The Use of Lithium-Ion Batteries as the Most Promising Traction

Current Sources

Lazizbek Daminov

1a

, Avaz Yangiboev

1b

, Rustamjon Mirzajonov

1c

and Yashnarbek Sharipov

2d

1

Tashkent State Technical University, 100095, University str. 2, Tashkent, Uzbekistan

2

Shakhrisabz Branch of the Tashkent Institute of Chemical Technology, 181306, Shahrisabz str. 20, Shahrisabz, Uzbekistan

Keywords: Lithium-Ion Batteries, Traction Current, Energy Efficiency.

Abstract: The article describes the advantages and disadvantages of using lithium-ion batteries as the most promising

traction current sources. The greatest number of cycles is typical for lithium titan ate batteries. This is

primarily due to the use of heavy metal as an anode material. This structure provides a long service life, high

charge-discharge currents, as well as a wide range of operating temperatures. The main disadvantage of this

type of battery is its low specific energy intensity compared to other materials. This is primarily due to the

low battery voltage level. The use of modified lithium nano-titanate makes it possible to increase the specific

energy intensity by 2 times, but this improvement significantly increases the cost of batteries.

1 INTRODUCTION

In most modern Li-Ion batteries, the negative

electrode is made of carbon materials. In such

batteries, not lithium metal or its alloys with other

metals are used as a negative electrode, but an

intercalation compound of carbon with lithium.

Carbon turned out to be a very convenient matrix for

intercalation (introduction) of lithium. The specific

volume of many carbons graphitized materials

changes by no more than 10% when a sufficiently

large amount of lithium is introduced. Carbon

electrodes containing not too much intercalated

lithium have a potential 0.5–0.8V higher than the

potential of the lithium electrode (Daminov et al.,

2022a). In order for the battery voltage to be high

enough, lithium cobalt oxides (lithium-cobalt),

manganese spinel, lithium iron phosphate, and so–

called multi-oxides (mixed oxides) were used as the

active material of the positive electrode. The potential

is approximately 4 V relative to the lithium electrode,

so that the operating voltage of the battery has a

characteristic value of 3.5−3.8 V. When the battery is

discharged, lithium is deintercalated from carbon

material (on the negative electrode) and lithium is

a

https://orcid.org/0000-0003-2179-9176

b

https://orcid.org/0000-0007-3750-0597

c

https://orcid.org/0000-0000-2838-9028

d

https://orcid.org/0000-0008-5289-8921

intercalated into oxide (on the positive electrode).

When charging, the processes go in the opposite

direction. Thus, there is no metallic lithium in the

entire system, and the discharge and charge processes

are reduced to the transfer of lithium ions from one

electrode to another. That is why the authors of such

a battery introduced the term ― lithium-ion battery.

At the same time, the name "rocking chair type

battery" (rocking chair cell) (Wei et al., 2024) or

"swing" batteries became stronger for this type of

batteries.

In the vast majority of lithium-ion batteries

brought to the stage of commercialization, the

negative electrode is made of carbon materials.

2 MATERIALS AND METHODS

The current-forming process on a negative electrode

is described by the equation 6C + xLi+ + xe- ↔

LixC6. The forward process corresponds to the

charge, and the reverse process corresponds to the

discharge of the battery.

310

Daminov, L., Yangiboev, A., Mirzajonov, R. and Sharipov, Y.

The Use of Lithium-Ion Batteries as the Most Promising Traction Current Sources.

DOI: 10.5220/0014263400004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 310-315

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

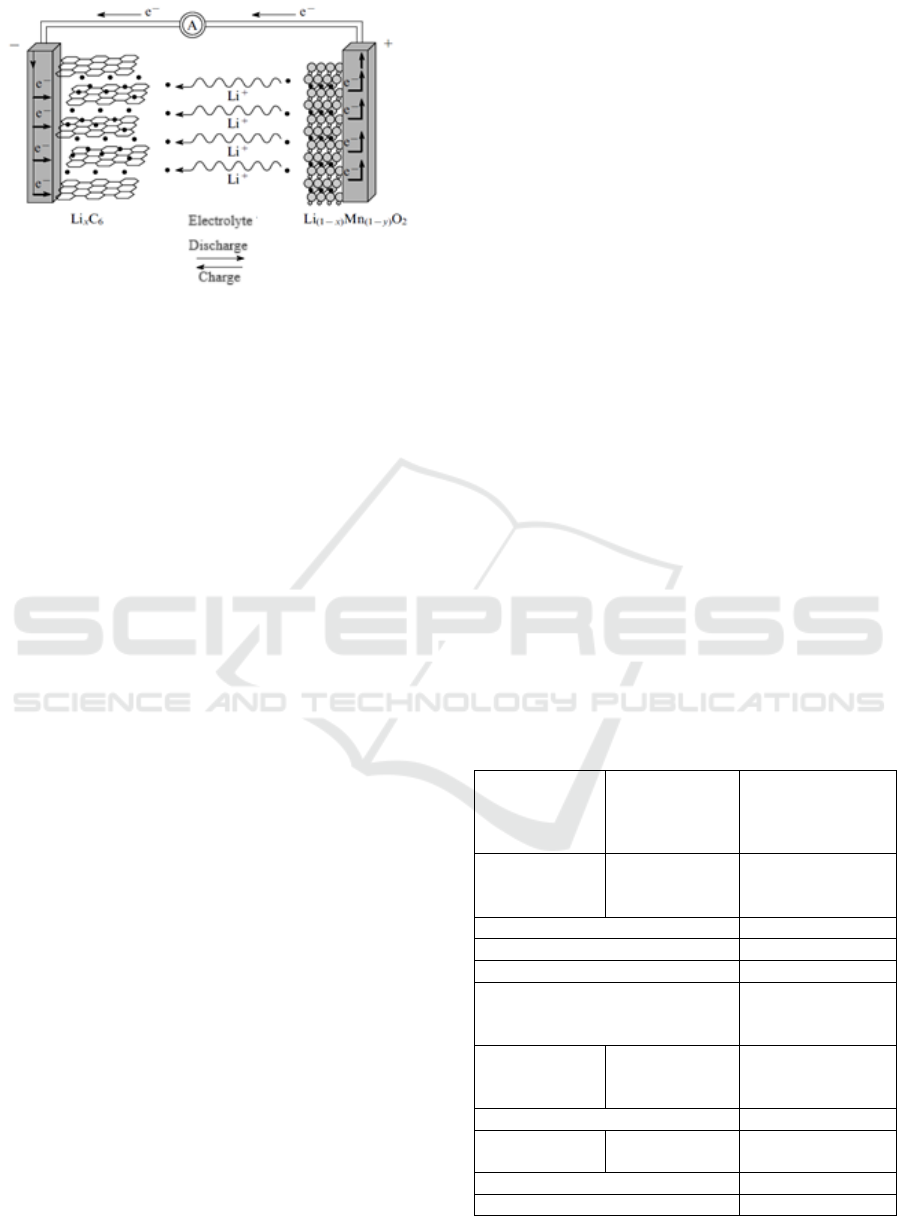

Figure 1: Schematic diagram of the operation of a lithium-

ion battery

A schematic diagram of the operation of a lithium-

ion battery is shown in Figure 1. On the left is a

negative graphite electrode. Its structure is

characterized by the presence of layers between

which lithium ions can be embedded (black dots). On

the right is a positive electrode made of lithium-

manganese spinel, in the structure of which lithium

ions can also be embedded. Solutions of lithium salts

in non-aqueous solvents are used as an electrolyte.

Lithium-ion batteries obey the laws common to all

types of batteries. An ideal battery should be

completely reversible: all electricity should be spent

only on current-generating charge and discharge

reactions (in other words, the current output of these

processes should be 100%). In a real battery, there are

always some processes (electrochemical and

chemical) in addition to current-forming reactions. A

certain amount of electricity is consumed for these

extraneous processes (usually irreversible). As a

result, at each cycle, the discharge capacity is less

than the amount of electricity consumed at the

previous stage of the charge. In addition, as cycling

goes on, the capacity decreases from cycle to cycle.

The nature of irreversible processes in batteries of

different electrochemical systems is different.

Processes on the positive electrode of a Li-ion

battery.

If a variety of active materials for the positive

electrode are used in primary lithium cells (meaning

non-rechargeable cells), then in lithium batteries the

choice of positive electrode material is limited.

Lithiated cobalt or nickel oxides, as well as lithium-

manganese spinels are used here. Currently, materials

based on mixed oxides or phosphates are increasingly

used as cathode materials. It is shown that the best

characteristics of the battery are achieved with

cathodes of mixed oxides. Technologies of cathode

surface coatings with finely dispersed oxides are also

being mastered. The problems of synthesis of these

compounds associated with the difference in the

structures of nickelate (layered hexagonal) and

lithium manganate (layered rhombohedral) were

overcome by using nickel and manganese double

hydroxide systems for synthesis, after which work

towards the synthesis of mixed oxides began to be

intensively carried out in different countries (USA,

CANADA, South Korea, China) (Matmurodov et al.,

2024, Wang et al., 2004, Shlyakhtin et al., 2004,

Kovtun et al., 2024, Musabekov et al., 2023).

High rated voltage, a gentle discharge curve, high

efficiency of the charging-discharge process, good

capacity and cyclability, acceptable self-discharge,

ease of production in industrial conditions explain the

most widespread use of lithium cobalt in

commercially developed LIAS, which provides a

reversible capacity of positive electrodes of 135-150

mAh/ g when cycling LIAS in the voltage range of

2.5-4.3 V. Smaller particle size, more uniform

distribution and the formation of small-sized

agglomerates of small spherical particles contribute

to improving the electrochemical characteristics of

the cathode material.

Modification of lithium – metal–oxide

compounds by doping them, including multidoping

with various elements. The introduction of the latter

improves the stability of the electrochemical

characteristics of the cathode material during cycling

by stabilizing its structure and reducing the tendency

to phase transitions.

Table 1: The main manufacturers of cathode materials.

Chemical

formula of the

cathode

material

Country of

origin

Manufacturing

company

LiCoO2 Japan Nippon Chemical

industry Co.;

Simimoto Co.

USA OMG

German

y

Merck KGA

South Korea Umicore

China Shanghai

Shanshan Science

& Technolo

gy

Co.

LiNi1-

yCoyO2

Japan Simimoto Co.;

Seimi Chemical

Co

German

y

Merk KGA

LiMn2O4 Japan Mitsui Mining &

Smeltin

g

Co. Ltd

USA FMC Corp

German

y

Merk KGA

The Use of Lithium-Ion Batteries as the Most Promising Traction Current Sources

311

The search for other compounds with stable

structures led to the creation of a cathode material

with the formula LiNi0.33MN0.33Co0.33O2.The

discharge capacity of the resulting compound, which

has good cyclability, at a final voltage of 4.3-4.6 V

was 159-200 mAh /g, respectively. Doping of this

compound with silicon leads to an increase in the

parameters of the crystal lattice, which is

accompanied by an increase in specific capacitance,

speed capabilities and cyclability, as well as a

decrease in impedance.

3 RESULTS AND DISCUSSION

During operation (cycling and storage) LIA the most

significant changes occur on electrodes made of

lithium-manganese spinals.

During table cycling at room temperature, the

relatively unstable two-phase structure of LiMn2O4

turns into a stable single-phase one with the loss of

Mn3+ and the formation of MnO2, which transforms

during lithium intercalation into inactive LiMnO2

with a layered structure. When a positive electrode

based on lithium-manganese spinel is recharged to

potentials below 3.5 V, a distortion of the crystal

structure according to Jan-Teller (Bazarov et al.,

2024, Chen et al., 2024, Yehorov et al., 2024, Sessa

et al., 2018, Uddin et al., 2016) appears, leading to the

dissolution of spinel and slow degradation of the

capacity during cycling.

Negative electrodes. Carbon materials

In the initial period of development of lithium-ion

batteries, many carbon materials with the ability to

reversibly intercalate lithium were investigated. The

earliest studies concerned the intercalation of lithium

into graphite. Graphitized materials include natural

and synthetic graphite, highly oriented pyrolytic

graphite, modified graphite materials, including

MCMB (from the English "mesocarbon

microbeads"), carbon powders. Only some types of

carbon materials are widely used commercially,

which can be divided into two groups: materials with

a highly ordered crystal structure and with a

disordered structure (Casals et al., 2017, Kandasamy

et al., 2017, El Ghossein et al., 2019, Müller et al.,

2019, Zhang et al., 2018, Burzy´nski et al., 2019a,

Dudley et al., 2017).

Every six carbon atoms form graphene sheets,

similar to honeycombs. These graphene sheets under

the action of Vandervaals forces form graphite layers,

the latter, located parallel to each other, form a

graphite structure. From the point of view of

crystallography, the term "graphite" is applicable

only to carbon forms having a linear spatial structure

with an ideal ordered arrangement of graphene layers.

There are two types of graphite phases – hexagonal

(α-phase) and rhombohedral (β-phase). The

rhombohedral phase is stable at lower temperatures

and therefore shows better stability during cycling.

To date, many different carbon materials have

been studied and the industry has mastered the

production of some special materials for the negative

electrodes of lithium-ion batteries. Examples of such

materials can be the MCMB material. However,

research on carbon materials for lithium-ion batteries

is still ongoing, with special attention being paid to

various nanofiber materials, nanotubes,

nanocomposites, graphene nanoparticles, etc. (Casals

et al., 2018, Jinlei et al., 2019, Lai et al., 2018, Zhang

et al., 2016).

Reversible processes on carbon materials

The maximum amount of lithium that can be

embedded in carbon is 1 lithium atom per 6 carbon

atoms (equation (1), 0<x<1). Lithium is embedded

through a prismatic surface. Insertion through the

basal surface is also possible, but only if there are

defects on this surface.

The mechanism of lithium intercalation into

graphite is the sequential filling of the space between

graphene layers with lithium. This process can be

described by a step index, which is equal to the

number of graphene layers between the two closest

lithium layers. At maximum filling, there will be only

one graphene layer between the lithium layers, and

this state will correspond to stage No. 1. Each stage is

characterized by a reversible potential and

corresponds to a certain concentration of lithium in

the graphite matrix. The transition through the steps

looks like this:

1. LiC72 + Li ↔ 2 LiC36

(Stage 8) (stage 4)

2. 3 LiC36 + Li ↔ 4 LiC27

(4 Stage) (3 Stage )

3. 2LiC27 + Li ↔ 3LiC18

(3 Stage) (2 Stage)

4. 2LiC18 + Li ↔ 3LiC12

(2 Stage) (2 Stage)

5. 2LiC12 + Li ↔ LiC6

(2 Stage) (1 Stage)

The mechanism of the introduction of lithium into

non-graphite carbon materials has not yet been fully

elucidated. But, at least, three types of interaction of

lithium and carbon material are assumed: interaction

with graphene layers, with the surface of polynuclear

aromatic planes and the introduction of lithium into

micro-voids on the frontal surface of the carbon

material. When lithium is intercalated into non-

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

312

graphite materials, lithium is filled simultaneously

throughout the entire volume of the carbon material,

so the charge-discharge curve has a smoothed

appearance, and there are no clear steps on the charge-

discharge curve (Nájera et al., 2017, Barcellona et al.,

2017, Umerov et al., 2024, DeHoog et al., 2018, Chin

et al., 2018, Daminov et al., 2022, DeSutter et al.,

2018, Fang et al., 2019, Xia et al., 2021).

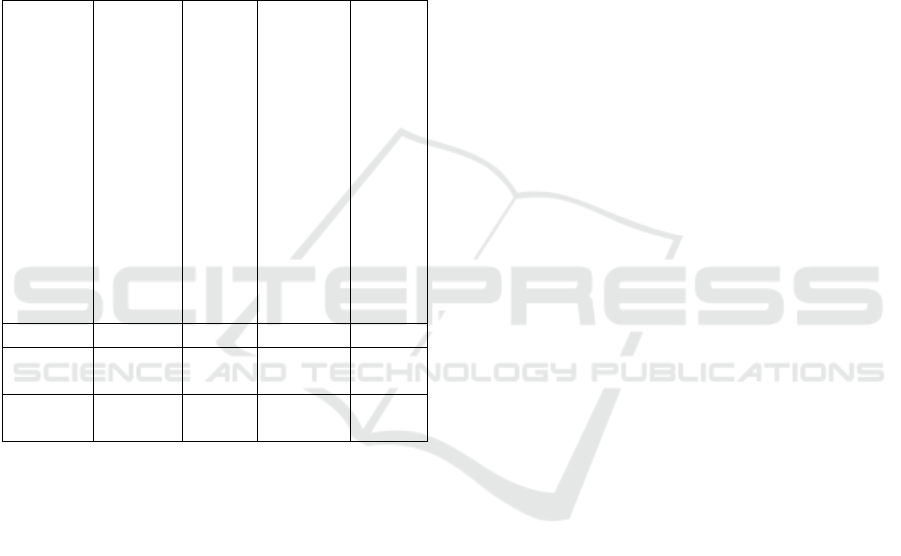

Table 4 shows a list of operational indicators of

LIA with different chemical composition of the

cathode and anode.

Table 4: Comparative characteristics of electrochemical

systems used for the production of lithium-ion batteries

Type

(formula)

of

electroch

emical

system,

cathode/a

node

materials

Speci

fic

energy

intensity

(Wh/kg)

Reso

u

rce, (the

number

o

f charge

d

ischarg

e

cycles o

f

1C

d

ischarg

e

depth 80

%

Permis

sible

charge/disc

harge rates

in units

that are

multiples

of the

nominal

capacity

With –

(hourly

discharge

current)

Oper

ating

temperat

ure range

without

the use

of

passive

or active

thermal

compens

ation

systems

1 2 3 4 5

LiCoO2/

C

150-190 ≤ 200 0,5С/1С -15-

+50

LiMn2O

4/C

135 ≤1500 2С/5С -30-

+50

4 CONCLUSIONS

Lithium-ion batteries have emerged as the most

promising source of traction current for modern

electric vehicles (EVs), primarily due to their superior

energy density, long cycle life, and relatively low

self-discharge rates. These batteries represent a

significant advancement over traditional lead-acid

and nickel-metal hydride batteries, offering a more

efficient and sustainable solution to meet the growing

demands of electric mobility.

One of the key advantages of lithium-ion batteries

is their high energy density, which allows for longer

driving ranges on a single charge. This makes them

ideal for EVs, where maximizing range is crucial for

consumer acceptance and widespread adoption.

Additionally, lithium-ion batteries are known for their

longevity, maintaining their capacity over many

charge-discharge cycles, which translates to a longer

operational lifespan for EVs.

Moreover, lithium-ion technology is

characterized by a relatively low self-discharge rate,

meaning that the batteries retain their charge for

extended periods when not in use. This feature is

particularly beneficial for EV owners who may not

use their vehicles daily, as it ensures that the battery

will still have a substantial charge even after being

idle for some time (Noh et al., 2019, Somakettarin et

al., 2019, Burzy´nski et al., 2019b, Venugopal et al.,

2019, Worwood et al., 2018, Fan et al., 2019, Han et

al., 2019, Harting et al., 2019, Hildebrand et al., 2018,

Osara et al., 2019, Kuo et al., 2019, Wu et al., 2018,

Daminov et al., 2022).

Another significant benefit of lithium-ion

batteries is their efficiency in energy conversion,

which reduces the overall energy loss during charging

and discharging. This efficiency contributes to lower

energy costs and supports the economic viability of

EVs in the long term.

However, challenges such as safety concerns,

particularly regarding thermal runaway, and the

environmental impact of battery production and

disposal, must be addressed to fully realize the

potential of lithium-ion batteries. Ongoing research

and development are focused on improving battery

safety, enhancing recycling processes, and exploring

alternative materials that could further reduce

environmental impact.

In conclusion, lithium-ion batteries stand out as

the most promising traction current sources for

electric vehicles, offering a combination of high

energy density, long cycle life, and efficiency. With

continued innovation and improvements, these

batteries are poised to play a pivotal role in the future

of sustainable transportation.

REFERENCES

Barcellona, S., Piegari, L.2007. Lithium ion battery models

and parameter identification techniques. Energies 2017,

10, 2007.

Bazarov, B.I., Sidikov, F.S., Usmanov, I.I., Magdiyev, K.I.

Computational determination of flow parameters of

thermostat for combustion engine cooling system. BIO

Web of Conferences, 2024, 105, 01022

Burzy´nski, D., Pietracho, R., Kasprzyk, L. 2019b.

Tomczewski, A. Analysis and modeling of the wear-out

process of a lithium-nickel manganese-cobalt cell

during cycling operation under constant load

conditions. Energies 2019, 12, 3899.

The Use of Lithium-Ion Batteries as the Most Promising Traction Current Sources

313

Burzy´nski, D.,, Kasprzyk, L. 2019a. The operation and

capacity fade modelling of the lithium-ion cell for

electric vehicles. E3S Web Conf. 2019, 108, 01017.

Casals, L C..García, A B. 2017.Second-life batteries on a

gas turbine power plant to provide area regulation

services. Batteries 2017, 3, 10.

Casals, L., Igualada, L., Corchero, C. The effect of building

energy management systems on Battery Aging. E3S

Web Conf. 2018, 61, 00014

Chen, W., Cheng, Z., Wen, Q., ... Volkova, O., Liu, J. Ya

High-Strength Nonoriented Electrical Steel with

Excellent Magnetic Properties Accomplished by Cu–Ni

Multialloying. Steel Research International, 2024

Chin, C., Gao, Z., Chiew, J., Zhang, C., 2018. Nonlinear

temperature-dependent state model of cylindrical

LiFePO4 battery for opencircuit voltage, terminal

voltage and state-of-charge estimation with extended

Kalman filter. Energies 2018, 11, 2467.

Dambone Sessa, S., Tortella, A., Andriollo, M., Benato, R.

Li-ion battery-flywheel hybrid storage system:

Countering Battery Aging during a grid frequency

regulation service. Appl. Sci. 2018, 8, 2330

Daminov O., Mirzajonov R., Turdiev J., Usmonov J.

Improving energy efficiency of electric vehicles.

International Conference on Electrical Facilities and

informational technologies (2022)b. "New Intelligence

Technology: Past, Present and Future". Turin

polytechnic university in Tashkent, Uzbekistan. August

10-13, 2022. pp. 61-64.

Daminov O.O., Juraboev A.Z., Daminov L.O., Kurbanov

A.M. (2022). Analysis of energy sources for electric

vehicles. International Conference on Electrical

Facilities and informational technologies (2022)a.

"New Intelligence Technology: Past, Present and

Future". Turin polytechnic university in Tashkent,

Uzbekistan. August 10-13, 2022. pp. 37-41.

Daminov O.O., Juraboev A.Z., Kersten S. Working process

of cells and batteries. Journal: Technical science and

innovation. 2022, №2. - P. 134-140

https://unilibrary.uz/articles/303207

De Hoog, J., Jaguemont, J., Abdel-Monem, M., Van Den

Bossche, P., Van Mierlo, J., Omar, N., 2018.Combining

an electrothermal and impedance aging model to

investigate thermal degradation caused by fast

charging. Energies 2018, 11, 804.

De Sutter, L., Berckmans, G., Marinaro, M., Smekens, J.,

Firouz, Y., Wohlfahrt-Mehrens, M., Van Mierlo, J.,

Omar, N. Comprehensive aging analysis of volumetric

constrained lithium-ion pouch cells with high

concentration silicon-alloy anodes. Energies 2018, 11,

2948.

Dudley, G., Blake, R., Lucas, L. 2017. Mars Express

Lithium Ion batteries performance analysis. E3S Web

Conf. 2017, 16, 06002

El Ghossein, N., Sari, A.,Venet, P. 2019. Lifetime

prediction of lithium-ion capacitors based on

accelerated aging tests. Batteries 2019, 5, 28.

Fan, J., Zou, Y., Zhang, X., Guo, H. 2019. A novel state of

health estimation method for lithium-ion battery in

electric vehicles. J. Phys. Conf. Ser. 2019, 1187,

022014.

Fang, Q., Wei, X., Lu, T., Dai, H., Zhu, J. 2019.A state of

health estimation method for lithium-ion batteries

based on voltage relaxation model. Energies 2019, 12,

1349.

Han, X., Feng, X., Ouyang, M., Lu, L., Li, J., Zheng, Y., Li,

Z. 2019. A comparative study of charging voltage curve

analysis and state of health estimation of lithium-ion

batteries in Electric Vehicle. Automot. Innov. 2019, 2,

263–275.

Harting, N., Wolff, N., Röder, F., Krewer, U. 2019. State-

of-health diagnosis of lithium-ion batteries using

nonlinear frequency response analysis. J. Electrochem.

Soc. 2019, 166, A277.

Hildebrand, S., Rheinfeld, A., Friesen, A., Haetge, J.,

Schappacher, F.M., Jossen, A., Winter, M. 2018.

Thermal analysis of lini0.4co0.2mn0.4o2/mesocarbon

microbeads cells and electrodes: State-of-charge and

state-of-health influences on reaction kinetics. J.

Electrochem. Soc. 2018, 165, A104.

Jinlei, S., Lei, P., Ruihang, L., Qian, M., Chuanyu, T.,

Tianru, W. Economic Operation Optimization for 2nd

use batteries in Battery Energy Storage Systems. IEEE

Access 2019, 7, 41852–41859.

Kandasamy, N., Badrinarayanan, R., Kanamarlapudi, V.,

Tseng, K., Soong, B.-H. 2017.Performance analysis of

machine-learning approaches for modeling the

charging/discharging profiles of stationary battery

systems with Non-Uniform Cell Aging. Batteries 2017,

3, 18.

Kovtun, O., Levchenko, M., Höntsch, S., ... Gräbner, M.,

Volkova, O. Recycling of iron-rich basic oxygen

furnace dust using hydrogen-based direct reduction.

Resources, Conservation and Recycling Advances,

2024, 23, 200225

Kuo, T.J., Lee, K.Y., Chiang, M.H. 2019. Development of

a neural network model for SOH of LiFePO4 batteries

under different aging conditions. IOP Conf. Ser. Mater.

Sci. Eng. 2019, 486, 012083.

Lai, X., Qiao, D., Zheng, Y., Yi, W. A novel screening

method based on a partially discharging curve using a

genetic algorithm and back-propagation model for the

Cascade Utilization of retired lithium-ion batteries.

Electronics 2018, 7, 399.

Matmurodov, F.M., Daminov, O.O., Sobirov, .Sh.,

Abdurakxmanova, M.M., Atakhanov, F.U.M. Dynamic

simulation of force loading of drives of mobile power

facilities with variable external resistance. E3S Web of

Conferences, 2024, 486, 03001

Müller, D., Dufaux, T., Birke, K.P. 2019. Model-based

investigation of porosity profiles in graphite anodes

regarding sudden-death and second-life of lithium ion

cells. Batteries 2019, 5, 49.

Musabekov, Z., Daminov, O., Ismatov, A. Structural

solutions of the supercharged engine in the output and

input system. E3S Web of Conferences, 2023, 419,

01015

Nájera, J., Moreno-Torres, P., Lafoz, M., de Castro, R.M.,

Arribas, J.R. 2017.Approach to hybrid energy storage

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

314

systems dimensioning for urban electric buses

regarding efficiency and battery aging. Energies 2017,

10, 1708.

Noh, T.-W., Ahn, J.-H., Lee, B.K. 2019. Cranking

capability estimation algorithm based on modeling and

online update of model parameters for Li-ion SLI

Batteries. Energies 2019, 12, 3365.

Osara, J., Bryant, M.2019. A thermodynamic model for

lithium-ion battery degradation: Application of the

degradation-entropy generation theorem. Inventions

2019, 4, 23.

Shlyakhtin O.A.,Yoon Y.S., Choi S.H., Oh Y.-J //

Electrochim.Acta.2004. – vol.50. - p.503.

Somakettarin, N., Pichetjamroen, A. 2019. Characterization

of a practical-based Ohmic series resistance model

under life-cycle changes for a lithium-ion battery.

Energies 2019, 12, 3888.

Uddin, K., Perera, S., Widanage, W., Somerville, L.,

Marco, J. Characterising lithium-ion battery

degradation through the identification and tracking of

electrochemical battery model parameters. Batteries

2016, 2, 13.

Umerov, F., Daminov, O., Khakimov, J., Yangibaev, A.,

Asanov, S. Validation of performance indicators and

theoretical aspects of the use of compressed natural gas

(CNG) equipment as a main energy supply source on

turbocharged internal combustion engines vehicles.

AIP Conference Proceedings, 2024, 3152(1), 030017

Venugopal, P., Vigneswaran, T. 2019. State-of-health

estimation of Li-ion batteries in electric vehicle using

INDRNN under variable load condition. Energies 2019,

12, 4338.

Wang X. et al. // J. Crystal Growth. 2004. – vol. 267. –

p.184.

Wei, X., Zhao, W., Ilatovskaia, M., ... Ma, G., Volkova, O.

Effect of Calcium Addition on the Aluminum Alloy

A201 Foam. Advanced Engineering Materials, 2024,

26(10), 2302093

Worwood, D., Algoo, R., McGlen, R.J., Marco, J.,

Greenwood, D. 2018. A study into different cell-level

cooling strategies for cylindrical lithium-ion cells in

automotive applications. Int. J. Powertrains 2018, 7,

199.

Wu, Y., Li, W., Wang, Y., Zhang, K. 2019. Remaining

useful life prediction of lithium-ion batteries using

neural network and bat-based particle filter. IEEE

Access 2019, 7, 54843–54854.

Xia, B., Chen, G.,Zhou, J., Yang, Y., Huang, R., Wang, W.,

Lai, Y., Wang, M., Wang, H. 2021. Online parameter

identification and joint estimation of the State of charge

and the state of health of lithium-ion batteries

considering the degree of polarization. Energies 2019,

12, 2939. Energies 2021, 14, 8072 32 of 33

Yehorov, A., Wei, X., Mazepa, S., Sherstneva, A.,

Volkova, O. Oxidation Behavior of MgO-C

Refractories Containing Metallic Aluminum, Calcium

Magnesium Aluminate Aggregates, and Carbores P.

Steel Research International, 2024

Zhang, C., Jiang, J., Zhang, L., Liu, S., Wang, L., Loh, P.

A. 2016. generalized SOC-OCV model for lithium-ion

batteries and the SOC estimation for LNMCO Battery.

Energies 2016, 9, 900.

Zhang, L., Lyu, C., 2018. Decomposition study of

degradation reasons for licoo2-based 14500 lithium-ion

batteries using a nondestructive method. IEEE Access

2018, 6, 44417–44432.

The Use of Lithium-Ion Batteries as the Most Promising Traction Current Sources

315