Analysis of the Maintenance System for Keys Combines in

Uzbekistan

Gulchehra Juraeva

a

, Nargiza Maxmudova

b

, Malika Saidova

c

and Gulnoz Abdikayimova

d

Tashkent State Technical University, 100095, University str. 2, Tashkent, Uzbekistan

Keywords: Combine Harvesters, Maintenance System, Uzbekistan.

Abstract: In the article, even today in Uzbekistan, the use of economical and modern new types of combine harvesters

for harvesting grain is recommended to the grain farmers of the Republic, by improving the quality of the

grain, using the harvesting technique in harvesting grain with high efficiency, to harvest it at a short

opportunity without loss, and to harvest the grown crop with high quality, and the effective use of, the

dependence on compliance with the harvesting procedure and timely maintenance and repair of combine

harvesters is described as the uniformity of all working parts of the highly productive and modern combines

"Keys-2166" and "Keys-2366", which are used for harvesting grain

1 INTRODUCTION

Today, even in Uzbekistan, economical and modern

new types of combine harvesters are used for

harvesting grain. "Keys" ' combine, "Keys-2166" and

"Keys-2366", were also included in such combine

harvesters, now numbering 1,730 units.

And before the grain of our republic, the task is to

improve the quality of the grain, to harvest it at a short

opportunity without loss by using the harvesting

technique with high efficiency.

Figure 1: Keys - 2366 grain combine working process.

a

https://orcid.org/0009-0009-8710-3769

b

https://orcid.org/0000-0001-6552-2510

c

https://orcid.org/0009-0003-1625-2616

d

https://orcid.org/0000-0003-3739-8430

Figure 2: The main working parts of the "Keys" grain

mowing combine: 1st -jacket; 2nd- reverse transporter; 3rd-

grain bunker; 4th -schnecks; 5th- grain cleaning part; 6th -

axial rotor milling-separation device.

Harvesting the grown crop with high quality and

the effective use of grain combines depends on the

preparation of fields for harvesting, the correct

adjustment of the working organs of combines,

compliance with the harvesting procedure and timely

maintenance and repair of combines (Babusenko,

1990).

316

Juraeva, G., Maxmudova, N., Saidova, M. and Abdikayimova, G.

Analysis of the Maintenance System for Keys Combines in Uzbekistan.

DOI: 10.5220/0014263800004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 316-320

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

All the working parts of the high-performance and

modern combines "Keys-2166" and "Keys-2366",

which are used in Uzbekistan to mow and harvest

grain, are the same, except that the rear axle of the

"Keys-2366" combine harvester is strengthened

(Kompleksnaya, 1985). The actual appearance of

these combines is in Figure 1, the constructive

structure is in Figure 2, and the technical description

is given in the table below.

2 MATERIALS AND METHODS

The main working parts of the" Keys " combine are

the jatka and the oblique transporter, the grain bunker

and the schnecks, the grain cleaning part, the axial

rotor mowing-separation device with high

permeability (Ekonomicheskaya, 2005).

The type of mowing apparatus of the Keys-2166

and Keys-2366 combines is rotor with a diameter of

610 mm, the range of their number of rotations is 530-

1260 min-1, the coverage angle of the deck is 360°.

In this combine, no somonelizer is placed on it, since

the work of milling the grain and separating the

ground grain is carried out with 1 working organ, that

is, a rotor. The grain cleaning part is air-granular and

is made up of upper and lower granules (Severny,

2001), (Spravochnik, 2003). Their total surface area

is 3.82 m2. The volume of the combine grain bunker

is 5100 l.

Accordingly, a 6-cylinder engine with

turbonadduv was installed in the combine, the power

of which is equal to 230 horsepower. A single refill

will take up to 350 litres of fuel to the fuel tank.

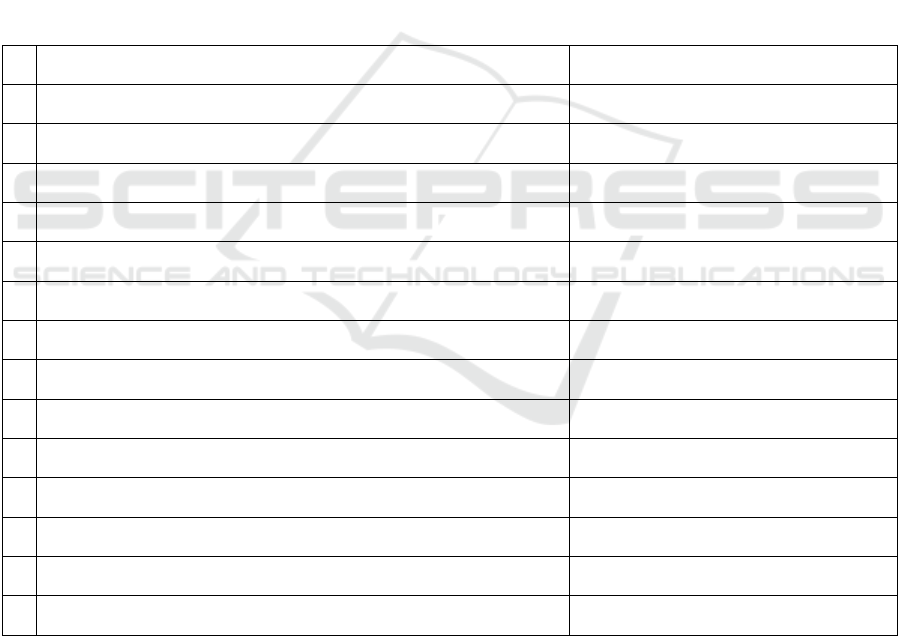

Table 1:Technical description of grain combines “Keys".

№

Specification name Keys--2166, 2366

1. Jatka range and coverage width 1010 (4,57-7,62 m)

2. Type of mllng machne rotor

3. Milling machine length or width, mm 2790

4. Mllng drum dameter, mm 610

5. Yanchish drum number of turns, ayl / min 530-1260

6. Deka's coverage angle, grade 360

7. Gran cleaner type Cleaning system

8. Gran cleanng surface, m

2

3,82

9. Don bunker sze, l 5110

10. Engne type 6- cylinder, turbonadovli

11. At full capacity, kW (o.k.) 171 (230)

12. Useful capacty, kW 160 (215)

13. Fuel tank capacty, l 350

14. Constructive mass, kg 9880

Repair and maintenance service systems available

in foreign and their analysis.

In foreign countries with progressive agricultural

production, the firm service of high-power tractors

has become an independent network of their economy

(Otchet, 2011).

The organizational structure of the FTs in

agriculture of foreign countries consists of General

agencies and dealers (internal and external), which

are firms-manufacturers and their sellers (Figure 3).

The results of experiments accumulated over

many years in foreign countries show that the rational

form of Organization of FTS is a dealer system

Analysis of the Maintenance System for Keys Combines in Uzbekistan

317

(Boyarshinov, 2013). In states such as the United

States, England, Germany, the Netherlands, the FTS

system consists mainly of three zvenos: a machine

company or firm, dealers and farms, that is, FTS

consumers [Figure 4].

Figure 3: Organizational structure of the FTS system, which

is practiced in agriculture of foreign countries. Around 7-9

thousand dealerships operate in the US.

The functions of dealer enterprises can be

conditionally divided into two groups. The first is the

sale of new equipment, devices and spare parts to

farmers and the implementation of marketing,

information and consulting and advertising related to

these activities. These account for 70-85% of the

activities of dealer enterprises (Makhkamov and

Irgashev, 2014).

The second function of dealer Enterprises is to

perform their technical service during the warranty

periods of the machines, repair the defective

machines in the farm field itself or in the workshop,

and inform machine firms about the types,

frequencies and causes of failures occurring in the

equipment. Such a technical service function will

consist of 20-25% of the total activity of the dealer

(Makhkamov and Irgashev, 2014).

3 RESULTS AND DISCUSSION

The repair and service facilities of a typical dealer

enterprise(shop)consist of an open area where new

equipment is put on display, a repair workshop,

service cars, a spare parts warehouse, a tool storage

room, car washing, Assembly and painting plots, an

office and a hall for customers. The dealership

employs around 10-20 highly qualified professionals,

depending on its size and size.

Figure 4: Organizational structure of the dealer system,

which is practiced in agriculture of foreign countries.

The customer pays the dealer based on the time of

work spent by him. The time spent (Go and come) by

the dealer's shop mechanic on the road is included in

the paid working time. Dealers of major agricultural

machinery companies in the United States serve 300-

500 regular customers(farmers)based at 50 km radi-

us.

The firms "Jon-dir" and "Interneyshnl" establish

small dealer enterprises with a service radius of 40-50

km. And the dealers of the firm" Caterpillar " serve

farmers at large radii. In this case, each dealer opens 3

- 8 small sections in the area in which he / she is

operating.

There are more than 200 agricultural machinery

enterprises in Russia, but some of them (Rostov

agricultural machinery plant, Krasnoyarsk tractor

plant, Volgograd tractor plant) have already

established their own dealerships in the regions, no

less.

To perform FTs on tractors of the Minsk Tractor

Plant (Republic of Belarus), a dealer Center

"Belorusyugservis" was opened in the Rostov region.

"MTZ" will provide the center with 25-30 percent

cheaper than its initial prices for its tractors during the

inter-season period. The center also makes a 2-10

percent discount on prices, depending on the size of

the tractors that dealers are buying.

According to the calculations of the specialists of"

Belarusyugservis", the establishment of firm

dealerships ensures that the maintenance of" MTZ "

tractors saves up to 25 percent of the costs spent by the

owners.

FRS system in force in

agriculture of foreign

countries

Chief agencies of

their firms

Dealers

Machinery firms

Dealer

system

practiced in

agriculture

by foreign

countries

Machinery

company

or firm

Independent

dealers

farms

Dependenc

y

Machinery

company or

firm

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

318

The Production Association "Agrotextractor" in

Ukraine has organized the work of providing firm

services to T-150k tractors in use in Russia. The

"Gomel agricultural machinery plant" of the Republic

of Belarus has established dealerships in the territories

of the Czech Republic, Hungary, Bulgaria and other

countries in Europe.

The Vilnius fuel apparatus plant has established its

own products in a number of districts of the state of

Lithuania, namely tsexs that overhaul fuel apparatus.

In Uzbekistan, the system of technical service for

agriculture (TS) has been formed to some extent. TS

consumers and performers are key elements of this

system. They operate within the framework of a

republic, a province and a district, that is, a three-level

system.

The provisions of the agreement on long-term

cooperation signed in 1996 between the government

of Uzbekistan and the company "Keys Corporeyshn"

defined the program of Joint Action Strategy in the

field of FTS. The tasks of the firm maintenance of

grain combines brought from the company" Keys

"were assigned to the joint venture" Özkeysservis".

The uzkeysservis enterprise was established on

September 4, 1997, based on the decision of the

Cabinet of Ministers of the Republic of Uzbekistan.

The functioning structure of"özkeysservis" consists of

its service department and Training Center, Service

Center, spare parts department and Central Warehouse

and 13 service centers in the Republic of

Karakalpakstan and regions (Figure 6).

Each of the service centers in the Republic of

Karakalpakstan and regions has a warehouse of

service cars, spare parts and repair materials, equipped

with high-precision equipment and stands, as well as

an office with modern equipment and communication

facilities. But do not have enough repair and service

points and the equipment necessary for them.

As a result, the failed complex nodes and

aggregates of the Keys combine are removed by the

mechanics of the service center and brought to the

Regional Center. Faulty nodes and aggregates

collected in the regional service center are brought to

the service center in the head office "Özkeysservis" for

correction.

The center's repair and spare parts specialists

repair and sort nodes and aggregates by type, and then

send them to the appropriate specialized tsexes.

Nodes and aggregates in a state of repair are

brought to the main service center and sent to their

customers, that is, to the regional service centers

where they were sent. This will take a lot of time and

will not allow you to start the combines by fixing them

in time.

In Uzbekistan, the system of technical service for

agriculture (TS) has been formed to some extent. TS

consumers and performers are key elements of this

system. They operate within the framework of a

republic, a province and a district, that is, a three-level

system.

The provisions of the agreement on long-term

cooperation signed in 1996 between the government

of Uzbekistan and the company "Keys Corporeyshn"

defined the program of Joint Action Strategy in the

field of FTS. The tasks of the firm maintenance of

grain combines brought from the company" Keys

"were assigned to the joint venture"

Özkeysservis".The uzkeysservis enterprise was

established on September 4, 1997, based on the

decision of the Cabinet of Ministers of the Republic of

Uzbekistan. The functioning structure

of"özkeysservis" consists of its service department

and Training Center, Service Center, spare parts

department and Central Warehouse and 13 service

centers in the Republic of Karakalpakstan and regions.

Each of the service centers in the Republic of

Karakalpakstan and regions has a warehouse of

service cars, spare parts and repair materials, equipped

with high-precision equipment and stands, as well as

an office with modern equipment and communication

facilities. But do not have enough repair and service

points and the equipment necessary for them.

4 CONCLUSIONS

As a result, the failed complex nodes and aggregates

of the Keys combine are removed by the mechanics

of the service center and brought to the Regional

Center. Faulty nodes and aggregates collected in the

regional service center are brought to the service

center in the head office "Özkeysservis" for

correction.

The center's repair and spare parts specialists

repair and sort nodes and aggregates by type, and then

send them to the appropriate specialized tsexes.

Nodes and aggregates in a state of repair are

brought to the main service center and sent to their

customers, that is, to the regional service centers

where they were sent. This will take a lot of time and

will not allow you to start the combines by fixing

them in time.

Repairs in the combines are not planned. The

reason is which part of the combined fails during the

harvest period is perceived as a random phenomenon,

and it is painted in the theory of probability.

Analysis of the Maintenance System for Keys Combines in Uzbekistan

319

REFERENCES

Babusenko sm. Proektirovanie remontno-obslujivayutshix

predpriyatiy. - 2-e izd., pererab. I dop. - M.:

Agropromizdat, 1990.-352s: year.

Kompleksnaya sistema technicheskogo obslujivania i

remonta mashin v selskom hozyaystve. Ch. 1. M.:

GOSNITI, 1985. - 144s

Severny A.E., Colchin A.V., Burenko L.A., 2001.

Obespechenie bezopasnosti pri technicheskom servise

selsko xazyeystvennay technical. - M.: FGNU

"Rosinformagropromtex".

Spravochnik injenera po technicheskomu servisu mashin I

oborudovania V APK. - M.: FGNU

"Rosinformagrotex", 2003. - 604s.

Ekonomicheskaya Otsenka proekta masterskoy, tsexa, plot,

preventoria, autogaraja selskoxozyaystvennogo

predpriyatia. Metodicheskie ukazaniya po

obosnovaniyu diplomnogo proekta. - Uchebnoe

posobie dlya selskokhozyaystvennix vuzov, - M.: UMS

"triad", 2005. - 25s.

Otchet o nauchno-issledovatelskoy rabote: ekstrennaya

diagnostic technicheskogo sostoyaniya detaley

aggregatov silovix peredach mashin i mashinov bex IX

razborki v period exploitasii. Tashkent 2011. Tashgtu.

-131 P.

Boyarshinov A.L. Nadezhnost I technicheskaya diagnostic

avtotraktornix sredstv.-M.: Forum: Infra-M.2013-243

P.

Makhkamov K.X, Irgashev A. etc. Tractor structures.

Episode 1. - Tashkent.: National Encyclopedia of

Uzbekistan.- 2014.

Makhkamov, K.X, Irgashev, A. etc., 2014. Tractor

constructs. Episode 2. - Tashkent.: National

Encyclopedia of Uzbekistan.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

320