A Concept for Accelerating Long-Term Prototype Testing Using

Anomaly Detection and Digital Twins

Vincent Nebel

1 a

, Pia Goßrau-Lenau

2

, Harshvardhan Agarwal

1 b

and Dirk Werth

1

1

August-Wilhelm Scheer Institute for Digital Products and Processes gGmbH, Saarbr

¨

ucken, Germany

2

Technology Center Drives, Miele & Cie. KG, Euskirchen, Germany

Keywords:

Anomaly Detection, Digital Twin, Prototyping, Machine Learning.

Abstract:

Developing mechanical components, especially complex assemblies like pumps, is a resource and time inten-

sive process. Testing pump prototypes for long-term durability is critical to ensure error-free operation of the

final product. Prototypes undergo material and operational tests to determine their expected lifespan, focus-

ing on defects caused by material degradation and water contamination. Long-term tests, lasting months, are

necessary to simulate real-world conditions, but limited test bench capacities create bottlenecks, restricting

material experimentation. Moreover, monitoring the internal state of pumps during tests is challenging. Un-

detected defects can worsen or trigger secondary issues, complicating the root cause analysis, which provides

valuable information for further product improvements. To address these challenges, a digital twin that inte-

grates geometry and material data, simulations, and sensor measurements was developed. This twin is used as

data source for machine learning based anomaly detection, allowing tests to stop sooner and preventing further

damage when first signs of a defect are detected. A modular serverless architecture is used to host the model

inference on the cloud, improving resource usage and scalability as well as reducing operational costs.

1 INTRODUCTION

The development of mechanical components is a

resource-intensive undertaking. It requires a lot of

time and effort to design different parts, select materi-

als, and construct working prototypes. To ensure error

free operation and longevity of the finished product,

the prototypes then have to be put through a variety

of tests. Many of these test require expensive equip-

ment and specific training which limits the possibili-

ties for parallelization. Especially for long-term tests,

this lack of parallelization can constitute a significant

bottleneck in the product development pipeline.

Complex assemblies, like pumps, consist of many

individual parts and hence are exposed to multiple dif-

ferent kinds of faults. To test such assemblies, it is

common to use a combination of material and operat-

ing tests. Since pumps for household appliances need

to run maintenance and error free for many years, the

central goal during prototype testing is to determine

the expected lifetime of a pump. In our case, most

of the defects, that we are interested in, are caused

a

https://orcid.org/0009-0009-2713-802X

b

https://orcid.org/0000-0001-6527-7658

by material degradation or water contamination over

time. The speed and severity of the degradation is

influenced by the forces that act on the materials dur-

ing operation as well as by the contamination of the

pumped water. In order to replicate these influences

when testing a new prototype, long-term tests, which

can last multiple months, are necessary. Since for ev-

ery iteration of a prototype a significant amount of

pumps needs to be tested and only a limited number

of test benches is available at a given time, this repre-

sents a severe bottleneck for the development of new

product revisions and limits the variety of materials

that can be tested.

Since it is not possible to monitor the inside of

a pump during operation testing, a defect might be-

come much more severe or even cause other issues

before it is noticed by the test operator. This can make

the identification of the root cause of the defect very

challenging or even impossible in some cases. There-

fore, it is very important to stop the testing procedure

as soon as possible once a fault occurs and examine

the pump to gain insights on possible improvements

to the pump construction or choice of materials.

To address these issues we propose using a digi-

tal twin to aggregate geometric models, material data,

Nebel, V., Goßrau-Lenau, P., Agarwal, H. and Werth, D.

A Concept for Accelerating Long-Term Prototype Testing Using Anomaly Detection and Digital Twins.

DOI: 10.5220/0013441500003950

In Proceedings of the 15th International Conference on Cloud Computing and Services Science (CLOSER 2025), pages 247-254

ISBN: 978-989-758-747-4; ISSN: 2184-5042

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

247

simulation results, and sensor measurements during

testing. The digital twin then acts as the single source

of data for detecting anomalies and classifying differ-

ent kinds of defects in the sensor measurements us-

ing machine learning (ML). This enables the operator

to stop the test earlier if an issue is detected, hence,

decreasing the probability of additional defects and

freeing up valuable test bench capacity. Furthermore,

knowledge about the degradation behavior of the used

materials is integrated to improve fault detection and

lifespan estimation. The aggregation of all relevant

data in a central digital twin also simplifies data ac-

cess for manual inspection of the test results, stream-

lining the product development and testing processes.

To ensure cost-effective operation and scalability,

the digital twin is hosted on the cloud and a serverless

architecture for model inference was developed. The

presented approach reduces the maintenance over-

head and simplifies the integration of additional test

benches, sensors, and analysis components by priori-

tizing modularity in the architecture design.

The remainder of this paper is structured as fol-

lows. Section 2 gives an overview of the general con-

struction of the pumps and the different defects that

can occur. Then, Section 3 discusses related work on

ML anomaly detection and serverless cloud comput-

ing. After that, the proposed concept is described in

detail in Section 4. Finally, Section 5 concludes this

work by summarizing and providing an outlook on

the next steps.

2 PUMP PROTOTYPE TESTING

In this work, the focus is on dry-running centrifugal

dishwasher pumps driven by a brushless permanent

synchronous motor (PMSM).

As shown in Figure 1, the pump complex of these

specific pumps can be divided into three main assem-

blies:

1. pump cover with tubular heating element and

pressure switch

2. pump housing with rotary vane mechanism and

water gate

3. main pump drive with pump impeller

The drive is controlled by an electronic frequency

converter which allows the pump to run speed con-

trolled.

Through rotor turning, the pump impeller,

mounted on the rotor shaft, is moved. It has different

blade geometries in the intake and outlet areas. Ro-

tation of the impeller creates a pressure gradient from

the center of the impeller to the outside, whereby the

Figure 1: Assemblies of the pump complex.

pressure increases in radial direction (see Figure 2).

The higher the speed, the higher in general the cen-

trifugal force and the associated delivery pressure of

the pump. In this way, the water enters the connected

pump housing and is pumped from there into an open

outlet nozzle and reaches different levels of the dish-

washer.

Figure 2: Main pump drive with impeller and approximate

flow paths.

The pump complex is subject to certain service

life requirements. For this reason, there are long-term

test benches for the pumps in which they are tested

(in this case separately from the device) for their ser-

vice life. The primary aims of the testing are partic-

ularly based on the development stage of the pump

and range from the qualification of prototypes to pilot

series releases and series releases.

There are various reasons for carrying out such

service life tests of pumps specially on test benches

developed for this purpose:

• fewer interactions than expected in the device

(individual pump system can be examined more

specifically)

• measuring points are more accessible

• operation of individual components outside the

specification is possible (limit or overload tests)

• control of the test environment

CLOSER 2025 - 15th International Conference on Cloud Computing and Services Science

248

Various faults are signs of wear that could occur dur-

ing the service life of a pump. Some typical ones are:

• defects in the hydraulic (e.g. concerning the im-

peller)

• deposits (of foreign materials)

• signs of ageing on seals

• damage to bearings

These can have a number of undesirable effects, e.g.:

• loss of function of the pump (worst case)

• increased power consumption (e.g. due to diffi-

culty of movement)

• reduced water delivery

• acoustic abnormalities

• leakages

The aim is to minimize errors and (material) wear as

far as possible in advance. The physical long-term

test is a way of testing different prototypes and pro-

viding direct feedback to the R&D department. Of

course, the number of test benches is limited and only

a certain number of variants can be tested in a certain

amount of time. This makes it quite important to be-

come aware of anomalies as early as possible using

suitable data analysis or machine learning and, ide-

ally, to be able to predict certain correlations or pa-

rameters.

2.1 Relevant Measured Variables

Suitable data is required for ML based anomaly de-

tection. Relevant (measured) variables that allow the

condition of a pump to be assessed must be identified.

The following measured variables are considered to

be particularly relevant for this pump type:

• motor phase current (because of the PMSM drive

proportional to the torque when the pump is in

control mode)

• pressure (difference between intake and outlet of

the pump)

• vibration / structure-borne noise (usually early ob-

servation of abnormalities possible)

• mechanical static friction torque of the sealing

system (measure for ease of movement of the seal-

ing system)

All these values are recorded by the test benches at

different, for the specific measurement appropriate,

frequencies and uploaded to the digital twin either im-

mediately or in batches.

3 RELATED WORK

This section outlines various state-of-the-art tech-

niques for anomaly detection and serverless machine

learning inference. A large variety of model archi-

tectures and methods has been proposed to detect

anomalies in different kinds of data. In the follow-

ing widely used methods and applications related to

pump testing are outlined.

The Local Outlier Factor (LOF) method (Breunig

et al., 2000) developed by Breunig et al. and ex-

tensions like the Cluster-Based Local Outlier Factor

(CBLOF) (He et al., 2003) work by using a measure

for the local density of a dataset and classifying out-

liers as points with substantially lower density than

their neighbors. While LOF uses the distance to the

k nearest neighbors to determine the local density,

CBLOF extends this idea by clustering the points (e.g.

using k-means) and calculating the density based on

cluster size and distance to other clusters.

Other approaches are to estimate Minimum Co-

variance Determinant (MCD) which provides a ro-

bust clustering of the data that can be used for out-

lier detection (Hardin and Rocke, 2004) or to use a

Histogram-Based Outlier Score (Goldstein and Den-

gel, 2012) which estimates the density based on the

frequency of samples in a bin of the univariate his-

togram of each feature.

Isolation Forests (Liu et al., 2008) are also used

for anomaly detection. They are particularly useful

for high-dimensional datasets. In this case anomalies

are determined via the path length needed to isolate a

specific sample averaged over multiple trees. Another

popular method is Bayesian Online Change Point De-

tection (BOCPD) (Adams and MacKay, 2007) which

is used to detect change points in time series data.

BOCPD works by maintaining a probability distribu-

tion over the run length, which is the time elapsed

since the most recent change point. When a new ob-

servation comes in, this distribution is updated using

Bayes’ theorem for inverting conditional probabili-

ties. This method can be adapted to manage time se-

ries with a non-constant baseline (e.g. different modes

of operation) and has been used to monitor the vibra-

tion of centrifugal pumps in HVAC systems (Lu et al.,

2020).

Generative Adversarial Networks (GAN) can also

be used for unsupervised anomaly detection as, e.g.,

shown by Liu et al. (Liu et al., 2020). A GAN con-

sists of two competing neural networks: a generator

and a discriminator. The generator tries to generate

realistic artificial data, while the discriminator distin-

guishes between real and artificial data. Using this

method, anomalies are identified by the discriminator

A Concept for Accelerating Long-Term Prototype Testing Using Anomaly Detection and Digital Twins

249

as non-real values.

Furthermore, different encoder-based architec-

tures have been proposed for anomaly detection

(Zhou and Paffenroth, 2017; Kieu et al., 2019; Siegel,

2020; Abhaya and Patra, 2023). In general, these

work by producing a latent representation of the in-

put using an encoder and reconstructing the inputs

through decoding. The difference between original

inputs and decoder outputs is then used as an anomaly

score.

Anomaly detection has also been used for the spe-

cific variables discussed in Section 2.1, which are es-

pecially relevant for pump testing.

For detecting pressure anomalies in axial piston

pumps Jiang et al. used a composite method that

combines Isolation Forest with a random convolu-

tional kernel for feature extraction and dynamic time

warping (DTW) to effectively handling time series

of varying lengths (Jiang et al., 2023). They vali-

dated their method using a specialized test bench for

pump failure simulations and showed that it outper-

formed traditional methods. In (Dong et al., 2023)

the authors tackle a similar challenge using a subse-

quence time series (STS) clustering-based approach.

Their method is a two step process consisting of a

step for identifying a ”norm cluster”, that represents

the normal behavior of the time series, by performing

multiple STS clustering operations and an anomaly

subsequence clustering step which clusters the re-

maining subsequences to detect anomalies. Addi-

tionally, DTW was utilized to enable the detection

of variable-length sub-sequences and enhance the ro-

bustness against variations in different operational pa-

rameters. Their method compared favorably to other

methods, such as Isolation Forest and LOF, particu-

larly in scenarios with recurrent anomalies and vary-

ing loads.

For working with vibration data to detect gear

and bearing faults in helicopters a semi-supervised

approach, that relies on training models using only

healthy signals due to the scarcity of faulty data in

real-world applications, was proposed in (Vos et al.,

2022). Long-strong-term memory regression was uti-

lized to remove deterministic components from the

signal and the residual signal classified using a one

class support vector machine. This method was

shown to be suitable for early fault detection. In (Hu

et al., 2022) vibration vectors, which consist of ampli-

tude and phase information of the measured vibration,

are used as the primary indicator for detecting anoma-

lies in the vibrations caused by a steam turbine and a

steam feed pump. The vibration vectors are extracted

using Fast Fourier Transform-Based Order Analysis

and Support Vector Data Description (Tax and Duin,

2004) is used to learn an acceptance region that can

self-evolve to accommodate changes in machine con-

ditions. This approach outperformed other methods

like MCD and Isolation Forest, especially when the

data distribution was non-Gaussian.

Ribeiro et al. conducted research on detect-

ing anomalies in the screw-tightening process using

angle-torque pairs. In (Ribeiro et al., 2021) they com-

pared three different unsupervised models (LOF, Iso-

lation Forest, and an Autoencoder based approach)

and used a supervised Random Forest as a bench-

mark. A realistic rolling window approach was em-

ployed to evaluate models over time, simulating real-

world use-cases with continuous data flow. They

found that the Isolation Forest Approach could com-

pete with the supervised approach in terms of accu-

racy while the Autoencoder performed slightly and

LOF noticeably worse. Based on those findings, the

authors concluded that in a real world application the

Autoencoder is to be preferred due to its better com-

putational efficiency. They confirmed this conclusion

in a follow-up study (Ribeiro et al., 2022) comparing

Isolation Forest and Autoencoder on a larger dataset.

In this scenario both models achieved similar accu-

racy, but the Autoencoder required 2.7 times less time

for training and 3.0 times less time for inference.

Initial investigations into the presented use-case

will focus on simple cluster-based methods, like

CBLOF, to establish a performance baseline. How-

ever, the existing work on related use-cases sug-

gest that significant improvements over that base-

line might be possible using more sophisticated ap-

proaches like the the method by Jiang et al. (Jiang

et al., 2023). Hence, the adaption of different meth-

ods to the specific use-case presented in this work and

an in-depth performance comparison is planned.

Serverless computing has gained popularity over

the last decade as it provides a cost-effective op-

tion for hosting cloud-based services with minimal

management overhead and built-in scalability (Has-

san et al., 2021; Shafiei et al., 2022). While the solu-

tions from large companies like Amazon, Microsoft,

and Google are most commonly used, open source so-

lutions like Apache OpenWhisk and custom imple-

mentations are actively worked on and researched (cf.

(McGrath and Brenner, 2017; Djemame et al., 2020)).

Furthermore, usage of serverless compute platforms

specifically for machine learning has grown in recent

years (Barrak et al., 2022). Even though cold starts

and GPU access still pose issues for serverless ML

deployments (Barrak et al., 2022; Kojs, 2023), it has

become a popular option, especially for model infer-

ence. Moreover, frameworks specialized for machine

learning inference like BATCH by Ali et al. (Ali et al.,

CLOSER 2025 - 15th International Conference on Cloud Computing and Services Science

250

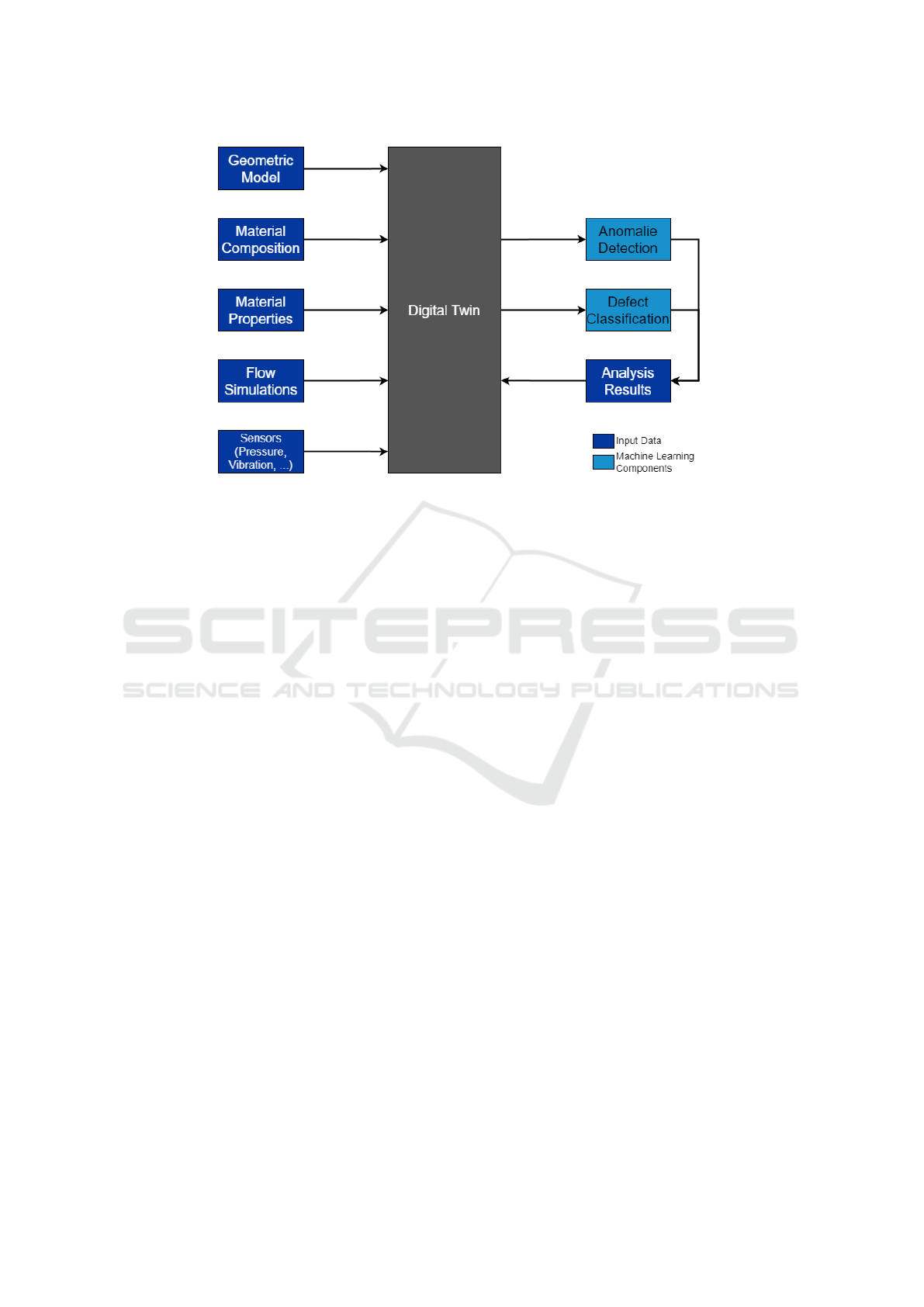

Figure 3: General Overview of the Digital Twin showing the different Input Data and Machine Learning Components.

2020) which utilizes an optimizer to obtain inference

tail latency guarantees and enable adaptive batch pro-

cessing, or INFless, a serverless platform purpose

built for the ML domain (Yang et al., 2022) promise

performance improvements over the available general

purpose solutions from the large cloud providers. For

the purpose of this work it was determined that a cus-

tom serverless architecture that uses Azure Functions

and is discussed in more detail in Section 4 is the best

choice because it allowed to use existing expertise and

reduces the complexity future maintenance.

4 CONCEPT

In this chapter the details of our solution concept are

described, the motivation and reasoning behind the

choices made are outlined, and an overview of the

developed digital twin and cloud architecture is pro-

vided.

In order to alleviate the impact of the testing bot-

tleneck on the product development and qualification

pipeline, accelerating the tests is essential. Since ac-

celerating the testing cycles themselves can place ad-

ditional strain on the materials, this would make it

much more difficult to correlate the testing results to

real world use. Shortening the long-term tests also is

not an option, because reaching a certain minimum

runtime is mandatory for product qualification. Con-

sequently, stopping test runs in which the pump did

fault or is showing sings of a defect that will lead

to a fault is the best available option for accelerating

the testing. This approach has the additional benefit

of simplifying the identification of the root cause of

a defect by preventing the development of follow-up

defects.

To achieve this, machine learning based anomaly

detection is used. For applying such an approach in

a product development setting where the used materi-

als, and therefore certain characteristics of the pumps,

change regularly, aggregating a broad spectrum of in-

formation on the pump prototypes and ensuring high

data quality are extremely important. For addressing

these challenges, we propose using a digital twin of

the pumps that combines the information about the

pump itself with detailed data on the materials used

and measurements from the long-term tests. The dig-

ital twin is stored in a cloud-based data platform that

allows fast and simple access to the data for manual

inspection or the creation of test reports and also pro-

vides various endpoints for automatic upload of data

from the test benches and connecting the ML compo-

nents of the system. Figure 3 shows an overview of

the data that is aggregated in the digital twin. Besides

the geometric model of the pump and corresponding

material compositions of the individual parts, the dig-

ital twin also contains in depth information on the

properties and aging characteristics of the different

materials and flow simulations that provide expected

values for the pressure measurements under different

conditions. These data are then combined with the

real world sensor measurements from the test bench.

The ML components receive this data from the digital

twin and store their analysis results in it.

For achieving good results using machine learn-

ing, the quality of the data plays a major role.

The data for the use-case presented in this work

is acquired using purpose built test benches which

A Concept for Accelerating Long-Term Prototype Testing Using Anomaly Detection and Digital Twins

251

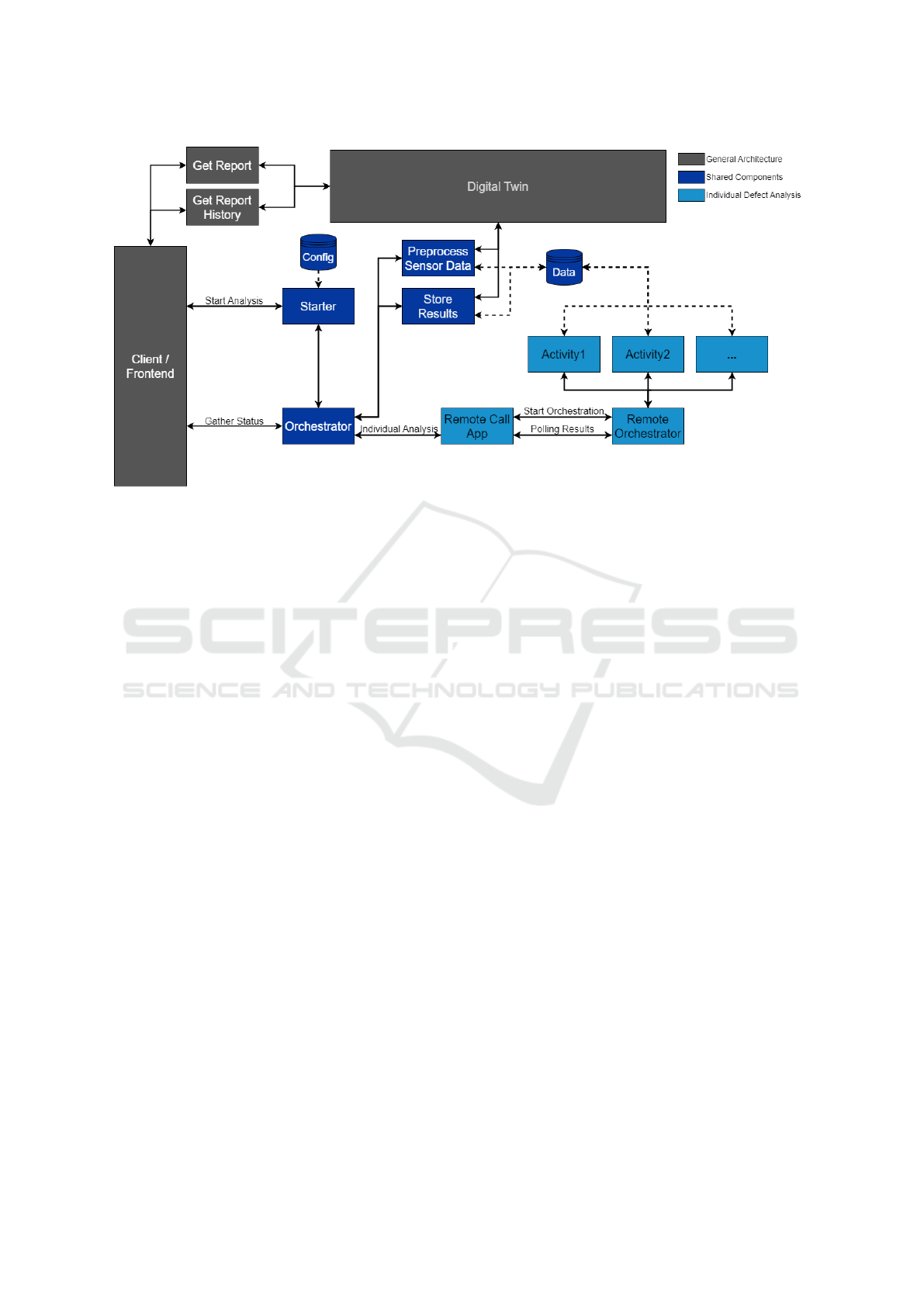

Figure 4: Structure of the Cloud Architecture used for Model Inference.

record the sensor data at different frequencies de-

pending on the specific measurement. Low frequency

data is immediately uploaded to digital twin, while

high frequency measurements, e.g. the phase current,

are stored locally using CSV files and uploaded as

batches in predefined time intervals. To mitigate sen-

sor drift, a calibration step is performed before test-

ing. Additionally, general information on the test-

ing conditions like water contamination, environment

temperature, and total runtime of the pump are inte-

grated to better represent expected changes over the

entire test time and, thus, improve the detection accu-

racy of abnormal pump behavior. Where necessary,

denoising and data transformations (e.g. normaliza-

tion or fast Fourier transform for phase current mea-

surements) will be performed by the cloud architec-

ture during the preprocessing step.

To run the ML inference a serverless approach was

chosen to reduce operational cost and maintenance ef-

fort. The models and data prepocessing pipelines are

deployed using Azure Functions, a serverless com-

pute solution developed and provided by Microsoft.

To efficiently work with the resource and runtime lim-

itations that follow from using Azure Functions, the

custom architecture depicted in Figure 4 was devel-

oped. The architecture enables the modularization of

the analysis pipeline across multiple function apps to

avoid resource bottlenecks. Furthermore, the chosen

orchestration approach allows the architecture to ef-

fectively handle function timeouts, which are espe-

cially likely when one of the functions has to perform

a cold start.

When an analysis is requested by the client, which

can either be done manually or automatically at pre-

defined points during a long-term test, a starter func-

tion gathers the configuration data for the specific

analysis and starts the orchestration. Via an end-

point returned by the starter function, the client can

then request status updates from the orchestrator. The

orchestrator triggers the data preprocessing pipeline,

which obtains all required data from the respective

endpoints of the digital twin platform, and the remote

function apps that handle further data processing and

inference for the different models. A separate model

is used for anomaly detection for each kind of sensor

data (cf. Section 2.1) as well as for the defect classi-

fication, allowing for even more modularity. The pre-

processed data and intermediate results are stored in a

data cache until all steps of the analysis are complete

and the finals results are stored in the digital twin.

5 CONCLUSION AND OUTLOOK

In this work the need for accelerating long-term tests

during product development was demonstrated in the

use-case of household appliance pumps. It was ar-

gued that the best option for achieving this is to em-

ploy anomaly detection to detect defects during test-

ing early, allowing to shorten the test time for defect

pumps and aid the classification of a defect and the re-

construction of its cause. Furthermore, a cloud archi-

tecture that handles model inference using a server-

less approach and relies on a cloud based digital

twin as data source for the machine learning compo-

nents was presented. The developed architecture can

CLOSER 2025 - 15th International Conference on Cloud Computing and Services Science

252

handle timeouts through the chosen orchestration ap-

proach and alleviate the impact of memory limitations

through its modularity. Furthermore, the modularity

ensures the expandability of the system, e.g. for inte-

grating new sensors or classifiers for additional kinds

of defects.

While the development and deployment of the

digital twin and other general architecture compo-

nents is already completed, the data acquisition and

model training is still in an early stage. Initial manual

investigation of the vibration and phase current data

show correlations between the measurements and the

state of the pump, but further experiments regarding

the pressure measurements are necessary as it proves

to be difficult to identify small scale leakages based

on the acquired data. At the time of writing, base-

line measurements using correctly functioning pumps

have been completed and long-term test for the first

defect category have started.

Once the data acquisition phase is completed, a

variety of different models and methods has to be

tested to determine the best approach for the pre-

sented use-case and additional long-term tests have

to be executed to validate the obtained results. Fu-

ture investigations should also focus on testing the

transferability of this approach to other product cat-

egories, e.g. turbines or gearboxes. As a first step

towards generalization, it is planned to apply the ap-

proach for other models of pumps once satisfactory

results have been achieved for the pumps addressed

in this work. Since the characteristics of the vibration

and other measurements change based on the design

of the pump, some amount of retraining will be neces-

sary to transfer the results to different pumps or other

product categories.

ACKNOWLEDGEMENTS

The authors thank the German Federal Ministry for

Economic Affairs and Climate Action (BMWK) for

financial support of the project ProDiNA through

project funding FKZ 01MN23016A. The project

ProDiNA is a joint effort of the August-Wilhelm

Scheer Institute for Digital Products and Processes

gGmbH, the Miele & Cie. KG, the adesso SE, the

dive solutions GmbH, and the Leibniz-Institute for

New Materials gGmbH.

REFERENCES

Abhaya, A. and Patra, B. K. (2023). An efficient method for

autoencoder based outlier detection. Expert Systems

with Applications, 213:118904.

Adams, R. P. and MacKay, D. J. C. (2007). Bayesian online

changepoint detection.

Ali, A., Pinciroli, R., Yan, F., and Smirni, E. (2020). Batch:

Machine learning inference serving on serverless plat-

forms with adaptive batching. In SC20: International

Conference for High Performance Computing, Net-

working, Storage and Analysis, pages 1–15.

Barrak, A., Petrillo, F., and Jaafar, F. (2022). Serverless on

machine learning: A systematic mapping study. IEEE

Access, 10:99337–99352.

Breunig, M. M., Kriegel, H.-P., Ng, R. T., and Sander, J.

(2000). Lof: identifying density-based local outliers.

SIGMOD Rec., 29(2):93–104.

Djemame, K., Parker, M., and Datsev, D. (2020). Open-

source serverless architectures: an evaluation of

apache openwhisk. In 2020 IEEE/ACM 13th Inter-

national Conference on Utility and Cloud Computing

(UCC), pages 329–335.

Dong, C., Tao, J., Chao, Q., Yu, H., and Liu, C. (2023). Sub-

sequence time series clustering-based unsupervised

approach for anomaly detection of axial piston pumps.

IEEE Transactions on Instrumentation and Measure-

ment, 72:1–12.

Goldstein, M. and Dengel, A. (2012). Histogram-based out-

lier score (hbos): A fast unsupervised anomaly de-

tection algorithm. KI-2012: poster and demo track,

1:59–63.

Hardin, J. and Rocke, D. M. (2004). Outlier detection in

the multiple cluster setting using the minimum covari-

ance determinant estimator. Computational Statistics

& Data Analysis, 44(4):625–638.

Hassan, H. B., Barakat, S. A., and Sarhan, Q. I. (2021). Sur-

vey on serverless computing. Journal of Cloud Com-

puting, 10(1):39.

He, Z., Xu, X., and Deng, S. (2003). Discovering cluster-

based local outliers. Pattern recognition letters, 24(9-

10):1641–1650.

Hu, D., Zhang, C., Yang, T., and Chen, G. (2022). An intel-

ligent anomaly detection method for rotating machin-

ery based on vibration vectors. IEEE Sensors Journal,

22(14):14294–14305.

Jiang, W., Ma, L., Zhang, P., Zheng, Y., and Zhang, S.

(2023). Anomaly detection of axial piston pump based

on the dtw-rck-if composite method using pressure

signals. Applied Sciences, 13(24):13133.

Kieu, T., Yang, B., Guo, C., and Jensen, C. S. (2019).

Outlier detection for time series with recurrent au-

toencoder ensembles. In Proceedings of the Twenty-

Eighth International Joint Conference on Artificial In-

telligence, IJCAI-19, pages 2725–2732. International

Joint Conferences on Artificial Intelligence Organiza-

tion.

Kojs, K. (2023). A survey of serverless machine learning

model inference.

Liu, F. T., Ting, K. M., and Zhou, Z.-H. (2008). Isolation

forest. In 2008 Eighth IEEE International Conference

on Data Mining, pages 413–422.

Liu, Y., Li, Z., Zhou, C., Jiang, Y., Sun, J., Wang, M., and

He, X. (2020). Generative adversarial active learning

A Concept for Accelerating Long-Term Prototype Testing Using Anomaly Detection and Digital Twins

253

for unsupervised outlier detection. IEEE Transactions

on Knowledge and Data Engineering, 32(8):1517–

1528.

Lu, Q., Xie, X., Parlikad, A. K., and Schooling, J. M.

(2020). Digital twin-enabled anomaly detection for

built asset monitoring in operation and maintenance.

Automation in Construction, 118:103277.

McGrath, G. and Brenner, P. R. (2017). Serverless com-

puting: Design, implementation, and performance.

In 2017 IEEE 37th International Conference on Dis-

tributed Computing Systems Workshops (ICDCSW),

pages 405–410.

Ribeiro, D., Matos, L. M., Cortez, P., Moreira, G., and Pi-

lastri, A. (2021). A comparison of anomaly detection

methods for industrial screw tightening. In Computa-

tional Science and Its Applications–ICCSA 2021: 21st

International Conference, Cagliari, Italy, September

13–16, 2021, Proceedings, Part II 21, pages 485–500.

Springer.

Ribeiro, D., Matos, L. M., Moreira, G., Pilastri, A., and

Cortez, P. (2022). Isolation forests and deep autoen-

coders for industrial screw tightening anomaly detec-

tion. Computers, 11(4):54.

Shafiei, H., Khonsari, A., and Mousavi, P. (2022). Server-

less computing: A survey of opportunities, challenges,

and applications. ACM Comput. Surv., 54(11s).

Siegel, B. (2020). Industrial anomaly detection: A com-

parison of unsupervised neural network architectures.

IEEE Sensors Letters, 4(8):1–4.

Tax, D. M. and Duin, R. P. (2004). Support vector data

description. Machine Learning, 54(1):45–66.

Vos, K., Peng, Z., Jenkins, C., Shahriar, M. R., Borghesani,

P., and Wang, W. (2022). Vibration-based anomaly de-

tection using lstm/svm approaches. Mechanical Sys-

tems and Signal Processing, 169:108752.

Yang, Y., Zhao, L., Li, Y., Zhang, H., Li, J., Zhao, M., Chen,

X., and Li, K. (2022). Infless: a native serverless sys-

tem for low-latency, high-throughput inference. In

Proceedings of the 27th ACM International Confer-

ence on Architectural Support for Programming Lan-

guages and Operating Systems, ASPLOS ’22, page

768–781, New York, NY, USA. Association for Com-

puting Machinery.

Zhou, C. and Paffenroth, R. C. (2017). Anomaly detec-

tion with robust deep autoencoders. In Proceedings

of the 23rd ACM SIGKDD international conference

on knowledge discovery and data mining, pages 665–

674.

CLOSER 2025 - 15th International Conference on Cloud Computing and Services Science

254