Legacy

Systems poses compatibility challenges, hindering

seamless IoT adoption. Maintenance and Reliability

require continuous monitoring to ensure sensors and

automated systems function without disrupting

warehouse operations.

4 RESULTS

4.1 Findings of Case Study Results

Case Study (H. Dinh, 2020): AI-Driven Supply

Chain Enhancement

The data collected from the Finnish logistics

company reveal several key findings related to the

impact of AI on inventory management:

AI4EIoT 2025 - Special Session on Artificial Intelligence for Emerging IoT Systems: Open Challenges and Novel Perspectives

496

• Improved Inventory Accuracy: The use of

AI in the form of machine learning and deep

learning has improved inventory accuracy

systems’ to a great extent. Some of the

improvements, which the company was able

to note after implementing the change

included; a marked decrease in the stock loss

differences and human mistake that were

prevalent during stock-take. Intelligent

systems offered features for real time

monitoring and prediction for physical

inventory as well as their digital counterpart.

• Efficiency Gains in Warehouse Operations:

Stock counting and replenishment has

benefited form the efforts made to automate

the processes that were once done manually.

Optimization of the supply picking and

replenishment routes has reduced the

durations taken and turnover rates hence faster

system operational rates.

• Employee Adaptation and Awareness: A

survey with the employees showed that there

was low to moderate understanding of AI

implementation. Some responses that stood out

include concerns about embracing change, and

thus adjusting to new technology that brings

improvement on the operational efficiency of

organizations by use of AI. But the company

ensured that employees undergo extensive

training; the effects of such aspect were

therefore reduced.

• Challenges and Future Prospects: In the

implementation part, integration problems

between new advanced AI technologies and

organizations’ existing systems were

mentioned as a problem. But for the present,

the company is hopeful about improving

predictive capabilities of AI and about

applying AI to more aspects of inventory

management in the future.

Case Study (Mermi, 2024): AI and Robotics in

Amazon's Fulfillment Centers

Amazon’s case study reveals a robust and advanced

application of AI in its fulfillment centers

• High-Level Automation and Accuracy: This

Company has embraced AI and robotics in

every process, from storage, replenishment of

stocks to picking of orders. Robotics has

helped enhance the rate and accuracy of

inventory with the support of AI to manage

real-time data integration throughout the

firm’s network of fulfillment centers globally.

• Scalability and Real-Time Inventory

Management: Robotics and automated

systems, as well as utilized AI algorithms,

help the company control significant amounts

of inventory at different locations. Other

outstanding features achieved through real-

time Inventory Management include reduction

of stockouts as well as cases of overstocking

since Amazon gets to track its demand and

supply levels in the most accurate manner

possible.

• Minimal Employee Interference: While the

AI and robots undertake most of the

responsibilities, employees are still in charge

of the running of the processes, monitoring,

repair, and decision making. Precision of work

whilst incorporating flexibility has been

boosted by the use of artificial intelligence

through adoption by Amazon.

• Challenges and Future Opportunities: It is

also essential to mention some of the problems

that Amazon faced in its AI/robotics journey,

namely, high initial expenses at the end of

which, the scaled-up value generated is

considered, and the difficulty of synchronizing

all the global centres of the company. The

company’s latest strategic direction in this

regard is to work on improving integration

between human employees and technology

tools to provide better quality and adaptability.

4.2 Answer to Research Questions

RQ 1: How can AI, IoT, and automation enhance

the accuracy of physical inventory count

processes?

These case studies confirm that AI, IoT, and

automation significantly enhance the precision of

physical inventory counting. Machine Learning

(ML) and Deep Learning (DL) improve inventory

tracking by eliminating human errors and ensuring

real-time stock data accuracy. The Finnish logistics

company experienced fewer discrepancies between

physical and virtual stock due to AI-based tracking.

Meanwhile, Amazon’s fulfillment centers leverage

robotics and AI to provide accurate real-time stock

updates, reducing errors associated with manual

labor. These technologies streamline replenishment,

picking, and order fulfillment, ensuring accurate

stock flow and optimal decision-making while

minimizing costly inventory mistakes. Figure 4

illustrates AI’s role in Amazon’s warehousing

operations. AI significantly enhances receiving, put-

away, storage, and fulfillment processes, improving

tracking and tracing to reduce errors. Robotics and

automation further optimize picking and packing

Enhancing Accuracy and Efficiency in Physical Count Processes: Leveraging AI, IoT, and Automation for Real-Time Inventory

Management in Supply Chain

497

operations, resulting in faster, more precise

outcomes. Additionally, IoT devices provide real-

time shipping and delivery data, enhancing customer

experience and improving overall organizational

efficiency in inventory management.

Figure 4: AI Technologies in Amazon’s Warehouse.

RQ 2: What efficiency improvements can be

achieved through real-time inventory

management using these technologies?

Real-time inventory management, powered by AI,

IoT, and automation, significantly boosts

productivity. These technologies enhance stock

tracking speed, data accuracy, and minimize

downtime. Amazon’s real-time inventory tool

synchronizes global fulfillment centers, preventing

stockouts and overstocking. Similarly, the Finnish

logistics firm reduced costs through AI-driven

inventory automation. These improvements enable

faster decision-making, reduce manual labor reliance,

and enhance responsiveness to inventory fluctuations,

resulting in leaner operations and lower costs across

warehouse management and supply chain processes.

5 DISCUSSION

5.1 Interpretation of Results

From the analyzed case studies highlight the value of

AI, IoT, and automation in enhancing inventory

accuracy and efficiency. Both the Finnish logistics

company and Amazon demonstrate AI’s impact on

improving stock tracking. AI enables the Finnish firm

to implement real-time inventory tracking and receive

alerts for discrepancies between physical stock and

system records. Amazon, leveraging AI, machine

learning, and robotics, optimizes automation for

precise inventory synchronization. By minimizing

human intervention, these technologies ensure

accurate stock updates, reducing errors and enhancing

operational efficiency. Overall, AI-driven inventory

management improves accuracy, streamlines

operations, and enhances decision-making in modern

supply chains.

In both cases, AI adoption required employees to

adapt to new ways of working. Initially, Finnish

logistics company employees resisted AI integration,

but later developed a positive outlook. While AI

reduced manual stocktaking, employees transitioned

to strategic roles, such as monitoring AI systems and

addressing issues. Similarly, Amazon’s AI-driven

robotics now handle most physical tasks, while

human workers focus on system oversight and

maintenance. This demonstrates that AI and

automation do not replace human labor but redefine

roles, shifting employees toward managing AI

operations and making strategic decisions, ultimately

enhancing workforce efficiency and technological

collaboration.

5.2 Environmental Impact of IoT in

Warehouses

The IoT adoption in warehouses increases energy use

and e-waste. Continuous power is needed for sensors,

RFID tags, and automation, raising electricity

demand. High-powered data centers and cloud

computing for real-time tracking to elevate the carbon

footprint, while wireless networks and edge

computing add to energy consumption for data

processing and transmission.

IoT advancements lead to frequent device

upgrades, generating e-waste. Hard-to-recycle

sensors, batteries, and hardware contribute to

environmental contamination, while short product

lifecycles further intensify the challenge of

sustainable disposal in warehouses.

To minimize these impacts, warehouses can

implement energy-efficient IoT solutions, use

recyclable materials in devices, and adopt sustainable

e-waste management practices to reduce energy

consumption and manage waste effectively.

5.3 Limitations

Despite the realization of AI, IoT, and automations

lead to better inventory management, change

implementation is not easy. In general, both case

studies investigated the issues firms face when

incorporating new technologies with legacy systems,

which sometimes slows down the advantages that

such technologies offer. They indicate the use of AI-

based systems requires considerable time and

resources modalities to be imparted in human

resource dealing with them. Small companies will be

AI4EIoT 2025 - Special Session on Artificial Intelligence for Emerging IoT Systems: Open Challenges and Novel Perspectives

498

unable to invest in such technology and training thus

putting them in a limited position as regards

implementing these innovations.

Both case studies focus on large companies with

the financial and organizational capacity to

implement AI, IoT, and automation. Amazon, as the

world’s largest e-commerce firm, leverages AI at

scale, benefiting from extensive technological

resources. However, these findings may not be

generalizable to smaller businesses with limited

resources, making them more applicable to large or

international firms rather than small and medium

enterprises (SMEs).

6 CONCLUSION

6.1 Summary of Findings

The study focuses on AI, IoT, and automation as key

factors that have revolutionized physical inventory

count through their ability to improve the precision

and speed of the processes in question. The proposed

studies, based on the experience of a Finnish logistics

company and Amazon, show that the use of AI and

automation strengthens the efficiency of inventory

management in terms of both precision and

productivity. They facilitate real time tracking of

products, minimize error and enhance efficiency of

the warehouse through repetitive tasks to these

technologies. This change of technology posed some

barriers to development since the initial employees

struggled to handle new systems, only to change their

roles to managers of these complex solutions once

they were able to adapt. Furthermore, both firms

demonstrate that large organizations can find scalable

solutions and that their success depends on these

organizations’ size and available resources.

6.2 Recommendations

Based on the findings, the following

recommendations are made for organizations

considering the integration of AI, IoT, and

automation into their inventory management

processes:

• Gradual Integration: To avoid the risks

mentioned above, organizations should take a

gradual approach when integrating AI and

automation, beginning with using them in

pilot projects or in some specific segments of

company activity. It enables assessment and

modeling depending on performance

outcomes to incorporate changes to meet new

demands.

• Employee Training and Reskilling: While

deploying intelligence and automation

technologies, organizations should ensure an

adequate training plan to create staff ready to

manage, operate and upkeep the technologies.

The utilization of these tools will be easier and

immediate if a workforce is already familiar

with them.

• Adaptation of Legacy Systems: IT

departments with legacy technologies already

in place should think through how AI and

automation will live alongside current

inventory management systems. Perhaps

instead of implementing completely new

systems of working, replacement could come

in a more integrated form where new

technologies build upon and improve the

existing structures.

6.3 Future Research

Future research should explore several avenues to

deepen our understanding of AI, IoT, and automation

in inventory management:

• Broader Industry Exploration: Engaging

different industries and organization sizes to

provide real-life case studies will give a

clearer understanding of the opportunities and

issues that revolve around AI and automation.

In particular, more effort dedicated to

scientific study of SMEs could offer means

that such companies can use to overcome

challenges related to implementing such

technologies.

• IoT’s Role in Real-Time Inventory

Management: Even though this research

provides a connection to IoT, it can be seen

that further potential of IoT in real-time stock

management was not investigated in this

study. Subsequent research must explore the

potential of IoT in creating bi-directional

visibility of inventory across various systems

and platforms to improve operational

inventory flexibility.

• Advanced AI Models and Predictive

Analytics: As artificial intelligence

progresses there is opportunity to enhance

inventory analytics through more advance

predictive methods. Future research could

aimed at how accurate demand forecasting

models are and the application of these models

Enhancing Accuracy and Efficiency in Physical Count Processes: Leveraging AI, IoT, and Automation for Real-Time Inventory

Management in Supply Chain

499

to enhance demand and supply management

and hence minimize wastage.

Thus, extended investigation of these three

prospective areas will allow researchers and

practitioners to advance further the use of AI, IoT,

and automation in inventory management,

contributing to greater businesses opportunities in

different industries.

REFERENCES

Ayoola V. B., Osam-Nunoo G., Chima Umeaku, and

Babatunde Olusola Awotiwon, “IoT-driven Smart

Warehouses with Computer Vision for Enhancing

Inventory Accuracy and Reducing Discrepancies in

Automated Systems,” Nov. 26, 2024.

https://www.researchgate.net/profile/George-Osam-

Nunoo/publication/386110610

Dash R., McMurtrey M., Rebman C., and Kar U. K.,

“Application of Artificial Intelligence in Automation of

Supply Chain Management,” Journal of Strategic

Innovation and Sustainability, vol. 14, no. 3, Jul. 2019,

Available: https://articlearchives.co/index.php/JSIS/

article/view/4867

Dinh H., “The Revolution of Warehouse Inventory

Management by Using Artificial Intelligence: Case

Warehouse of Company X,” www.theseus.fi, 2020.

https://www.theseus.fi/handle/10024/346144

Kargah-Ostadi N., Waqar A., and Hanif A., “Automated

Real-Time Roadway Asset Inventory using Artificial

Intelligence,” Transportation Research Record: Journal

of the Transportation Research Board, p.

036119812094492, Aug. 2020, doi: https://doi.org/

10.1177/0361198120944926.

Khan, N. Jhanjhi Z., Hamid D. H. T. B. A. H., and Omar H.

A. H. B. H., “Internet of Things (IoT) Impact on

Inventory Management: A Review,” www.igi-

global.com, 2024. https://www.igi-global.com/chapter/

internet-of-things-iot-impact-on-inventory-

management/339252

Kumar P., Choubey D., Raimat Amosu O., and Mariam

Ogunsuji Y., “AI-enhanced inventory and demand

forecasting: Using AI to optimize inventory

management and predict customer demand,” World

Journal of Advanced Research and Reviews, vol. 23,

no. 1, pp. 1931–1944, Jul. 2024, doi: https://doi.org/

10.30574/wjarr.2024.23.1.2173.

Ma X., Wang Zeyu, Ni X., and Ping G., “Artificial

intelligence-based inventory management for retail

supply chain optimization: a case study of customer

retention and revenue growth,” Journal of Knowledge

Learning and Science Technology ISSN 2959-6386

(online), vol. 3, no. 4, pp. 260–273, Oct. 2024, doi:

https://doi.org/10.60087/jklst.v3.n4.p260.

Mermi M., “Applications of Artificial Intelligence in

Warehouse Management: Case Study of Amazon,”

ﺔﻣﺍﺪﺘﺴﻤﻟﺍ ﺔﻴﻤﻨﺘﻟﺍﻭ ﺭﺎﻤﺜﺘﺳﻻﺍﻭ ﻞﻳﻮﻤﺘﻟﺍ ﺔﻠﺠﻣ , vol. 9, no. 2, pp. 30–

45, Dec. 2024, Accessed: Dec. 15, 2024. [Online].

Available: https://asjp.cerist.dz/index.php/en/article/

256756

Mukherjee A., “Robotic process automation with Blue

Prism to optimize inventory management,”

opus4.kobv.de, Aug. 01, 2021. https://opus4.

kobv.de/opus4-haw/frontdoor/index/index/docId/3661.

None Shivam and Gupta M., “Inventory and warehouse

management in industry 4.0: a BPR perspective,”

Journal of Information Technology Case and

Application Research, pp. 1 –36, Nov. 2024, doi:

https://doi.org/10.1080/15228053.2024.2433926.

Olugbenga Madamidola, Daramola O., Kolawole Akintola,

and Olawale Adeboje, “A Review of Existing Inventory

Management Systems,” International Journal of

Research in Engineering and Science, vol. 12, no. 9, pp.

40–50, Sep. 2024, Available:

https://www.researchgate.net/profile/Olugbenga-

Madamidola/publication/383947700

Soori M., Arezoo B., and Dastres R., “Internet of things for

smart factories in industry 4.0, a review,” Internet of

Things and Cyber-Physical Systems, vol. 3, no. 1, pp.

192–204, 2023, doi: https://doi.org/10.1016/

j.iotcps.2023.04.006.

Ugbebor F., Adeteye M., and Ugbebor J., “Automated

Inventory Management Systems with IoT Integration to

Optimize Stock Levels and Reduce Carrying Costs for

SMEs: A Comprehensive Review,” Deleted Journal,

vol. 6, no. 1, pp. 306–340, Nov. 2024, doi:

https://doi.org/10.60087/jaigs.v6i1.257.

Vaka D. K., “Integrating inventory management and

distribution: A holistic supply chain strategy,”

International Journal of Managing Value and Supply

Chains, vol. 15, no. 2, pp. 13–23, Jun. 2024, doi:

https://doi.org/10.5121/ijmvsc.2024.15202.

Vigneshwaran Gowrishankar, Arunkumar Jagadeesan, Raj

K., Gupta K., and Kiruthiga T., “Process Automation

for Enhanced Supply Chain Management with Internet

of Things (IoT),” pp. 1272–1278, Jul. 2024, doi:

https://doi.org/10.1109/aic61668.2024.10731110.

Vinolyn Vijaykumar, Mercy P., Agnes L., Leena H. M., and

Savarimuthu C., “Convergence of IoT, Artificial

Intelligence and Blockchain Approaches for Supply

Chain Management,” Apress eBooks, pp. 45–89, Jan.

2024, doi: https://doi.org/10.1007/979-8-8688-0315-

4_2.

AI4EIoT 2025 - Special Session on Artificial Intelligence for Emerging IoT Systems: Open Challenges and Novel Perspectives

500