Research and Development of a Technological Process and Stamping

Equipment for Radial Extrusion of the “Picabur Body” Part

Fatkhulla Abdullaev

a

, Shakhrukh Akhmadaliyev

b

, Kamoliddin Khasanov

c

and Rufat Abdullaev

d

Tashkent State Technical University, 100095, University str. 2, Tashkent, Uzbekistan

Keywords: Radial Extrusion, Contour Upsetting, Stamping.

Abstract: The article talks about the production of the “Picabur Body” part using resource-saving extrusion stamping

technology. The energy method and the finite element method were chosen as the research method. A

kinematic version of the methods of radial extrusion with contour upsetting and a design diagram of the radial

extrusion process are given. The deformation center and stress-strain state during extrusion stamping of the

above part are determined. The mechanism and sequence of filling the working cavity of the die are revealed.

The scheme of the die and its main working elements during extrusion stamping of the Pickabur Body are

also given. The principle of operation of die tooling and technological equipment, which was used in radial

extrusion stamping, is described.

1 INTRODUCTION

In developed countries, the development of heavy,

mining, and light industries has a positive effect on

the economy of their countries. In the manufacture of

“Picabur body”, widely used in various branches of

mechanical engineering, with flanges or thickenings

of various configurations, one of the promising

technologies is cold radial extrusion. A feature of

radial extrusion technology is the ability to actively

regulate the deformation and force parameters of the

process by changing the kinematics of movement of

the forming tool. Quite a lot of work has been devoted

to studying the process of radial extrusion. However,

practically until now the influence of nonmonotonic

deformation in the processes of cold radial extrusion

has not been considered. New combined methods of

radial extrusion, which themselves contribute to the

healing of damage to metals during deformation, have

practically not been developed or investigated. The

resulting gap hinders the implementation of cold

radial extrusion processes for the production of rod

parts with a wide flange. One of these new combined

a

https://orcid.org/0000-0002-3934-9336

b

https://orcid.org/0000-0002-4188-0126

c

https://orcid.org/0000-0000-2838-9028

d

https://orcid.org/0009-0009-4352-1138

methods of cold die forging is the method of radial

extrusion with contour upsetting, which is being

developed taking into account the effective use of

non-monotonic deformation. When developing new

combined extrusion methods, it is necessary to

determine the force mode, evaluate the deformability

of the workpiece and determine their advantage. At

present, technological processes of radial extrusion

with contour upsetting have not yet been studied.

In this regard, the study of the technological

process of radial extrusion from the “Picabur body”

is an urgent problem.

2 MATERIALS AND METHODS

In the world improvement of product quality and

labor in the engineering industry speeding up

production due to increased productivity the

occurrence of the process is of particular importance.

At the same time bending of the surface layer of metal

in the production of tools One of the important tasks

is to increase the endurance and operational time is

294

Abdullaev, F., Akhmadaliyev, S., Khasanov, K. and Abdullaev, R.

Research and Development of a Technological Process and Stamping Equipment for Radial Extrusion of the “Picabur Body” Part.

DOI: 10.5220/0014262600004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 294-300

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

considered. The material for the research was the

picabur body, which is produced by extrusion

stamping from St3 steel at Geoburtechnica.

3 RESULTS AND DISCUSSION

The method is based on the theory of plastic flow,

since it allows one to determine the kinematic, stress

and deformation states at any point in the zone of

plastic deformation, and take into account anisotropy,

non-stationarity and the history of deformation. The

following basic assumptions are used: the material is

considered rigid-plastic, and strain or rate hardening

is taken into account by the average value of the yield

stress over the deformation zone; Contact friction

forces during ordinary extrusion obey Siebel's law,

and when extruding with active friction forces, they

obey Amonton's law.

Theoretical analysis is carried out in the following

sequence:

1. The source of plastic deformation of the

workpiece is divided into areas convenient for setting

the field of suitable flow velocities in them. The

specified expressions for flow rates can include both

specific dependences, justified experimentally, and

functions of a general form

v

x

= v

x

(x, y, z, t),

v

y

= v

y

(x, y, z, t),

v

z

= v

z

(x, y, z, t), (1)

At the boundaries between regions, the continuity

condition can be observed in a relaxed form,

satisfying the condition of constant flow in integral

form.

2. Based on the flow rates (1), the components of the

strain rate are found:

ξy =

(

+

). (2)

3. Each region contains the intensity of strain rates.

ξ

1

=

𝜉

𝜉

(3)

If it is necessary to simplify the solution, the value

of the strain rate intensity is averaged over one or

several coordinates and in the process of further

analysis is considered independent of these

coordinates.

4. Expressions (2) and (3) are substituted into the

equations for the relationship between stresses and

strain rates

σ

y

=𝜕

𝜎+

𝜉

(4)

Where 𝜕𝑦 - Kronecker symbol.

5. From the joint solution of the system of equilibrium

equations

= 0,

(5)

taking into account expressions (4), the stresses

are found. Arbitrary integration constants are found

from the boundary conditions. If necessary, to

simplify the solution of the system, the Huber-Mises

energy plasticity condition is used in the form

σ

ii (max)

– σ

jj (min)

= βσ

3

(6)

where β is the Lode coefficient, which for an

isotropic material is taken equal to its average value β

= 1, 1.

The use of a simplified plasticity condition that

does not take into account the tangential stresses

instead of the flow law associated with the exact

energy condition is not a disadvantage, since, on the

one hand, it allows one to avoid a decrease in

accuracy using approximate integration methods, and

on the other hand, the analysis showed that all the

main terms obtained from the proposed method, the

stress formulas coincide with those obtained on the

basis of the associated flow law, and the minor terms

give a slight overestimation of the result, which,

firstly, is consistent with the upper estimate method,

and secondly, makes it possible to compensate for the

mismatch of tangents that is always present in the

boundary conditions for non-zero friction stresses,

which cannot be taken into account in existing

momentless theories of plasticity.

6. Based on the found stresses, based on the

coupling equations (4) and kinematic boundary

conditions, the specific form of the velocity functions

specified at the beginning of the solution in general

form is determined.

7. If it is necessary to take into account the

anisotropy of the properties of the initial workpiece,

the plasticity condition and the relationship between

stresses and strain rates from the theory of plasticity

of anisotropic Mises -Hill bodies are used. The

analysis of this theory made it possible to introduce

an indicator of the form k = σ

sp

/ σ

sz

(where σ

sz

is the

yield stress along the axis of the workpiece, σ

sp

is the

yield stress in the radial direction), and obtain the

plasticity conditions of an anisotropic body in the

form

Research and Development of a Technological Process and Stamping Equipment for Radial Extrusion of the “Picabur Body” Part

295

𝜎

− 𝜎

= β𝜎

,

𝜎

− 𝜎

= β𝜎

.

(7)

In these expressions, the coefficient values are in the

interval

k≤ 𝛽≤2 /

√

4− 𝑘

at k<1, interval k≤ 𝛽≤

2 /

√

4− 𝑘

k >1.

If k = 1, then the interval of change of the

coefficient P completely coincides with the interval of

change of the Lode coefficient used in the theory of

plasticity of an isotropic body

8. A.A. Ilyushin’s formula is integrated, relating the

strain rate to the accumulated strain

ξi

_

=

=

+𝑣

+ 𝑣

+ 𝑣

, (8)

resulting in accumulated deformation

e

i

= f (x , y , z) (9)

where C - is an arbitrary constant.

9. Lagrange expressions are integrated

v

x

=(x , y , z , t)=

v

x

=(x , y , z , t)=

v

x

=(x , y , z , t)=

(10)

As a result, the dependences of the current

coordinates of the particle (Eulerian coordinates) on

the initial coordinates (Lagrange coordinates) and

time are found:

x = ψ

1

(x

0

, y

0

, z

0

, t )

y = ψ

2

( x

0

,y

0

,z

0

,t)

z = ψ

3

(x

0

,y

0

,z

0

,t) (11)

10. Using expressions (11), the initial coordinates of

the particle are determined from the condition 𝑒=𝑒

,

for 𝑒=𝑒

, 𝑥=𝑥

, 𝑦=𝑦

, t = 0, 𝑧=𝑧

. An

arbitrary constant value e

0 is found

, taking into account

the history of deformation;

e

10

=0, if the original workpiece has no accumulated

deformation. For convenience, you can replace the

time with the punch stroke

s=v

0

t (12)

where v

0

is the speed of movement of the punch.

11. Using expressions (11), the sizes of zones in

which material points in the process of deformation

pass the same path are determined; the deformation

field in such zones is stationary.

12. If necessary, the directions of the fibers of the

macrostructure are found using expressions (11). By

taking the initial coordinates of any material point of

any fiber of interest to the researcher and substituting

them into expressions (11), it is possible to determine

where this point will move at a certain value of the

working stroke s. By repeating this procedure for a

sufficient number of points on a single fiber, the shape

and position of that fiber macrostructure in the

stamped product can be determined.

13. For a certain value of the working stroke,

according to formula (9), the average value of the

accumulated deformation in the zone of plastic

deformation is calculated, from which the average

value of the yield stress of the workpiece is

determined.

14. To determine the size of the source of plastic

deformation, the principle of minimum specific

deforming force (minimum of the total deformation

energy) is used. For a hardening material,

minimization is carried out taking into account the

dependence of the average yield stress on the

accumulated deformation, which in turn depends on

the size of the source. The shape of individual flanges

of the site of plastic deformation is determined by

found expressions for flow velocities.

16. As a result of such calculations, a diagram of

the change in force during extrusion is constructed,

showing the effect of hardening of the workpiece

material on the force characteristics of the process.

15. To obtain intercomparable solutions suitable

for determining the optimal geometry of the tool, it is

necessary to satisfy the following requirements when

fulfilling points 1 and 5: design schemes, kinematics

and boundary conditions must transform into one

another in the limiting cases of different tool shapes.

The final criterion for checking intercomparability is

the comparison of formulas specific deforming force

in related cases of different tool shapes. In order to

expand the applicability of formulas, for hollow

products it is advisable to choose calculation schemes

suitable for analysis not only at the quasi-stationary

stage of extrusion, but also under bottom effect

conditions.

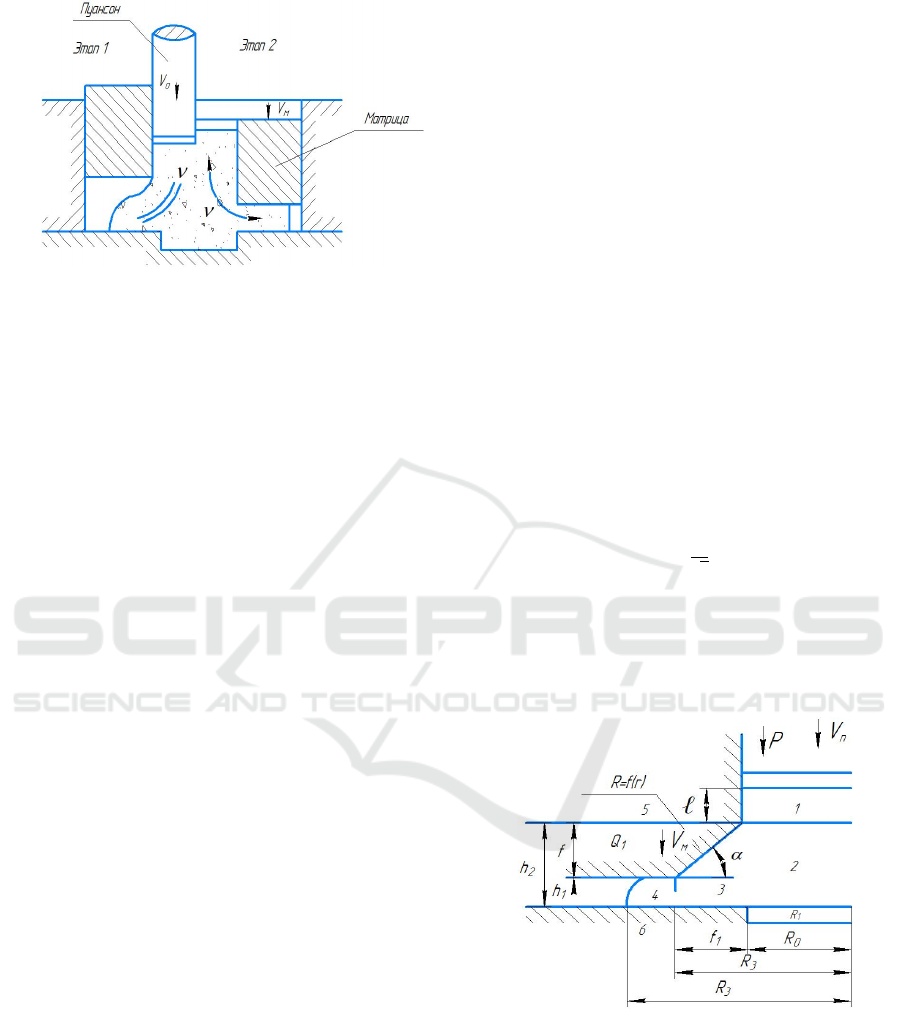

The process of radial extrusion is divided into two

stages (Fig. 1.);

- at the first stage, the metal is deformed by

moving the punch at speed 𝑉

in order to form a

thickening in some part of the product;

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

296

Figure 1: Kinematic version of radial extrusion methods

with contour upsetting.

- at the second stage, only such a separate

thickening is deformed with forced movement of the

matrix at speed 𝑉

м

, subject to the release (removal) of

the punch. It is the removal of the punch at the second

stage that creates the opportunity to control by

deformation. Due to the fact that at the second stage

only the contour part of the thickening is deposited,

this process is called the “extrusion process with

contour settlement”.

It was established that when studying the force

regime and deformability for the process of radial

extrusion (as the first stage of fishing with contour

settlement), the influence of the angle of the straight

transition edge was not sufficiently clarified.

The entire process of deformation by extrusion

with contour upsetting is divided into two stages: and

the first stage occurs as usual radial extrusion and is

called “upsetting by extrusion.” For the first stage, the

force mode was analyzed taking into account the

influence of the angle of the straight transition edge.

The energy method makes it possible to take into

account the main features of the process and

simultaneously determine both the active deforming

force developed by the punch and the reactive force

perceived by stationary tools. An upper estimate of

such forces can be obtained from the energy balance

if it includes the powers developed by reactive forces

at the virtual speeds of movement of the

corresponding parts of the tool, and the linearization

of all powers relative to the virtual and specified

speeds of the tool is carried out.

Solutions were carried out using the following

assumptions:

- normal component of the discontinuity

velocity vector, discontinuities have only components

directed along the block boundaries;

- specific contact forces friction on the contact

surface constant and proportional to the flow

resistance of the material;

- the workpiece material is homogeneous and

non-strengthening;

- the speed of the tool is constant.

We accept the following kinematic possible

velocity fields, a state of separate rigid blocks and

satisfying the kinematic boundary conditions and the

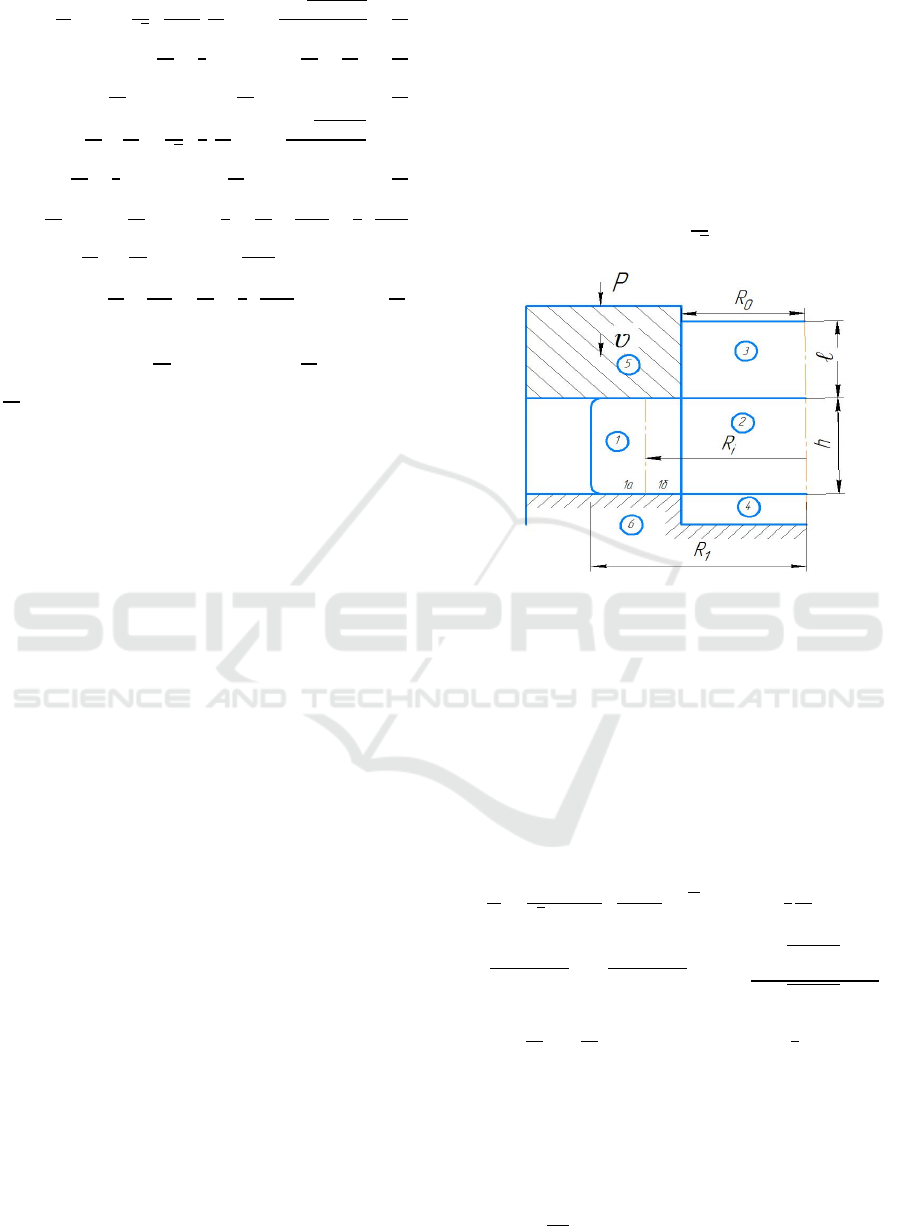

unexpectedness condition (Fig. 2). The accepted

kinematically possible velocity fields are based on

those established as a result of experimental studies

of the shape and source of plastic deformation.

The forces of deformation and opening were

determined from the power balance equation of

external and internal forces at kinematically possible

speeds of movement:

𝜌 𝜗

𝜋𝑅

+𝑞𝑣

𝜋

(

𝑅

−𝑅

)

=𝑊

+𝑊

+𝑊

(13)

where: - power of plastic deformation in zones 2,3,4:

𝑊

=∑𝑊

=∑6

∭6

𝑑𝑣; (14)

- power of shear forces on the velocity discontinuity

surfaces between zones 1-2, 2-3, 2-6, 3-4:

𝑊

с

=∑𝑊

с

=∑

√

∬

𝑢

𝑑𝑠; (15)

- power of contact friction forces on the surfaces of

contact with the tool: 1 and 5, 3 and 5, 4 and 5:

𝑊

=∑𝑊

=∑𝜇6

∬

𝑢

𝑑𝐶. (16)

Figure 2: Calculation diagram of the radial extrusion

process

Having calculated the powers of the forces of

plastic deformation, shear and contact friction,

substituting the found power values and the power

balance equation 1, separating the terms containing

𝑣

and 𝑣

м

we get:

Research and Development of a Technological Process and Stamping Equipment for Radial Extrusion of the “Picabur Body” Part

297

=1+

√

+ 2𝜇

𝑙𝑛

+

2𝑙𝑛

+

𝑡𝑔𝜎+ 2𝜇

−

−

+

1,14

2𝑙𝑛

+0,5𝑦−1𝑛

+0,2𝑡𝑔𝜎

2𝑙𝑛

−

𝑙𝑛

;

=

√

+2𝜇

(

𝑠

−

𝑡𝑔𝜎

)

𝑙𝑛

−

𝑦 𝑡𝑔

𝜎−𝑠

−1

𝑡𝑔𝜎 + 2𝜇

−

+2𝑙𝑛

+1,14

𝑙𝑛

−

+

−

1

ln

+

𝑦𝑡𝑔𝜎 + 2

+0,2 0,5𝑡𝑔𝜎−

−

𝑙𝑛

+

− 𝑡𝑔𝜎

𝑙𝑛

(17)

Where 𝑦=

−1; 𝑥=1+

; 𝑠=𝑡𝑔𝜎+

.

The second stage of the extrusion process with

contour upsetting represents the stages of contour

upsetting of the thickening formed at the first stage,

provided there is a movable punch. Design diagrams

are shown (in Fig. 3).

From the analysis of experimental studies, it was

established that the change in the dimensions of the

workpiece occurs in two stages:

1 - upsetting of the workpiece without changing

the length of the workpiece rod (size l), as long as the

dimensions of the workpiece or the friction conditions

are such that 𝑅

<𝑅

( 𝑅

is the radius of the

separation boundary of the metal flow). This is the

initial stage in the case of a large cavity height.

2-combination of the settlement of the annular

part of the workpiece with the formation of a rod, the

total height of which continuously increases if the

dimensions of the workpiece lead to the value 𝑅

>

𝑅

. This corresponds to the last stages with a decrease

in the height of the cavity (or as the matrices approach

each other).

An analysis of the power mode for the second

stage, which has more important implications for the

analysis of the technological characteristics of this

process, was carried out. The assumptions discussed

above are used. We accept the following kinematic

possible velocity fields, consisting of individual rigid

blocks and satisfying the boundary conditions and the

incompressibility condition. The accepted

kinematically possible velocity fields are based on the

shape and source of plastic deformation established

as a result of experimental studies.

The energy balance equation will be written as:

р 𝑣

𝜋

(

𝑅

−𝑅

)

=𝑊

+𝑊

+𝑊

(18)

where 𝑊

is the power of plastic deformation in

zones 1 and 2

𝑊

=∑𝑊

=∑6

∭6

𝑑𝑣

- the power of shear forces on the velocity

discontinuity surfaces between zones 1-2; 2-3 and 2-

4;

𝑊

с

=∑𝑊

с

=∑

√

∬

𝑢

𝑑𝑠; (19)

Figure 3: Design diagram for the second stage.

- power of contact friction forces on contact

surfaces 1 and 3 with tool 5

𝑊

=∑𝑊

=∑𝜇6

∬

𝑢

𝑑𝑐; (20)

Substituting all the found values of powers and

transformations into the energy balance equation (4),

we obtained a formula for determining the relative

specific deformation force:

=

√

√

3

𝑅

+𝐻+

+ℎ𝑅

+

𝑅

+3𝑅

−

𝑅

+3𝑅

−𝑅

𝑙𝑛

+

4𝜇

𝑙

+4

𝑅

(

2𝑅

−𝑅

−𝑅

)

+

(

𝑅

+𝑅

−

−2𝑅

)

(21)

The varying radius of metal separation

determination R

1

is determined by solving the

equation

Р

Р

=0.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

298

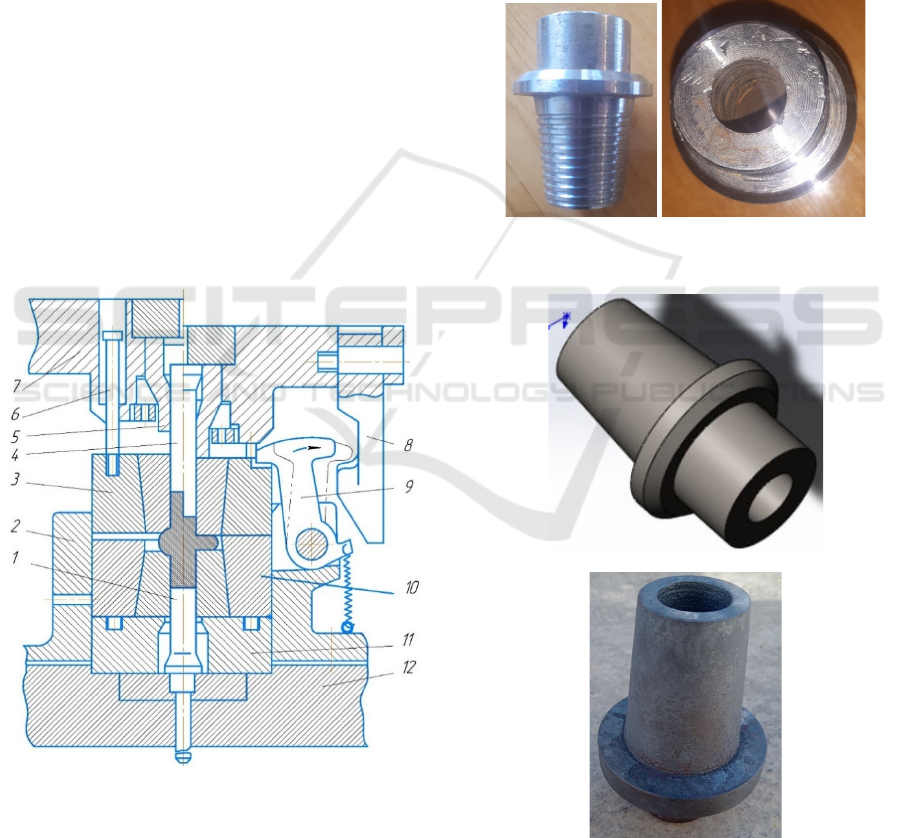

The stamp for this part has its own characteristics.

The matrix is made of two parts with a horizontal

connector plane. The receiving cavity is made in one

of the semi-matrices. The basic scheme of the die for

radial extrusion is shown in Fig. 2. The stamp is made

of steel 5ХНМ. Molybdenum disulfide with mineral

oil was used as a lubricant.

The die contains a punch 4 mounted on the upper

movable plate 7 with a pressure sleeve 5 covering it,

as well as an upper half-matrix 3 connected to the

plate 7 by means of rods 6. On the lower plate 12 is

mounted matrix holder 2, in which is installed the

lower half-matrix 10. In the vertical cavity of the half

matrix 10 is placed counter punch 1, covered by a

support sleeve 11. When clamped together, the half-

matrixes form a working annular cavity. The

mechanism of locking of the half-matrixes after their

clamping is made in the form of at least two hinged

(as a rule attached to the matrix holder) 2 rotary (in

the vertical or horizontal plane) spring-loaded levers

9. The levers interact their working front edge with

the upper end of the upper half-matrix 3. The rear side

of each of the locking levers interacts with the drive

mechanism, made in the form of, for example, a

pneumatic cylinder or a spring-loaded pusher 8,

hinged to the movable plate 7.

Figure 4: Schematic diagram of a die for radial extrusion

After clamping the half-matrixes, they are locked

by levers rotated by the pushers. Half-matrixes under

the action of metal extruded into the transverse cavity

and sawing forces are extended to contact with the

working edge of the levers 9. At the final stage of

deformation, the sleeve 5 comes into contact with the

half-matrix 3 and moves it downwards synchronously

with the punch, which leads to a decrease in the cavity

height and metal deposition in the flange area. This

frees the levers 9, which due to springing are

accelerated back to the initial position and do not

prevent the lifting of the upper half-matrix with the

movable plate 7 during the idle stroke of the press

slide.

Taking into account all the above calculations, it

was decided to test the theoretical research data in

practice. As a result of the experimental work, the

following results were obtained (Fig. 5; 6):

Figure 5: General view of the “Pikabur body” obtained by

cutting

Figure 6: Forging produced by precision stamping by radial

extrusion with contour upsetting

Research and Development of a Technological Process and Stamping Equipment for Radial Extrusion of the “Picabur Body” Part

299

4 CONCLUSIONS

1. A new method of extrusion with contour upsetting

has been developed, which uses the positive effect

of the influence of non-monotonic deformation on

the ultimate shape change of workpieces. The

main technological parameters of the processes

are established on the basis of studies of the force

regime, stress-strain state and workpiece

deformability.

2. Experiments on force modes were carried out to

verify the reliability of the theoretical calculation.

The discrepancy between calculated and

experimental data in most cases did not exceed

20-25%.

REFERENCES

Abdullaev, F. S., Akhmadaliev, Sh. Sh., Zagidullin, R. R.,

& Ismailov, Kh. U. (2021, December). Mathematical

model of axisymmetric flow in the extraction of a drill

body "pickabur" used in drilling operations.

International scientific and scientific-technical

conference on “Practical and innovative scientific

research: current problems, achievements and

innovations (dedicated to the memory of professor

A.A.Yusupkhodjaev)” 6 th December, 2021 (p. 300).

Abdullaev, F. S., Zagidullin, R. R., & Akhmadaliev, Sh. Sh.

(2021). Analyz metoda dozirovaniya iskhodnyx

zazhetok po masse. Universum: technical science, (1-

1), 31-33.

Abdullaev, F. S., Zagidullin, R. R., & Akhmadaliev, Sh. Sh.

(2021). Analyz metoda dozirovaniya iskhodnyx

zazhetok po masse. Universum: technical science, (1-

1), 31-33.

Abdullayev, F. S., Khasanov, K. A., & Abdullayev, R. F.

(2021, December). Pikabur body detail and stamp

project for its production. International scientific and

scientific-technical conference on “Practical and

innovative scientific research: current problems,

achievements and innovations (dedicated to the

memory of professor A.A.Yusupkhodjaev)” 6 th

December, 2021 (p. 307).

Akhmadaliev, Sh. Sh., Zagidullin, R. R., & Usmonjonov, S.

I. (2021, December). Experimental equipment for

obtaining a "pickabur" used in drilling operations.

International scientific and scientific-technical

conference on “Practical and innovative scientific

research: current problems, achievements and

innovations (dedicated to the memory of professor

A.A.Yusupkhodjaev)” 6 th December, 2021 (p. 295).

Aliev I. S. Teoretichesky analysis of the process of

combinirovannogo radialnogo obratnogo

vydavlivaniya /I. S. Aliev, N. S. Grudkina // Obrabotka

metallov davleniem: sb. Nauch. tr. – Kramatorsk:

DGMA, 2008. – No. 1 (19). - S. 55–60.

Alieva L. I Perspektive razvitiya protsesov tochnoy

obemnoy shtampovki vydavlivaniem / L. I. Alieva, Ya.

G. Zbankov // Visnik DDMA. – 2008. – No. 1 (11). - S.

13-19.

Golenkov V.A. Teoriya obrabotki metallov davleniem:

uchebnik dlya vuzov / V.A. Golenkov, S.P. Yakovlev,

S.A. Golovin, S.S. Yakovlev, V.D. Kuhar. Pod ed. V.A.

Golenkova, S.P. Yakovleva. - M.: Mashinostroenie,

2009. - 442 p

Khasan, I., Fatkhulla, A., Shahkrukh, A., & Rafail, Z.

(2021). Determination of the stress-strain state by

stamping extrusion of axisymmetric parts. International

Journal of Mechatronics and Applied Mechanics, (10),

123-128.

Vorontsov A. L. Analytic study of combined discharge of

dissimilar materials in the extrusion of rod-like articles.

Russian Engineering Research, 2000, vol. 20, № 11, pp.

47–51.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

300