Sustainability in Product Models: Leveraging Adjacent Information

for CO

2

Profiling in Configurations

Anders Jakobsen

a

and Torben Tambo

b

Department of Business Development and Technology, Aarhus University, Birk Centerpark 15, Herning, Denmark

Keywords: Product Configuration System, Configuration Management, Sustainability Adjacency, Adjacent Information,

Environmental Computation, Product Lifecycle Management.

Abstract: This paper introduces the concept of Sustainability Adjacency as a framework for integrating adjacent

information into CO₂ profiling and product configuration systems. By leveraging supplementary data, such

as supplier emissions, logistics, and lifecycle assessments, the framework enables a comprehensive evaluation

of a product’s sustainability impact. Current sustainability initiatives often operate in silos, neglecting broader

trade-offs like transportation emissions in refurbishment or end-of-life scenarios. The proposed framework

addresses these gaps by centralizing critical data, ensuring its propagation across organizational functions to

prioritize low-emission configurations. Through an action research approach, the study highlights systemic

barriers, including data quality issues, supplier transparency, and misaligned workflows, that hinder CO₂

profiling efforts. The findings emphasize the importance of dynamic data integration and cross-functional

collaboration in aligning sustainability with operational and financial goals. This paper contributes to

advancing sustainable product models and outlines actionable steps for organizations to embed sustainability

into product lifecycle management effectively.

1 INTRODUCTION

The growing importance of sustainability requires

organizations to define, design, control and

operationalize systems to maximize the value of

product offerings over the complete product life

cycles (Krikke, 2011; Brundage et al., 2018; Di

Biccari et al., 2018). This is further intensified by the

European Commission through the introduction of

new proposals addressing critical aspects of climate

change and environmental degradation, with the aim

of achieving a climate-neutral continent by 2050

(Campo Gay et al., 2024). According to (McKinsey

& Company, 2020), there is a correlation between the

assessment of product components and carbon

emission profiles, whereas organizations have set

explicit emission-reduction goals. Moreover, the

robustness of information, data and system

capabilities determines the computed CO

2

profile,

helping organizations meeting greenhouse-gas

(GHG) regulatory targets and reporting requirements

a

https://orcid.org/0009-0006-4196-9469

b

https://orcid.org/0000-0001-8491-7286

(Hallstedt, 2017; Chauvy et al., 2019; He et al., 2019;

Jakobsen et al., 2024a).

Despite these advancements, accurately profiling

CO

2

emissions across complex product

configurations remains a significant challenge for

many organizations (Jakobsen et al., 2024a). This

complexity arises from the need to integrate diverse

data sources and adjacent information to generate

reliable and actionable insights (Chauvy et al., 2019).

Impactful CO

2

profiling requires robust

information systems and knowledge management

that account for variability in materials, production

processes, and supply chain dynamics (Shafiee et al.,

2018; Campo Gay et al., 2024; Jakobsen et al.,

2024a). Leveraging adjacent information, such as

lifecycle assessments, material flow data, and energy

consumption metrics, can enhance the accuracy of

these profiles (Krikke, 2011; Badurdeen et al., 2018;

Brundage et al., 2018; Kalita et al., 2021). As

organizations strive to meet greenhouse-gas (GHG)

reduction targets and align with regulatory demands,

developing scalable systems for dynamic CO

2

Jakobsen, A. and Tambo, T.

Sustainability in Product Models: Leveraging Adjacent Information for CO 2 Profiling in Configurations.

DOI: 10.5220/0013467200003929

In Proceedings of the 27th International Conference on Enterprise Information Systems (ICEIS 2025) - Volume 1, pages 121-135

ISBN: 978-989-758-749-8; ISSN: 2184-4992

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

121

profiling has become a critical priority (McKinsey &

Company, 2024). These systems not only improve

compliance but also enable strategic decision-making

to enhance sustainability across product lifecycles

(Badurdeen et al., 2018; Di Biccari et al., 2018).

This complexity highlights the importance of

leveraging advanced digital tools like life cycle

assessment (LCA) configurators, which enable

organizations to integrate sustainability

considerations early in the product development

phase. Dynamic assessment of environmental

impacts, including CO

2

profiling, is facilitated by

automating processes and integrating real-time data

(Campo Gay et al., 2024). Leveraging adjacent

information, such as lifecycle data, material

properties, and energy consumption metrics to

improve accuracy and comprehensiveness for the

sustainability element of the product model. The

potential of this is demonstrated by Zubair et al.

(2024) as integrating LCA with digital tools in

building construction could lower CO

2

equivalent

emissions by roughly 29% during the raw material

phase, 16% in the operational phase, and 21% at the

end-of-life stage when compared to traditional

practices. Such advancements highlight the role of

data-driven methodologies in aligning product

configurations with sustainability objectives,

ultimately promoting informed choices that balance

technical performance and environmental impact

(Campo Gay et al., 2024; Jakobsen et al., 2024a).

Product modelling is a representation of

structured product information and data in respect to

material selection, design choices, and part ranges,

which impact the sustainability outcomes of product

models (Lee et al., 2007; Badurdeen et al., 2018).

Leveraging adjacent information, sustainability

becomes a system property and not a property of

individual elements of systems (Ceschin &

Gaziulusoy, 2016). This perspective emphasizes that

sustainability become apparent from the interactions

and interdependencies within the system relatively

than from isolated components (Ceschin &

Gaziulusoy, 2016). In product modelling, adjacent

information e.g., supply chain data, LCA, energy use

patterns, and end-of-life disposal options, enables a

holistic evaluation of a product's sustainability impact

(Campo Gay et al., 2024; Jakobsen et al., 2024a). This

systems-level approach ensures that material

selection, design configurations, and part choices

align with sustainability objectives, accounting for

trade-offs and synergies across the entire lifecycle.

Therefore, the purpose of this paper is to explore

the role of adjacent information in advancing

sustainable design practices through enhanced

product modelling in a computing environment.

Specifically, it aims to identify the types of adjacent

information required for optimizing solutions in

documenting environmental labels and declarations,

such as lifecycle data, material properties, and supply

chain metrics. By examining how such data

interconnects within product modelling frameworks,

this study seeks to demonstrate how adjacent

information facilitates the development of data-

driven methodologies for sustainability. Additionally,

this paper seeks to demonstrate the integration of

these elements into a computing system enhances the

sufficiency and accuracy of sustainable design

practices.

2 THEORETICAL

BACKGROUND

2.1 Sustainability in Product Lifecycle

Management

Quantifying the environmental performance of

products and conducting comprehensive

environmental evaluations are guided by the

principles outlined in ISO 14040 and further

elaborated through the detailed methodological

framework provided in ISO 14044 (Campo Gay et al.,

2024). However, sustainability information is not

easily shared between stages in the product lifecycle

as there is a gap in manufacturing through data and

knowledge sharing (Brundage et al., 2018). This is

intensified in industry as more data is being generated

at exceptional rates and variation than ever before

(Komoto et al., 2020). Product Lifecycle

Management (PLM) involves the synchronisation of

product design, manufacturing workflows, software

platform interoperability, and the continuous

synchronization of data across various enterprise

applications (Jakobsen et al., 2024b). Literature

connects PLM and sustainability into sustainable

product lifecycles and designs considering the three

important aspects, i.e., economics, social, and

environmental (Kalita et al., 2021). In other words,

maximizing the product lifecycle profit, and

minimizing energy and water usage over the complete

lifetime (Kalita et al., 2021). Jakobsen et al. (2024b)

highlight that the relationship between PLM and

sustainability remains ambiguous, emphasizing the

need for a comprehensive assessment of data

interoperability to support sustainable practices and

optimize product lifecycle management within digital

systems. Additionally, sustainable practices in PLM

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

122

must address critical decisions on material selection,

design methodologies, and product end-of-life

processes, including recycling, reuse, and

disassembly (Vila et al., 2015). These phases,

described as the foundation of Green PLM, require

integrating eco-design principles, advanced

manufacturing processes, and efficient waste

management strategies to minimize environmental

impacts for sustainability (Vila et al., 2015). In other

words, knowledge, information, and data for PLM in

respect to sustainability is used for the materials and

processes selection based on product modelling

criteria needed in the design of product parts (Vila et

al., 2015).

2.2 CO

2

Profiling and Environmental

Impact Assessment

The assessment of sustainability in products has

become an area of increasing focus among both

academic researchers and industry professionals. The

development of CO₂ profiles for product models is

constrained by defined system boundaries, as

illustrated in figure 1. These profiles and their impact

assessments are primarily centred on Global

Warming Potential (GWP), a key component of Life

Cycle Assessment (LCA) analysis (Brunø et al.,

2013; Briem et al., 2019; Campo Gay et al., 2022).

Consequently, the evaluation of CO₂ profiles for

product models relies on analysing the environmental

impacts of a product system within the framework of

an LCA (Brunø et al., 2013; Briem et al., 2019;

Campo Gay et al., 2022)

Figure 1: System boundary, adopted from (Briem et. al

2019).

The attributional LCA methodology is structured

around a defined framework and specific objectives.

From a PLM perspective, attributional LCA

traditionally adopts a static and retrospective

approach to evaluating the product lifecycle (Briem

et al., 2019). However, the development of CO₂

profiles and the assessment of environmental impacts

in product modelling depend on informed decision-

making, driven by the availability of environmental

data and sustainable options (Campo Gay et al., 2022;

Campo Gay et al., 2024). Additionally, Campo Gay

et al. (2022) emphasize that the construction of a CO₂

profile relies on available options and product

specifications. To reduce the CO₂ equivalent, it is

essential to prioritize sustainable choices and

integrate these into the customer's decision-making

process. This can be achieved, for example, using a

computing configurator that facilitates sustainability

considerations and guides customers toward more

environmentally friendly options (Shafiee et al.,

2018; Campo Gay et al., 2024; Jakobsen et al.,

2024a). Furthermore, effective CO₂ profiling depends

not only on product-specific data but also on adjacent

information, such as supply chain emissions, material

sourcing, and manufacturing processes (Helo et al.,

2024). Integrating this broader spectrum of data

ensures a more accurate and holistic representation of

a product's environmental impact, thereby enhancing

the customer's ability to make informed and

sustainable choices.

2.3 Adjacent Information in Product

Models

The concept of adjacent information in product

models refers to the supplementary data and

contextual knowledge that exist outside the core

technical specifications of a product but remain

critically relevant to its analysis and decision-making

processes (Bates, 1989; Nonaka & Takeuchi, 1995).

This supplementary information includes elements

such as supply chain logistics, environmental

impacts, material sourcing, manufacturing practices,

and end-of-life considerations. Integrating adjacent

information into product models allows for a more

comprehensive evaluation, bridging the gap between

isolated product data and the broader lifecycle

impacts (Bates, 1989; Nonaka & Takeuchi, 1995).

For example, while a product model might detail the

material composition and structural design, adjacent

information can provide insights into the CO₂

emissions associated with raw material extraction,

transportation, or production methods.

This integration emphasizes the compilation of

multiple information systems, such as enterprise

resource planning (ERP), manufacturing execution

systems (MES), and LCA tools, to enhance product

documentation and decision-making (Badurdeen et

al., 2018; Komoto et al., 2020; Jakobsen et al.,

2024a). These systems contribute product insights

into dynamic and interconnected factors, such as

environmental compliance, cost analysis, and

production scalability. By consolidating adjacent

information into product models, organizations can

Sustainability in Product Models: Leveraging Adjacent Information for CO 2 Profiling in Configurations

123

move beyond static documentation and adopt a

holistic, context-aware approach.

The contextual relevance of adjacent information

lies in its ability to inform decisions that extend

beyond the technical engineering design paradigm,

such as aligning production goals with sustainability

metrics or optimizing resource allocation to reduce

waste (Krikke, 2011; Shafiee et al., 2018). In simpler

terms, adjacent information helps connect the dots

between the technical details of a product model and

the broader objectives of an organization, such as

reducing the environmental impact. This can be

translated into supporting the structure of selecting

eco-friendly materials, improving logistics to

minimize emissions, or designing products that are

easier to recycle at the end of their life (Shafiee et al.,

2018; Campo Gay et al., 2022; Campo Gay et al.,

2024).

2.4 Computing Environments for

Sustainable Design

The computation of LCA knowledge in a product

modelling environment is a complex task, and it is not

well understood how this knowledge can be

automatically implemented into systems (Campo Gay

et al., 2024). According to Campo Gay et al. (2022)

literature is very limited within this area and suggest

applying the Product Variant Master technique

(PVM) to assess the knowledge from domain experts

in an ontology model. The principles of modelling

mechanical products and systems theory are applied

to define the structure within the PVM (Mortensen et

al., 2010). This structures the configuration system's

structure and its computing environment, aligning it

with the product families to be modelled, and the user

requirements for the configuration system

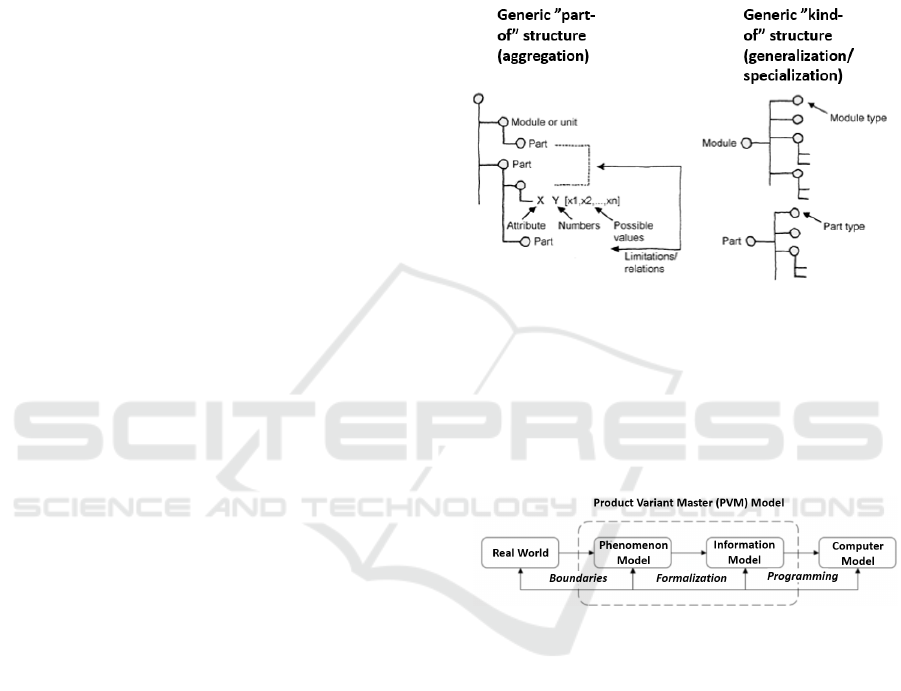

(Mortensen et al., 2010). Figure. 2. Demonstrates the

principles of PVM. A product variant master

comprises two main components. The first

component, known as the "part-of" model

(represented on the left-hand side of the product

variant master), includes the modules or parts

common to the entire product family (Mortensen et

al., 2010). Each module or part is further detailed with

attributes that define their properties and

characteristics.

The second component (illustrated on the right-

hand side) outlines how a product part can exist

across multiple variants. These two structural types,

"part-of" and "kind-of," correspond to the

aggregation and specialization structures found in

object-oriented modelling (Mortensen et al., 2010).

Similar to the "part-of" model, the individual parts

here are also characterized by attributes.

Additionally, the product variant master specifies the

critical relationships between modules or parts,

including the rules governing their permitted

combinations (Mortensen et al., 2010). This is

visually represented by connecting lines between

modules or parts, accompanied by the relevant

combination rules.

Figure 2: Principles of the Product Variant Master, adopted

from (Mortensen et al., 2010).

The PVM technique serves as a tool for data

collection and communication, organizing product

knowledge to facilitate discussions about the product

model (Campo Gay et al., 2022). This is illustrated

below in figure 3.

Figure 3: Conversion of knowledge from the real world to

the computing model, adopted from (Shafiee et al., 2019).

The computing environment for product modelling

for sustainable designs requires product knowledge

within the defined solution space (possible

configurations) (Shafiee et al., 2019). The

computation of product modelling tools is employed

for documenting and facilitating communication in

product configurations (Shafiee et al., 2019). The

product modelling manages the increasing

complexities of software development, allowing

engineers to operate and communicate at more

abstract levels while ensuring comprehensive

documentation within its computing environment

(Shafiee et al., 2019). In addition, Shafiee et al.

(2019) emphasize the PVM technique to enhance

knowledge sharing across organizational units, which

contributes considerably to an organization’s

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

124

performance. Having an impactful system for the

sustainability aspect of documenting the structure,

attributes, and constraints modelled within the

computing environment is essential, as well as

ensuring communication between developers and

domain experts (Badurdeen et al., 2018; Shafiee et al.,

2019; Komoto et al., 2020; Jakobsen et al., 2024a).

The complexity of knowledge sharing and

communication of product models remains a

challenging task. The integration and complexity of

adjacent information, such as supply chain data,

environmental impacts, and operational constraints

into product models remains underexplored. This gap

is significant as adjacent information can enhance

decision-making by enabling a more holistic view of

the product lifecycle within sustainable design

context. The novelty of adjacent information into

computing environments supports the alignment of

sustainable practices with organizational goals,

linking abstract product knowledge and real-world

applications. Addressing this gap is crucial for

advancing computing environments that can manage

the complexities of sustainability-driven product

design and configuration processes.

3 RESEARCH METHOD

This paper aims to contribute to the literature on

sustainability in product models by leveraging

adjacent information for CO₂ profiles in

configurations. The overall objective is to develop a

framework of adjacency for sustainable configuration

processes. This involves collecting examples and

cases of adjacent information relevant to

configuration management for sustainability in

product models. To provide a foundation for the

proposed framework an action research methodology

was chosen as it facilitates experimentation aimed at

improving conditions within an existing organization,

enables the application of methods in real-world

settings (Gummesson, 2000) and simultaneously

contributing to literature (Shani & Pasmore, 1982).

The action research methodology for this study is

conducted in an industrial manufacturing company,

specializing in energy-efficient fluid management

and pumping technologies. This collaboration is done

to meet the stated research objectives to generate and

collect knowledge in the current solution space of

adjacency for product modelling. The concept of

adjacency aligns closely with knowledge

management principles, addressing challenges in

situations where existing organizational systems and

resources are insufficient to solve emergent system-

level problems (Shafiee et al., 2018).

In the context of this action research study,

adjacency is an extension of knowledge management

(Shafiee et al., 2018). The approach was designed as

an iterative and participatory process involving the

creation, storage, transfer, and application of

knowledge, actively engaging stakeholders to

enhance the knowledge business value chain and

address practical challenges within the organizational

setting. This approach includes the identification and

collection of adjacent information in product models

across the complete business value chain and

throughout the entire lifecycle of adjacency

knowledge. The assessment involves mapping

systems, data, information, and knowledge to align

with sustainability goals in product models for CO₂

profiling (Shafiee et al., 2018).

Data was collected through a combination of

qualitative and participatory methods. This included

conducting interviews and workshops with key

stakeholders, reviewing internal documents and

reports, and observing existing practices within the

organization. The collected data focused on

identifying instances of adjacent information relevant

to configuration management and sustainability in

product models. These activities ensured the

inclusion of real-world insights and examples, which

form the empirical foundation for developing the

proposed framework of adjacency for sustainable

configuration processes.

3.1 Case Company

The case company analysed in this study is a global

leader in advanced fluid management and energy-

efficient pumping technologies, headquartered in

Denmark. Despite its strong market position and

extensive experience in producing high-quality

solutions across various industries, the company faces

significant challenges in addressing the growing

complexity of sustainability in product models.

Currently, the most advanced form of sustainability

documentation available for its product models is

Environmental Product Declarations (EPDs) based

on LCA data.

The organization operates within a distributed

knowledge network where critical information on

sustainability is scattered across various departments.

However, existing systems and workflows do not

adequately support the resolution of systemic issues

related to sustainable product modelling. This gap

results in reliance on manual and internal problem-

solving efforts to meet documentation requirements

Sustainability in Product Models: Leveraging Adjacent Information for CO 2 Profiling in Configurations

125

for product models, often through ad-hoc processes

and emergent knowledge-sharing practices.

As a consequence, the company struggles to

establish cohesive and efficient methods for

integrating sustainability into its product

configuration processes. The knowledge required to

address these challenges evolves dynamically within

the organization, characterized by a high degree of

improvisation and the gradual development of

routines to manage the demands of sustainable

product modelling. This study explores how these

challenges can be addressed by leveraging adjacent

information to create a more structured and impactful

approach to sustainability in product models.

4 FINDINGS

Table 1 showcase a schematic representation of

sustainability adjacency within the case company.

The table provides a structured understanding of

sustainability elements in relation to adjacent

information flows across various corporate functions.

It highlights the ways in which these functions

contribute or fail to contribute to CO₂ profiling within

product models. Furthermore, the evolvement of

sustainability interpretations and representations over

time has led to the establishment of several dedicated

corporate functions in this domain, some of which are

also embedded at the divisional level. These

functions, ranging from Corporate Social

Responsibility (CSR) to LCA, and Environmental,

Social, and Governance (ESG) initiatives, offer

unique perspectives and data islands that either

directly or indirectly inform the company’s

sustainability practices. The table thus serves as a

foundation for understanding the fragmented yet

evolving landscape of sustainability in the

organization.

This schematic outline reveals a diverse set of

sustainability elements, each attached within distinct

corporate functions. For example, while CSR

primarily focuses on supplier assessments and social

inclusivity, its role in CO₂ profiling remains indirect,

offering contextual support rather than direct

integration into product models. Similarly, the

Retrofit function emphasizes economic sustainability

through market opportunities for extending product

life cycles, yet it lacks measurable contributions to

CO₂ profiling. In contrast, functions like ESG and

LCA emerge as pivotal contributors. ESG facilitates

alignment with sustainability legislation and

integrates raw material and production data into

reporting frameworks, thereby supporting CO₂

profiling efforts. LCA, on the other hand, provides the

most robust connection, directly addressing life cycle

impacts and forming a core data source for CO₂

profiling within product configurations.

The findings also underscore significant gaps in

integration, particularly in functions such as Quality

and Financial. While these functions are crucial for

compliance and governance, their contributions to

sustainability often remain isolated from broader

CO₂-focused initiatives. This fragmentation is further

compounded by the existence of "data islands," which

slow unified information sharing and systemic

alignment. Such challenges highlight the need for a

more cohesive framework that bridges adjacent

information across corporate functions to enhance the

organization’s capacity for sustainability-driven

innovation.

The findings also reveal that customers are

primarily driven by sustainability factors such as

water and electricity savings, with a growing

emphasis on the CO₂ profile of product models.

However, a critical gap exists within the case

company, as its adjacent information systems and

workflows do not sufficiently align with the

customers’ focus on CO₂ profiling. Current

sustainability documentation relies on Environmental

Product Declarations (EPDs), which are generated

through LCA data. These processes are heavily

dependent on manual data handling, such as the use

of Excel spreadsheets and tacit knowledge sharing.

This reliance on fragmented and labour-intensive

methods prevents the seamless integration of adjacent

information into product models, thereby limiting the

company’s ability to meet customer expectations for

transparent and comprehensive CO₂ profiling.

Addressing this misalignment will be essential for

bridging the gap between customer demands and the

company’s internal capabilities, ensuring that

sustainability initiatives are both impactful and

scalable.

4.1 Mapping Sustainability Adjacency

in Product Life Cycle Models

To address the critical gaps identified in the case

company's sustainability practices, it is essential to

map sustainability adjacency across the product life

cycle. By structuring the analysis around distinct

phases of the product life cycle: (1) Mining, (2)

Production, (3) Operation, and (4) End of Life, the

table 2 highlights not only the system information

storage supporting each phase but also the associated

data gaps and challenges. This approach offers a

comprehensive

funnel through which to evaluate the

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

126

Table 1: Schematic representation of sustainability adjacency.

Function Data

islands

Integrated

data

Sustainability

Focus

CO₂ Profiling in

Product Models

CSR Broad assurance for responsible

behaviour. Supplier assessment. Specific

ruleset control, e.g. modern slavery act,

conflict minerals, child labour, dual-use

products, general human rights, labour

rights, supply chain inclusivity, water

stewardship

Reports on

each

separate

issue

Supplier

assessments

Social and

environmental

aspects

Indirectly relevant:

Supplier data can

inform the social

and environmental

dimensions of

product models

Retro-fit In the case company, a separate entity has

been tasked with creating a business area

of product retrofitting. There is no

evidence of greenhouse gas reduction by

doing so. However, it is important to

present the opportunity to the market

Operating

proce-

dures

Product data

catalogue

Product data

manage-ment

Warehou-sing

Economic

sustainabili-ty

by extending

product life

cycles and

exploring

retrofitting

Not relevant: The

focus is on

exploring market

opportunities for

retrofitting

Social

econo-

mic

action

For many years, the case company have

operated an inclusive workshop for

impaired persons. The workshop receives

products from worldwide and do various

disassembling and circularity tasks

Perfor-

mance

reports.

Circular

impact

None Social

sustaina-bility

Limited relevance:

highlights circular

economy practices

ESG The ESG function is specifically tasked

with data collection and reporting in

formalized frameworks of sustainability

management. Typically, alignment with

national and EU legislation in the field

ESG

reporting

Certain

production

figures are

used. E.g. to

present data on

use of raw

materials and

subassemblies

Holistic

sustaina-bility

covering

environ-

mental, social,

and

governance

dimensions

Relevant: ESG data

includes integrating

raw material use

and production

characteristics into

product models,

CO₂ profiling

LCA Looking at specific products for design-

time, (configure-time), production-time,

in-use, and end-of-life issues. This can

relate to specific materials, assemblies,

residuals, and behaviours

Spread-

sheet for

representati

on

None Environmenta

l sustaina-

bility through

the evaluation

of lifecycle

impacts and

material usage

Highly relevant:

LCA addresses the

environ-mental

impacts of product

mo-dels across their

lifecycle: data for

CO₂ pro-filing

product

configurations

Quality The quality function would look at

product compliance and – in some cases

– production optimization. The focus is

originally customer satisfaction, but this

seems to play a smaller role. Quality is

related to both suppliers, and internal

processes. Increasingly the compliance

element is non- related to either, but

rather related to regulatory and legislative

requirements

Quality

reports

Quality

approvals and

documents on

parts and

subassemblies.

Some work

instructions

Regulatory

compliance

and process

optimization

for sustaina-

bility

Partially relevant:

Quality assurance

contributes to

compliance but

offers limited CO₂ -

specific data

Finan-

cial

Financially related sustainability

governance issues. Include internal and

arms-length controls, sustainable

taxation, anti-corruption, anti-money

laundering, KYC, independence of key

profiles, and financial resilience

Financial

and non-

financial

audits are

document-

ted as

islands

Financial data

Transactional

approvals

Credit

approvals

Governance-

related

sustaina-bility,

focusing on

ethical and

financial

practices.

Not relevant:

Primarily focused

on governance and

financial

accountability

Sustainability in Product Models: Leveraging Adjacent Information for CO 2 Profiling in Configurations

127

Table 2: Mapping Sustainability Adjacency in Product Life Cycle Models.

Life Cycle

Phase

Description System Information

Storage

Data Gaps & Challenges

Mining Extraction of raw materials (e.g.,

metals, minerals) needed for

p

roduction.

ERP, LCA Tools Limited supplier transparency, incomplete

environmental data on sourcing, and

difficult

y

inte

g

ratin

g

with LCA tools.

Produc-

tion

Manufacturing and assembly of

components and products.

PLM, MES, ERP Fragmented data between systems, lack of

real-time environmental monitoring, and

insufficient inte

g

ration with CO₂ models.

Opera-

tions

Use phase, including energy

consumption and performance

monitorin

g

.

IoT Platforms, ERP,

CRM

Inconsistent data from IoT devices, lack of

standardized metrics for CO₂ profiling

durin

g

o

p

eration.

End-of-

life

Disposal, recycling, or

repurposing of the product after

its operational life.

ERP, LCA Tools,

Sustainability Plat-

forms

Inadequate tracking of recycled materials,

limited data on actual end-of-life scenarios,

and manual processing of environmental

data.

interplay between corporate functions, data systems,

and the organization’s ability to meet customer

demands for CO₂ profiling.

The mining phase, while ERP and LCA tools play a

role in tracking raw material sourcing and

environmental data, significant barriers such as

limited supplier transparency and fragmented data

hinder the integration of sustainability insights.

Similarly, during the production phase, the reliance

on PLM, MES, and ERP systems is accompanied by

challenges such as the lack of real-time

environmental monitoring and insufficient CO₂

model integration. These gaps continue to later

phases, such as the operation and end-of-life stages,

where inconsistent IoT data, inadequate tracking of

recycled materials, and manual data processing

remain obstacles to achieving seamless sustainability

alignment.

The quality of data has been identified as the most

critical factor for achieving traceability within the

product life cycle. Supplier transparency and

fragmented data, already evident at the initial phase

of the life cycle, the mining phase operate as

significant barrier. At this stage, raw material

suppliers often report and document LCA data of

questionable quality, likely due to inconsistencies in

data collection, lack of standardized reporting

frameworks, or limited oversight. This lack of reliable

data flows throughout the supply chain, affecting

subsequent phases such as production and operation.

The poor data foundation established during mining

impacts not only the accuracy of downstream

processes but also the integrity of outputs like EPDs,

which are critical for communicating sustainability

credentials to customers. Furthermore, these

limitations hinder the ability to produce strict and

transparent CO₂ profiling for product models,

undermining internal capabilities of trust in the

product documentation in respect to sustainability

documentation.

The quality of data is not only a critical factor for

traceability but also a foundation for achieving

effective configuration management of product

models and accurate CO₂ profiling. At its core, high-

quality data serves as the foundation for creating

reliable product configurations that reflect

environmental impacts across the life cycle. When

supplier transparency and fragmented data are

compromised, the ripple effects saturate throughout

the supply chain, leading to inaccuracies in material

and process data. This, in turn, undermines the ability

to build accurate and detailed life cycle inventories,

which are essential for configuring sustainable

product models. Given this context of product

configuration management, poor data quality

impedes the integration of sustainability attributes

into product configurators. For example, if the LCA

data originating from raw material suppliers is

incomplete or inconsistent, it becomes challenging to

model the environmental impact of materials and

components in a way that aligns with customer

expectations for CO₂ transparency.

Emphasizing data quality within the broader

context of sustainability adjacency contributes to a

more intense understanding of the systemic barriers

to CO₂ profiling. These findings expand the horizon

by uncovering critical misalignments in the

documentation and reporting processes of product

models’ life cycles, offering actionable insights into

areas that require strategic improvement. Improving

sustainability adjacency within the case company

means advancing stronger connections between

multiple systems and aligning sustainability elements

with adjacent information flows. By bridging gaps

between systems in respect to sustainability data,

configuration management, and life cycle reporting,

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

128

the case company positions itself to respond

proactively to regulatory requirements and market

expectations.

4.2 Structuring Computation of

Sustainability Data

The ability to compute sustainability data successfully

centres on the structured organization adjacent

information in product models across product life

cycle phases. Each phase: (1) Mining, (2) Production,

(3) Operation, and (4) End of Life, represents a distinct

perspective or "view" within the broader system

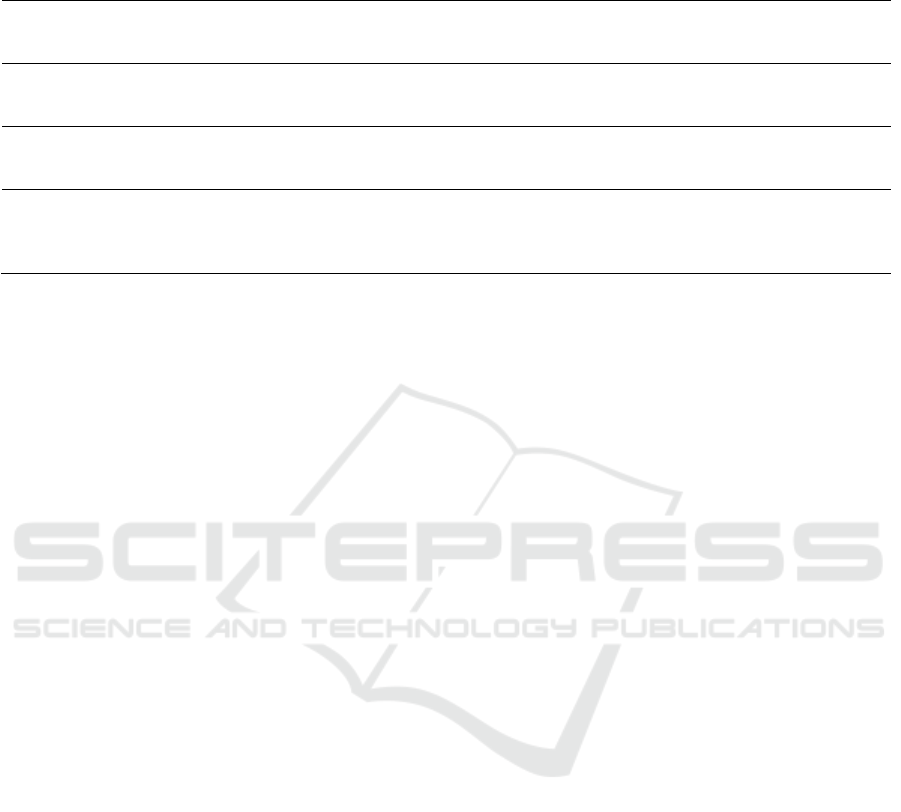

boundaries of sustainability assessment. The figure 4

illustrates how sustainability data can be modularly

structured, connecting attributes, limitations, and

relations specific to each phase. By employing this

modular approach, the case company can better

capture the intricate interdependencies between raw

material sourcing, production processes, operational

Figure 4: Modular data structure with connected attributes

and relations.

energy consumption, and end-of-life disposal or

recycling. This structure not only supports LCA but

also enables a cohesive integration of sustainability

data into product configuration processes, forming the

foundation for accurate CO₂ profiling and EPDs.

The practical application of structuring

sustainability data is exemplified in the

computational integration of life cycle data for the

THETA series pumps. Utilizing EPD data, this

approach aligns life cycle stages: (1) Production (A1-

A3), (2) Transportation (A4), (3) Assembly (A5), (4)

Use (B6), and (5) End of Life (C1-C4), with adjacent

systems such as ERP and PLM to create a modular

framework for CO₂ profiling. This method highlights

the critical role of LCA data quality in configuration

management.

Each life cycle phase is treated as a distinct

module containing specific attributes and relations.

For example, the Production phase includes raw

material data (e.g., percentages of cast iron, copper,

and plastics) and energy consumption metrics, while

the Use phase incorporates operational electricity

usage (e.g., 46.88 kWh/year for Gr1 pumps).

Similarly, the End of Life phase captures recycling

potentials (e.g., 1.62 kg of recyclable cast iron) and

waste fractions. These modules are computationally

linked to adjacent systems to streamline data

integration. ERP systems provide sourcing data for

raw materials and transportation emissions (e.g.,

0.0322 Liters of fuel/100km for a 500km transport

distance), while PLM systems link product variants to

their respective material configurations and life cycle

impact data. IoT platforms contribute real-time

energy consumption metrics, enabling continuous

monitoring of operational impacts.

The modular LCA structure allows for dynamic

CO₂ profiling by aggregating data across life cycle

phases. The total CO₂ profile for a pump

configuration can be calculated by summing input

material emissions (e.g., 12.5 kg CO₂ eq. for A1-A3),

energy use during operation (e.g., 14.5 kg CO₂ eq. for

B6 over 10 years), and recycling benefits at the end

of life (e.g., -1.33 kg CO₂ eq. from Module D). This

modular approach also facilitates scenario modelling,

enabling comparisons between configurations with

varying material compositions or energy efficiencies.

Integrating this computational framework into

configuration management tools further enhances its

utility. Embedding modular LCA data into the

product configurator allows customers to select

product options (e.g., high-recycled-content

materials) and view real-time CO₂ impact estimates.

"Kind-of" relations within the configuration process

enable categorization into sustainability-focused

variants, such as Standard vs. Eco-variant THETA

pumps. Furthermore, sustainability dashboards

visualize life cycle emissions for each configured

Sustainability in Product Models: Leveraging Adjacent Information for CO 2 Profiling in Configurations

129

product, broken down by module (e.g., A1-A3, B6),

providing transparency and actionable insights for

customers.

This structured approach not only improves data

traceability but also enhances the organization’s

ability to align with customer expectations and

regulatory demands. By integrating modular

sustainability data into adjacent systems, the case

company achieves greater sustainability adjacency,

bridging critical gaps in its documentation and

reporting processes. This ensures that CO₂ profiling

and EPDs are accurate, configuration-specific, and

aligned with strategic objectives. Ultimately, this

method supports the case company’s broader goals of

advancing sustainability integration across its product

models and life cycle stages, while fostering

innovation in sustainable product development.

4.3 Computing Automated Co

2

Profiling

The findings from the case study on the THETA-

series pumps highlight the transformative potential of

automating CO₂ profiling in the case company’s

product configuration processes. Following the

computation concept of Campo Gay et al. (2024) the

quantification of environmental metrics should be

established using the appropriate environmental unit.

This proposal follows the EPD standard as it includes

a list of environmental units associated with a

particular Product Category Rules (Campo Gay et al.,

2022). According to the EPD standard, the selected

environmental impact indicator unit was kg CO₂ eq.

The automation of CO₂ profiling relies heavily on

the seamless integration of multiple data sources and

systems, with the product configurator serving as the

central platform to interconnect these systems. This

integration allows for real-time computation of

product model emissions across all relevant life cycle

phases. By aggregating data from disparate systems,

the configurator ensures that emissions are calculated

dynamically and with precision, offering significant

improvements in efficiency and transparency

compared to traditional manual approaches. The

product configurator orchestrates the flow of data

between critical systems, including PLM systems,

ERP systems, IoT platforms, and EPD/LCA

databases. Each of these systems contributes and

provides essential data to the profiling process. PLM

systems provide material composition and

manufacturing data, such as the percentage of cast

iron, copper, and plastics used in production. ERP

systems supply logistical information, including

transport distances and fuel consumption, which are

necessary for calculating transportation emissions.

IoT platforms monitor real-time operational data,

such as energy consumption during the use phase,

ensuring high-resolution and up-to-date metrics.

Lastly, EPD/LCA databases deliver recycling rates

and end-of-life impact factors, enabling the accurate

assessment of emissions and benefits during the

product disposal phase.

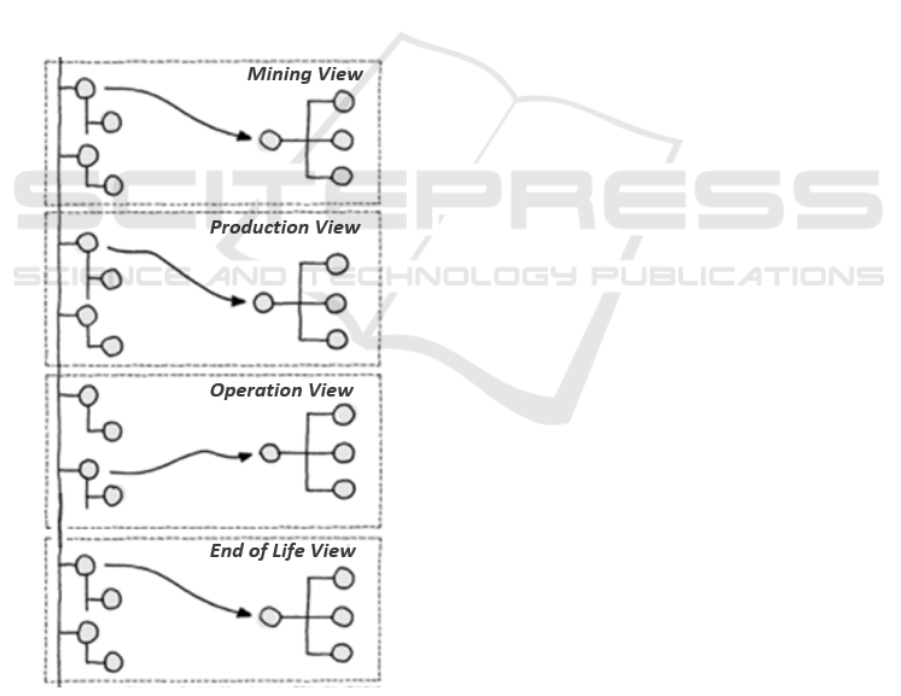

The integration of these systems into the product

configurator ensures that data is aggregated and

processed in real time. For example, in the case of the

THETA-series pumps, material composition data

retrieved from the PLM system indicates that the

product consists of 60% cast iron, 30% copper, and

10% plastics, resulting in a production-phase impact

of 12.5 kg CO₂ eq. Transportation data from the ERP

system reveals that a transport distance of 500 km,

with fuel consumption of 0.0322 liters per km,

contributes 0.32 kg CO₂ eq. IoT-enabled monitoring

of operational energy consumption over the pump’s

10-year lifetime adds 14.5 kg CO₂ eq., while end-of-

life recycling data from the EPD database offsets

emissions by -1.33 kg CO₂ eq., reflecting the

recycling of 1.62 kg of cast iron. These values are

aggregated to compute a total CO₂ profile of 26.67 kg

CO₂ eq. for the product configuration as demonstrated

in figure 5.

Figure 5: CO2 profile break-down structure.

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

130

Figure 6: Sustainability Adjacency Measurement Model.

The product configurator facilitates not only real-time

computation of emissions but also scenario modelling

and customer interaction. By dynamically updating

the CO₂ profile based on configuration choices, the

configurator enables customers and engineers to

simulate the impact of various design options, such as

selecting recycled materials or optimizing energy

efficiency. Choosing recycled steel in the production

phase reduces emissions by 30%, offering customers

clear insights into the sustainability benefits of their

decisions. This interconnected system architecture is

critical for leveraging the computation of CO₂

profiles for each configured product models. By

adopting this automated CO₂ profiling breakdown

structure, the case company not only improves the

efficiency and accuracy of its sustainability

assessments but also strengthens its ability to align

with regulatory requirements and meet evolving

customer expectations. Moreover, the integration of

multiple data sources into a unified platform positions

the case company in sustainable environment of

product configuration, leveraging advanced

computational tools to drive environmental

responsibility.

4.4 Sustainability Adjacency

Measurement Model

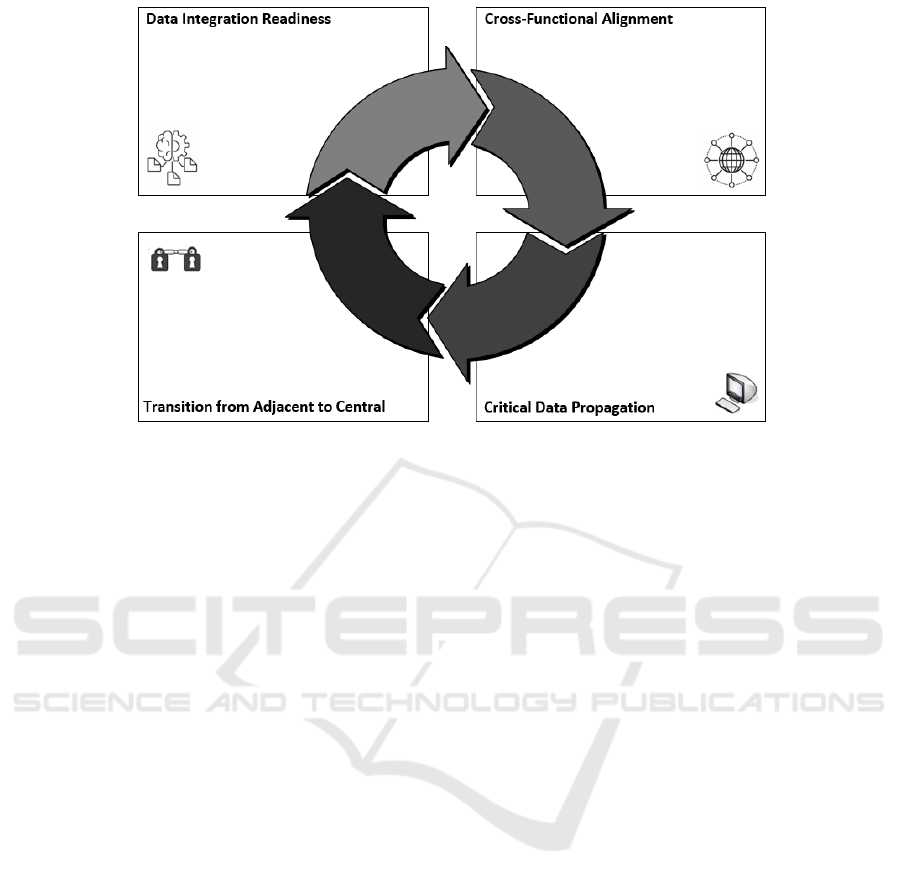

To address the integration of adjacent information

and enhance sustainability in product models, this

paper proposes the Sustainability Adjacency

Measurement Model. The proposed model was

developed in close collaboration with the case

company. The primary focus was on addressing a key

organizational challenge: consolidating LCA data

from suppliers into a unified platform. This model

provides a structured framework to evaluate an

organization’s maturity in leveraging adjacent data

for sustainability-driven product design and

configuration processes. The model is designed to

ensure that critical sustainability data transitions

seamlessly from isolated systems to centralized

decision-making processes.

The proposed model (figure 6), represents key

components of the framework, starting from

foundational data integration readiness and

culminating in the transition from adjacent to

centralized decision-making for sustainability.

Arrows indicate the flow and interdependence

between the key components, highlighting the

progression towards actionable insights.

The Data Integration Readiness evaluates the

organization’s ability to integrate “island” data

sources into a centralized system. These data sources

include isolated repositories, legacy systems, and

departmental datasets that are often inaccessible or

incompatible with centralized platforms. Integration

readiness involves both technical and organizational

readiness.

The Cross-Functional Alignment assesses

collaboration between departments (e.g., CSR,

finance, operations) to ensure consistent

sustainability strategies. Cross-functional alignment

emphasizes the coordination of efforts to ensure

sustainability data and insights are shared,

understood, and acted upon across all relevant

Sustainability in Product Models: Leveraging Adjacent Information for CO 2 Profiling in Configurations

131

functions. The relevance of this alignment seeks to

break down organizational silos to achieve holistic

sustainability outcomes. In other words, ensuring

critical data is accepted, interpreted consistently, and

utilized across functions. This is essential and critical

to avoid conflicting strategies, e.g., approving an

environmentally friendly supplier in CSR while

finance disapproves due to cost concerns.

Critical Data Propagation measures the extent

to which critical data from specialist departments

(e.g., PLM) influences organizational decision-

making. This component evaluates whether data

relevant to sustainability, such as CO₂ profiles,

supplier compliance, or material assessments, is

effectively transmitted and utilized at higher

organizational levels. This facilitates the integration

of domains in relation to specialist knowledge,

ensuring critical sustainability metrics are prioritized.

Impactful propagation of such data bridges the gap

between departmental silos and sustainability-related

actions.

The Transition from Adjacent to Central

evaluates how effectively adjacent sustainability data

transitions into actionable insights for product design

and operations. Adjacent data refers to supplementary

information such as supplier environmental

performance, lifecycle assessments, and operational

efficiency metrics, which are critical but not

originally centralized. The transition enables

organizations to transform fragmented or

supplementary data into strategic inputs that directly

impact product development, supply chain decisions,

and sustainability reporting. For example,

incorporating adjacent supplier data (e.g., CO₂

emissions from logistics) into centralized product

design decisions.

4.5 Distributed Sustainability Data

Adjacency for Systems

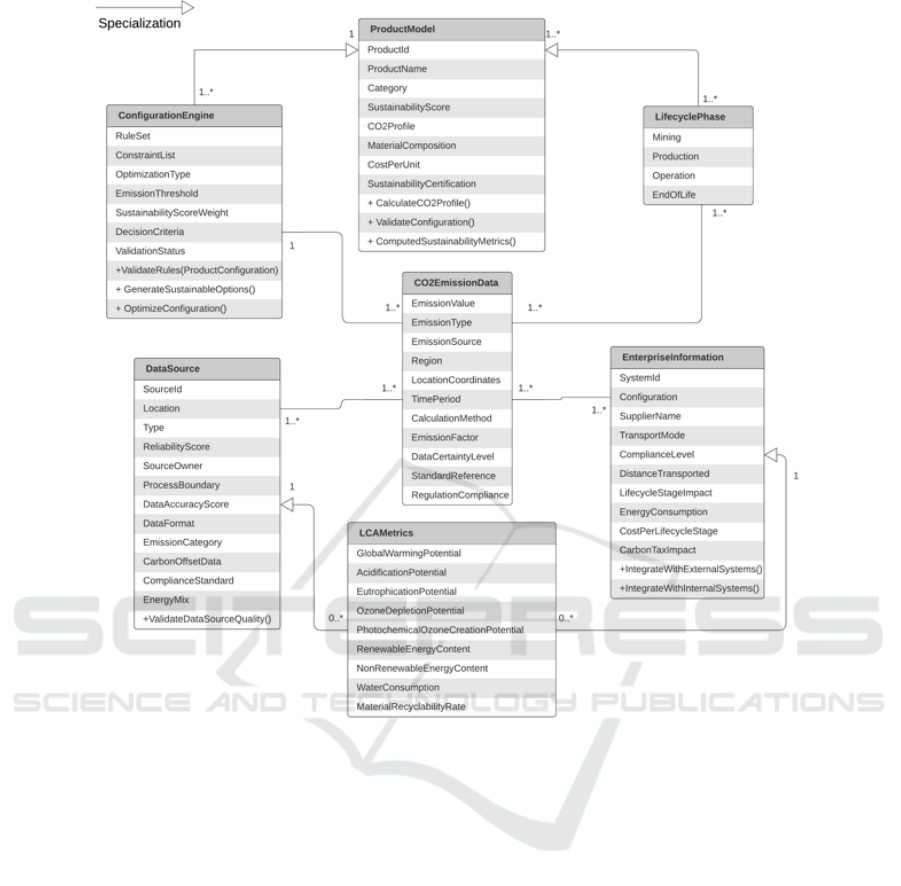

The Sustainability Adjacency Measurement Model

aligns seamlessly with the developed UML diagram

(figure 7) by emphasizing the systematic integration

of sustainability data across distributed information

systems. The quadrant-based approach highlights

critical enablers such as Data Integration Readiness,

Cross-Functional Alignment, Critical Data

Propagation, and the Transition from Adjacent to

Central, which are foundational elements reflected in

the UML's structured interconnections between key

entities like ProductModel, DataSource, and

EnterpriseInformation. For example, the UML

notation emphasis on data accuracy and reliability

metrics directly supports the Data Integration

Readiness quadrant by ensuring that sustainability

data from multiple sources can be seamlessly

incorporated into centralized configurations.

Similarly, the propagation of CO2EmissionData

across various lifecycle phases mirrors the Critical

Data Propagation quadrant, enabling real-time

decision-making and alignment with sustainability

objectives. Together, these models provide a robust

mechanism to operationalize sustainability within

complex systems, bridging the gap between adjacent

information sources and centralized decision

frameworks.

From a computational perspective, the

Sustainability Adjacency Measurement Model

leverages modular data structures and relational

mappings, as demonstrated in the UML notation, to

address systemic barriers in sustainability data

management. The model’s Data Integration

Readiness component is operationalized through

entities like DataSource and EnterpriseInformation,

which utilize attributes such as ProcessBoundary,

DataAccuracyScore, and EnergyMix to assess and

validate the completeness and accuracy of incoming

sustainability data. These attributes enable seamless

integration of heterogeneous data streams into

centralized systems, such as ConfigurationEngine,

which employs rule-based optimization algorithms to

align product configurations with sustainability

thresholds.

Critical Data Propagation is implemented via

directed relationships between CO2EmissionData

and downstream entities like LifecyclePhase and

LCA Metrics. This propagation ensures that

sustainability metrics such as

GlobalWarmingPotential and

EutrophicationPotential are dynamically computed

and passed through the system to inform both

operational decisions and long-term strategic

planning. By leveraging these interconnections, the

UML notation translates adjacent data into actionable

insights, enhancing the scalability and robustness of

sustainability-driven computational workflows.

Furthermore, the framework's ability to accommodate

distributed architectures allows for concurrent

processing and integration across multi-tiered

systems, ensuring consistency and reliability in

sustainability calculations.

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

132

Figure 7: UML Representation. Sustainability Adjency Measurement Model.

5 DISCUSSION & CONCLUSION

A critical aspect of this paper lies in the concept of

sustainability adjacency, which emphasizes the need

for continuous integration of supplementary, yet

crucial, data sources into centralized sustainability

decision-making processes. But also realising that

most data in the field exist isolated and out of reach

in more holistic decision-making processes.

Embedding CO₂ profiling into product configuration

systems leverages adjacent information, such as

supplier emissions data, logistics, and end-of-life

scenarios, to create a more comprehensive lifecycle

assessment. This approach addresses critical gaps in

current sustainability initiatives, such as the

underestimation of transportation emissions in

refurbishment or take-back programs, which often

neglect the broader environmental trade-offs. By

integrating adjacent data into real-time decision-

making, organizations can prioritize low-emission

options throughout a product’s lifecycle, ensuring

sustainability objectives are not siloed but actively

influence every stage of design and configuration.

This shift not only enhances transparency and

operational efficiency but also equips businesses to

meet evolving regulatory requirements and customer

expectations in a sustainability-driven market.

The sustainability adjacency framework aims to

highlight organizational areas requiring greater

attention, particularly where current sustainability

initiatives operate as isolated efforts rather than being

dynamically aligned with data flows or processes

such as product development activities. The

framework seeks to capture and map critical data,

ensuring its propagation to a central level where CO₂

product profiles become integral to decision-making.

By embedding this data into the product configuration

process, the framework ensures that low-emission

Sustainability in Product Models: Leveraging Adjacent Information for CO 2 Profiling in Configurations

133

configurations are consistently prioritized. This also

establishes shared organizational constraints and

interdependencies across departments, fostering

streamlined collaboration. For instance, a rule within

the framework could ensure that a product component

chosen for its low carbon footprint is simultaneously

cost-effective and compliant with procurement

policies, balancing environmental, financial, and

operational goals.

However, the impact of CO₂ profiling face several

systemic barriers, including data quality issues,

supplier transparency, and misaligned workflows.

These challenges hinder the seamless adoption of

sustainability initiatives and reduce the accuracy and

reliability of CO₂ assessments. Data quality issues

and/or inconsistent or incomplete data from internal

and external sources is a major barrier to effective

CO₂ profiling. Lifecycle data often originates from

disparate systems, including supplier databases,

operational records, and environmental reports,

which may not align in format, granularity, or

reliability. Poor data quality compromises the

accuracy of CO₂ profiles, leading to suboptimal

decision-making. Addressing this requires

implementing robust data governance practices, such

as standardization of data formats, validation

protocols, and real-time data integration.

A significant portion of a product’s CO₂ emissions

appears from supply chain activities. However,

suppliers lack the systems or willingness to provide

detailed environmental data. This complexity creates

gaps in the lifecycle assessment, limiting the ability

to generate accurate CO₂ profiles. Encouraging

supplier transparency through collaborative

frameworks, standardized reporting requirements,

and sustainable practices can mitigate this issue,

fostering better alignment between suppliers and

manufacturers.

Organizational silos and disconnected

processes can prevent sustainability data from being

integrated into decision-making. Procurement teams

may focus on cost efficiency without access to

environmental data, while product developers might

prioritize design functionality over sustainability.

Misaligned workflows result in fragmented efforts

that fail to capitalize on sustainability opportunities.

Addressing this requires restructuring workflows to

embed sustainability data and objectives into core

operations, ensuring collaboration and alignment

across all departments.

The adoption of the sustainability adjacency

framework carries significant implications for

industries heavily reliant on complex supply chains

and internal business units. As consumer demand for

sustainable products continues to intensify,

businesses face increasing pressure to allocate

resources toward adopting and integrating CO₂

profiling into product models. However, this effort

often conflicts with maintaining both internal

consistency and external credibility, as the

complexity of creating, managing, and aligning

sustainability data across multiple systems remains

largely uncharted. Without robust strategies to

address these challenges, organizations risk

fragmenting their sustainability efforts, undermining

their ability to deliver measurable environmental

impact.

REFERENCES

A. B. Shani and W. A. Pasmore, “Towards a new model of

the action research process,” in Academy of

Management Proceedings, 1982, pp. 208–212.

Badurdeen, F., Aydin, R., & Brown, A. (2018). A multiple

lifecycle-based approach to sustainable product

configuration design. Journal of Cleaner Production,

200, 756–769. https://doi.org/10.1016/

j.jclepro.2018.07.317

Bates, M. J. (1989). The design of browsing and

berrypicking techniques for the online search interface.

Online Review, 13(5), 407–424. https://doi.org/

10.1108/eb024320

Briem, A.-K., Betten, T., Held, M., Wehner, D., &

Baumann, M. (2019). Environmental Sustainabilityin

the Context of Mass Personalisation – Quantification of

the Carbon Footprint with Life Cycle Assessment.

International Journal of Industrial Engineering and

Management, 10(2), Article 2. https://doi.org/

10.24867/IJIEM-2019-2-237

Brundage, M. P., Bernstein, W. Z., Hoffenson, S., Chang,

Q., Nishi, H., Kliks, T., & Morris, K. C. (2018).

Analyzing environmental sustainability methods for

use earlier in the product lifecycle. Journal of Cleaner

Production, 187, 877–892. https://doi.org/10.1016/

j.jclepro.2018.03.187

Brunø, T.D., Nielsen, K., Taps, S.B., Jørgensen, K.A.

(2013). Sustainability Evaluation of Mass

Customization. In: Prabhu, V., Taisch, M., Kiritsis, D.

(eds) Advances in Production Management Systems.

Sustainable Production and Service Supply Chains.

APMS 2013. IFIP Advances in Information and

Communication Technology, vol 414. Springer, Berlin,

Heidelberg. https://doi.org/10.1007/978-3-642-41266-

0_22

Campo Gay, I., Hvam, L., & Haug, A. (2022). Automation

of Life Cycle Assessment Through Configurators: 10th

International Conference on Mass Customization

and<br/>Personalization – Community of Europe.

Proceedings of the 10th International Conference on

Mass Customization and Personalization – Community

of Europe (MCP-CE 2022), 19–25.

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

134

Campo Gay, I., Hvam, L., Haug, A., Huang, G. Q., &

Larsson, R. (2024). A digital tool for life cycle

assessment in construction projects. Developments in

the Built Environment, 20, 100535.

https://doi.org/10.1016/j.dibe.2024.100535

Ceschin, F., & Gaziulusoy, I. (2016). Evolution of design

for sustainability: From product design to design for

system innovations and transitions. Design Studies, 47,

118–163. https://doi.org/10.1016/j.destud.2016.09.002

Chauvy, R., Meunier, N., Thomas, D., & De Weireld, G.

(2019). Selecting emerging CO2 utilization products

for short- to mid-term deployment. Applied Energy,

236, 662–680. https://doi.org/10.1016/

j.apenergy.2018.11.096

Di Biccari, C., Mangialardi, G., Lazoi, M., Corallo, A.

(2018). Configuration Views from PLM to Building

Lifecycle Management. In: Chiabert, P., Bouras, A.,

Noël, F., Ríos, J. (eds) Product Lifecycle Management

to Support Industry 4.0. PLM 2018. IFIP Advances in

Information and Communication Technology, vol 540.

Springer, Cham. https://doi-org.ez.

E. Gummesson, “Taking off and landing: The route from

preunderstanding to understanding,” in Qualitative

methods in management research, London, UK, 2000,

pp. 57–82.

Hallstedt, S. I. (2017). Sustainability criteria and

sustainability compliance index for decision support in

product development. Journal of Cleaner Production,

140, 251–266. https://doi.org/10.1016/

j.jclepro.2015.06.068

He, B., Shao, Y., Wang, S., Gu, Z., & Bai, K. (2019).

Product environmental footprints assessment for

product life cycle. Journal of Cleaner Production, 233,

446–460. https://doi.org/10.1016/j.jclepro.2019.06.078

Helo, P., Mayanti, B., Bejarano, R., & Sundman, C. (2024).

Sustainable supply chains – Managing environmental

impact data on product platforms. International Journal

of Production Economics, 270, 109160.

https://doi.org/10.1016/j.ijpe.2024.109160

Jakobsen, A. M. S. Ø., Tambo, T., & Kadenic, M. D.

(2024). Understanding the dimensions of PLM and

Sustainability: A Systematic Literature Review.

Proceedings of the 2025 The 12th International

Conference on Industrial Engineering and

Applications.

Jakobsen, A., Tambo, T., & Kadenic, M. (2024). Greener

Information Systems for Product Configuration

Management: Towards Adaptation to Sustainability

Requirements. 2, 100–109. Scopus. https://doi.org/

10.5220/0012737200003690

Kalita, H., Kumar, K., & Davim, J. P. (2021). Chapter

One—Current tools and methodology for a sustainable

product life cycle and design. In K. Kumar, D. Zindani,

& J. P. Davim (Eds.), Sustainable Manufacturing and

Design (pp. 3–17). Woodhead Publishing.

https://doi.org/10.1016/B978-0-12-822124-2.00001-9

Komoto, H., Bernstein, W. Z., Kwon, S., & Kimura, F.

(2020). Standardizing environmental performance

evaluation of manufacturing systems through ISO

20140. Procedia CIRP, 90, 528–533.

https://doi.org/10.1016/j.procir.2020.02.043

Krikke, H. (2011). Impact of closed-loop network

configurations on carbon footprints: A case study in

copiers. Resources, Conservation and Recycling,

55(12), 1196–1205. https://doi.org/10.1016/

j.resconrec.2011.07.001

Lee, G., Eastman, C. M., & Sacks, R. (2007). Eliciting

information for product modeling using process

modeling. Data & Knowledge Engineering, 62(2), 292–

307. https://doi.org/10.1016/j.datak.2006.08.005

McKinsey & Company. (2020). Design cost-effective,

carbon-abated products with resource cleansheets

[Article]. https://www.mckinsey.com/capabilities/

operations/our-insights/design-cost-effective-carbon-

abated-products-with-resource-cleansheets

McKinsey & Company. (2024). What is the future of

sustainability? https://www.mckinsey.com/featured-

insights/mckinsey-explainers/what-is-the-future-of-

sustainability

Mortensen, N. H., Hvam, L., & Haug, A. (2010). Modelling

Product Families for Product Configuration Systems

with Product Variant Master: 19th European

Conference on Artificial Intelligence. ECAI 2010.

Nonaka, I. and Takeuchi, H. (1995) The Knowledge-

Creating Company: How Japanese Companies Create

the Dynamics of Innovation. Oxford University Press,

New York.

Shafiee, S., Friis, S. C., Lis, L., Harlou, U., Wautelet, Y., &

Hvam, L. (2019). A Database Administration Tool to

Model the Configuration Projects: 2018 International

Conference on Industrial Engineering and Engineering

Management (IEEM2018). Proceedings of 2018 IEEE

International Conference on Industrial Engineering and

Engineering Management (IEEM), 341–345.

https://doi.org/10.1109/IEEM.2018.8607654

Shafiee, S., Kristjansdottir, K., Hvam, L., & Forza, C.

(2018). How to scope configuration projects and

manage the knowledge they require. Journal of

Knowledge Management, 22(5), 982–1014.

https://doi.org/10.1108/JKM-01-2017-0017

Zubair, M. U., Ali, M., Khan, M. A., Khan, A., Hassan, M.

U., & Tanoli, W. A. (2024). BIM- and GIS-Based Life-

Cycle-Assessment Framework for Enhancing Eco

Efficiency and Sustainability in the Construction

Sector. Buildings, 14(2). Scopus. https://doi.org/

10.3390/buildings14020360

Sustainability in Product Models: Leveraging Adjacent Information for CO 2 Profiling in Configurations

135