Study of the Functional Properties of Soy Protein Additives in Meat

Products

Abdunabi Fathullaev

a

and Saboxat Ibragimova

b

Tashkent State Agrarian University, 100140, University str. 2, Tashkent, Uzbekistan

Keywords: Soy Protein Additives, Functional Properties, Meat Products.

Abstract: Functional properties of traditional soy concentrate and its analogue were investigated in this paper. Besides

that, a comparative analysis of functional-technological, structural mechanical properties and quality traits of

thermally treated ground meat systems was carried out and deeply examined

.

1 INTRODUCTION

At present, there is a lack of food rich in easily

digestible proteins in the diet of the population. One

of the ways to solve this problem is to replace animal

proteins with vegetable ones, which are both cheaper

and healthier (Isaev et al., 2020). Soy is the only crop

that contains high quality protein. Soy protein is well

balanced in essential amino acids other than

methionine and cysteine. In terms of the protein

complex and the content of essential amino acids

(lysine and tryptophan), soy protein is closer to

proteins of animal origin, therefore, animal and

human organisms spend minimal efforts to convert

soy protein into proteins of their body (Antipova and

Glotova, 2006), (Golubev et al., 2003).

Meat products contain 15-20% protein. Among

vegetable legumes (beans, peas), vegetable soybeans

have no equal in terms of protein content (44-45%)

and oil (20-22%) in the phase of green beans (Lisitsyn

et al., 2005). This is a very highly nutritious crop and

the inclusion of vegetable soybeans in the diet allows

to enrich food with essential proteins and other

nutrients for the body (Lisitsyn et al., 2005),

(Lisitsyn, 2000).

Numerous studies confirm that soybean seeds

contain antioxidants. Its use in food helps to increase

the body's immunity and reduce allergies. Unlike

meat, soy is free of cholesterol and saturated fatty

acids, which lead to heart disease, cancer and

osteoporosis. It has been noticed that soy effectively

a

https://orcid.org/0009-0003-1168-8258

b

https://orcid.org/0000-0003-1129-2456

lowers blood cholesterol levels, optimizes the glucose

content in it in diabetes, helps to strengthen bones,

prevents the development of heart and blood vessel

diseases, and reduces the risk of kidney and liver

stones. Soy contains a very rare fatty acid, omega-3,

which is essential for brain development in newborns,

reducing the risk of heart disease and cancer. It

contains many anticarcinogenic substances that

prevent and stop the development of cancerous

tumors (Lisitsyn, 2000), (Rogov, 2009), (Fathullaev

and Turabjanov, 2009).

The use of soybeans is carried out in several

directions, among which the following lines are

highlighted: Soy protein is produced from raw beans

using a multi-stage processing technology that

removes indigestible components and concentrates

the protein. The type of final product depends on the

type of processing. Protein can take the form of a

concentrate, isolate, or flour. In addition to protein,

soy products contain no less valuable components -

fiber, isoflavones, and saponins (Fathullaev and

Turabjanov, 2008).

The ideal raw material for the production of

concentrates is full fat extruded soybeans. The

content of vitamins and essential amino acids in

concentrates is much higher than in other types of

proteins of animal and plant origin (Antipova and

Glotova, 2006), (Fathullaev and Turabjanov, 2008).

On the basis of protein, highly effective protein-

vitamin and mineral complexes are obtained - soy

protein concentrates, consisting of soy proteins,

Fathullaev, A. and Ibragimova, S.

Study of the Functional Properties of Soy Protein Additives in Meat Products.

DOI: 10.5220/0014262800004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 301-304

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

301

vitamins, minerals and enzymes (Isaev et al., 2020),

(Fathullaev, 2020).

The introduction of soy protein concentrates,

consisting mainly of salt-soluble proteins, into meat

systems ensures the formation of meat emulsions,

stabilizes their properties, increases the level of fat

absorption, water-binding capacity and stickiness of

minced meat. As a result, the output of finished

products increases, the likelihood of the formation of

broth-fatty edema is excluded, and the product is solid

and juicy (Fathullaev, 2020).

In terms of its functional and technological

properties, soy protein concentrate acts similarly to

the structure-forming muscle proteins of lean meat.

However, unlike multicomponent meat and dairy

proteins, soy protein concentrate is homogeneous and

this makes it easy to predict the nature of

technological changes in meat emulsions when

working with it and control it (Antipova and Glotova,

2006), (Lisitsyn, 2000).

Due to the stability of the composition and

functional and technological properties, soy protein

concentrate provides a significant improvement in the

quality of meat emulsions prepared from low grade

raw materials with a wide range in the content of

muscle, adipose and connective tissue, as well as

from ice cream and thawed meat (Lisitsyn et al.,

2005), (Lisitsyn, 2000).

Soy protein concentrate can be used both for the

production of a wide range of traditional meat

products and for the production of new types of

products (Fathullaev, 2020). At the same time, the

optimal level of its introduction into the formulations

of various types of meat products is: for boiled

sausages, frankfurters, small sausages - 2-4%, for

products such as ham in a shell - 2-4%, for salty pork

products (when added in brines) - 12%, for pates

(molded, wrapped and canned) - 3-6%, for chopped

semi-finished products - up to 7%, for dry fermented

sausages - 2-3%.

2 MATERIALS AND METHODS

The value of the output of finished products is one of

the criteria that determine the economic feasibility of

the production of cooked sausages. At the same time,

it is closely related to the functional properties of the

proteins of the minced meat system, which determine

the juiciness of the finished product.

One of these properties is the ability of minced

meat to retain bound moisture during heat treatment.

In our opinion, water-retention capacity (WRC) and

structural-mechanical characteristics are the key

functional properties for assessing the quality of

cooked sausages.

The water-holding capacity data indicate that the

moisture-holding capacity of heat- treated minced

meat does not differ significantly. The WRC of the

control sample, the main recipe component of which

is grade 1 beef, is slightly lower than in the samples

containing 25% suspension of modified soy

concentrate and 25% suspension of soy concentrate.

These data confirm the previously obtained

functional properties of the modified soy concentrate

and soy concentrate.

The use of 25% modified soy concentrate in the

production of cooked sausages instead of an

equivalent amount of raw meat allows to create a

stable emulsion that retains weakly bound moisture

when heated (Fathullaev, 2020).

The structural and mechanical properties of

sausages were determined using the INSTRON

laboratory installation of the city sanitary

epidemiological station (Fathullaev, 2020).

3 RESULTS AND DISCUSSION

Characterizing soy protein concentrates as functional

ingredients, the following indicators were chosen as

the main criteria for assessing their structural

similarity with meat systems: solubility, water

retention capacity, critical concentration of gelation,

emulsion stability, and fat retention capacity of dry

preparations.

Solubility is used as a primary indicator of the

quality of the dietary protein. For example, an increase

in protein solubility helps to increase the stability of

the emulsions stabilized by it. The most important

functional protein families include the critical

concentration of its gelation, at which a spatial

network is formed in the entire volume of the system.

Amino acid composition data indicate that all

samples, regardless of the content of other modified

proteins, contained a full range of essential amino

acids. Minor differences in indicators were due to the

research methodology and did not go beyond the

permissible deviations. The objective of this study was

to investigate protein processing behavior and

determine its key functional properties for combined

meat products containing other plant- derived

proteins.

Table 1. shows the amino acid composition of the

protein of defatted soy flour and its with other

analogues. Control samples 1 and 3 are traditional soy

protein preparations, and samples 2 and 4 are their

modified counterparts.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

302

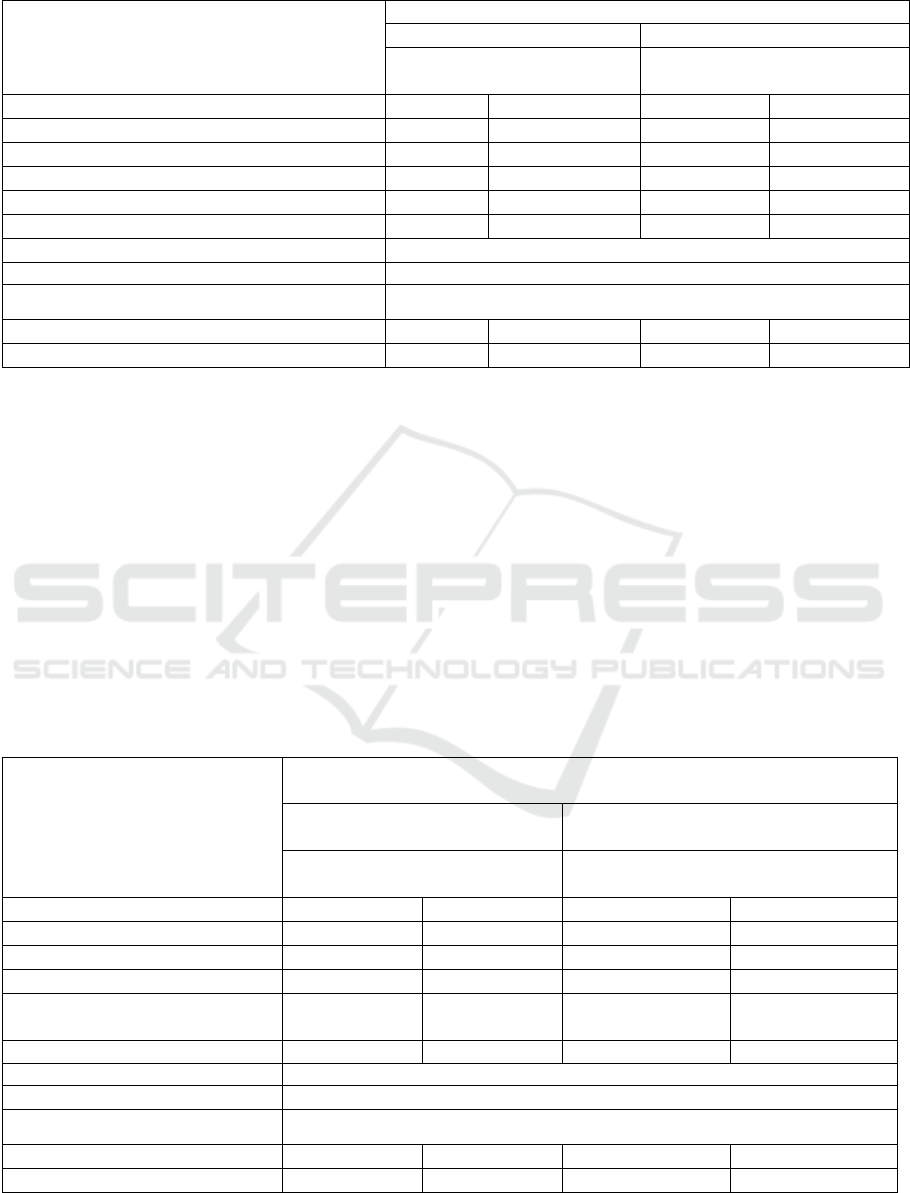

Table 1: Protein amino acid composition of defatted soy flour.

Index

Functional properties of modified soy concentrate and soy concentrate

Inwater

In 2.5% sodium chloride solution

Modified soy Concentrate control Modified soy Concentrate control

pH of 5% suspension

6.9 6.7 6.3 6.2

Solubility at t

0

, %:

20

0

С

51 57 48 46

72

0

С

57 74 51 61

Water retention capacity of the preparation, g water/g

5.0 5.5 4.5 5.0

Emulsion stability at t

0

:

20

0

С Resilient

72

0

С

»

Critical concentration of gelation at t

0

:

»

4

0

С

18.2 16.7

16.7 18.2

20

0

С

18.2 16.7 16.7 19.0

Amino acid composition data indicate that all

samples, regardless of the content of other modified

proteins, contained a full range of essential amino

acids. Minor differences in indicators were due to the

research methodology and did not go beyond the

permissible deviations. The objective of this study was

to investigate protein processing behavior and

determine its key functional properties for combined

meat products containing other plant- derived

proteins.

The studies were carried out in a wide pH range

depending on the salt concentration and temperature

conditions. The fat-holding capacity of the

preparation was 1.0 g oil for both samples. The values

of the indicators of solubility, water retention

capacity and critical concentration of protein gelation

of the modified soybean concentrate are comparable

with the same indicators of the protein of soybean

concentrate produced from local soybean seeds.

When determining emulsion stability, no

stratification of emulsions stabilized by samples of

soy concentrates occurred. The absence of significant

differences in the functional properties of the protein

of modified soy concentrates and exogenous analogs

confirms their identity. The functional properties of

soy concentrate (control) and its modified analogue

are given in Table 2.

Table 2: Indicators of the functional properties of soy concentrate.

Index

Functional properties of modified soy concentrate and soy concentrate

In water

In 2.5% sodium chloride solution

M o d i f i e d s o y c o n c e n t r a t e c o n t r o l M o d i f i e d s o0y Concentrate control

pH of 5% suspension

6.9 6.7 6.3 6.2

Solubility at t

0

, %:

20

0

С

51 57 48 46

72

0

С

57 74 51 61

Water retention capacity of the

preparation, g water/g

5.0 5.5 4.5 5.0

Emulsion stability at t

0

:

20

0

С Resilient

72

0

С

»

Critical concentration of gelation at t

0

:

»

4

0

С

18.2 16.7 16.7 18.2

20

0

С

18.2 16.7 16.7 19.0

Study of the Functional Properties of Soy Protein Additives in Meat Products

303

The fat-holding capacity of the preparation was

1.0 g oil/g preparation for both samples. The values

of the indicators of solubility, water retention

capacity and critical concentration of protein gelation

of the modified soybean concentrate are comparable

with the same indicators of the protein of soybean

concentrate produced from local soybean seeds.

When determining emulsion stability, no

stratification of emulsions stabilized by samples of

soy concentrates occurred. The absence of significant

differences in the functional properties of the protein

of modified soy concentrates and exogenous analogs

confirms their identity.

Studies have shown that the most effective

interaction of plant and meat proteins occurs when

25% of modified soy concentrate is replaced. This

sample was selected for further research. At the

second stage, the objects of study were boiled sausage

"Extra" 1st grade, in the formulation of which there is

no vegetable protein (sample 1-control), the content

of a 25% suspension of modified soy concentrate

(sample 2).

Analysis of the data presented allows us to

characterize samples containing a suspension of

modified soy concentrate and soy concentrate as

having a high yield and a low value of the mass loss

index during heat treatment. Indicators of weight loss

of the studied mincemeat vary from 13% (without

vegetable protein preparation) to 11.2% and 11.3%,

containing suspensions of modified soy concentrate

and soy concentrate, respectively.

4 CONCLUSIONS

The presented data indicate that the introduction of

modified soy concentrate and soy concentrate into the

composition of the minced meat system is

accompanied by a decrease in the values of the cutting

work and shear stress indicators. As a result, the use

of highly functional soy products leads to a

significant improvement in properties that determine

the structural and mechanical characteristics of

combined minced products. The use of 25% modified

soy concentrate and soy concentrate in cooked

sausages improves texture, increases product yield,

makes the product easy to cut.

Thus, in terms of the range of functional properties,

all studied concentrates correspond to soy protein

concentrates produced by traditional technology. A

characteristic feature of the preparations is a slight

dependence of protein solubility on temperature and

sodium chloride content in solution. The research

results indicate a similar behavior of suspensions of

modified soy concentrates and soy concentrates from

soybeans of local varieties in cooked sausages.

REFERENCES

Antipova L.V., Glotova I.A., Use of secondary collagen-

containing raw materials of the meat industry, 384

(GIORD Press, Saint Petersburg, 2006)

Fathullaev A., European Journal of Technical and Natural

Sciences 3, 63-72 (2020)

Fathullaev A., International Journal of Psychosocial

Rehabilitation 24(8), 5858-5864 (2020)

Fathullaev A., Polish Journal of Science 1(24), 23-30

(2020)

Fathullaev A., S.M. Turabjanov, J. Chemistry and

Chemical Technology 4, 74-76 (2008)

Fathullaev A., Turabjanov S.M., International Magazine

Austria, 63-69 (2018)

Golubev V.N., Chicheva-Filatova L.V., Shlenskaya T. V.,

Nutritional and biological active additives, 208

(Academia Press, Moscow, 2003)

Isaev S., Begmatov I., Goziev G., Khasanov S., IАP

Publishing 883(1), 012080 (2020)

Lisitsyn A.B., Lipatov N.N., Kudryashov L. S.,

Aleksakhina V. A., Production of meat products based

on biotechnology, 369 (VNIIMP Press, Moscow,

2005)

Lisitsyn A.B., Processing and use of by-products of the

meat industry and environmental protection, 101

(VNIIMP Press, Moscow, 2000)

Rogov I. A., Technology of meat and meat products, 356

(Kolos Press, Moscow, 2009)

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

304