Facility Layout Generation Using Hierarchical Reinforcement Learning

Shunsuke Furuta

1

, Hiroyuki Nakagawa

1,2

and Tatsuhiro Tsuchiya

1

1

Graduate School of Information Science and Technology, Osaka University, 1-5 Yamadaoka, Suita, Osaka, Japan

2

Graduate School of Environmental, Life, Natural Science and Technology, Okayama University,

3-1-1 Tsushima-naka, Kita-ku, Okayama, Japan

Keywords:

Machine Learning, Hierarchical Reinforcement Learning, Facility Layout Problem, Layout Design.

Abstract:

Facility Layout Problem (FLP), which is an optimization problem aimed at determining the optimal place-

ment of facilities within a specified site, faces limitations in existing methods that use genetic algorithms (GA)

and metaheuristic approaches. These methods require accurately specifying constraints for facility placement,

making them difficult to utilize effectively in environments with few skilled workers. In layout generation us-

ing reinforcement learning-based methods, the need to consider multiple requirements results in an expanded

search space, which poses a challenge. In this study, we implemented a system that adopts hierarchical rein-

forcement learning and evaluated its performance by applying it to existing benchmark problems. As a result,

we were able to confirm that the system could stably generate facility layouts that meet the given conditions

while addressing the issues found in previous methods.

1 INTRODUCTION

Facility Layout Problem (FLP) (Drira et al., 2007)

is an optimization problem that involves designing

appropriate arrangements of facilities within a site.

Since facility layout significantly impacts factors such

as operational costs, it is essential to consider require-

ments like interrelationships between facilities during

the design process. Furthermore, with the rapid pace

of technological advancements, the frequency of re-

designing existing factories has increased, necessitat-

ing quick layout design solutions. Given these cir-

cumstances and the NP-hard (Ripon et al., 2010) na-

ture of FLP’s computational complexity, metaheuris-

tic approaches, which provide approximate solutions,

have primarily been proposed. Additionally, rein-

forcement learning, a type of machine learning, has

recently been applied to this problem. However,

metaheuristic methods face challenges in requiring

exploration for each case, resulting in a limited range

of adaptability. Moreover, in the case of existing rein-

forcement learning methods, the learning process for

the complex FLP leads to an expanded search space,

making it difficult to generate facility layouts quickly.

In this study, we propose a facility layout sys-

tem for FLP using hierarchical reinforcement learn-

ing. Hierarchical reinforcement learning optimizes

policies—strategies for addressing the target prob-

lem—without requiring training data. Its hierarchical

structure allows for the reduction of the search space

and efficient optimization of policies. We evaluated

the performance of the proposed method by applying

it to benchmark problems for FLP.

The structure of this paper is as follows. Section 2

discusses the research background, including existing

studies on FLP, reinforcement learning, and hierarchi-

cal reinforcement learning. Section 3 introduces the

proposed facility layout generation system using hi-

erarchical reinforcement learning. Section 4 presents

the evaluation experiments and results related to the

proposed method. Section 5 provides a discussion of

the experimental results, and Section 6 concludes the

study and outlines future research directions.

2 BACKGROUND

2.1 Reinforcement Learning

Reinforcement learning (Kaelbling et al., 1996) is a

machine learning method that enables a system to

learn optimal actions for a given problem through

its own trial-and-error process, without requiring pre-

prepared training data. The learning process in rein-

forcement learning progresses through the interaction

of the following two components:

150

Furuta, S., Nakagawa, H. and Tsuchiya, T.

Facility Layout Generation Using Hierarchical Reinforcement Learning.

DOI: 10.5220/0013098200003890

In Proceedings of the 17th International Conference on Agents and Artificial Intelligence (ICAART 2025) - Volume 3, pages 150-157

ISBN: 978-989-758-737-5; ISSN: 2184-433X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

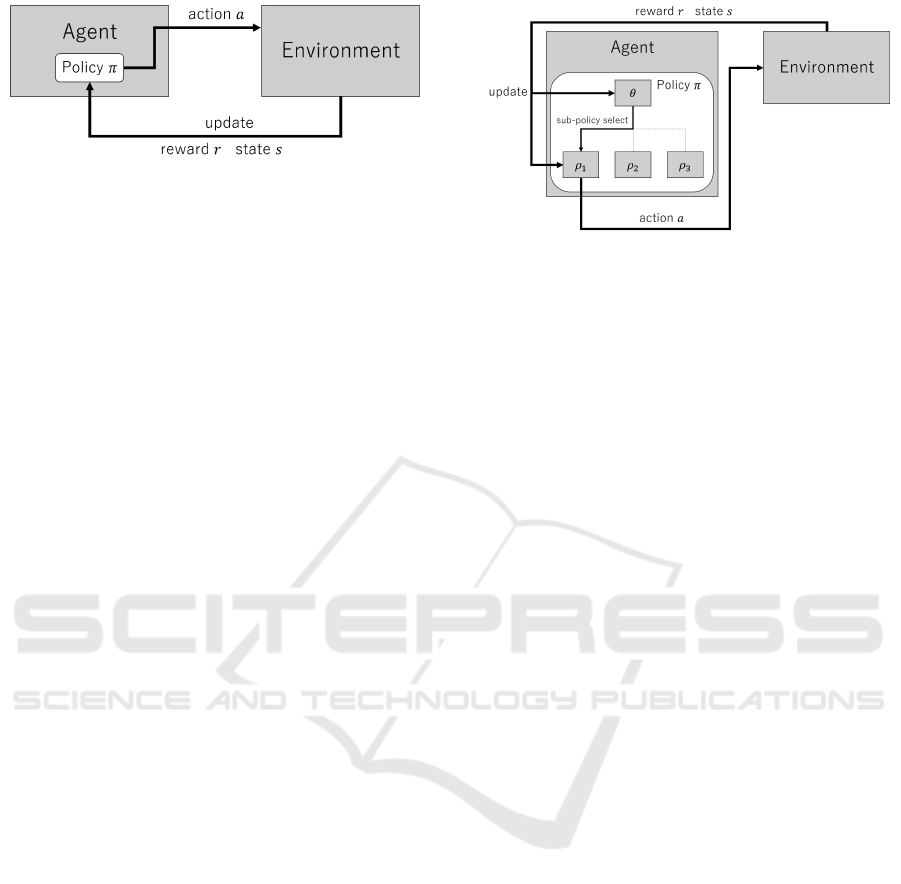

Figure 1: Overview of Reinforcement Learning.

• Agent: The learning system responsible for se-

lecting actions.

• Environment: The setting in which the agent per-

forms the target problem.

The agent selects actions based on a probability

distribution called a policy. The agent then performs

the selected action in the environment and receives a

reward from the environment. Subsequently, it tran-

sitions to a new state and updates its policy. By re-

peating this cycle, the agent learns to solve the target

problem. Specifically, the period until the agent takes

one action is called a step, and the entire process from

the beginning to the end of the problem is referred to

as an episode.

Examples of reinforcement learning algorithms

include Q-learning and Deep Q-Networks (DQN)

(Arulkumaran et al., 2017). These algorithms calcu-

late the value of actions, referred to as Q-values, and

learn to improve these values. Q-learning manages Q-

values in a table, while DQN uses neural networks to

handle high-dimensional tables of Q-values.

2.2 Hierarchical RL

Hierarchical reinforcement learning (Sutton et al.,

1999) is a type of reinforcement learning character-

ized by its hierarchical policy structure. This struc-

ture allows for more abstract learning in higher-level

policies, which is said to reduce the search space (Di-

etterich, 2000). In FLP, as the number of facilities to

be arranged increases, the unallocated space becomes

more limited, making it desirable to have allocation

strategies tailored to each situation. Therefore, this

study focuses on Meta Learning Shared Hierarchies

(MLSH), proposed by Frans et al. (Frans et al., 2017).

In MLSH, the policy structure consists of two lay-

ers: a master policy and multiple sub-policies. Each

sub-policy attempts sub-tasks derived from the target

problem, learning optimal actions suited to specific

situations. This allows the higher-level policy to only

learn how to select the appropriate sub-policy for a

given situation. Figure 2 illustrates master policy θ

selecting sub-policy ρ

1

.

Figure 2: Meta Learning Shared Hierarchies.

2.3 Existing Methods

As mentioned earlier, methods for solving FLP have

primarily focused on metaheuristic methods (Husoon

et al., 2022) such as Genetic Algorithms (GA) since

early studies like (Meller and Bozer, 1997) and (Kar

Yan Tam, 1992). These methods are characterized by

incorporating rules for appropriate facility layouts as

input when generating layouts. For instance, Paes et

al. proposed an FLP solution combining GA with

a divide-and-conquer approach (Paes et al., 2017),

optimizing facility layouts based on constraints such

as material handling costs. However, such methods

generate solutions only for predefined cases, making

them highly dependent on the skill of the user who

sets the parameters and limited in their ability to adapt

to layouts involving many facilities.

On the other hand, research utilizing reinforce-

ment learning for FLP is also being advanced. Xin-

han et al. (Di and Yu, 2021a) proposed a furni-

ture arrangement method using Deep Q-Networks

(DQN). This method enables the generation of lay-

outs that satisfy room constraints, but its learning

is limited to single pieces of furniture. They also

proposed a method utilizing multi-agent deep rein-

forcement learning (Di and Yu, 2021b), which al-

lows each agent to learn furniture arrangement strate-

gies that satisfy constraints from various perspectives,

enabling the creation of suitable 3D layouts from

a three-dimensional viewpoint. However, even this

method cannot handle the arrangement of multiple

pieces of furniture. Meanwhile, Ikeda et al. (Ikeda.

et al., 2023) proposed a method that combines rein-

forcement learning with the Analytic Hierarchy Pro-

cess (AHP) (Saaty, 1980) to generate layouts that con-

sider the relationships between facilities. AHP is a

decision-making approach that determines the most

effective option based on objective evaluation val-

ues calculated by weighting multiple evaluation crite-

ria that constitute the problem. This method allows

for the appropriate arrangement of multiple facility

groups. However, the success rate of layout gener-

Facility Layout Generation Using Hierarchical Reinforcement Learning

151

ation remains around 34%, indicating challenges in

achieving stability in the learning process for layout

generation.

3 FACILITY LAYOUT SYSTEM

Based on the issues identified in the existing studies

discussed in Section 2.3, we propose a facility layout

generation system utilizing MLSH. The objectives of

the generated layouts are as follows:

• Placing all facilities within the site without gaps.

• Placing related facilities as close as possible.

In this environment, site area, sizes of facilities,

and their relationships are predefined. (We call a pair

of the two different facilities a relationship and as-

sume that a relationship is assigned a non-negative

real number called the strength.) The agent of the pro-

posed method learns constraints and rules for optimal

facility placement through repeated operations of ac-

tually placing facilities. Subsequently, using learned

master policy and sub-policies, layouts can be gener-

ated for any given set of facilities.

3.1 Learning Environment

The environment of FLP and the facility placement

actions selected by the agent, are defined as follows:

1. The site and facility are defined as cuboids repre-

sented by (width, length).

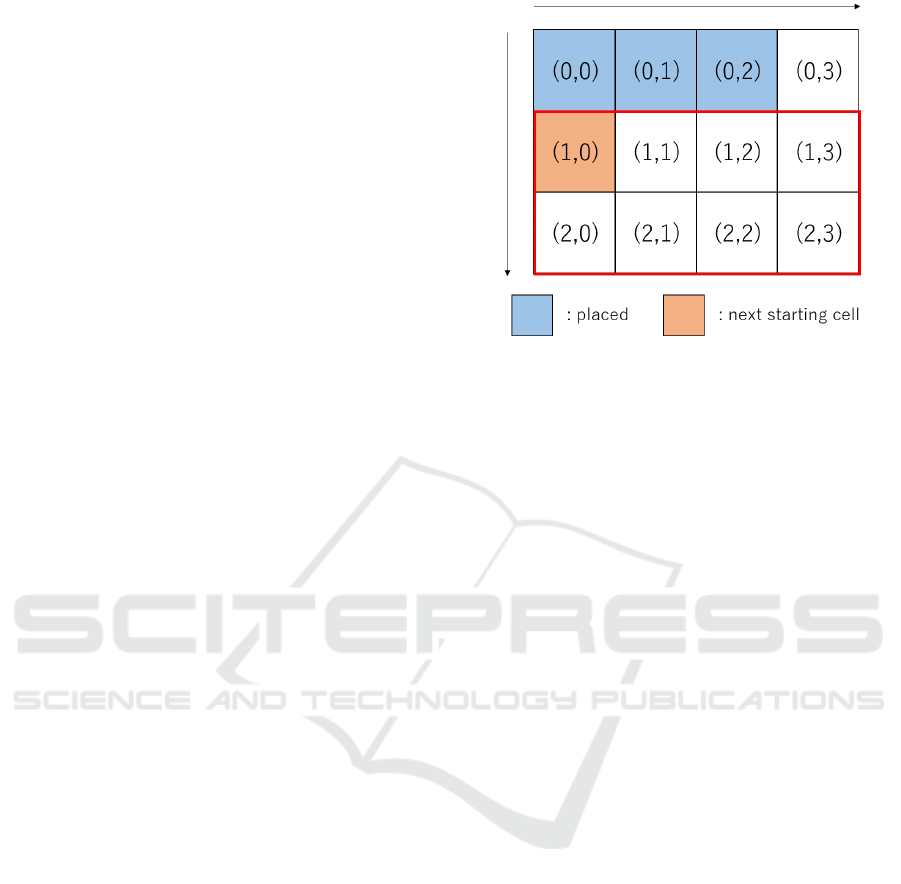

Figure 3 shows a site with (width, length) = (4, 3).

2. The site information is represented as a two-

dimensional array, with (0, 0) as the starting point,

where the right direction corresponds to width and

the downward direction corresponds to length,

both taken as positive directions.

3. Facilities are also considered when rotated by 90

degrees.

4. The relationship between facilities is expressed in

the form (relationship strength, facility 1, facility

2) and defined at the start of each episode.

5. The starting point for placing facilities is defined

randomly at the start of each episode. Subse-

quently, the next starting point will be the loca-

tion in the unplaced area where the largest possi-

ble rectangle can be formed.

In Figure 3, the starting point is (0, 0). In this case,

the largest rectangle in the unplaced area starts at

(1, 0), so the next starting point will be (1, 0).

6. facility placement actions (a) to (d) are defined as

follows:

Figure 3: Starting point.

(a) Select one facility with the maximum product

of width and length.

(b) Select one facility with the maximum evalua-

tion value of P

rel

.

P

rel

=

∑

r∈R

relation

r

∗ D

r

(1)

• R : Set of relationships with already allocated

facilities.

• relation

r

: Strength of relationship r.

• D

r

: Reciprocal of Manhattan distance be-

tween facilities in relationship r. The distance

is measured between the center coordinates of

two facilities.

(c) Select one facility with the maximum evalua-

tion value of P

both

.

P

both

=

∑

r∈R

(relation

r

∗ 0.5 + space ∗ 0.5) ∗ D

r

(2)

• R : Set of relationships with already allocated

facilities.

• relation

r

: Strength of relationship r.

• space : The product of width and length of the

unplaced facility under consideration.

• D

r

: Reciprocal of Manhattan distance be-

tween facilities in relationship r.

(d) Select one facility that can be placed randomly.

P

both

considers both the strength of relationships

and the width and length of the facilities. These

values are normalized to ensure that neither has

an overwhelming influence on the result.

7. The agent’s state consists of the following two el-

ements((a) and (b)):

(a) Site area satisfaction

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

152

The ratio of the area occupied by allocated fa-

cilities to the total site area. If all facilities are

placed without gaps, this value is 1.

(b) Facility relationship satisfaction

The sum of T (equation (3)) for each already

allocated facility is compared to the total sum

of relationship strengths. If the Manhattan dis-

tance between all related facilities is 1, this

value is 1.

T =

∑

r∈A

relation

r

∗ D

r

(3)

• A : Set of relationships with other already allo-

cated facilities.

• relation

r

: Strength of relationship r.

• D

r

: Reciprocal of Manhattan distance between

facilities in relationship r.

8. The reward R

ac

for the agent’s actions is as fol-

lows. Here, the increase rate of the facility area

before and after placement is denoted as A, and

the increase rate from equation (3) is denoted as

B. Additionally, cases where a facility is placed is

denoted as true, and cases where a facility could

not be placed is denoted as f alse.

R

ac

=

(

0.5 ∗ A + 0.5 ∗ B if true

0 if f alse

(4)

The reward R

end

at the end of the episode is as

follows. In the following equation (5), let N

unp

represents the number of unallocated facilities.

R

end

= −1.0 ∗ N

unp

(5)

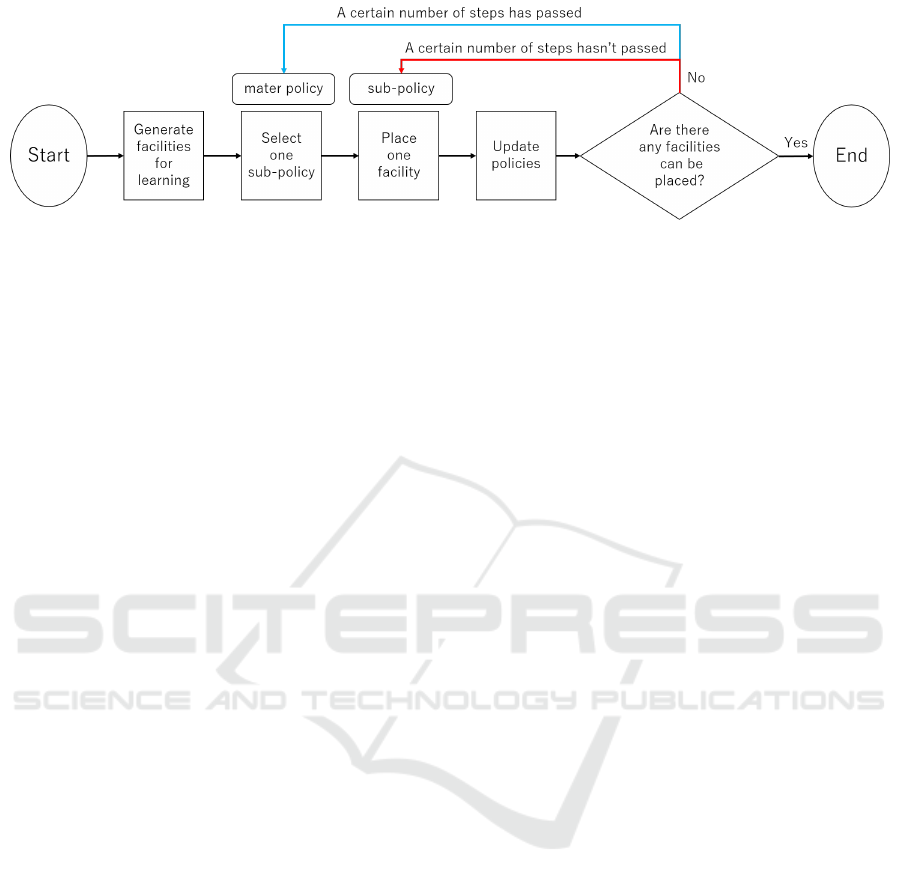

3.2 Learning Method

This section explains the learning process of MLSH

agent within a single episode. Figure 4 illustrates

this flow. First, facilities with random widths and

lengths are generated until the total area of the facility

group exceeds the site area, defining the facility group

for learning. At this point, the relationships between

facilities are also set. Second, after a certain num-

ber of steps, the master policy selects one sub-policy.

At other times, the previously selected sub-policy is

used. Third, the selected sub-policy performs one fa-

cility placement action based on its own probability

distribution. It then receives a reward based on the

placement results using equation (4) and updates the

selected master policy and sub-policy. The second

and third steps are repeated thereafter. Finally, when

no facilities can be placed, a reward is given accord-

ing to the number of unplaced facilities using equation

(5), and the episode ends.

3.3 Layout Generation Method

This section explains the method for generating facil-

ity layouts using the master policy and sub-policies

after training.

First, set the (width, length) of the site where the

facility layout generation will actually be performed.

Second, set the group of facilities to be placed and

the relationships between these facilities for the ac-

tual facility layout generation (these information must

be predefined). Third, after a certain number of steps,

master policy selects one sub-policy based on a proba-

bility distribution (if a certain number of steps has not

passed, the same sub-policy as the previous attempt

is selected). Fourth, selected sub-policy chooses one

facility placement action, and attempts to place one

facility on the site. The third and fourth steps are re-

peated thereafter.

At the end of each episode, there are two possi-

ble outcomes: either there are no unplaced facilities

remaining, or some remain unplaced. When no un-

placed facilities exist, it means that all facilities have

been successfully placed. In this case, facility layout

system outputs the generated facility layout.

4 EXPERIMENT

We conducted experiments to evaluate the effective-

ness of the proposed system utilizing MLSH. Using

the facility groups and relationships between facilities

from benchmark problem (Meller and Bozer, 1997).

4.1 Verification of Layout Generation

4.1.1 Experimental Overview

In this experiment, to evaluate the stability of the lay-

out generation of the proposed system, we measured

the ratio of generated facility layouts in which all fa-

cilities could be placed (referred to as success rate).

The number of steps for facility placement actions

during learning was set to a maximum of 180,000

times, the number of updates for master policy was

set to a maximum of 3,600 times, and the total number

of updates for sub-policies was set to a maximum of

2,160 times. Additionally, the number of steps for fa-

cility placement actions during layout generation was

set to 5,000 times. The success rate was calculated

for every 10,000 steps of facility placement actions

during learning, based on the results generated by the

learned agent, and the changes in its increase or de-

crease were also confirmed.

Facility Layout Generation Using Hierarchical Reinforcement Learning

153

Figure 4: Flow of one learning episode.

4.1.2 Experimental Results

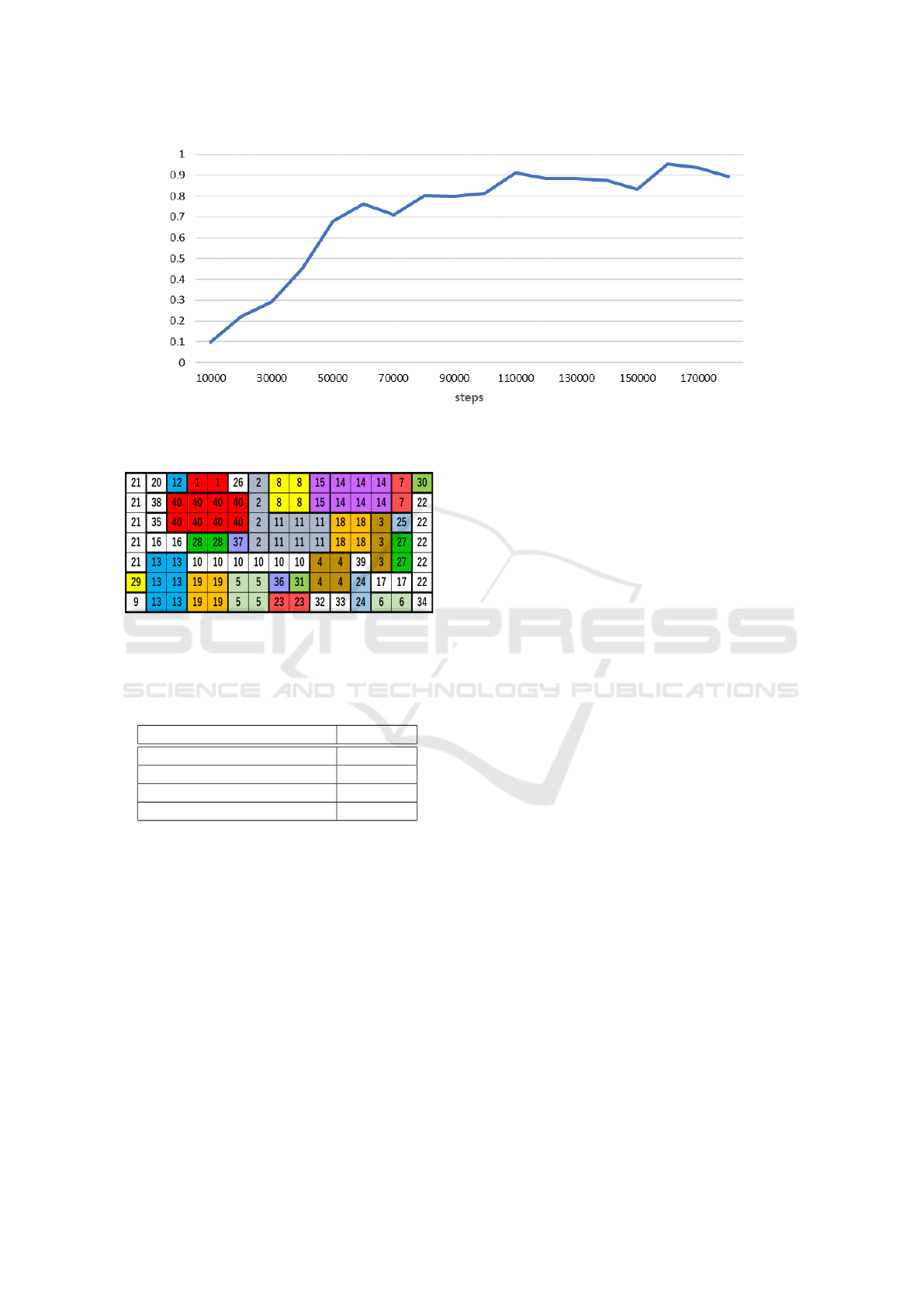

Figure 5 shows the graph results indicating the re-

lationship between the number of steps for facility

placement actions required for learning and the suc-

cess rate. In learning with a smaller number of steps,

the success rate was less than 50%, but from 80,000

learning steps onwards, a stable result was obtained

with the success rate converging to 80% to 90%. This

confirms that learning with MLSH meets the objec-

tive of ”Placing all facilities within the site without

gaps.”

As an example, a facility layout generated using

master policy and sub-policies trained with 180,000

steps is shown in Figure 6.

4.2 Evaluation of Generated Layout

4.2.1 Experimental Overview

This experiment confirmed whether the placement

considered the relationships between facilities while

being able to place all facilities. The evaluation crite-

ria used DI analysis, a facility layout analysis method.

DI analysis evaluates the facilities placed in the lay-

out based on the product of the distance between fa-

cilities (Distance) and the intensity of the relationship

between facilities (Intensity). Since this study aims

for shorter distances between facilities with stronger

relationships, the product of Distance and Intensity

should be small. Therefore, we calculated the follow-

ing P

DI

, and determined that the smaller this value,

the higher the layout evaluation.

P

DI

=

∑

x∈I

relation

x

∗ L

1

x

(6)

• I : Set of all relationships

• relation

x

: Strength of relationship x

• L

1

x

: Manhattan distance between facilities in re-

lationship x

Similar to experiment in Section 4.1, the number

of steps for facility placement actions during learning

was set to a maximum of 180,000 times, the number

of updates for master policy to a maximum of 3,600

times, and the total number of updates for sub-policies

to a maximum of 2,160 times. Additionally, the num-

ber of steps for facility placement actions during lay-

out generation was set to 5,000 times. The average

value of P

DI

was calculated for every 10,000 steps

of facility placement actions during learning, based

on the results generated by the learned agent, and its

changes were also monitored.

Furthermore, the calculated average value of P

DI

was compared with the execution results of the ex-

isting method by Ikeda et al. (Ikeda. et al., 2023).

This existing method selects facilities based on the

objective evaluation values of each facility, calculated

from the weights called ”combination rate”, which

are derived using AHP with Q-learning and DQN al-

gorithms for facility area and facility relationships.

The higher ”combination rate”, the more emphasis is

placed on the relationships between facilities. For ex-

ample, ”combination rate” of 0.9 indicates ”relation-

ship between facilities : facility area = 9:1”.

4.2.2 Experimental Results

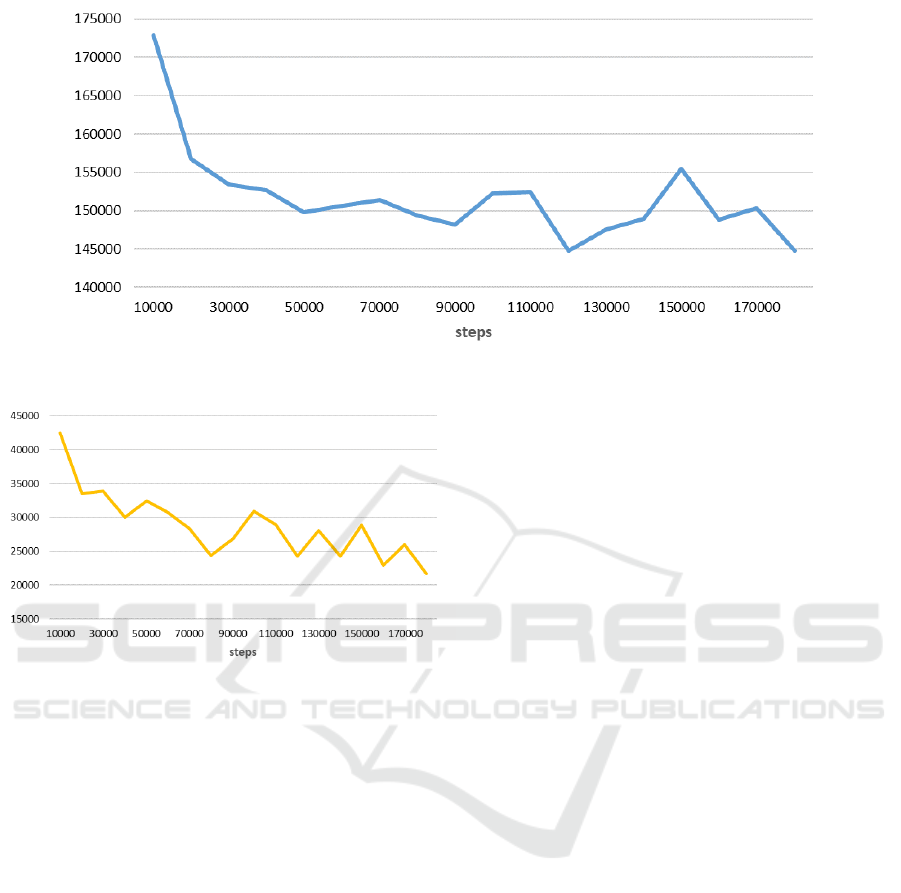

Figure 7 shows a graph illustrating the relationship

between the number of action steps required for facil-

ity placement during learning and the average value

of P

DI

. Although there is some variation with the in-

crease in the number of steps required for learning,

a decreasing trend is observed. This confirms that

the proposed method can learn to place facilities with

significant relationships as close together as possible

across the entire facility layout.

Meanwhile, Table 1 compares the average value

of P

DI

of proposed method after 180,000 learning

steps with those of existing methods by Ikeda et al.

(Q-learning+AHP and DQN+AHP). In the table, R

s

refers to ”combination rate” mentioned in Section

4.2.1.

From Table 1, it was confirmed that the proposed

method could achieve learning and layout generation

that consider the relationships between facilities bet-

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

154

Figure 5: The success rate of facility layout generation.

Figure 6: Example of facility layout by proposed method

trained with 180,000 steps. The numbers indicate the fa-

cility numbers, and facilities with the same color represent

those with particularly strong relationship.

Table 1: comparison of the average of P

DI

.

method P

DI

DQN + AHP (R

s

: 0.9) 139,525.0

DQN + AHP (R

s

: 0.5) 146,259.5

Q-Learning + AHP (R

s

: 0.9) 175,487.5

Ours (MLSH) 144,824.9

ter than Q-learning, as the average value of P

DI

is

lower than that of the combination of Q-learning +

AHP, even when ”combination rate” that most empha-

sizes the relationships between facilities is 0.9. On the

other hand, in comparison with DQN + AHP, when

the synthetic ratio is 0.9, the proposed method had

a higher average P

DI

value, resulting in a lower lay-

out evaluation. However, when ”combination rate” is

lower than 0.9, i.e., when more emphasis is placed on

the sufficiency of the site area (as shown in Table 1

for ”combination rate” of 0.5), the evaluation based

on P

DI

is higher than that of DQN, indicating that the

proposed method does not necessarily perform worse

than DQN + AHP.

5 DISCUSSION

In experiment in Section 4.1, we verified whether fa-

cility layouts could be stably generated, with facilities

being placed tightly on the site, using MLSH. As a re-

sult, by using MLSH agent trained with 80,000 steps,

we achieved a success rate of around 80%, and it was

confirmed that by increasing the number of learning

steps, layouts could be generated with a success rate

of 80% to 90%. This outcome can be attributed to

the imposition of rewards indicated by equation (5).

According to equation (4), during each facility place-

ment attempt, a negative reward is not incurred even

if facility placement cannot be achieved. However,

when all facilities cannot be placed by the end of an

episode, a negative reward is given, which encourages

learning that prioritizes facility placements enabling

all facilities to maximize return.

In experiment in Section 4.2, we compared and

evaluated the proposed method and existing method

using DI analysis. As a result, we were able to achieve

a facility layout generation with higher evaluation

than Q-learning+AHP, but there were cases where the

evaluation was lower than DQN+AHP. The method

by Ikeda et al., which was used for comparison, ob-

jectively evaluates each facility during layout gener-

ation based on ”combination rate” of AHP for the

facility area and the relationships between facilities,

and selects facilities based on these evaluation values.

Therefore, unlike the proposed method, the existing

method takes into account the relationships between

all facilities, which is believed to be the reason for the

inferior results compared to DQN+AHP. On the other

hand, the relationship between the number of learning

steps in the proposed method and the variance value

of P

DI

is as shown in Figure 8. From this graph, it can

Facility Layout Generation Using Hierarchical Reinforcement Learning

155

Figure 7: The average of P

DI

for the facility layouts.

Figure 8: The variance of P

DI

for the facility layouts.

be suggested that the proposed method is capable of

learning to consider the relationships between facili-

ties, as indicated by the decreasing trend in variance

corresponding to the number of learning steps.

6 CONCLUSION AND FUTURE

WORKS

6.1 Conclusion

This study focuses on Facility Layout Problem (FLP),

which involves devising the optimal arrangement of

facilities on a site. We propose a facility layout gen-

eration system using MLSH to improve the efficiency

of generating layouts that take multiple requirements

into account while being independent of user skill by

enabling the system itself to learn the constraints and

rules for appropriate facility placement.

Applying the proposed system to a benchmark

problem, we confirmed that it could generate layouts

where all facilities are placed without gaps within the

specified site. Furthermore, we evaluated whether the

system could consistently generate layouts with all

facilities placed on the site, using a metric referred

to as the success rate. Additionally, we examined

whether the generated layouts considered the rela-

tionships between facilities based on DI analysis and

compared the results with those of existing reinforce-

ment learning-based method.

From the perspective of success rate, the proposed

method demonstrated stable performance, achieving

the success rate of 80% to 90% in the latter stages

of training, indicating that it could consistently gen-

erate layouts with all facilities placed without gaps.

However, in terms of layout evaluation using DI anal-

ysis, the proposed method occasionally performed

worse compared to existing methods that consider

facility relationships during layout generation using

AHP. Overall, considering the very high probability

of generating layouts with all facilities placed and the

system’s increasing ability to account for facility re-

lationships as training progresses, the usefulness of

MLSH for FLP has been demonstrated.

6.2 Future Work

Looking ahead, based on the evaluation experiments

and issues with MLSH, we aim to address the fol-

lowing feature additions and specification changes in

future research.

6.2.1 Environmental Settings

From the evaluation experiments of the generated lay-

outs using DI analysis conducted in Section 4.2, it was

found that the proposed method sufficiently learned to

meet the site’s area requirements, but the learning effi-

ciency concerning the relationships between facilities

was not as high as that for the area requirements. In

the current environment, as shown in equation (4), the

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

156

reward related to the relationships between facilities is

only partially calculated during facility placement ac-

tions. This suggests that the relationships between fa-

cilities do not significantly contribute to the reinforce-

ment learning objective of maximizing profit. There-

fore, since the reward in equation (5) improved the

success rate of layout generation, we plan to examine

whether applying a similar reward to the relationships

between facilities can further reduce the DI analysis

evaluation values. For example, a method that im-

poses negative rewards on the number of relationships

between facilities with distances exceeding a certain

value at the end of an episode, thereby encouraging

the placement of facilities considering their relation-

ships to ensure that the distances between facilities

fall within a certain range, can be mentioned.

6.2.2 Improvement of MLSH

Not limited to MLSH, hierarchical reinforcement

learning, which divides the target problem into multi-

ple sub-tasks for learning, is said to contribute to re-

ducing the exploration space during learning due to its

structure of having multiple sub-policies. However,

it has been pointed out that methods that automati-

cally acquire such sub-policies may result in all sub-

policies converging to the same policy, thereby losing

diversity among them. In response to this, Huo et al.

proposed a method that updates MLSH sub-policies

to differentiate them from each other using similar-

ity measures of probability distributions, such as KL

divergence, thereby effectively utilizing the multi-

ple sub-policies (Huo et al., 2023). Experiments on

various tasks have shown that this method increases

the rewards compared to conventional MLSH. In this

study, we aim to introduce such methods that lever-

age the structural advantages of MLSH to optimize

the learning of facility relationships.

REFERENCES

Arulkumaran, K., Deisenroth, M. P., Brundage, M., and

Bharath, A. A. (2017). Deep Reinforcement Learn-

ing: A Brief Survey. IEEE Signal Processing Maga-

zine, 34(6):26–38.

Di, X. and Yu, P. (2021a). Deep Reinforcement Learning

for Producing Furniture Layout in Indoor Scenes.

Di, X. and Yu, P. (2021b). Multi-Agent Reinforcement

Learning of 3D Furniture Layout Simulation in Indoor

Graphics Scenes. CoRR, abs/2102.09137.

Dietterich, T. G. (2000). Hierarchical Reinforcement Learn-

ing with the MAXQ Value Function Decomposition.

Journal of Artificial Intelligence Research, 13:227–

303.

Drira, A., Pierreval, H., and Hajri-Gabouj, S. (2007). Fa-

cility layout problems: A survey. Annual Reviews in

Control, 31(2):255–267.

Frans, K., Ho, J., Chen, X., Abbeel, P., and Schulman, J.

(2017). Meta Learning Shared Hierarchies.

Huo, L., Wang, Z., Xu, M., and Song, Y. (2023). A Task-

Agnostic Regularizer for Diverse Subpolicy Discov-

ery in Hierarchical Reinforcement Learning. IEEE

Transactions on Systems, Man, and Cybernetics: Sys-

tems, 53(3):1932–1944.

Husoon, O. O., Kadhim, D. A., and Raheem, K. M. H.

(2022). Reconfigration of manufacturing facility lay-

out using meta heuristic particle swarm optimization.

AIP Conference Proceedings, 2386(1):050013.

Ikeda., H., Nakagawa., H., and Tsuchiya., T. (2023). Au-

tomatic Facility Layout Design System Using Deep

Reinforcement Learning. In Proceedings of the 15th

International Conference on Agents and Artificial In-

telligence - Volume 2: ICAART, pages 221–230. IN-

STICC, SciTePress.

Kaelbling, L. P., Littman, M. L., and Moore, A. W. (1996).

Reinforcement learning: a survey. J. Artif. Int. Res.,

4(1):237–285.

Kar Yan Tam (1992). Genetic algorithms, function opti-

mization, and facility layout design. European Jour-

nal of Operational Research, 63(2):322–346. Strate-

gic Planning of Facilities.

Meller, R. D. and Bozer, Y. A. (1997). Alternative

Approaches to Solve the Multi-Floor Facility Lay-

out Problem. Journal of Manufacturing Systems,

16(6):457–458.

Paes, F. G., Pessoa, A. A., and Vidal, T. (2017). A hy-

brid genetic algorithm with decomposition phases for

the Unequal Area Facility Layout Problem. European

Journal of Operational Research, 256(3):742–756.

Ripon, K. S. N., Glette, K., Høvin, M., and Torresen, J.

(2010). A Genetic Algorithm to Find Pareto-optimal

Solutions for the Dynamic Facility Layout Problem

with Multiple Objectives. In Wong, K. W., Mendis, B.

S. U., and Bouzerdoum, A., editors, Neural Informa-

tion Processing. Theory and Algorithms, pages 642–

651, Berlin, Heidelberg. Springer Berlin Heidelberg.

Saaty, T. L. (1980). The analytic hierarchy process (AHP).

The Journal of the Operational Research Society,

41(11):1073–1076.

Sutton, R. S., Precup, D., and Singh, S. (1999). Between

MDPs and semi-MDPs: A framework for temporal

abstraction in reinforcement learning. Artificial Intel-

ligence, 112(1):181–211.

Facility Layout Generation Using Hierarchical Reinforcement Learning

157