The Influence of Germanium and Silicon on the Mechanical

Properties of Al-Cu Alloys

Sarvar Tursunbaev

1a

, Mukhayyokhon Saidova

1b

, Sharofuddin Mardonakulov

1c

,

Mohichekhra Boltaeva

2d

, Nilufar Isakulova

3e

and Shohruh Hudoykulov

1f

1

Tashkent State Technical University, 100095, University str. 2, Tashkent, Uzbekistan

2

Jizzakh Branch of the National University of Uzbekistan, Jizzakh, Uzbekistan

3

Uzbekistan State University of World Languages, 100138 Tashkent, Uzbekistan

Keywords: Microalloying, Mechanical Properties, Al-Cu Alloys.

Abstract: The article describes the process of microalloying an aluminum-copper alloy with germanium and silicon

oxides. Germanium oxide is part of an alloy enclosed in a special aluminum coating. 5% silicon is added to

the alloy compared to the same amount of charge. germanium oxide, on the other hand, is introduced in

various amounts from 0.1% to 0.3% compared to the charge. The samples were cast in an electric resistance

furnace at a temperature of 750 °C. The hardness and wear resistance of the obtained samples in terms of

mechanical properties were tested by experiments. The microstructures of the samples were analyzed using a

metallographic microscope. Changes in the microstructure and mechanical properties of the samples were

studied by comparison with samples without the addition of germanium oxide and silicon. The article also

develops a graph of the dependence of mechanical properties on alloying elements. Based on the experiments

conducted, the article presents the authors' conclusions on the last of them.

1 INTRODUCTION

The growing demand for non-ferrous alloys has led to

an increase in experience and research aimed at

further improving their properties. Changing their

composition by including various elements in the

composition of non-ferrous alloys also leads to an

improvement in the properties of alloys (Dai et al.,

2022, Zakharov and Fisenko, 2017, Rooy, 1990,

Shaw et al., 2003, Tang et al., 2013). Currently,

advanced research centers are conducting various

studies in this direction. A number of scientific

studies, including on aluminum alloys, are aimed at

obtaining high-quality foundry products with an

increase in their casting and mechanical properties

(Efzan et al., 2014, Zebarjad and Sajjadi, 2014,

Azarniya et al., 2019). The world's leading countries

a

https://orcid.org/0000-0003-2516-3597

b

https://orcid.org/0009-0007-0870-4802

c

https://orcid.org/0009-0008-0964-3519

d

https://orcid.org/0009-0007-5354-3999

e

https://orcid.org/0000-0001-9646-4640

f

https://orcid.org/0009-0002-0144-9236

in this field are Canada, the USA, Japan, China,

Sweden, Germany, Russia, Ukraine and others. In the

above-mentioned countries, as well as in Uzbekistan

in subsequent years, due to the increase in the number

of non-ferrous alloys in the production of foundry

products in the foundry sector of the industry, great

attention is paid to creating a technology for

producing high-quality, durable foundry products

based on an effective method that ensures resource

conservation. (Novák et al., 2023, Tursunbaev et al.,

2023a,b, Nosir and Bokhodir, 2023, Turakhujaeva et

al., 2023). The article analyzes the change in the

properties of D16 grade aluminum alloy from

aluminum-copper alloys by including germanium

oxide and silicon in its composition.

Tursunbaev, S., Saidova, M., Mardonakulov, S., Boltaeva, M., Isakulova, N. and Hudoykulov, S.

The Influence of Germanium and Silicon on the Mechanical Properties of Al-Cu Alloys.

DOI: 10.5220/0014270000004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 381-384

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

381

2 MATERIALS AND METHODS

The D16 grade aluminium alloy contains 94.7%

aluminium. On the other hand, copper, the main

alloying element, is 4.9%. A resistance furnace was

used to melt the samples. The furnace used is mainly

designed for the manufacture of small parts, up to 3

kg of metal can be liquefied in the crucible. The

furnace crucible is made of graphite material, which

helps to cast liquid metal without sticking to the base

of the crucible (Kholmirzaev et al., 2023, Ma et al.,

2023, Nodir et al., 2022).

The hardness of the samples obtained in the

experiments was measured by the Brinell method. At

the same time, there should be no oil, rust, scratches

on its surface, it should be smooth and smooth. For

this, the surface is ground on a fine-toothed egg or

grindstone. The smallest thickness of the sample (s)

must be at least ten times greater than the depth of the

submerged trace of the submerged ball (H): in this

case, the value of S 10 H is determined by the

formula:

ℎ

0.102𝑃

𝜋𝐷𝐻𝐵

where R is the load on the sample, N or kg.k; D is the

diameter of the sphere, mm; HB is the Brinell

hardness of the material " kg / mm2. The hardness of

the test sample according to Brinell (HB).

Figure 1: Hardness tester model 187.5 F HBRV.

Experiments used the HBRV -187.5 F model

hardness tester (Fig.1). The sample size was prepared

in a 35x5mm circle shape and a Brinell Press was

used.

Abrasive wear is the destruction of a material as a

result of mechanical influences, when a cutting and

scratching action occurs in the presence of a relative

velocity of movement of solid particles or particles.

Abrasive wear occurs when two pairs of parts come

into contact with each other under mutual friction,

and the hardness of one material is higher than that of

the other.

The wear resistance of the samples was

determined in experiments on a diamond disk device

(Fig.2). Wear resistance was determined by weight

loss. At certain intervals, the samples were held on a

rotating disk under the same force.

Figure 2: A device with a diamond disc that determines

wear resistance.

3 EXPERIMENTS AND RESULTS

Samples were cast according to the chemical

composition shown in Table 1. The samples were

melted in a resistance furnace at a temperature of 750°

C. The samples were poured into sand-clay molds

(Fig. 3). In experiments, 0.1% to 0.3% germanium

oxide was introduced into the aluminum alloy. After

germanium oxide was introduced into later samples

in the same composition, silicon was added as an

alloying element in an amount of 5% compared to the

charge.

Figure 3: Mold for samples (1) and casting process (2).

To determine the hardness of the cast samples, first

cutting was performed on a lathe, and then grinding

of the samples (Fig.4).

Figure 4: Polished samples.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

382

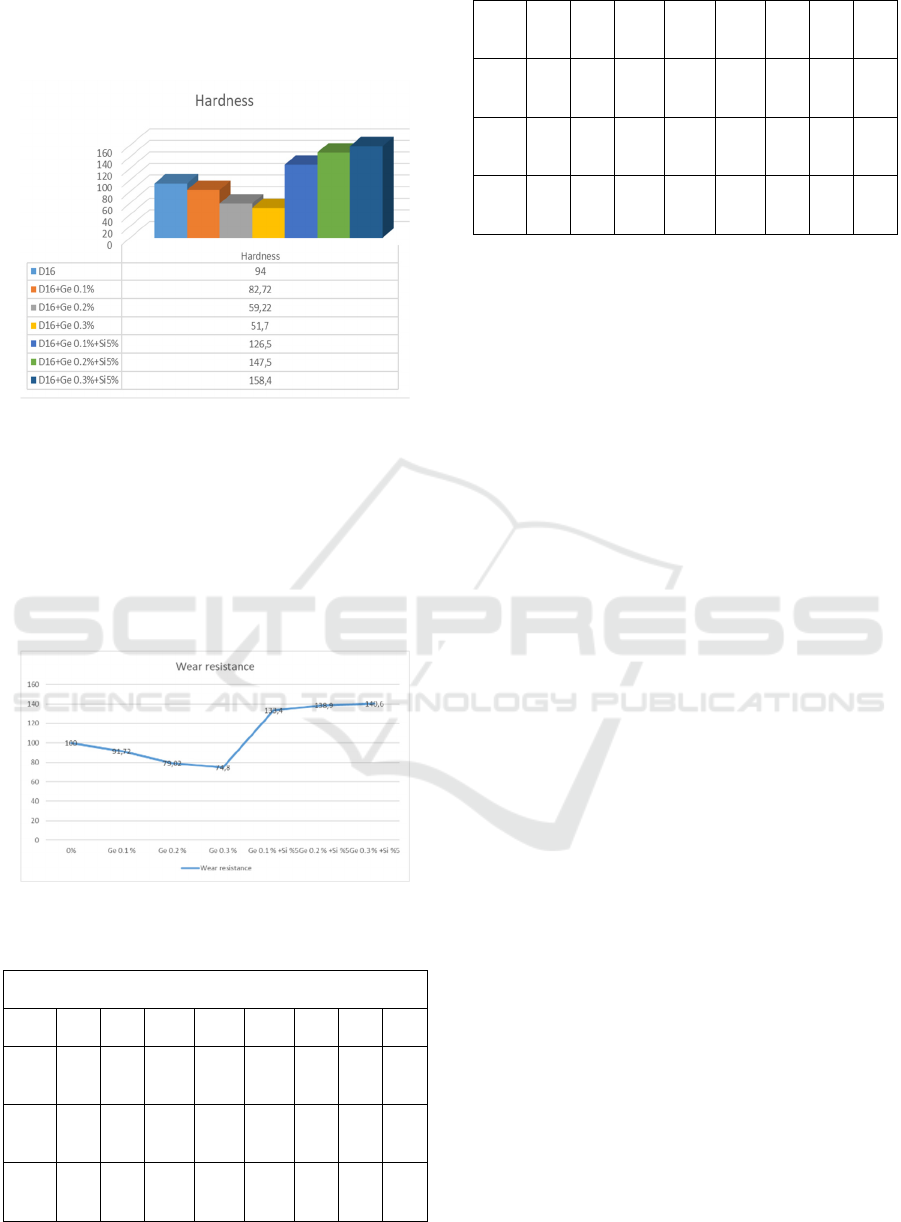

The hardness of the samples from three points

was checked and the average was calculated. The

measurement results are given in Figure 5 below.

Figure 5: Hardness measurement results.

The wear resistance of the cast samples was tested

using a device for measuring wear resistance using 6

minutes of the same force, i.e. using a device with a

force of 3 Newton. The wear resistance was

determined by differences in the weight of the

samples before and after the tests. Wear resistance

was carried over as a percentage of weight loss, and

link graph were developed (Fig.6.).

Figure 6: Link graph.

Table 1: Chemical composition of samples.

Percentage of elements in mass accounting, %

Al Si Fe Cu Mn Mg Ti Zn Ge

91-

94,7

0,5 0,5

3,8-

4,9

0,3-

0,9

1,2-

1,8

0,1 0,3 -

91-

94,7

0,5 0,5

3,8-

4,9

0,3-

0,9

1,2-

1,8

0,1 0,3 0,1

91-

94,7

0,5 0,5

3,8-

4,9

0,3-

0,9

1,2-

1,8

0,1 0,3 0,2

91-

94,7

0,5 0,5

3,8-

4,9

0,3-

0,9

1,2-

1,8

0,1 0,3 0,3

91-

94,7

5,5 0,5

3,8-

4,9

0,3-

0,9

1,2-

1,8

0,1 0,3 0,1

91-

94,7

5,5 0,5

3,8-

4,9

0,3-

0,9

1,2-

1,8

0,1 0,3 0,2

91-

94,7

5,5 0,5

3,8-

4,9

0,3-

0,9

1,2-

1,8

0,1 0,3 0,3

4 CONCLUSIONS

Experiments have shown that the introduction of

germanium oxide into the alloy led to a decrease in its

mechanical properties. Including the hardness of

Germanium oxide, as the content increased, the

hardness decreased to 38-40%. The wear resistance

has also decreased, respectively, as well as the

hardness. In subsequent studies, the addition of

silicon to the aluminium alloy led to an increase in

mechanical properties. The introduction of more than

5% silica into the sample compared to the charge

increased the hardness of the samples to 40-58%, and

the wear resistance to 33-40%. According to the

research results, it was found that germanium in

germanium oxide, remaining in the process of

liquefaction of the alloy in the aluminium-copper

system, improved the microstructure of the alloy,

which led to an increase in the mechanical properties

of samples with a silicon element.

REFERENCES

Azarniya, A., Taheri, A. K., & Taheri, K. K. (2019).

Recent advances in ageing of 7xxx series aluminum

alloys: A physical metallurgy perspective. Journal of

Alloys and Compounds, 781, 945-983.

Dai, Y., Yan, L., & Hao, J. (2022). Review on micro-

alloying and preparation method of 7xxx series

aluminum alloys: progresses and prospects. Materials,

15(3), 1216.

Efzan, E., Kong, M. N., Kok, C. K. (2014). Effect of

alloying element on Al-Si alloys. Advanced materials

research, 845, 355-359.

Kholmirzaev,N.,Turakhodjaev,N.,Saidmakhamadov,

N.,Khasanov, J.,Saidkhodjaeva, S., & Sadikova, N.

(2023) Development of Technology of Making Shafts

from Steel Alloy 35XGCL. In International Conference

on Reliable Systems Engineering (pp. 216-223). Cham:

Springer Nature Switzerland.

The Influence of Germanium and Silicon on the Mechanical Properties of Al-Cu Alloys

383

Ma, Z., Zhong, T., Sun, D., Qian, B., Turakhodjaev, N.,

Betsofen, S., & Wu, R. (2023). Microstructure and

Anisotropy of Mechanical Properties of Al-3Li-1Cu-0.4

Mg-0.1 Er-0.1 Zr Alloys Prepared by Normal Rolling

and Cross-Rolling. Metals, 13(9), 1564.

Nodir, T., Sherzod, T., & Shukhrat, C. (2022).

Technologies for extraction of copper from copper slag

by flotation. International Journal of Mechatronics and

Applied Mechanics, (11), 45-51.

Nosir, S., & Bokhodir, K. (2023). Development of

Liquefaction Technology 280X29NL to Increase the

Strength and Brittleness of Castings. Lecture Notes in

Networks and Systems, 534 LNNS, 105–

115.https://doi.org/10.1007/978-3-031-15944-2_10

Novák, P., Benediktová, D., Mestek, S., Tsepeleva, A., &

Kopeček, J. (2023). Aluminum alloys with natural ratio

of alloying elements manufactured by powder

metallurgy. Journal of Alloys and Compounds, 931,

167440.

Rooy, E. L. (1990). Introduction to aluminum and

aluminum alloys. In Properties and selection:

nonferrous alloys and special-purpose materials (pp. 3-

14). ASM International.

Shaw, L., Villegas, J., Luo, H., Zawrah, M., & Miracle, D.

(2003). Effects of process-control agents on mechanical

alloying of nanostructured aluminum alloys.

Metallurgical and Materials Transactions A, 34, 159-

170.

Tang, Z., Gao, M. C., Diao, H., Yang, T., Liu, J., Zuo, T.,

& Egami, T. (2013). Aluminum alloying effects on

lattice types, microstructures, and mechanical behavior

of high-entropy alloys systems. Jom, 65, 1848-1858.

Tursunbaev, S., Turakhodjaev, N., Odilov, F.,

Mardanokulov, S., & Zokirov, R. (2023)a. Change in

wear resistance of alloy when alloying aluminium alloy

with germanium oxide. E3S Web of

Conferences,401.https://doi.org/10.1051/e3sconf/2023

40105001

Tursunbayev, S., Turakhodjayev, N., Mardanokulov, S.,

Zokirov, R., & Odilov, F. (2023)b. The effect of lithium

on the mechanical properties of alloys in the Al-Li

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

384