Adopting Artificial-Intelligence Systems in Manufacturing: A

Practitioner Survey on Challenges and Added Value

Richard May

1

, Leonard Cassel

2

, Hashir Hussain

1

, Muhammad Talha Siddiqui

1

, Tobias Niemand

3

,

Paul Scholz

4

and Thomas Leich

1

1

Harz University of Applied Sciences, Wernigerode, Germany

2

Fraunhofer Institute for Production Technology IPT, Aachen, Germany

3

Siemens Mobility GmbH, Brunswick, Germany

4

Hilti AG, Th

¨

uringen, Austria

Keywords:

Artificial Intelligence, Machine Learning, Manufacturing, Industry 4.0, Added Value, Challenges, Survey.

Abstract:

Artificial-Intelligence Systems (AIS) are reshaping manufacturing by optimizing processes, enhancing effi-

ciency, and reducing costs. Despite this potential, their adoption in practice remains challenging due to lim-

ited understanding of technological complexities and practical hurdles. In this study, we present findings of a

survey involving 26 manufacturing AIS practitioners, highlighting key challenges, strategies for implement-

ing AIS more effectively, and perceived added value. Data preparation, deployment, operation, and change

management were identified as the most critical phases, emphasizing the need for robust data management

and scalable, modular (i.e., configurable) solutions. Predictive maintenance, driven by supervised learning,

dominates current AIS, aligning with industry goals to reduce downtime and improve productivity. Despite

the benefits, broader applications, such as real-time optimization and advanced quality control, seem to remain

underutilized. Overall, the study aims to provide insights for both practitioners and researchers, emphasizing

the importance of overcoming these barriers to facilitate the adoption of AIS in advanced manufacturing.

1 INTRODUCTION

In the context of Smart Manufacturing (SM), ma-

chines, their components, and mobile devices (e.g.,

cyber-physical systems, their sensors, and robots)

consistently generate vast amounts of data (Xiang

et al., 2024). This data holds significant value for

applications that leverage it to create added value

through applying machine-learning (ML) tasks and

operations, such as classification using neural net-

works (Schuh and Scholz, 2019). Here, a variety of

working areas arise, for example, recommender sys-

tems, visual object recognition, or robotics, offering

added value, such as optimizing manufacturing ef-

ficiency, saving time, or reducing costs (Monostori

et al., 2016; Plathottam et al., 2023). When ML is

integrated into a comprehensive system, encompass-

ing data collection, processing, and actionable in-

sights, to deliver such added value, the resulting sys-

tem is typically called Artificial-Intelligence Systems

(AIS) (Chryssolouris et al., 2023).

There is already a variety of AIS solutions for

manufacturing in research, for example, in the con-

text of condition monitoring or predictive mainte-

nance (Romanssini et al., 2023; May et al., 2023b;

Ross et al., 2024). However, the transfer of such solu-

tions from theory into practice is often impaired, i.e.,

only a few approaches from science are implemented

in manufacturing companies (Schuh et al., 2020; Naz

et al., 2024). Nevertheless, to benefit from the ad-

vantages of AIS and maintain competitiveness, some

companies still have integrated AIS into their manu-

facturing workflows (Kovi

ˇ

c et al., 2024). In research

(cf. Section 5), there are currently studies that inves-

tigate their adoption, motivating further research and

developments by following best practices (Plathottam

et al., 2023). Nevertheless, there is limited under-

standing how manufacturing experts, i.e., practition-

ers who actively deal with AIS, their development,

and integration, consider AIS key challenges and their

actual added value as essential incentives to adopt

such systems in real-world settings. Consequently,

May, R., Cassel, L., Hussain, H., Siddiqui, M. T., Niemand, T., Scholz, P., Leich and T.

Adopting Artificial-Intelligence Systems in Manufacturing: A Practitioner Survey on Challenges and Added Value.

DOI: 10.5220/0013489600003964

In Proceedings of the 20th International Conference on Software Technologies (ICSOFT 2025), pages 87-98

ISBN: 978-989-758-757-3; ISSN: 2184-2833

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

87

there is a gap in research to expert knowledge and ex-

periences related to the conception, implementation

issues, and application of AIS in practice. Unfortu-

nately, in-depth know-how and experiences in AIS

are still rare, given the slow adoption of AIS and the

novelty of them in manufacturing companies (Schuh

et al., 2020).

To explicitly address this gap, we report a sur-

vey of 26 European AIS experts from the manufac-

turing domain in this paper. By relying on the sample

size selected, the quantity of insights is balanced with

the depth of qualitative analysis considering the lim-

ited pool of experienced specialists in this niche field.

Based on the insights, our goal is to understand

the state of challenges AIS practitioners face in

manufacturing including handling strategies, and

to what extent AIS are currently valuable from

a real-world perspective. To the best of our knowl-

edge, there is currently no comparable study (i.e., the-

matic focus, sample) focusing on AIS expert opin-

ions, in particular from a software-oriented perspec-

tive, in this context.

Overall, our contributions are:

• Insights into current challenges AIS practition-

ers face in manufacturing and how they can be ad-

dressed.

• Insights into the extent to which the introduc-

tion of AIS in manufacturing is currently valuable.

• A repository containing the questionnaire and all

participants responses for replication purposes.

1

Overall, our study aims to provide a deeper un-

derstanding of challenges and the perceived added

value of AIS in manufacturing. In this way, we

hope to support both researchers and practitioners

to ensure more optimized development and adoption

processes. Note that some challenges and insights

might be transferable to other domains or domain-

independent, which, however, emphasizes their rel-

evance even more. Moreover, our results have not yet

been validated, which, however, is already planned in

future follow-up studies.

The paper is structured as follows: After giving a

thematic introduction in Section 1, we provide some

further essential information on SM and AIS in Sec-

tion 2. After that, we go into detail regarding our

method applied in Section 3, precisely, we present the

study’s goal and research question and describe the

study design and conduct. In the following Section 4,

we provide an overview of the survey results. These

results are then discussed in Section 5, structured ac-

cording to the research questions. Additionally, we

1

https://doi.org/10.5281/zenodo.14449236

describe potential threats to the validity in this sec-

tion. Finally, after giving an overview of related work

in Section 6, we conclude our paper in Section 7.

2 BACKGROUND

In this section, essential background information are

given. Precisely, the theoretical foundation integrates

SM as the primary application domain and AIS as the

enabling technological framework, exploring their in-

teraction in transforming manufacturing processes.

2.1 Smart Manufacturing

SM is defined as the integration of advanced tech-

nologies and data-driven processes to enhance pro-

duction systems. Examples of such technologies

include Internet-of-Things-enabled sensors for real-

time monitoring, AI-driven analytics for predictive

maintenance, and robotics for automated assembly

lines (Kusiak, 2018).

The advanced technologies are intended to en-

able greater flexibility, efficiency, and quality in pro-

duction through the networking and integration of

machines, plants and systems. It is predicated on

the principles of production management, which fo-

cus on the design, planning, monitoring, and con-

trol of production systems to achieve strategic goals

of timeliness, cost efficiency, and quality (i.e., the

strategic triangle) (Schuh and Schmidt, 2014). These

goals are typically interconnected, whereby optimiz-

ing cost efficiency, for example, might lead to stream-

lined processes that also improve production qual-

ity but could potentially increase delivery times if

not carefully managed (Bolstorff and Rosenbaum,

2007). To address these challenges, SM incorpo-

rates lean-manufacturing principles, aiming to opti-

mize processes and increasing organizational prof-

itability through continuous improvement (Jeziorek,

1994; Scholz, 2022).

Central to SM is the utilization of data, which

forms the basis for deriving information, knowledge,

and actionable wisdom. Data quality is critical for

the successful implementation of ML and other ad-

vanced technologies in production systems. It en-

compasses attributes such as consistency, relevance,

and accuracy (Vogelsang and Borg, 2019). The qual-

ity of data must meet specific criteria, including inter-

pretability, consistency, relevance, completeness, ac-

cessibility, timeliness, editability and freedom of er-

rors. This transformation of traditional manufacturing

into a dynamic, technology-driven ecosystem is a re-

sponse to the modern demands of the manufacturing

ICSOFT 2025 - 20th International Conference on Software Technologies

88

industry (Schuh et al., 2020).

2.2 Artificial Intelligence Systems

AIS are designed to perform tasks traditionally as-

sociated with human intelligence (Scotti, 2019). It

is achieved by leveraging advanced computational

methods to process large volumes of data and recog-

nize patterns (Mehak et al., 2023). The concept of

AI was first introduced by John McCarthy in 1956

and has since evolved into a pivotal technology in the

data-intensive landscape of Industry 4.0 (Mijwil and

Abttan, 2021). The increasing variability and com-

plexity of process and product data renders traditional

manual approaches increasingly impractical, partic-

ularly for human operators (Ridzuan and Zainon,

2019). AIS efficiently address these challenges by au-

tomating decision-making processes and optimizing

operational procedures.

At the core of AIS are ML algorithms, which con-

struct computational models based on training data

as opposed to explicit programming (Rebala et al.,

2019). Through an iterative process of refinement and

adapting their internal architecture during training,

these systems are capable of continuously improving

their ability to meet specific task objectives (El Naqa

and Murphy, 2015). The quality of the training data

is of high importance for the attainment of reliable

and effective outcomes. The employment of advanced

techniques, such as deep learning, for example, by

utilizing neural networks inspired by the human brain,

enables AIS to analyze complex, high-dimensional

data with precision (Mijwil and Abttan, 2021; Schuh

et al., 2020). AIS employ a wide range of learn-

ing strategies, including supervised learning, unsu-

pervised learning, reinforcement learning, and hybrid

strategies (e.g., semi-supervised learning) to adapt to

a variety of tasks, for example, classification or re-

gression (Monostori, 2003; Kotsiantis et al., 2007; Ge

et al., 2017; May et al., 2023b). The practical im-

pact of AIS is exemplified by their working areas and

applications in industrial production, such as the pre-

diction of machine breakdowns or the optimization of

process controls (Rowley, 2007).

3 METHOD

Next, we go into detail regarding our method used.

More specifically, our goal and research questions are

first described, followed by an overview of the study

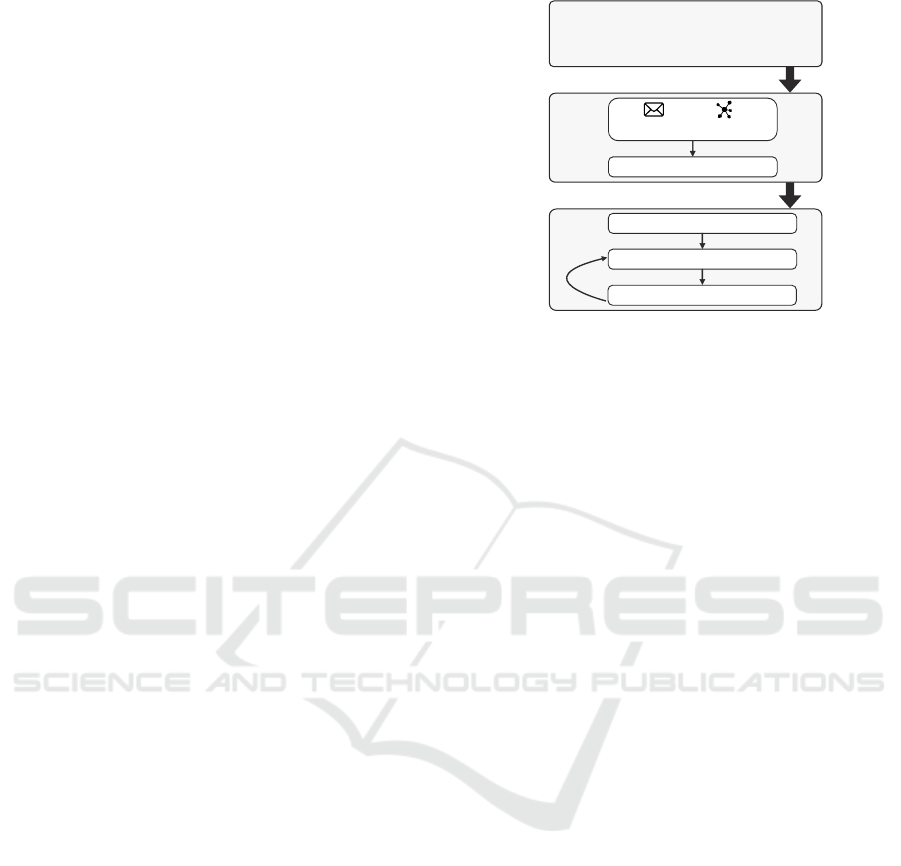

design and the study conduct (cf. Figure 1).

e-mail

94+

27

2. survey distribution

LinkedIn

survey participation

1. questionnaire conception

S1: demographic data

S2: challenges

S3: experiences

3. selection and analysis

discussing & concluding

response screening

coding and analysis

26

revision

Figure 1: Methodological overview of the survey study;

numbers indicate amount of practitioners.

3.1 Goal and Research Questions

The goal of our study was to understand the state of

challenges AIS practitioners face in manufacturing,

their strategies in handling these and to what extent

AIS are currently valuable from a real-world perspec-

tive. We defined two Research Questions (RQ) that

drive our research:

RQ

1

Which challenges do practitioners face

in AIS development, and how are they ad-

dressed?

First, our goal was to identify current trends of

AIS development challenges. Furthermore, our

focus is on insights in handling such challenges

effectively as well as open issues to be consid-

ered in the future.

RQ

2

To what extent do AIS implementations

currently add value in manufacturing prac-

tice according to practitioners’ perceptions?

Second, the aim was to determine whether the

introduction of AIS is considered valuable from

a practical point of view. In addition, the cur-

rent incentives for implementing AIS in man-

ufacturing and trends in actual implementation

are analyzed.

3.2 Study Design

In the following paragraphs, the design of the survey

study is described, focusing on the questionnaire

design and structure and the participant selection.

Questionnaire. Our survey was oriented toward es-

tablished guidelines and quality criteria for conduct-

ing surveys with (online) questionnaires in software-

Adopting Artificial-Intelligence Systems in Manufacturing: A Practitioner Survey on Challenges and Added Value

89

engineering research (Moll

´

eri et al., 2016).

Generally, the third and fourth author created the

draft of the questionnaire (English), followed by sev-

eral major adaptions by the first author based on dis-

cussions with the second, third and forth authors. This

step led to an introduction text including a basic con-

sent form for all participants and 11 questions classi-

fied into three sections; taking around 10–15 minutes

to answers. The other authors contributed as review-

ers during a single round of questionnaire evaluation.

The survey was created based on the Microsoft

Forms platform. All data was anonymized (i.e., no

conclusions about participants or organizations could

be drawn) and securely stored on a German server

(i.e., considering privacy standards of the European

Union).

Section 1 (demographics): The first section refers to

the participants’ demographic data. Here we asked

for the years of experience (Q

1

, single choice), the

companies’ main industries (Q

2

, multiple choice),

and the practitioners’ employment area in their

company (Q

3

, multiple choice). For Q

2

and Q

3

,

the practitioners had the opportunity to select an

other (free text) option. Additionally, for each of the

questions, we offered the option to select prefer not

to say, ensuring a higher degree of privacy if needed.

Section 2 (challenges): In the second section, we

focused on the challenges AIS practitioners face in

manufacturing. Precisely, first we asked whether AIS

are already deployed/implemented in their company

as part of their day-to-day business practice (Q

4

,

5-level Likert scale on agreement). The following

questions referred to the development phases where

the greatest challenges occur (Q

5

, multiple choice),

the key challenges (Q

6

, free text), and strategies to

overcome the challenges (Q

7

, free text).

Section 3 (experiences): In the last section, we asked

for own experiences the practitioners made while de-

veloping AIS. For reasons of clarity, they had to fo-

cus on one AIS that has been implemented most fre-

quently in their company and they have been most

involved with. Here, we first asked for the use case

of the considered AIS for context purposes (Q

8

, sin-

gle choice). The following question referred to the

implemented learning strategies (Q

9

, single choice).

For Q

8

and Q

9

, we additionally offered the option to

select other (free text). Finally, we focused on the

added value of the implemented AIS, involving two

questions on the actual reasons for implementing the

AIS (Q

10

, free text) and whether the implementation

was worthwhile from an economic point of view chal-

lenges (Q

11

, 5-level Likert scale on agreement).

Participants. We only recruited practitioners who ac-

tively work in the field of AIS, for example, including

programmers or data scientists who have in-depth ex-

perience with AIS in real-world contexts. Precisely,

to be able to answer our research questions satisfac-

torily, we focused solely on AIS practitioners in the

manufacturing industry, strictly limiting the sample

size to a specific niche field. We did not define any

further restrictions.

To reach potential participants, we relied on four

channels for distribution, including: 1) the profes-

sional network of the authors, 2) a manually cre-

ated mailing list that included AIS practitioners, 3)

the LinkedIn network of the first author, and 4) dis-

tributing the survey invitation through participants

(i.e., snowballing). Note that all invited people work

mainly in one European country, limiting the external

validity of our study.

3.3 Conduct

The survey was distributed by the first author on May

22, 2024 based on the defined channels, leading to a

total of 89 practitioners reached via mail, five partic-

ipants recruited via LinkedIn (i.e., a post in the first

author’s personal network), and an unknown number

of practitioners we reached via the other two chan-

nels (i.e., professional network, unrestricted number

of snowballing iterations). All data was systemat-

ically collected in a shared Microsoft forms project

(i.e., a total of 27 responses), providing the option to

download an Excel spreadsheet with all results. As an

initial step, the first author screened all data to check

whether all responses have a sufficient data quality

(i.e., quality validation and verification), resulting in

the exclusion of one participant due to empty response

fields. After that, the first author considered a total of

26 participants for the data analysis after a short dis-

cussion with the third and forth authors.

Overall, the data analysis was performed by the

third and forth authors. Besides the questions which

already offered certain categories, we built on open

coding and card sorting for all free-text responses

(e.g., Q

6

, Q

7

). More specifically, the third and

fourth authors identified recurring patterns and as-

signed suitable categories, which were reviewed, dis-

cussed, and partly revised with/by the first and second

authors in two rounds until consensus was reached.

An overview of all relevant methodological steps is

given in Figure 1.

ICSOFT 2025 - 20th International Conference on Software Technologies

90

4 RESULTS

In this section, we describe the results of our survey,

structured according to the questionnaire sections.

Table 1: Response overview for demographics (n=26).

question answers responses

Q

1

: years of experience

0 to 2 2 8 %

3 to 5 7 27 %

6 to 10 7 27 %

11+ 10 38 %

Q

2

: main industry

manufacturing 20 42 %

IT 14 29 %

research 10 21 %

logistics 3 6 %

prefer not to say 1 2 %

Q

3

: employment area

research & development 23 89 %

operations 11 42 %

quality 3 12 %

management 2 8 %

other 2 8 %

4.1 Demographics

Most participants (65%) have at least six years of ex-

perience in developing AIS in the manufacturing do-

main (Q

1

), including 38% with more than 11 years

and 27% with six to 10 years. The remaining practi-

tioners have between three and five years (27%) or a

maximum of two years of experience (8%).

The companies’ main industries (Q

2

) are quite di-

verse, ranging from manufacturing (42%) over infor-

mation technology (29%) and research (21%) to lo-

gistics (6%). One participant selected the prefer not

to say option. The practitioners’ employment areas

(Q

3

) mainly relate to research & development (89%)

and operations (42%). Others include quality (12%),

management (8%), and risk analysis (4%). All re-

sponses concerning the demographics are given in Ta-

ble 1. Note that participants could select more than

one option for Q

3

.

4.2 Challenges

Overall, not surprisingly, 69% of the practitioners

agreed or strongly agreed that AIS are currently im-

plemented in their company and part of the day-to-

day business practice (Q

4

). 27% neither agreed nor

disagreed and 4% disagreed. As illustrated in Figure

2 regarding the most challenging phases (Q

5

), 73%

referred to data preparation. Interestingly, 65% each

selected deployment, operation, and change manage-

ment. Less practitioners selected testing (37%). The

Table 2: Response overview for experiences (n=26).

question answers responses

Q

8

: use case

Prediction

failures 13 50 %

quality parameters 4 15 %

Assistance

parameter control 2 8 %

scheduling/planning 2 8 %

other 5 19 %

Q

9

: learning strategy

supervised 20 77 %

not known 3 12 %

semi-supervised 1 4 %

unsupervised 1 4 %

other 1 4 %

Q

10

: added value

effort/downtime 12 46 %

system efficiency 11 42 %

quality 8 31 %

costs 6 23 %

decision making 5 19 %

Q

11

: worthiness

Agree 15 58 %

Neither agree/disagree 7 27 %

Strongly agree 4 15 %

least challenging phases seemed to be design (27%)

and implementation (23%). Typical challenges (Q

6

,

cf. Figure 3) mainly relate to data quality and the AIS

customization and configuration process (46% each).

System adaptability and meeting stakeholder expec-

tations were described by 23% each. Others relate to

data handling (19%), system efficiency (15%), change

management, and system scalability (12% each).

Strategies for handling such challenges (Q

7

) are

quite manifold, such as ensuring high data quality

(46%), more traditional testing or validation of data

quality or functions (42%), using AIS templates as

basis for designing new systems (27%), or mak-

ing more effort in ensuring high data (processing)

quality (23%). Two solutions referred more to the

requirements-engineering process (12%) and clear

stakeholder communication to avoid change manage-

ment efforts (19%). Others are related to iterative fea-

ture integration (12%). Interestingly, some practition-

ers (12%) stated that it is currently hardly possible to

handle common challenges and that experience is key.

4.3 Experiences

As shown in Table 2, the most use cases (Q

8

) fo-

cused on the prediction of machine or component fail-

ures (50%). Less relate to the prediction of quality

parameters (15%), assistance of scheduling or plan-

ning tasks, or manufacturing parameter control (8%

each). Five use cases were only selected once, such

as fraud and solvency risk management. Interestingly,

Adopting Artificial-Intelligence Systems in Manufacturing: A Practitioner Survey on Challenges and Added Value

91

data preparation

design

implementation

deployment

operation

testing

0%

100%

20

7

6

18

17

10

change management

17

Figure 2: Development phases ranked by their perceived

challenge (Q

5

); numbers indicate participants who selected

each phase (multiple selections possible).

regarding the learning strategies (Q

9

), AIS are mainly

based on supervised learning (77%). Others are sig-

nificantly less mentioned, such as unsupervised learn-

ing and semi-supervised learning (4% each). 12% of

the practitioners stated that they did not exactly know

the implemented learning strategies.

We defined five categories related to the incentives

for implementing AIS (Q

10

). The major incentives are

the reduction of effort and system downtime (46%),

improvements in system efficiency (42%), and the

optimization of process quality (31%). Furthermore,

some participants referred to saving costs (23%) and

enhanced decision making (19%). Not surprisingly,

the majority of the participants selected regarding the

worthiness of AIS implementations in manufactur-

ing business practice (Q

11

) that they (strongly) agree

(73%). 27% neither agreed nor disagreed; none of the

practitioners expressed disagreement.

Looking solely on responses related to the predic-

tion of machine or component failures, such solutions

are typically based on supervised learning (85%) and

implemented to reduce efforts and downtime (54%)

as well as to save costs (39%) and increase system

efficiency (31%). Surprisingly, besides 61% who

(strongly) agreed that the implementation was worth-

while, 39% neither agreed nor disagreed.

5 DISCUSSION

In the following section, the results are discussed ac-

cording to the RQ related to challenges (RQ

1

)

and added value (RQ

2

), also providing statements

made by the participants in the survey. Precisely, we

present 10 relevant insights based on the survey re-

sults. Note that these insights might be transferable to

other domains or even domain-independent, empha-

sizing their value.

adapt

ability

cust

omiz

ation

12 12

6 6

5

4

3

3

0

2

4

6

8

10

12

14

da

t

a quality

s

tak

eholder

e

xpect

a

tions

da

t

a handling

ef

ficiency

change

managemen

t

scalability

amount of participants

challenge

Figure 3: AIS key challenges (Q

6

); numbers indicate

amount of participants.

5.1 RQ

1

: Challenges

Our data highlights several insights, including im-

plications and trends, surrounding the challenges

practitioners face in AIS development within the

manufacturing domain.

Insight

1

: Data Readiness. Not surprisingly, the

prominence of data preparation as a challenging phase

(73%) suggests a systemic issue related to data readi-

ness. Overall, this findings is already know and likely

stems from fragmented legacy systems and a lack of

standardization in data formats within manufacturing

environments (Meyer et al., 2018). The implication

here is that companies may need to prioritize founda-

tional investments in data management infrastructure

before pursuing advanced AIS initiatives that possi-

bly lead to cost-intensive issues, i.e., being aware of

the ”garbage-in garbage-out” principle (Kilkenny and

Robinson, 2018). We argue, that automated, strictly

verified tools for data preprocessing, cleaning, and en-

richment could become increasingly important to ad-

dress this bottleneck (Kovalenko et al., 2023), as also

stated by one participant:

“[. . . ] consider infrastructure requirements early in the

system design process [. . . ] apply techniques for data

augmentation / synthesis to enrich datasets” (P14)

Insight

2

: Post-development issues and change

management. Interestingly, equally challenging

phases, such as deployment, operation, and change

management (65%), indicate persistent difficulties in

post-development phases (cf. Figure 2), for example,

regarding new manufacturing workflows, varying

target environments, or data (source) variability over

time (Sorensen et al., 2018). These challenges are

likely to be intensified by the known problem of

staff resistance to change and the complexity of

integrating AIS into existing manufacturing work-

flows (Arias-P

´

erez and V

´

elez-Jaramillo, 2022). This

highlights the need for robust change-management

ICSOFT 2025 - 20th International Conference on Software Technologies

92

strategies and the design of user-centric systems that

facilitate smoother transitions. Clear stakeholder

communication and iterative system rollouts may

provide competitive advantages by addressing such

barriers directly (Sorensen et al., 2018). Additionally,

IT compliance and meaningful governance structures

should be integrated into these strategies, as they play

a crucial role in ensuring sustainable deployment and

operation, particularly in multi-site settings.

Insight

3

: Experience Dependency and Stakehol-

der Integration. Interestingly, some practition-

ers emphasized that handling post-development and

change-management challenges effectively is typi-

cally experience-based, pointing to a gap in standard-

ized frameworks or best practices for AIS develop-

ment and usage:

“[. . . ] experience is important and [you need] a bit of

luck” (P10)

We argue that the dependency on individual ex-

pertise highlights the need for greater formalization

of knowledge sharing (Lepore et al., 2022). This also

includes actively involving manufacturing employees

as key stakeholders, leveraging their process exper-

tise, and fostering collaboration with AI developers.

By qualifying and incentivizing employees, orga-

nizations can address concerns about automation,

reduce the need for costly recruitment, and may

ensure long-term knowledge retention. Empowered

employees are better positioned to identify potentials,

co-design solutions, and support AIS deployment

and data preparation, ensuring alignment with pro-

duction realities (Jaiswal et al., 2023). We argue

that these challenges arise mainly in deployment,

operation, and change management (cf. Figure 2) but

influence all development stages. Early stakeholder

communication and timely user feedback are crucial

for adapting AIS to real-world needs and ensuring

sustainable organizational development (Sorensen

et al., 2018).

Insight

4

: Integration Across Technological Vari-

ability. An essential insight of our study is that sev-

eral challenges also lie in configuration processes,

particularly in adapting models and systems dynam-

ically to varying environments and parameters. Reli-

able as well as secure configurations and adaptions

during deployment and operation are essential but

complex, with misconfigurations being a significant

bottleneck (L

´

opez Mart

´

ınez et al., 2010; Zhang et al.,

2022). Recurring issues here may primarily refer to

AIS misbehavior (May et al., 2024b), for example,

due to the integration of older and newer technolo-

gies, which must work together within systems char-

acterized by varying production volumes and fluc-

tuating product mixes. This variability, combined

with diverse technological requirements, often leads

to unique error patterns that are difficult to detect and

learn from due to limited data in low-volume scenar-

ios (Windmann et al., 2024). We emphasize that AIS

incidents can also threaten IT security and functional

safety (May et al., 2024b). In particular, adversar-

ial attacks (Li et al., 2022) exploiting vulnerabilities

that emerged due to misconfigurations may lead to

compromised and/or false model outcomes. In this

case, AI technology is deliberately misused by ma-

licious actors who want to harm a company. In the

worst case, such issues can result in cyber-physical

systems’ failure and large economic damage (Hasan

et al., 2024; Alharthi and Brand

˜

ao, 2024). Moreover,

misbehavior of AIS, for example, related to robotics,

may lead to risks to human life (May et al., 2024b).

We argue that the key to managing this com-

plexity is the use of scalable and adaptable AIS, i.e.,

AIS that securely integrate dynamic configuration

mechanisms (Lee et al., 2019; Yavich et al., 2023).

For example, techniques such as product-line en-

gineering including feature modeling can help to

maintain variants (i.e., configurations) of an AIS

family while relying on cost-effective reusability of

features Pohl et al. (2005); May et al. (2023a, 2024a).

Additionally, we argue that (highly-)configurable

systems can be trained on high-volume products with

well-documented error patterns and then applied to

other products with different characteristics. This

transferability allows for more effective handling of

technological and production variability, particularly

during the critical phases of design, deployment, and

operation.

Insight

5

: Balancing configurability, Feature Pri-

oritization, and Stakeholder Alignment. Surpris-

ingly, we identified that that some practitioners re-

lied on the use of templates as a foundation for

AIS systems (27%) and iterative feature integration

(12%). These trends reflect a growing trend toward

configurable and agile development practices (Schuh

et al., 2020; May et al., 2023b). Such approaches

enhance flexibility and adaptability, allowing teams

to respond to evolving requirements efficiently. Fu-

ture AIS development may focus on plug-and-play

components, no-code/low-code solutions, and itera-

tive refinements to support integration and configura-

tion efforts, while ensuring scalability, alignment with

stakeholder needs, and future-proof design (May and

Adler, 2024). Early involvement of stakeholder rep-

Adopting Artificial-Intelligence Systems in Manufacturing: A Practitioner Survey on Challenges and Added Value

93

resentatives is essential to define scenarios, use cases,

and user stories, ensuring a shared understanding of

the ”big picture”, even in agile settings (Sorensen

et al., 2018). Developers and customers must align

their priorities, balancing critical features with long-

term benefits, such as lifecycle cost reductions and ef-

ficiency improvements. Establishing a Minimum Vi-

able Product (MVP) with a stable scope and scalable

design allows for lower-priority features to be con-

sidered later without jeopardizing project timelines or

budgets (Soldatos, 2024). However, such approaches

may also limit general feature richness, as noted by

one participant in the context of using restricted tem-

plates:

“[. . . ] however, you restrict the number of possible

features which are potentially interesting for customers

[leading to a] problem of customer satisfaction” (P7)

Interestingly, while restricting the number of fea-

tures is partly perceived as a limitation, other prac-

titioners explicitly utilize such limitations to reduce

development effort and focus on the stakeholders’ ac-

tual needs, for example, in the context of basic fea-

tures versus attractive features (Brandt and Scharioth,

1998; Chitturi et al., 2008):

“limiting [. . . ] function[s] as much as possible to fit the

need of the stakeholders” (P15)

Insight

6

: Integrative Development Strategies. We

found several relationships between challenges and

strategies. For example, the frequent mention of data

quality issues obviously aligns with the widespread

effort to improve data quality, its validation, and pro-

cessing. Similarly, the acknowledgment of change-

management difficulties corresponds to a focus on

clear stakeholder communication. At best, several

strategies are applied in a connected way (i.e., work-

flow) as suggested by one participant:

“[1.] continuous communication and feedback loops be-

tween development team and operator/user who works

with the results. [2.] trying to fix wrong MLS decisions

through fast data rework. [3.] visual inspection of re-

sults.” (P19)

We note that although our findings may be rele-

vant and useful in certain contexts, not all challenges

and strategies are equally important in every context.

So, some challenges and strategies might be more

relevant to specific subdomains depending the the

unique settings in every company, for example,

technological variability in the context of software or

hardware in drilling or sawing AIS (e.g., condition

monitoring, predictive maintenance). Here, practi-

tioners have to prioritize according to the specific

requirements of use cases and sometimes have to deal

with contradictory recommendations.

RQ

1

: Challenges

Key challenges include poor data quality, per-

sistent post-development and change-management

hurdles, and the complexity of configuring AIS

for dynamic and variable environments in a re-

liable and secure manner. Associated solution

strategies should focus on enhancing data readi-

ness, adopting modular development practices

for greater flexibility, and implementing robust

change-management approaches. Nonetheless,

the reliance on individual expertise underscores

the need for standardized frameworks/best prac-

tices to ensure consistent and scalable solutions.

5.2 RQ

2

: Added Value

Insight

7

: AIS Value and Optimization. Not

surprisingly, the perceived value of AIS implemen-

tations is widely positive. This finding reflects the

significant impact of AIS on improving operational

efficiency, reducing system downtime, and opti-

mizing processes. The dominant use case for AIS

is the prediction of machine or component failures

(50%), highlighting the importance of predictive

maintenance in minimizing unplanned downtime

and ensuring manufacturing continuity (May et al.,

2023b). Beyond predictive maintenance, other

use cases such as quality parameter prediction,

scheduling assistance, and manufacturing parameter

control are less prevalent. However, these applica-

tions have a profound impact on manufacturing as

they influence decision-making processes critical

to production and product quality measurement, as

well as production planning. For example, such AIS

can optimize machine utilization, sequencing, and

material disposition, transforming how production is

managed (Soldatos, 2024). Nevertheless, we argue

that expanding AIS into strategic and operational

domains, such as advanced quality control and

real-time process optimization, offers significant

potential to enhance their value across a wide range

of manufacturing functions.

Insight

8

: Learning Strategy Dependence. The

dependency on supervised learning (77%) indicates a

preference for structured and well-defined approaches

in manufacturing settings (Schuh et al., 2020; May

et al., 2023b). However, the limited mention of

ICSOFT 2025 - 20th International Conference on Software Technologies

94

unsupervised and semi-supervised learning implies a

missed opportunity to explore these methods, which

may be particularly useful in identifying hidden

patterns or optimizing processes with less labeled

data (Qi and Luo, 2022). Encouraging experimenta-

tion with diverse learning strategies could broaden

the scope of AIS and enhance their adaptability to

more complex manufacturing scenarios.

Insight

9

: Adoption Incentives. The leading incen-

tives for AIS adoption, including reducing effort and

downtime (46%), improving system efficiency (42%),

and optimizing quality (31%), align with core manu-

facturing goals of enhancing productivity and mini-

mizing costs which are closely related to the strategic

triangle (Schuh and Schmidt, 2014). Not surprisingly,

the motivations are often mutually dependent, high-

lighted by one participant’s statement:

“Improved accuracy in predicting quality parameters

and machine failures, resulting in reduced downtime and

maintenance costs, optimized manufacturing processes

and improved decision-making capabilities” (P9)

Insight

10

: Value Perception and Acceptance.

Surprisingly, The fact that 23% of the respondents

neither agreed nor disagreed with the statement

that the introduction of AIS is worthwhile makes

it clear that it may be difficult to demonstrate a

concrete benefit from the investment. This could be,

for example, due to fluctuations in implementation

success or the lack of clear benchmarks to measure

the contribution of AIS in different contexts. Starting

with an MVP that already demonstrates clear value

helps practitioners build confidence and support

for further investments (Soldatos, 2024). Overall,

the results indicate a positive but quite inconsistent

acceptance of AIS in manufacturing. While the

value of the technology for predictive maintenance

and operational efficiency is widely recognized (Ro-

manssini et al., 2023), its wider adoption continues

to be hampered by technical and organizational bar-

riers. We believe that future efforts should focus on

removing these barriers, in particular by diversifying

use cases and improving the reusability, configura-

bility, and scalability of AIS solutions. Here, again,

we recommend to consider techniques such as on

product-line engineering (Pohl et al., 2005; Uysal

and Mergen, 2021). In addition, clearer cost-benefit

analysis and success metrics could help confirm the

return on AIS investment for practitioners who are

still unsure. Furthermore, a careful assessment of

trade-offs in applying certain recommendations over

others could enhance the decision-making process

for practitioners.

RQ

2

: Added Value

AIS are widely perceived as valuable, with bene-

fits like reducing downtime, improving efficiency,

and optimizing quality. The primary applica-

tion seems to be predictive maintenance, though

broader use cases remain underutilized. Despite

positive perceptions, inconsistent outcomes, chal-

lenges in demonstrating ROI, reusability, and scal-

ability may limit wider adoption.

5.3 Threats to Validity

There are several limitations, i.e., threats to validity,

in our work, which are described in the following.

In detail, we focus on internal (i.e., extent to which

causal conclusions can be drawn), external validity

(i.e., generalizability of findings), and construct

validity (i.e., how variables are measured).

Internal Validity. Overall, we might misinterpret

certain free-text responses from participants. How-

ever, we intentionally included multiple researchers

to ensure a balanced analysis. Another threat to the

internal validity of our study is the selection bias of

participants, as they were mainly recruited through

LinkedIn and the authors’ professional networks,

which could bias our sample of AIS practitioners. To

reduce this bias, we asked AIS practitioners to share

the survey with other practitioners. Another issue

is response bias, as respondents may give socially

desirable answers, especially on sensitive AIS topics

such as actual added value. To address this, we have

provided anonymity and a prefer not to say options.

External Validity. Our study’s findings may not

be completely generalizable across all AIS profes-

sionals, potentially reflecting regional influences. To

address this issue, we employed multiple distribution

channels and encouraged participants to share the

survey. Considering that a larger sample (>26

participants) and a higher return rate (>30%) could

enhance generalization, we argue that our findings

are still valuable. Further, 65% of the participants

bring at least six years of practical experience in

AIS development, enhancing our confidence in the

results. We note that our results and findings (i.e.,

insights) have not yet been evaluated (i.e., validated),

for examples based on comparing related studies.

However, a validation of our study is already planned

in the context of future research, in particular related

to configuration issues in manufacturing AIS.

Adopting Artificial-Intelligence Systems in Manufacturing: A Practitioner Survey on Challenges and Added Value

95

Construct Validity. Our questionnaire, which in-

cludes concepts like AIS use cases and learning strate-

gies, might have been misunderstood. To mitigate

this, we based questions on established terms and def-

initions of the AIS community, ensuring that these are

familiar to experts. While Likert scales and closed-

ended questions might miss some nuances, we addi-

tionally included open-ended questions for more de-

tailed insights. We also screened responses for out-

liers in data and response times, resulting in the ex-

clusion of one participant.

6 RELATED WORK

AIS in manufacturing, their challenges, and as-

sociated strategies have been addressed in various

overview contexts, for example, concerning predic-

tive maintenance, quality control, or operational ef-

ficiency. Studies like those by Nelson et al. (2023)

systematically reviewed AI applications in manufac-

turing, discussing societal implications, such as work-

force impact and security concerns. Additionally, Ko-

valenko et al. (2023) discussed the integration of

AI into manufacturing systems, emphasizing the ne-

cessity for seamless human-AI collaboration and ro-

bust data infrastructure. Furthermore, Espina-Romero

et al. (2024) did a bibliometric analysis regarding the

challenges and opportunities in AI implementation

within manufacturing.

Empirical studies focusing on the perspectives of

manufacturing practitioners, i.e., work that is closely

related to our study, remain rather limited although

they offer valuable insights into the real-world im-

plementation and issues of AIS. Culot et al. (2020)

reported a delphi study with 76 participants from

practice and research to assess most common expec-

tations and issues of Industry 4.0 in manufacturing

with AI identified as one essential pillar with asso-

ciated potentials. Demlehner et al. (2021) conducted

a delphi study with 39 practitioners to identify valu-

able use cases of AIS in car manufacturing with high

added value. Kutz et al. (2022) focused on the suc-

cess factors and barriers of AIS implementation based

on ten semi-structured interviews, pointing toward

challenges regarding data, operational processes, and

stakeholder engagement.

The related work, while clearly underscoring the

importance of understanding practitioner experiences,

provides somewhat overlapping insights, however,

with an other thematic focus or target group. So, un-

like prior work that predominantly focused on techni-

cal advancements, use cases, or more general chal-

lenges, our work explores not only the challenges

manufacturing experts face but also their strategies

for overcoming them. Additionally, we asked for the

practical added value of AIS from a business perspec-

tive, providing unique insights into whether AIS im-

plementations are perceived as worthwhile in current

manufacturing practices. This practitioner-centered

approach offers a novel, additional perspective, com-

plementing existing literature and addressing the gap

in understanding the practical realities of AIS adop-

tion in the manufacturing industry.

7 CONCLUSION

In this paper, we explored the practical challenges

and perceived value of implementing AIS in the

SM industry through a survey of experienced prac-

titioners. Our findings highlight that while current

AIS offer significant potential in areas such as pre-

dictive maintenance and efficiency optimization, sev-

eral barriers hinder their wider adoption. Key chal-

lenges include data quality issues, complex integra-

tion processes, configurability and scalability com-

plexities, and organizational resistance to change. De-

spite these hurdles, the survey indicates a positive

perception of AIS, with most participants agreeing

on their economic and operational benefits. How-

ever, the need for standardized development frame-

works, clearer benchmarks for success, and diversi-

fied (i.e., highly-configurable) AIS beyond predictive

maintenance remains critical for further advancement.

Note that our findings are currently not validated, em-

phasizing the need for further follow-up case stud-

ies and comparative studies based on secondary data

sources. Nevertheless, we emphasize that our results

are a highly valuable first steps towards a better un-

derstanding of AIS, their transferability from theory

into practice, actual business needs, and success in

real-world manufacturing environments.

Moreover, future research and development

should focus on addressing our identified barriers.

Here, we strongly recommend to focus on prioritizing

modular, configurable, and scalable AIS solutions,

enhancing data-management practices, and fostering

industry-wide collaboration to share best practices.

We believe, by tackling these challenges, the manu-

facturing industry can further realize the transforma-

tive potential of AIS, driving innovation, efficiency,

and competitiveness in modern manufacturing.

ICSOFT 2025 - 20th International Conference on Software Technologies

96

REFERENCES

Alharthi, N. W. and Brand

˜

ao, M. (2024). Physical and dig-

ital adversarial attacks on grasp quality networks. In

International Conference on Robotics and Automation

(ICRA), pages 1907–1902. IEEE.

Arias-P

´

erez, J. and V

´

elez-Jaramillo, J. (2022). Ignor-

ing the three-way interaction of digital orientation,

not-invented-here syndrome and employee’s artificial

intelligence awareness in digital innovation perfor-

mance: A recipe for failure. Technological Forecast-

ing and Social Change, 174:121305.

Bolstorff, P. and Rosenbaum, R. (2007). Supply chain ex-

cellence: A handbook for dramatic improvement us-

ing the scor model. Journal of Supply Chain Manage-

ment, 39(4):38.

Brandt, D. R. and Scharioth, J. (1998). Attribute life cycle

analysis. alternatives to the kano method. In Market-

ing Research Congress, pages 413–430. ESOMAR.

Chitturi, R., Raghunathan, R., and Mahajan, V. (2008). De-

light by design: The role of hedonic versus utilitarian

benefits. Journal of marketing, 72(3):48–63.

Chryssolouris, G., Alexopoulos, K., and Arkouli, Z. (2023).

Artificial intelligence in manufacturing systems. In A

Perspective on Artificial Intelligence in Manufactur-

ing, pages 79–135. Springer.

Culot, G., Orzes, G., Sartor, M., and Nassimbeni, G. (2020).

The future of manufacturing: A delphi-based scenario

analysis on industry 4.0. Technological forecasting

and social change, 157:120092.

Demlehner, Q., Schoemer, D., and Laumer, S. (2021). How

can artificial intelligence enhance car manufacturing?

a delphi study-based identification and assessment of

general use cases. International Journal of Informa-

tion Management, 58:102317.

El Naqa, I. and Murphy, M. (2015). What is machine learn-

ing? In Machine Learning in Radiation Oncology,

pages 3–11.

Espina-Romero, L., Guti

´

errez Hurtado, H., R

´

ıos Parra,

D., Vilchez Pirela, R. A., Talavera-Aguirre, R., and

Ochoa-D

´

ıaz, A. (2024). Challenges and opportunities

in the implementation of ai in manufacturing: A bib-

liometric analysis. Sci, 6(4):60.

Ge, Z., Song, Z., Ding, S. X., and Huang, B. (2017). Data

mining and analytics in the process industry: The role

of machine learning. IEEE Access, 5:20590–20616.

Hasan, S. M., Shahid, A. R., and Imteaj, A. (2024). Evaluat-

ing sustainability and social costs of adversarial train-

ing in machine learning. IEEE Consumer Electronics

Magazine.

Jaiswal, A., Arun, C. J., and Varma, A. (2023). Reboot-

ing employees: Upskilling for artificial intelligence in

multinational corporations. In Artificial Intelligence

and International HRM, pages 114–143. Routledge.

Jeziorek, O. (1994). Lean production. Lean Production,

pages 3–27.

Kilkenny, M. F. and Robinson, K. M. (2018). Data qual-

ity:“garbage in–garbage out”.

Kotsiantis, S. B., Zaharakis, I., Pintelas, P., et al. (2007). Su-

pervised machine learning: A review of classification

techniques. Emerging Artificial Intelligence Applica-

tions in Computer Engineering, 160(1):3–24.

Kovalenko, I., Barton, K., Moyne, J., and Tilbury, D. M.

(2023). Opportunities and challenges to integrate

artificial intelligence into manufacturing systems:

Thoughts from a panel discussion [opinion]. Robotics

& Automation Magazine, 30(2):109–112.

Kovi

ˇ

c, K., Tominc, P., Prester, J., and Pal

ˇ

ci

ˇ

c, I. (2024). Arti-

ficial intelligence software adoption in manufacturing

companies. Applied Sciences, 14(16):6959.

Kusiak, A. (2018). Smart manufacturing. International

Journal of Production Research, 56:508 – 517.

Kutz, J., Neuh

¨

uttler, J., Spilski, J., and Lachmann,

T. (2022). Implementation of ai technologies in

manufacturing-success factors and challenges. In In-

ternational Conference on Applied Human Factors

and Ergonomics (AHFE), pages 24–28.

Lee, W.-Y., Lee, Y., Jeong, J. S., Yu, G.-I., Kim, J. Y.,

Park, H. J., Jeon, B., Song, W., Kim, G., Weimer,

M., et al. (2019). Automating system configuration of

distributed machine learning. In International Con-

ference on Distributed Computing Systems (ICDCS),

pages 2057–2067. IEEE.

Lepore, D., Dubbini, S., Micozzi, A., and Spigarelli, F.

(2022). Knowledge sharing opportunities for indus-

try 4.0 firms. Journal of the Knowledge Economy,

13(1):501–520.

Li, Y., Cheng, M., Hsieh, C.-J., and Lee, T. C. M. (2022). A

review of adversarial attack and defense for classifica-

tion methods. The American Statistician, 76(4):329–

345.

L

´

opez Mart

´

ınez, P., Barros, L., and Drake, J. M. (2010).

Scheduling configuration of real-time component-

based applications. In International Conference on

Reliable Software Technologies (Ada-Europe), pages

181–195. Springer.

May, R. and Adler, S. (2024). Experiences in develop-

ing configurable digital twin-assisted xR applications

for industrial environments. In International Work-

ing Conference on Variability Modelling of Software-

Intensive Systems (VaMoS), pages 1–5. ACM.

May, R., Alex, A., Suresh, R., and Leich, T. (2024a).

Product-line engineering for smart manufacturing: A

systematic mapping study on security concepts. In In-

ternational Conference on Software Technologies (IC-

SOFT), pages 323–330. SciTePress.

May, R. et al. (2023a). A systematic mapping study on se-

curity in configurable safety-critical systems based on

product-line concepts. In International Conference

of Software Technologies (ICSOFT), pages 217–224.

SciTePress.

May, R., Kr

¨

uger, J., and Leich, T. (2024b). Sok: How

artificial-intelligence incidents can jeopardize safety

and security. In International Conference on Avail-

ability, Reliability and Security (ARES), pages 1–12.

ACM.

May, R., Niemand, T., Scholz, P., and Leich, T. (2023b).

Design patterns for monitoring and prediction ma-

chine learning systems: Systematic literature review

and cluster analysis. In International Conference

Adopting Artificial-Intelligence Systems in Manufacturing: A Practitioner Survey on Challenges and Added Value

97

of Software Technologies (ICSOFT), pages 209–216.

SciTePress.

Mehak, R., Ashima, M., and Kiran, R. (2023). Artificial

intelligence. International Journal of Advanced Re-

search in Science, Communication and Technology,

3(7):20–30.

Meyer, O., Rauhoeft, G., Schel, D., and Stock, D. (2018).

Industrial internet of things: covering standardization

gaps for the next generation of reconfigurable produc-

tion systems. In International Conference on Indus-

trial Informatics (INDIN), pages 1039–1044. IEEE.

Mijwil, M. M. and Abttan, R. A. (2021). Artificial intelli-

gence: a survey on evolution and future trends. Asian

Journal of Applied Sciences, 9(2).

Moll

´

eri, J. S., Petersen, K., and Mendes, E. (2016). Survey

guidelines in software engineering: An annotated re-

view. In International Symposium on Empirical Soft-

ware Engineering and Measurement (ESEM), pages

1–6.

Monostori, L. (2003). Ai and machine learning techniques

for managing complexity, changes and uncertainties in

manufacturing. Engineering Applications of Artificial

Intelligence, 16(4):277–291.

Monostori, L., K

´

ad

´

ar, B., Bauernhansl, T., Kondoh, S., Ku-

mara, S., Reinhart, G., Sauer, O., Schuh, G., Sihn, W.,

and Ueda, K. (2016). Cyber-physical systems in man-

ufacturing. Cirp Annals, 65(2):621–641.

Naz, F., Kumar, A., Agrawal, R., Garza-Reyes, J. A., Ma-

jumdar, A., and Chokshi, H. (2024). Artificial intel-

ligence as an enabler of quick and effective produc-

tion repurposing: an exploratory review and future re-

search propositions. Production Planning & Control,

35(16):2154–2177.

Nelson, J. P., Biddle, J. B., and Shapira, P. (2023). Applica-

tions and societal implications of artificial intelligence

in manufacturing: A systematic review. arXiv preprint

arXiv:2308.02025.

Plathottam, S. J., Rzonca, A., Lakhnori, R., and Iloeje, C. O.

(2023). A review of artificial intelligence applications

in manufacturing operations. Journal of Advanced

Manufacturing and Processing, 5(3):e10159.

Pohl, K. et al. (2005). Software product line engineering:

Foundations, principles, and techniques. Springer.

Qi, G.-J. and Luo, J. (2022). Small data challenges in big

data era: A survey of recent progress on unsuper-

vised and semi-supervised methods. IEEE Transac-

tions on Pattern Analysis and Machine Intelligence,

44(4):2168–2187.

Rebala, G., Ravi, A., and Churiwala, S. (2019). An intro-

duction to machine learning. Springer.

Ridzuan, F. and Zainon, W. M. N. W. (2019). A review on

data cleansing methods for big data. Procedia Com-

puter Science, 161:731–738.

Romanssini, M., de Aguirre, P. C. C., Compassi-Severo, L.,

and Girardi, A. G. (2023). A review on vibration mon-

itoring techniques for predictive maintenance of rotat-

ing machinery. Eng, 4(3):1797–1817.

Ross, N. S., Sheeba, P. T., Shibi, C. S., Gupta, M. K., Ko-

rkmaz, M. E., and Sharma, V. S. (2024). A novel

approach of tool condition monitoring in sustainable

machining of ni alloy with transfer learning models.

Journal of Intelligent Manufacturing, 35(2):757–775.

Rowley, J. (2007). The wisdom hierarchy: Representations

of the dikw hierarchy. Journal of information science,

33(2):163–180.

Scholz, P. (2022). Applikation maschinell lernender Sys-

teme in der vernetzten adaptiven Produktion. Ap-

primus Wissenschaftsverlag.

Schuh, G. and Schmidt, C. (2014). Produktionsmanage-

ment. Springer.

Schuh, G. and Scholz, P. (2019). Development of a frame-

work for the systematic identification of ai application

patterns in the manufacturing industry. In Portland In-

ternational Conference on Management of Engineer-

ing and Technology (PICMET), pages 1–8. IEEE.

Schuh, G., Scholz, P., Leich, T., and May, R. (2020). Iden-

tifying and analyzing data model requirements and

technology potentials of machine learning systems in

the manufacturing industry of the future. In Inter-

national Scientific Conference on Information Tech-

nology and Management Science (ITMS), pages 1–10.

IEEE.

Scotti, V. (2019). Artificial intelligence. IEEE Instrumen-

tation & Measurement Magazine, 23(3):27–31.

Soldatos, J. (2024). Artificial intelligence in manufactur-

ing: enabling intelligent, flexible and cost-effective

production through AI. Springer Nature.

Sorensen, D. G. H., Brunoe, T. D., and Nielsen, K. (2018).

Challenges in production and manufacturing systems

platform development for changeable manufacturing.

In International Conference on Advances in Produc-

tion Management Systems (APMS), pages 312–319.

Springer.

Uysal, M. P. and Mergen, A. E. (2021). Smart manufac-

turing in intelligent digital mesh: Integration of en-

terprise architecture and software product line engi-

neering. Journal of Industrial Information Integra-

tion, 22:100202.

Vogelsang, A. and Borg, M. (2019). Requirements engi-

neering for machine learning: Perspectives from data

scientists. In International Requirements Engineering

Conference Workshops (REW), pages 245–251. IEEE.

Windmann, A., Wittenberg, P., Schieseck, M., and Nigge-

mann, O. (2024). Artificial intelligence in industry

4.0: A review of integration challenges for industrial

systems. arXiv preprint arXiv:2405.18580.

Xiang, W., Yu, K., Han, F., Fang, L., He, D., and Han, Q.-

L. (2024). Advanced manufacturing in industry 5.0: A

survey of key enabling technologies and future trends.

Transactions on Industrial Informatics, 20(2):1055–

1068.

Yavich, R., Malev, S., Volinsky, I., and Rotkin, V. (2023).

Configurable intelligent design based on hierarchical

imitation models. Applied Sciences, 13(13):7602.

Zhang, L., Hao, S., and Ming, M. (2022). A real-time detec-

tion method of software configuration errors based on

fine-grained configuration item types. Scientific Pro-

gramming, 2022:1–13.

ICSOFT 2025 - 20th International Conference on Software Technologies

98