Analysis of Technologies for Improving Steel Purity by Controlling

Slag Content

Nosir Saidmakhamadov

1a

, Nozimjon Kholmirzaev

2b

, Valida Bekchanova

1c

, Furkat Odilov

3d

,

Ibrokhimjon Tukhtaboev

1e

, Bokhodir Karimov

1f

and Murodilla Gaybullaev

1g

1

Namangan Engineering-Construction Institute, Technology of Machine Building Department,

160100, Namangan, Uzbekistan

2

Tashkent State Technical University, Foundry Technologies Department 100057, Tashkent, Uzbekistan

3

Andijan Institute of Economics and Construction, Civil Engineering Department 170100, Andijan, Uzbekistan

Keywords: Steel Purity, Slag Control, Casting Quality.

Abstract: This article analyzes the composition and reactions of slag formed during steel melting, as well as the

influence of liquid slag on the quality of cast products. The importance of using slag-forming fluxes and

accelerating the oxidation process of elements in the process of melting the alloy is mentioned. By adding

flux to the liquid metal, the slag was completely separated from the liquid metal by accelerating the formation

process. In addition, the quality of cast products was improved by separating them from the liquid metal, since

the addition of slag during the process of pouring liquid metal into the ladle and casting mold affects the

quality of the casting.

1 INTRODUCTION

Improving the quality of steel requires the reduction

of harmful elements, mirrors and gas pores in its

composition, as well as the prevention of liquid metal

fluidity and the formation of cracks, as well as

obtaining high-quality cast products. Improved

quality of bulk products ensures long – term use.

Generally, the steels used in most products have a

high Cr – C system content, and the steel grades

produced by the researchers are no exception, can be

seen in the table 1. Factors affecting the service life

of steel are: non-metallic inclusions, segregation, etc.

Among these factors, the effect of non-metallic

additives on steels has been studied using various

methods (Saidmakhamadov, 2024; Patrik, 1997;

Kholmirzaev et al., 2023; Nodir et al., 2021). In these

studies, non-metallic inclusions play the role of

a

https://orcid.org/0000-0002-7460-5972

b

https://orcid.org/0009-0008-9662-4796

c

https://orcid.org/0009-0003-2903-3914

d

https://orcid.org/0009-0001-0727-6451

e

https://orcid.org/0000-0002-1779-9435

f

https://orcid.org/0000-0003-1615-2757

g

https://orcid.org/0000-0008-2274-2571

fatigue concentration points and finally lead to the

initiation and growth of fatigue cracks

(Saidmakhamadov, 2024). Non – metallic inclusions

such as Al

2

O

3

, SiO

2

, TiO

2

, etc. can cause the casting

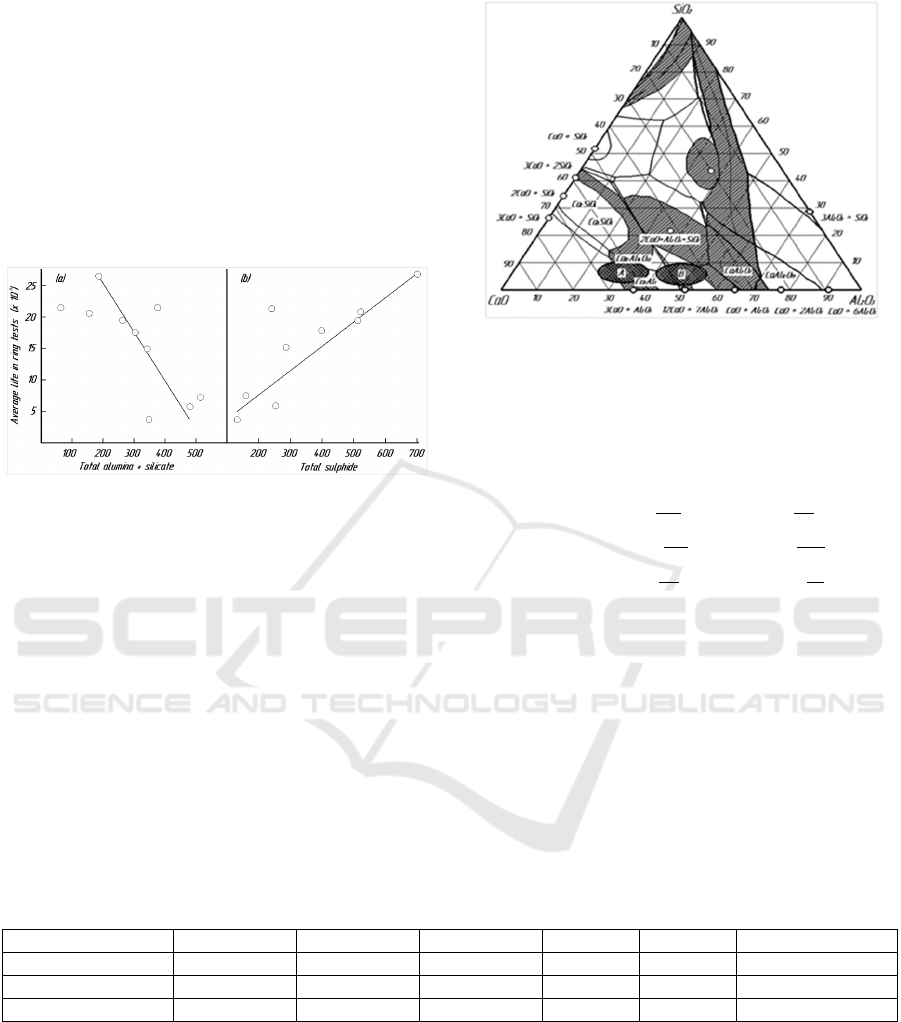

to crack. As shown in Fig. 1 – a, Al

2

O

3

and SiO

2

additions in steel reduced the service life of the

bearing steel. At the same time, the sulfide present in

the form of MnS as inclusions reduced the strength of

the casting due to the inclusions and therefore

negatively affected the working time of the part (see

Fig. 1. b). However, taking into account the general

harmful effects of sulfur, its presence in steel should

be limited to an appropriate range (Nosir & Bokhodir,

2023; Kholmirzaev et al., 2024a).

Saidmakhamadov, N., Kholmirzaev, N., Bekchanova, V., Odilov, F., Tukhtaboev, I., Karimov, B. and Gaybullaev, M.

Analysis of Technologies for Improving Steel Purity by Controlling Slag Content.

DOI: 10.5220/0014268600004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 333-337

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

333

2 MATERIALS AND METHODS

Thefore, it is necessary to control the slag content to

remove Al

2

O

3

inclusions from steel. The adsorption

capacity of slag for Al

2

O

3

can be improved by

reducing the activity of Al

2

O

3

or the melting

temperature of the slag, which contributed to the mass

transport of Al

2

O

3

(Kholmirzaev, 2023; Nodir v et al.,

2022; Tursunbaev et al., 2023; Tursunbaev et al.,

2024; Kholmirzaev et al., 2024b).

Figure 1: Correlation between mean lifetime and inclusion

content: calculations based on total inclusions (x 750)

observed in 516 fields with a total area of ~9 mm

2

.

The slag composition range satisfying these

conditions should be close to the Al2O3 – CaO binary

system. The composition of the slag used with steel

must also take into account the re – oxidation of the

steel being liquefied by the SiO2 in the slag. If the

former is considered more important, the relevant

composition range should be close to the saturation

region of CaO, marked as region A in Fig. 2.

However, if the latter is considered more important,

the composition should be located in region B. The

chemical composition of the tested steels as a sample

is presented in Table 1.

Figure 2: Control of slag content of steel.

Reoxidation of molten steel with low oxide in slag

As shown in the following equations, low-grade

oxides such as FeO and MnO in the slag reacted with

the oxide former in the molten steel to form non-

metallic inclusions.

3(FeO) + 2Al = (Al

2

O

3

) + 3Fe 1 a

3(MnO) + 2Al = (Al

2

O

3

) + 3Mn 1 b

3(SiO

2

) + 4Al = 2 (Al

2

O

3

) + 3Si 1 c

From the equations (1 a) and (1 b), when the

amount of FeO and MnO in the slag is high, non –

metallic inclusions are formed, so it is very important

to reduce the content of FeO and MnO in the slag.

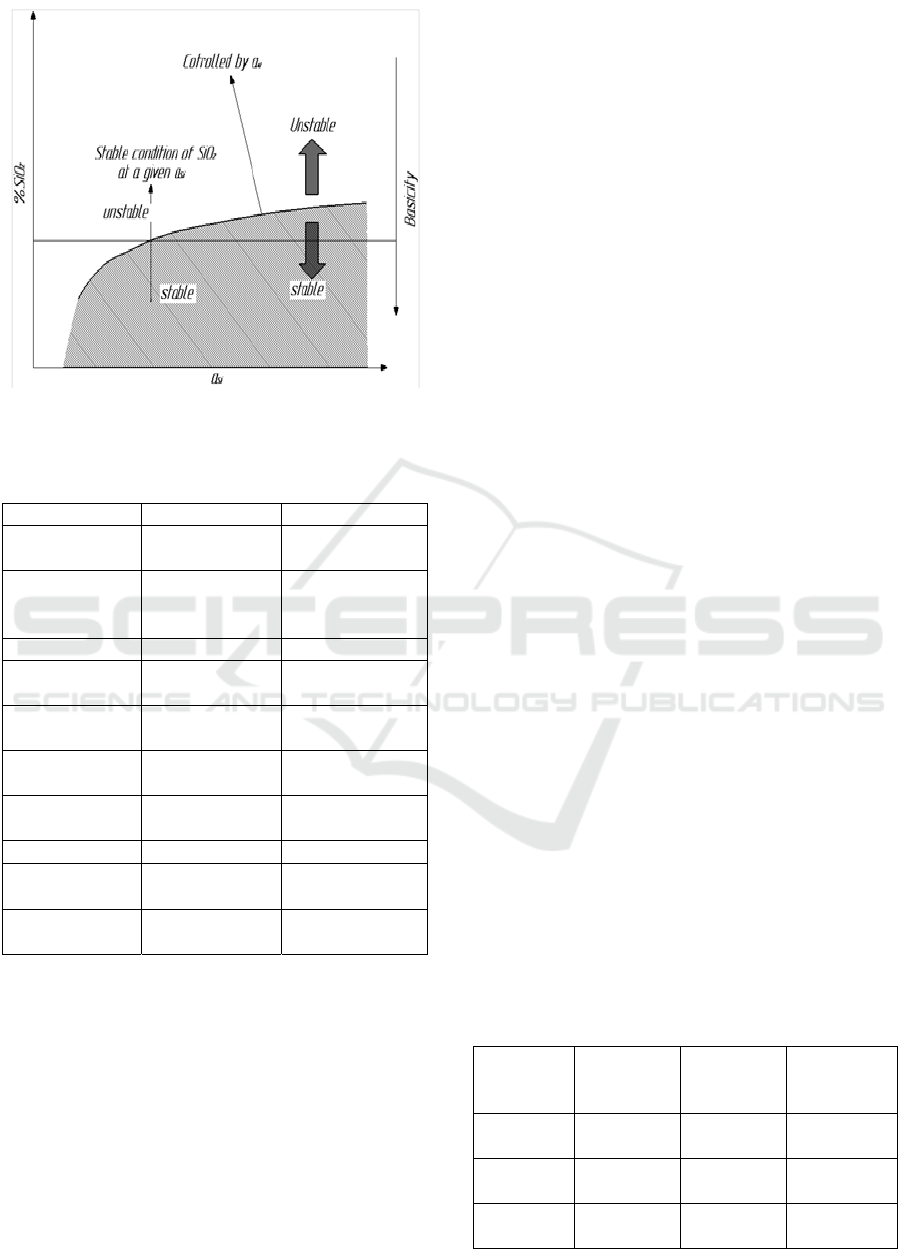

However, as shown in Figure 3, the reoxidation

behavior of SiO

2

is different from that of FeO and

MnO because Si is a stronger oxidizing element than

Fe and Mn. Consequently, if the basicity of the

molten slag is controlled to some extent, reoxidation

of the molten steel by SiO

2

in the slag does not occur

and can therefore be prevented by controlling the slag

composition.

Table 1: Chemical composition of steel, weight – %.

Standard/grade C Si Mn P S Cr

J/SUJ1 0·95-1·10 0·15-0·35 <0·50 <0·025 <0·025 0·90-1·20

I/SUJ2 0·95-1·10 0·15-0·35 <0·50 <0·025 <0·025 1·30-1·60

S/SUJ3 0·95-1·10 0·40-0·70 0·90-1·15 <0·025 <0·025 0·90-1·20

Effect of oxygen content at end of blow in BOF

on steel cleanliness. Since blowing in BOF (basic

oxygen furnace) reduces the amount of oxygen in the

molten steel from the formation of non – metallic

inclusions, it affects the purity of the steel and should

therefore be taken into account. Table 2 shows the

production process of bearing steel in an electric arc

furnace. The process consists of BOF – ladle furnace

-RH degassing – continuous casting, and the

operation schemes of the technological units greatly

affected the purity of the bearing steel. In this study,

the following three tests were conducted to remove

non – metallic inclusions from molten steel: changing

the deoxidation method, controlling the slag

composition, and using the oxygen content

efficiently.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

334

Figure 3:

Effect of slag base on SiO

2

and total oxygen

content of steel.

Table 2: Comparison of traditional and improved methods.

Process Traditional Improved

Chemical

process

Oxidation

Oxidizing

order: FeSi,

FeMn, Al

Oxidizing order:

Al, FeMn, FeSi

Slag formation

Electric arc

furnace

Temperature

control

Heating the

furnace

Heating the

furnace

Slag formation

Addition of

CaO, CaF

2

Addition of

CaO, Al

2

O

3

Remove

attachments

Degassing Usage: 25 min Usage: 25 min

Remove

attachments

Continuous

pouring

Cast formation Cast formation

Change of CaO/Al

2

O

3

value. Al

2

O

3

absorption

capacity of slag changed depending on its

composition. If the slag composition is saturated with

CaO, the activity of Al

2

O

3

additions decreases, and

thus improved thermodynamic conditions have

appeared. However, additives may be less effective

due to higher melting temperatures. When the slag

composition is at a low melting temperature, the

absorption capacity is increased, but the

thermodynamic equilibrium condition is worsened.

In the traditional method, the slag composition

was in the CaO saturation region, but the improved

method changed the composition to the low melting

temperature region, as shown in Table 3. In the

traditional method, before heating the arc in a slag

furnace, CaO and a small amount of CaF

2

are added

to accelerate the slag formation process. However,

despite the addition of CaF

2

, the slag was not

completely melted and most of the slag solidified

after arc heating. In this study, in order to solve this

problem, the following ratio was controlled between

1 · 7 and 1 · 8 by slightly increasing the addition of

%CaO/%Al

2

O

3

and decreasing the addition of CaO.

Change the oxidation method. In the traditional

method, FeSi, FeMn and Al were added sequentially

during the charge loading (see Table 2). In this case,

the oxides are 3(MnO) + 2Al = (The oxides formed

during the oxidation of Al were SiO

2

and MnO, but

when Al was added, the oxides changed to Al

2

O

3

due

to the closeness of Al to oxygen. However, the

composition of the oxides did not reach the state of

thermodynamic equilibrium.

Therefore, the composition of SiO

2

and MnO

higher than the thermodynamic equilibrium state and

the slag alkalinity was low and the slag oxidation

level was high. Al, then FeMn and FeSi were added

in the new method to improve the basis and degree of

oxidation. By reversing the addition order, Al

2

O

3

oxides are formed first and then only a small fraction

of the oxide composition should be Al

2

O

3

. As a result,

the basicity is higher and the oxidation level of the

slag is lower than in the traditional method.

A decrease in the amount of oxygen during

infusion. Reducing the amount of oxygen in the liquid

metal during casting to improve steel purity has

reduced gas voids in the casting. Because it can be the

main source of additives. However, when the amount

of oxygen decreased, the dephosphorylation process

was disrupted.

Therefore, liquid metal dephosphorization was

required. In this study, liquid metal

dephosphorization was performed in a liquid metal

pretreatment station, before the BOF (basic oxygen

furnace) operation, to reduce the oxygen content

during casting.

Table 3: Temperature change.

Softening

temperatur

e

Melting

temperatur

e

Liquefactio

n

temperature

Traditiona

l

0

C

1468 1505 >1510

Improved

0

C

1347 1349 1368

Difference

, K

121 156 ~142

Analysis of Technologies for Improving Steel Purity by Controlling Slag Content

335

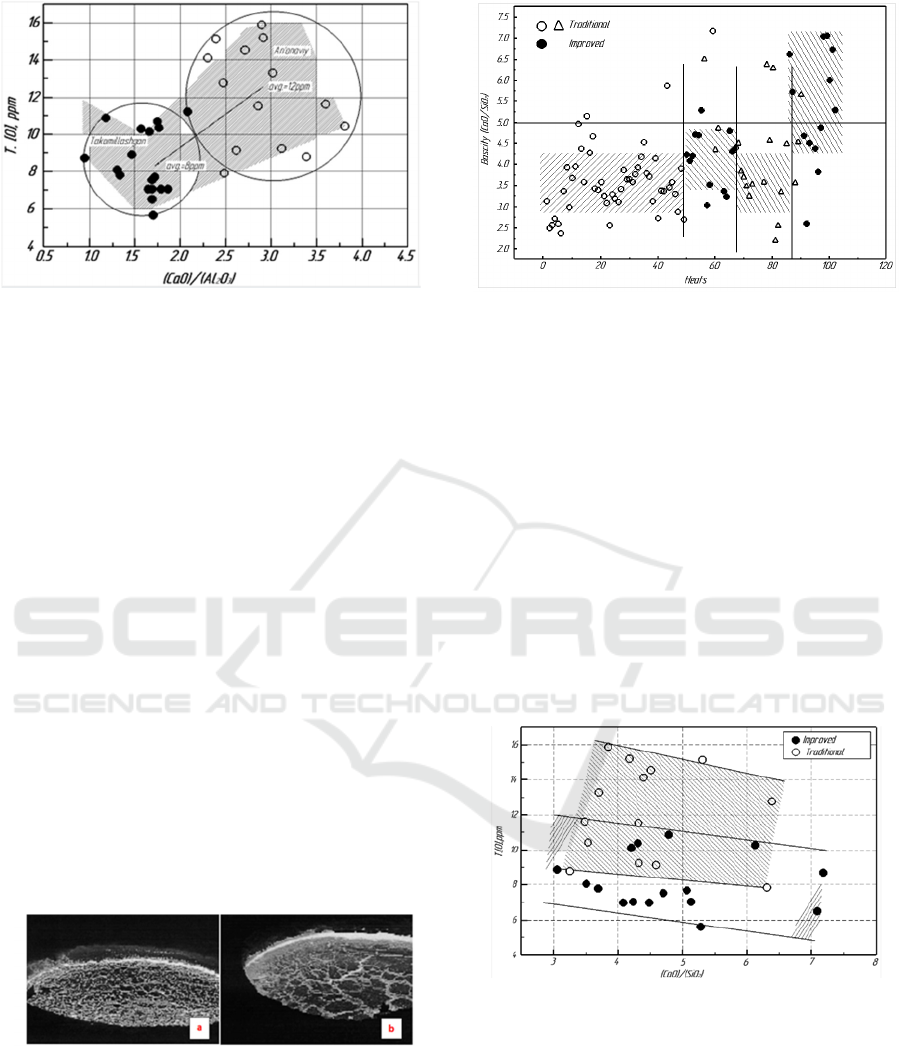

Figure 4: Comparison of total oxygen T.[O] between

improved and conventional methods of liquefaction.

3 RESULTS AND DISCUSSION

Effect of %CaO/%Al

2

O

3

ratio on casting quality. The

change in slag composition after RH degassing is

shown in Figure 4. The %CaO/%Al

2

O

3

(C/A) value

in the conventional method was 2 · 0 to 4 · 4, but the

C/A ratio was 1 · 2 to 2 · 0 in the improved method.

Total oxygen value was minimum at C/A=1 · 7

regardless of T. [O] method. Therefore, in steels, a

C/A ratio of 1 · 7 gave the best results for improving

steel purity. This is because lowering the slag melting

temperature is more effective than controlling the slag

composition to reach the CaO saturated region.

Figure 15 shows a comparison of slag formation

between conventional and improved methods after

arc heating in an electric arc furnace. As shown in this

picture, in the traditional method, most of the slag is

solidified, but in the improved method, the molten

slag is spread uniformly over the top of the furnace.

During operation (cycling and storage) LIA the

most significant changes occur on electrodes made of

lithium-manganese spinals.

Figure 5: Comparison of slag condition after treatment in

an electric arc furnace. a) solid slag, traditional method; b)

liquid slag, improved method.

Therefore, it can be confirmed that the melting

temperature of the slag has decreased and as a result,

the absorption capacity of the inclusion has increased

with the improved method.

Figure 6: Modifying slag basicity by improving reoxidation

method and slag control.

Total oxygen T.O can be reduced from 12 to 8

ppm using the improved method over the

conventional method (see Figure 4).

Changing the composition of slag with a new

reoxidation method. The slag composition of

traditional and improved methods can be compared in

Figure 6. In the conventional reoxidation process, the

slag basicity was in the range of 3 ·5 – 4 · 5 due to

oxidation of Si and Mn, but in the improved method,

the basicity was 4 · 5 – 7 · 0 because Al was oxidized

before Si and Mn. Figure 7 shows the relationship

between slag basicity and T.[O] for solidification.

Although T.[O] decreased slightly after increasing

basicity, slag basicity had little effect on T.[O]

compared to other factors such as C/A ratio.

Figure 7: Rectangle.

To investigate these processes, the SiO

2

stability

zone was calculated using the bearing steel

composition with the following equations.

3(SiO

2

) + 4Al=2(Al

2

O

3

) + 3Si (2 a)

lo

g

K=

–

6 · 947 + 47645/T (2 b)

Calculation – the composition of the steel used in

the books is 0 · 99C – 0 · 3Mn – 1 · 3Cr (wt – %) and

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

336

the activity coefficient was calculated from these

values: the results are shown in figure 1.7. The

soluble Al and Si content of steel, i.e. 0 ·02 – 0 · 03

wt – % and 0 · 20 wt – %, respectively, fall into the

rectangle shown in Fig. 7. In this area, if the basicity

is greater than 4, SiO

2

does not act as an oxygen

source. Therefore, basicity does not affect the purity

of steel.

4 CONCLUSIONS

1. When removing inclusions from bearing steel

containing (wt. – %) 0 · 99C – 0 · 3Mn – 1 · 3Cr

with a slag basicity higher than 4, steel purity is

not affected because SiO

2

is stable and oxygen

does not act as a source.

2. Controlling the %CaO/%Al

2

O

3

ratio is the most

effective method for removing inclusions from

bearing steels, and its value was most effective at

1 · 7 – 1 · 8. Using this method, total oxygen

T.[O] can be reduced from 10 – 12 ppm to 5 – 8

ppm.

3. T.[O] of the bearing steel is reduced due to the

reduction of oxygen content due to the moving

contact of the liquid metal during casting.

However, when %CaO/%Al

2

O

3

> 2 · 0, the

amount of oxygen at impact does not have a

significant effect because the equilibrium T.[O]

is too high to reach equilibrium during

steelmaking.

REFERENCES

Kholmirzaev, N. , Turakhodjaev, N., Saidmakhamadov, N.,

Khasanov, J., Bektemirov, A., 2024a. Effects of

titanium (Ti) contents on the wear resistance of low-

alloy steel alloys. E3S Web of Conferences, EDP

Sciences, 525, 03003.

Kholmirzaev, N., Khasanov, J., Abdullayev, B.,

Saidkhodjaeva, S., Bektemirov, A., Sadikova, N., ... &

Nurdinov, Z., 2024b. Improving the technology of

obtaining highquality castings from steel in sand-clay

molds. E3S Web of Conferences, 525, 03012.

Kholmirzaev, N., Turakhodjaev, N., Saidmakhamadov, N.,

Khasanov, J., Saidkhodjaeva, S., & Sadikova, N., 2023.

Development of Technology of Making Shafts from

Steel Alloy 35XGCL. Lecture Notes in Networks and

Systems, 762. https://doi.org/10.1007/978-3-031-

40628-7_18.

Nodir, T., Nosir, S., Shokhista, S., Furkat, O., Nozimjon,

K., & Valida, B., 2021. Development of 280x29nl alloy

liquefaction technology to increase the hardness and

corrosion resistance of cast products. International

Journal of Mechatronics and Applied Mechanics,

1(10), 154–159.

https://doi.org/10.17683/IJOMAM/ISSUE10/V1.19

Nodir, T., Sarvar, T., Kamaldjan, K., Shirinkhon, T.,

Shavkat, A., Mukhammadali, A., 2022. International

Journal of Mechatronics and Applied Mechanics, (11),

52–56. https://doi.org/10.17683/ijomam/issue11.7

Nosir, S., & Bokhodir, K., 2023. Development of

Liquefaction Technology 280X29NL to Increase the

Strength and Brittleness of Castings. Lecture Notes in

Networks and Systems, 534.

https://doi.org/10.1007/978-3-031-15944-2_10.

Patrik, O.L.J., 1997. Hungarian Mining and Metallurgical

Society/The Institute of Materials, 2, 137.

Saidmakhamadov, N., Turahodjaev, N., Tursunbaev, S.,

Zokirov, R., Tadjiev, N., Abdullaev, K., Hamroev, V.,

Rakhmanov, U., Juraev, J., 2024. Improving the design

of the lining of the ball mill used to improve the quality

of grinding. E3S Web of Conferences, 525, 02017.

Tursunbaev, S., Turakhodjaev, N., Mardonakulov, S., &

Toshmatova, S., 2024. Effect of germanium oxide on

the properties of aluminum casting details in

agricultural machinery. BIO Web of Conferences, 85.

https://doi.org/10.1051/bioconf/20248501024.

Tursunbaev, S., Turakhodjaev, N., Odilov, F.,

Mardanokulov, S., & Zokirov, R., 2023. Change in

wear resistance of alloy when alloying aluminium alloy

with germanium oxide. E3S Web of Conferences, 401.

https://doi.org/10.1051/e3sconf/202340105001.

Analysis of Technologies for Improving Steel Purity by Controlling Slag Content

337