Optimization of Food Inputs in Restaurants in Metropolitan Lima

Through Prediction and Monitoring Based on Machine Learning

Marcos Olivos

a

, Alexandre Motta

b

and Pedro Castaneda

c

Faculty of Information Systems Engineering, Peruvian University of Applied Sciences (UPC), Lima, Peru

Keywords: Machine Learning, Prediction, Restaurants, Waste Reduction, Predictive Models, Artificial Intelligence.

Abstract: This work presents the development of a web-based monitoring and prediction system designed to optimize

food supply in restaurants in Metropolitan Lima, addressing challenges such as efficient inventory

management and food waste reduction. The solution employs six Machine Learning models (Random Forest,

Gradient Boosting, Ridge Regression, Lasso Regression, Linear SVR, and Neural Network), evaluated using

accuracy metrics such as Mean Squared Error (MSE), Root Mean Squared Error (RMSE), and Mean Absolute

Error (MAE). Among the models, Gradient Boosting demonstrated the best performance, with an MSE of

0.0032, RMSE of 0.057, and MAE of 0.027, outperforming the others in terms of accuracy, including Neural

Network and Random Forest, which also offered competitive results. While the approach was developed in

the specific context of Metropolitan Lima, the applied methods and obtained results can be adapted to other

urban markets with similar dynamics, demonstrating broader applicability. This system not only promotes

more efficient and sustainable inventory planning, but also contributes to the economic growth of restaurants

by optimizing resources and improving their profitability in a highly competitive environment.

1 INTRODUCTION

This article addresses inefficient inventory

management in restaurants in Metropolitan Lima, a

problem that generates food waste and affects the

economic and environmental sustainability of these

establishments. According to the United Nations

(2019; as cited in Wu & Teng, 2022), approximately

one third of the food produced globally is wasted each

year, which equates to large-scale economic and

environmental losses, so improving accuracy in

purchasing planning is crucial.

Existing solutions to improve inventory

management in restaurants have explored various

Machine Learning techniques, showing their

potential in resource optimization. In the study

carried out by Wu and Teng (2023), a machine

learning system was implemented in a restaurant

chain in Peru, managing to reduce food waste from

200-400 kg per day to just 115 g per customer in a

standard buffet. However, despite the advances made

in the implementation of Machine Learning solutions

a

https://orcid.org/0009-0000-1745-930X

b

https://orcid.org/0009-0004-0375-2002

c

https://orcid.org/0000-0003-1865-1293

for inventory management, the adaptation of these

tools to specific contexts such as that of Metropolitan

Lima remains a challenge, mainly due to the

variability in consumption patterns and the quality of

the available data. In addition, most current models

lack mechanisms to automatically adjust and are not

designed to adapt to fluctuations in demand, which

can lead to situations of oversupply or shortage of

inputs, limiting their effectiveness in dynamic

environments.

This work proposes a web-based prediction

system adapted to local needs, which integrates not

only a single algorithm, but several Machine

Learning models. These models will be dynamically

adjusted based on consumption statistics and patterns,

allowing the system to optimally adapt to the specific

conditions of each restaurant, thus optimizing the

supply of inputs and reducing waste.

The following sections of the paper will address

the state of the art, system design, results, discussions,

conclusions, and future projections.

144

Olivos, M., Motta, A. and Castaneda, P.

Optimization of Food Inputs in Restaurants in Metropolitan Lima Through Prediction and Monitoring Based on Machine Learning.

DOI: 10.5220/0013233700003950

In Proceedings of the 15th International Conference on Cloud Computing and Services Science (CLOSER 2025), pages 144-150

ISBN: 978-989-758-747-4; ISSN: 2184-5042

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

2 RELATED WORKS

Several studies highlight the importance of advanced

technologies in optimizing supply chains in the food

sector. Dadi et al. (2021) highlights the use of

machine learning and other digital tools to reduce

human intervention and improve accuracy in data

management, resulting in a significant reduction in

waste and optimization of response times. Along

these lines, Islam et al. (2021) present a demand

forecasting approach along with an optimization

model that increases supply chain efficiency by 15%

and reduces costs by 10%, by minimizing uncertainty

in supplier selection and order allocation. In addition,

Birkmaier et al. (2022) propose an advanced

forecasting system that reduces historical data bias by

75%, allowing for better synchronization between

supply and demand for perishable products, which

increases in-store quality and optimizes inventory

freshness. Finally, the study by Beheshti et al. (2022)

introduces a closed supply chain model in peri-urban

areas, which increases the waste collector's expected

profits by 30% and improves the profitability of the

chain through the application of recycling techniques

and flexibility contracts.

On the other hand, reducing waste in the food

supply chain has been a key objective in several

recent studies. Birkmaier et al. (2022) show that an

advanced forecasting system can prevent waste

generation by optimizing the synchronization

between supply and demand, which considerably

reduces the volume of discarded food. Sharma et al.

(2022) integrates smart devices such as the e-nose, e-

eye, and e-tongue to monitor food quality in real time,

achieving a 30% decrease in food waste thanks to the

implementation of this technology. Meanwhile,

Herron et al. (2022) implement a "First Expire, First

Out" (FEFO) management model to reduce losses in

the retail trade of perishable products, showing that

after 8 hours at more than 4°C, the risk of loss of

product shelf life increases by 43.8%. Similarly,

Kumar (2023) implements machine learning to

improve the accuracy of demand prediction, which

allows reducing food waste, with a decrease in

prediction error, achieving an RMSE of 18.83 and an

MAE of 14.18 in his predictions.

Furthermore, advances in demand prediction

techniques have proven to be essential for effective

inventory management in the food sector, allowing

companies to anticipate supply needs and adjust their

strategies. Posch et al. (2022) employ Bayesian

modeling methods and generalized additive models

(GAMs), achieving a mean absolute error (MAD) of

2.681 and a root mean square error (MSE) of 14.133

in predicting food and beverage sales in restaurants,

which is significantly higher than traditional

approaches. Likewise, Migueis et al. (2022) use long-

term memory neural networks (LSTM) to forecast

demand for fresh fish, achieving an RMSE of 27.82

and a MAE of 20.63, which reduces inventory

buildup and improves accuracy in stock levels.

Finally, the study by Makridis et al. (2023)

implements a prediction system for food safety using

time series and NLP, achieving a mean square error

(MSE) of 0.922 in predicting food recalls, thus

optimizing food safety and inventory management.

By synthesizing these findings, this work

underscores the importance of integrating advanced

forecasting systems, waste reduction strategies, and

demand prediction techniques to develop a

comprehensive and adaptive solution for inventory

management. Unlike previous approaches, which

often focus on isolated elements or specific contexts,

this research combines multiple machine learning

models into a unified framework that allows for

dynamic adjustments to varying conditions.

3 SYSTEM DESIGN

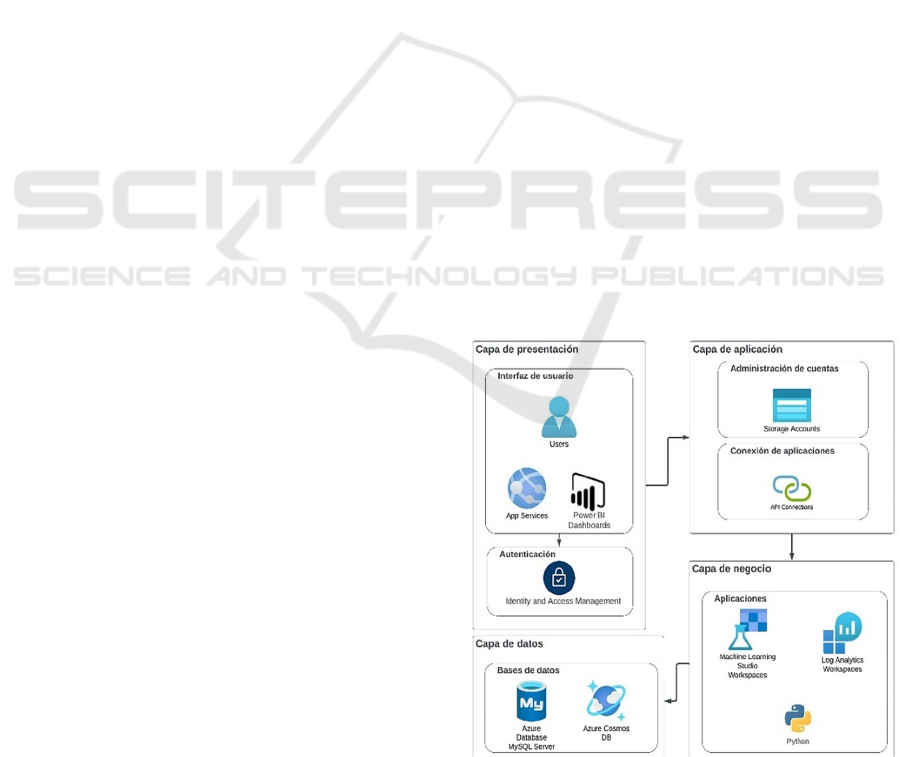

3.1 Architecture

The logical architecture of the web system has been

designed to optimize the prediction and monitoring of

the supply of inputs in restaurants in Metropolitan

Lima.

Figure 1: Logical architecture of the web system.

Optimization of Food Inputs in Restaurants in Metropolitan Lima Through Prediction and Monitoring Based on Machine Learning

145

Figure 1 explains that the solution effectively

integrates advanced technologies such as Machine

Learning, Python, and Azure cloud platforms,

strategically distributed across four layers:

Presentation, Application, Business, and Data. On the

other hand, with the implemented machine learning

algorithms, the system allows an accurate prediction

of demand, which contributes to improving inventory

planning and reducing the loss of inputs. In addition,

the platform offers an interface accessible from web

and mobile devices, supported by Power BI for the

visualization of data in real time, which facilitates

continuous and detailed monitoring. In the backend,

processes are automated, and alerts are implemented

that simplify data-driven decision making. Finally,

the infrastructure has been designed to be scalable

and adaptable to the changing needs of the restaurant

sector, ensuring efficient and sustainable

management of food inputs.

3.1.1 Presentation Layer

The presentation layer is designed to offer an

accessible and dynamic user experience through

Azure App Services. Users interact with the

application from this interface, which can be either a

web app or a mobile app. In addition, dashboards

generated by Power BI are integrated into this layer,

providing interactive visualizations and detailed

reports on system performance, based on information

stored in databases. This layer allows users to manage

the system and visualize data efficiently and securely.

3.1.2 Application Layer

The application layer acts as an intermediary between

the presentation and business/data layers. It ensures

that user requests are handled correctly. In this layer,

APIs are controlled to handle requests to the database

and other external services. Storage Accounts provide

secure storage of files and documents that may be

required for the application, while API Connections

allow integration with other external services, such as

payment gateways or authentication services.

3.1.3 Business Layer

In this layer, data is processed and business rules that

define the application logic are executed. Data

processing is done using Python, which also handles

predictions and advanced calculations using machine

learning algorithms. To ensure robust processing,

platforms such as Machine Learning Studio

Workspaces are integrated, which allows prediction

models to be trained and deployed. In addition, the

application status is continuously monitored using

Log Analytics Workspaces to ensure performance

and detect any possible anomalies or errors.

3.1.4 Data Layer

The data layer stores all the information necessary for

system operation, including user configurations,

roles, transactions, and historical records. Azure

Cosmos DB provides a highly scalable system for

managing non-relational data and real-time data,

while Azure Database MySQL Server manages

structured relational data. Data is synchronized and

analyzed to generate reports in Power BI, which

connects to dashboards and provides key

visualizations for administrators.

3.2 Methodology

3.2.1 Dataset

The dataset initially consisted of synthetic data

created to simulate typical restaurant sales patterns,

sourced from publicly available information, industry

reports, and general sales trends. This synthetic data

included daily sales figures, types of dishes sold,

preparation times, and inventory management details,

providing a foundation for testing and refining the

initial machine learning models. Once the initial

model was developed, it was validated with real data

extracted from the sales and inventory systems of a

restaurant. The real dataset spans a full year and

incorporates both seasonal trends and variations in

demand, offering a more accurate representation of

the restaurant’s operations. This combination of

synthetic and real data allowed for a thorough

evaluation of the system's ability to adapt to actual

conditions, enhancing the reliability of the results and

ensuring that the model could effectively optimize

inventory management and reduce food waste in a

real-world setting.

3.2.2 Model

The model implemented for the prediction and

monitoring of food supply in restaurants in

Metropolitan Lima is based on a machine learning

approach that integrates various algorithms to

maximize the accuracy of the predictions. This

framework follows a data flow that ranges from the

initial collection of information to the visualization of

results in real time.

In this context, data preprocessing plays a crucial

role, as it ensures the quality of the information used

for model training. This process involves data

CLOSER 2025 - 15th International Conference on Cloud Computing and Services Science

146

cleaning, which removes duplicate entries and

corrects errors, as well as normalizing values and

transforming categorical variables into numerical

ones.

3.2.3 Indicators

The success indicators used in evaluating model

accuracy are based on common prediction error

metrics, each with its own particular characteristics.

Table 1 below describes the indicators that will be

used to evaluate the system's performance and its

effectiveness in predicting and monitoring the supply

of inputs in restaurants. These metrics are essential to

ensure that the system meets the established

objectives and can make adjustments in real time

based on the results obtained.

Table 1: List of indicators to assess the accuracy of the

prediction.

Metrics Description Equation

Mean

Squared

Error

(MSE)

Calculates the average of

the squared errors

between the predicted

values and the actual

values. It penalizes large

errors, useful for normal

distributions. (IBM, 2024)

𝑀𝑆𝐸

1

𝑛

𝑦

𝑦

Root

Mean

Squared

Error

(RMSE)

It is the square root of the

MSE, representing the

errors in the same units as

the predicted values. It

facilitates interpretation

by users. (IBM, 2024)

𝑅𝑀𝑆𝐸

∑

𝑦

𝑦

𝑁𝑃

Mean

Absolute

Error

(MAE)

Calculates the average of

the absolute differences

between predicted and

actual values, without

giving extra weight to

large errors. (IBM

Cognos, 2024)

𝑀𝐴𝐸

1

𝑛

𝑌

𝑌

3.2.4 Training

To begin training the model, extensive data

preprocessing was performed, including cleaning,

normalization, and transforming categorical variables

into numerical ones, ensuring that the model could

optimally learn from the information provided. In

addition, several machine learning algorithms were

implemented, including Random Forest, Gradient

Boosting, Ridge Regression, Lasso Regression,

Linear SVR, and neural networks (MLP).

Finally, the performance of each model was

evaluated using metrics such as Mean Squared Error

(MSE), Root Mean Squared Error (RMSE) and Mean

Absolute Error (MAE), which allowed comparing

and selecting the most efficient model for predicting

food input demand. This comprehensive approach not

only optimizes the Machine Learning model, but also

contributes to more effective supply management in

the restaurant.

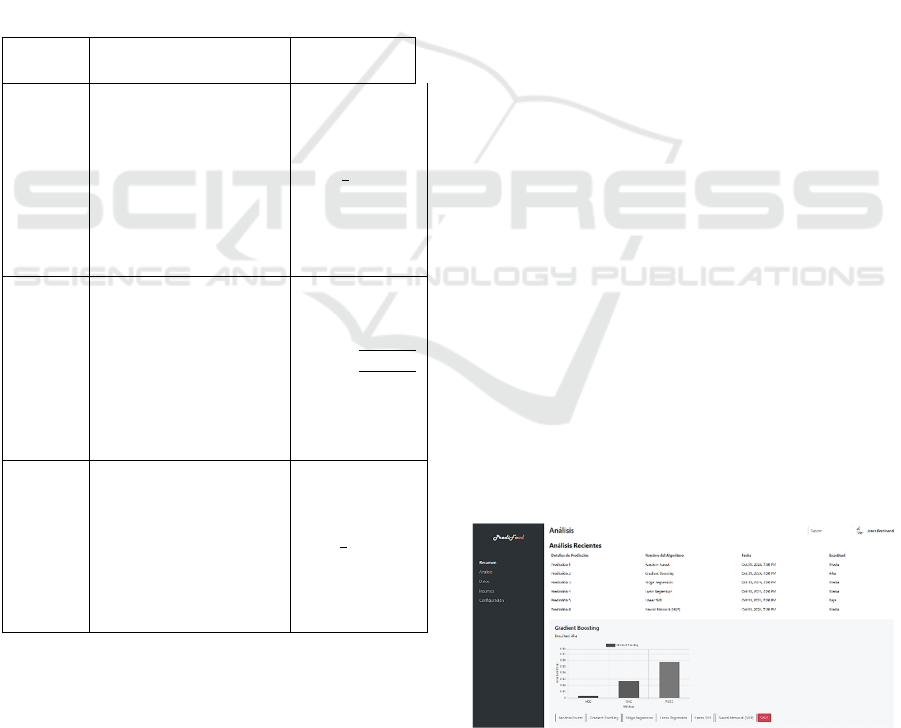

3.2.5 Interfaces

The web-based prediction and monitoring system

interface, developed in Azure, offers an intuitive and

dynamic environment designed to optimize workflow

and usability. Users can interact with dashboards

displaying key data such as supply levels,

consumption trends, and demand forecasts. These

visualizations provide a clear overview, helping users

make informed decisions about inventory and

procurement. A key feature is the Machine Learning

algorithm module, which shows performance metrics

and enables users to assess prediction accuracy. As

new data is added, the system automatically compares

the updated predictions, allowing users to adjust

parameters and improve future forecasts.

The interface also includes an alert system that

notifies users if discrepancies are detected between

the model’s predictions and the incoming data,

signaling when adjustments may be needed. This

allows for timely intervention and ensures more

accurate predictions. Additionally, the system is

flexible and customizable, adapting to specific

restaurant needs and evolving demand patterns.

Accessible across a range of devices, the interface

provides a scalable solution for efficient inventory

management and waste reduction.

Figure 2: Summary of prediction percentages with machine

learning.

Optimization of Food Inputs in Restaurants in Metropolitan Lima Through Prediction and Monitoring Based on Machine Learning

147

4 RESULTS

This section shows the results obtained by evaluating

six selected Machine Learning models: Random

Forest, Gradient Boosting, Ridge Regression, Lasso

Regression, Linear SVR, and Neural Network (MLP).

These models were trained and evaluated to predict

inventory demand in restaurants, seeking to reduce

food waste and optimize purchase planning. The

evaluation metrics used include the Mean Squared

Error (MSE), Root Mean Squared Error (RMSE), and

Mean Absolute Error (MAE), which measure the

performance of each model in terms of accuracy and

adaptive capacity.

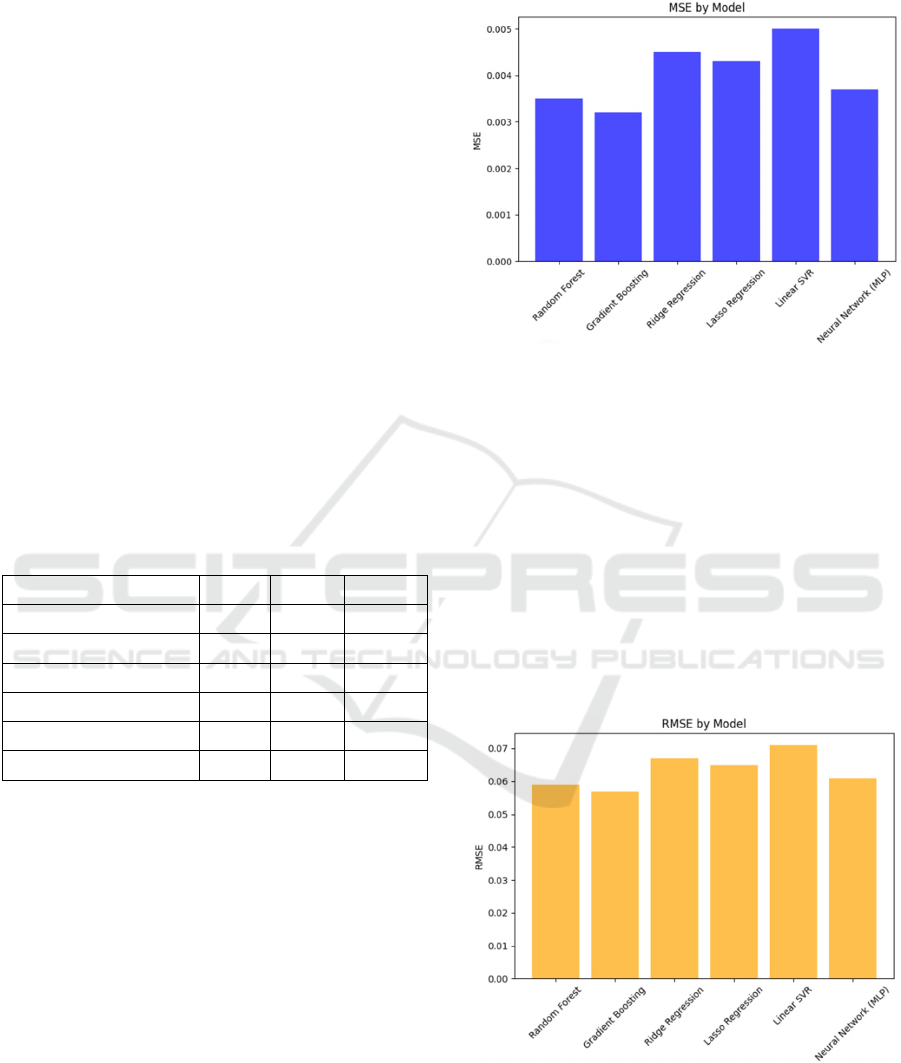

4.1 Results Table

Table 2 presents the results of the metrics for each of

the evaluated models. This table highlights the MSE,

RMSE and MAE values, which allow the error in the

predictions of each model to be quantified. These

results directly inform the prediction of ingredient

quantities needed for optimal restaurant inventory

management.

Table 2: List of results according to indicators.

Models MSE RMSE MAE

Random Forest 0.0035 0.059 0.028

Gradient Boosting 0.0032 0.057 0.027

Ridge Regression 0.0045 0.067 0.031

Lasso Regression 0.0043 0.065 0.030

Linear SVR 0.0050 0.071 0.034

Neural Network (MLP) 0.0037 0.061 0.029

The values obtained in MSE, RMSE, and MAE reveal

that the Gradient Boosting model obtained the lowest

values in all the metrics, indicating a minimum error

in the inventory demand predictions. These

percentages are instrumental in calculating the

necessary ingredients for various dishes, enabling a

more precise weekly forecast of their required

quantities. The Random Forest and Neural Network

(MLP) models also show competitive performance,

albeit with slight increases in the error metrics

compared to Gradient Boosting.

4.2 Metric Comparison Charts

To visually illustrate the performance of the models,

several graphs were generated that allow a detailed

comparison of the MSE, RMSE and MAE metrics

between the evaluated models.

4.2.1 Bar Chart for MSE

Figure 3: Comparison of Mean Squared Error (MSE)

between Models.

Figure 3 shows the mean squared error (MSE) values

for each model. This graph shows that Gradient

Boosting and Random Forest have the lowest MSE

values, suggesting a greater ability of these models to

minimize squared errors in their predictions. This

implies that compared to other models, Gradient

Boosting and Random Forest are more effective in the

accuracy of their estimates, which is crucial for

informed decision making in the context of data

analysis.

4.2.2 Bar Chart for RMSE

Figure 4: Root Mean Squared Error (RMSE) Analysis for

Prediction Accuracy.

Figure 4 presents the root mean square error (RMSE)

values, which reflect the average of the squared errors

on the same scale as the data. Gradient boosting keeps

CLOSER 2025 - 15th International Conference on Cloud Computing and Services Science

148

the RMSE lowest, making it the model with the most

accurate prediction, closely followed by random

forest and neural network (MLP).

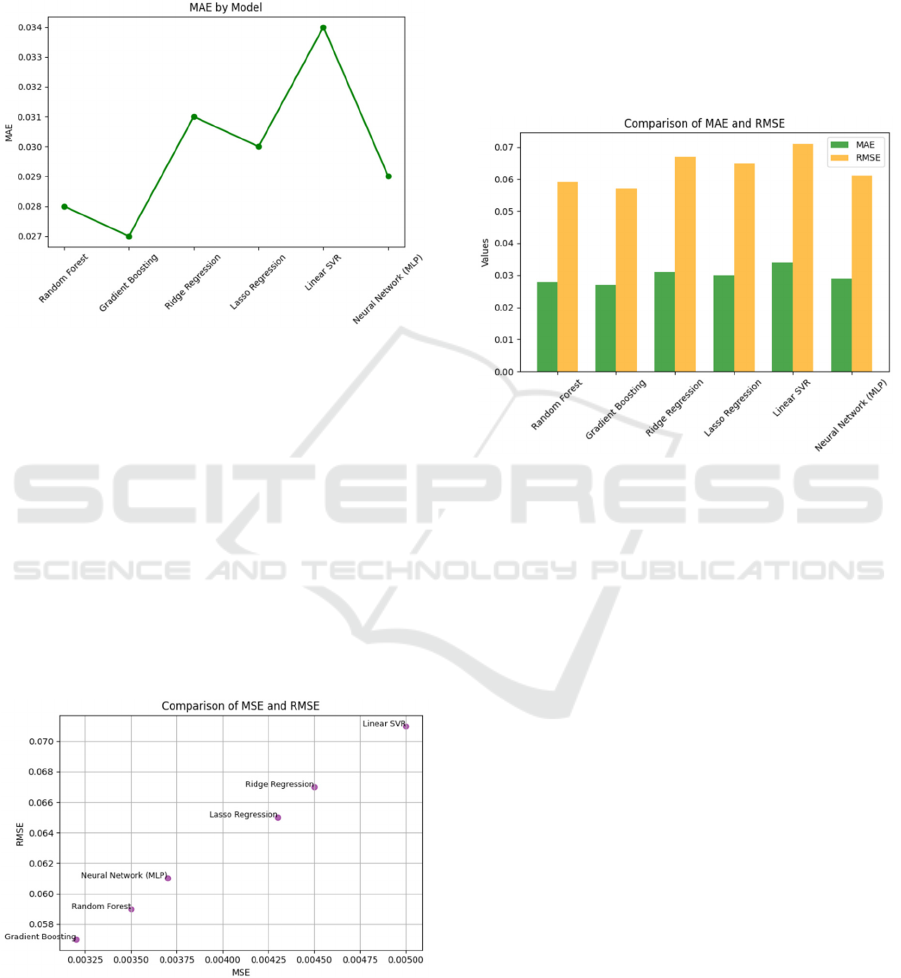

4.2.3 Line Chart for MAE

Figure 5: Mean Absolute Error (MAE) Evaluation in

Inventory Forecasting.

In Figure 5, the Mean Absolute Error (MAE) values

for each model are shown, providing a clear view of

the average absolute errors. Gradient Boosting and

Random Forest stand out again with low values,

suggesting their effectiveness in minimizing absolute

errors in inventory demand predictions. This level of

precision supports better planning for weekly

ingredient needs, helping estaurants avoid

overstocking and reducing waste.

4.2.4 Scatter Plot for Comparison of MSE

and RMSE

Figure 6: Scatter Plot: Relationship between MSE and

RMSE in Models.

Figure 6 presents a scatterplot comparing the Root

Mean Square Error (MSE) and Root Mean Square

Error (RMSE) for each model, highlighting the

relationship between these two error metrics.

Gradient Boosting and Random Forest exhibit

consistency by maintaining low values across both

metrics. This reliability in prediction accuracy further

enhances the ability to forecast ingredient

requirements efficiently, ensuring smoother

inventory management.

4.2.5 Grouped Bar Chart for MAE and

RMSE

Figure 7: Comparison of MAE and RMSE Metrics in

Evaluated Models.

Figure 7 presents a scatterplot comparing the Root

Mean Square Error (MSE) and Root Mean Square

Error (RMSE) for each model, highlighting the

relationship between these two error metrics. It is

observed that Gradient Boosting and Random Forest

maintain low values in both metrics, demonstrating

consistency in the accuracy of the predictions.

5 DISCUSSIONS

The results of this work demonstrate significant

improvements in demand prediction and inventory

management in restaurants in Metropolitan Lima,

surpassing in accuracy studies such as Kumar et al.

(2023), which achieved an RMSE of 18.83 and an

MAE of 14.18. Our system employs models such as

Gradient Boosting and Random Forest, which

automatically adjust to daily variations, optimizing

supply and reducing waste of inputs, which

distinguishes it from previous approaches, such as the

Bayesian model of Posch et al. (2022) with an MSE

of 14.133, or the system of Birkmaier et al. (2022),

which reduces historical biases in perishable data by

75% but lacks local adaptability. This solution not

Optimization of Food Inputs in Restaurants in Metropolitan Lima Through Prediction and Monitoring Based on Machine Learning

149

only contributes to existing knowledge in inventory

prediction but could also be implemented in other

food sector environments, such as hotels, where input

optimization is key to reducing costs and increasing

sustainability.

6 CONCLUSIONS

This work demonstrates the effectiveness of a

prediction and monitoring system for optimizing the

supply of inputs in restaurants in Metropolitan Lima,

achieving a significant reduction in food waste and an

improvement in inventory management. The

implementation of Machine Learning provides an

accurate estimate of demand, adapting to

consumption variations and the particularities of the

restaurant sector. The advantages of this system

include more efficient resource planning and a

positive impact on the operational and economic

sustainability of establishments. However, the

limitations of the system lie in its dependence on data

quality and its adjustment to specific patterns, which

could require further improvements to increase its

adaptability. The results can be applied to inventory

optimization in other food sectors, and future research

could integrate new data sources and improve the

automation of the system, thus increasing its impact

on the sustainability of the sector.

ACKNOWLEDGMENTS

The authors are grateful to the Dirección de

Investigación de la Universidad Peruana de Ciencias

Aplicadas for the support provided for this research

work through the economic incentive.

REFERENCES

Beheshti, S., Heydari, J., & Sazvar, Z. (2021). Food waste

recycling closed loop supply chain optimization

through renting waste recycling facilities. Sustainable

Cities And Society, 78, 103644. https://doi.org/10.1016/

j.scs.2021.103644

Birkmaier, A., Imeri, A., & Reiner, G. (2024). Improving

supply chain planning for perishable food: data-driven

implications for waste prevention. Journal Of Business

Economics, 94(6), 1-36. https://doi.org/10.1007/s11

573-024-01191-x.

Dadi, V., Nikhil, SR, Mor, RS, Agarwal, T., & Arora, S.

(2021). Agri-Food 4.0 and Innovations: Revamping the

Supply Chain Operations. Production Engineering

Archives 27 (2), 75-89. https://doi.org/10.30657/pea.20

21.27.10 .

Herron, C. B., Garner, L. J., Siddique, A., Huang, T.,

Campbell, J. C., Rao, S., & Morey, A. (2022). Building

“First Expire, First Out” models to predict food losses

at retail due to cold chain disruption in the last mile.

Frontiers In Sustainable Food Systems, 6.

https://doi.org/10.3389/fsufs.2022.1018807.

Islam, S., Amin, S., & Wardley, L. (2021). Machine

learning and optimization models for supplier selection

and order allocation planning. International Journal Of

Production Economics, 242, 108315. https://doi.org/

10.1016/j.ijpe.2021.108315 .

Kumar, I., Rawat, J., Mohd, N., & Husain, S. (2021).

Opportunities of Artificial Intelligence and Machine

Learning in the Food Industry. Journal Of Food

Quality, 2021, 1-10. https://doi.org/10.1155/2021/

4535567 .

Makridis, G., Mavrepis, P., & Kyriazis, D. (2022). A deep

learning approach using natural language processing

and time-series forecasting towards enhanced food

safety. Machine Learning, 112(4), 1287-1313.

https://doi.org/10.1007/s10994-022-06151-6.

Miguéis, V., Pereira, A., Pereira, J., & Figueira, G. (2022).

Reducing fresh fish waste while ensuring availability:

Demand forecast using censored data and machine

learning. Journal Of Cleaner Production, 359, 131852.

https://doi.org/10.1016/j.jclepro.2022.131852 .

Posch, K., Truden, C., Hungerländer, P., & Pilz, J. (2022).

A Bayesian approach for predicting food and beverage

sales in staff canteens and restaurants. International

Journal Of Forecasting, 38(1), 321-338. https://doi.org/

10.1016/j.ijforecast.2021.06.001 .

Sharma, P., Vimal, A., Vishvakarma, R., Kumar, P., De

Souza Vandenberghe, L.P., Gaur, V.K., & Varjani, S.

(2022). Deciphering the blackbox of omics approaches

and artificial intelligence in food waste transformation

and mitigation. International Journal Of Food

Microbiology, 372, 109691. https://doi.org/10.1016/j.ij

foodmicro.2022.109691 .

Wu, C. E., & Teng, C. (2022). Reducing Food Waste in

Buffet Restaurants: A Corporate Management

Approach. Foods, 12(1), 162. https://doi.org/10.3390/

foods12010162

CLOSER 2025 - 15th International Conference on Cloud Computing and Services Science

150