Preparation of High-Strength Details from Modified Steel Alloy

110G13L

Shukhrat Chorshanbiev

a

, Gapur Atajanov

b

, Farruh Abdullaev

c

and Ibrokhim Nasirkhujaev

d

Tashkent State Technical University, 100095, University str. 2, Tashkent, Uzbekistan

Keywords: High-Strength Steel, 110G13L Alloy, Ferromanganese Modification.

Abstract: In this article, in order to increase the friction of parts made of 110G13L modified steel (tank tracks (tracks),

plows for tractors, railway relays, various parts that work under strong impact and friction), the Faculty of

Mechanics of Tashkent State Technical University, “Casting Technologies Research work was carried out in

the laboratory of the department. Ferromanganese-85 was added as a modifier to 110G13L steel in different

amounts (0.1., 0.2., 0.3., 0.4., 0.5%) and melted in an induction melting furnace during the research. The

chemical properties, hardness and structures of the molten samples were checked in the latest modern devices,

and based on the results of the conducted research, it was found that the ductility of the steel parts increased.

1 INTRODUCTION

The scientists of the world conducted extensive

research on the possibility of changing the structure of

steel by heating and cooling the alloy, changing its

internal structure, chemical, physical and mechanical

properties, heating and cooling, and achieved results.

Today, machine-building is the main consumer of

metals produced in our country. In the machine tool

industry, in the automotive and aviation industry, in

electronics and radio engineering, many machine and

accessory parts are made from metals.

Metals used in technology are mainly divided into

two groups - ferrous and non-ferrous metals. Ferrous

metals include iron and its compounds (cast iron, steel,

ferroalloys). The remaining metals and their alloys

form the group of non-ferrous metals. Until now, iron

and its alloys, considered the main machine-building

material, are of particular importance among metals.

Iron and its alloys make up 90% of metals produced

worldwide. This is explained by the fact that ferrous

metals have important physical and mechanical

properties, as well as the fact that iron ores are widely

distributed in nature, and the production of cast iron

and steel is cheap and uncomplicated (Turakhodjayev

et al., 2020a, b; Enloe et al. 2015).

a

https://orcid.org/0009-0007-7690-7089

b

https://orcid.org/0002-0009-8137-3942

c

https://orcid.org/0000-0001-6126-4028

d

https://orcid.org/0009-0007-8527-1826

The fact that metals have the ability to melt various

elements allows the atoms of the substance

surrounding the metal to diffuse into the metal at a

high temperature, as a result of which the chemical

composition of the surface layer of the metal changes.

Diffusion of atoms into a metal is a chemical process,

but temperature plays a major role in the course of this

process, so the diffusion process cannot be considered

a purely chemical process. Such processing, which

changes the chemical composition of the surface layer

of the alloy, is called chemical-thermal processing

(Turakhodjayev et al., 2023). Types of chemical-

thermal operation are described in detail when we

study the literature of our country and foreign

scientists. In recent years, the method of changing the

structure of alloys while working under pressure is

being used more and more widely (Umidjon et al.

2023; Ya Kozlov et al. 2003).). Such processing of

alloys is called thermomechanical processing. When

the alloy is deformed, not only its external appearance

changes, but also a lump is formed in it, and this

lumped alloy is thermally treated. Therefore, it is

necessary to include thermomechanical performance

in the process of studying literature specific to our

various scientific research work of thermal

performance. (Mirbabaev, 2004).

Chorshanbiev, S., Atajanov, G., Abdullaev, F. and Nasirkhujaev, I.

Preparation of High-Strength Details from Modified Steel Alloy 110G13L.

DOI: 10.5220/0014262500004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 287-293

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

287

In the scientific research centers of many

developed countries, special attention is paid to the

development of competitive techniques and

technologies in order to increase the mechanical

properties of modified steels of the 110G13L brand.

The leading scientists of the world, that is, Chinese

scientist Li Huayun, Yuan Li conducted research on

the topic "Effect of modifiers on the microstructure of

high manganese steel". A modifier with potassium and

sodium elements was selected for the experiment

(Wang et al. 2019). As a result of the research, they

found that it can reduce austenite grains and

intercrystalline carbides, reduce the amount of pearlite

in the microstructure of cast steel. British scientist

Kuanshun Luo and Chinese scientist Jingshi Ju

conducted research on the topic of "Crack resistance

and crack mechanisms of high-manganese austenitic

Gadfield steel by dry friction" (Turakhodjaev et al.,

2020; Turakhodjaev et al., 2023

; Najafabadi, et al.2014). Vietnamese scientists

Duvong Nam Nguyen and May Khan Pfamom and

Japanese scientist Duvong-Nguyen Nguyen jointly

conducted a study on the topic "Effect of rare earth

metals on the structure and mechanical properties of

high-manganese steel under impact loads" and

reported that the mechanical properties were improved

through the thermal treatment regime.

Gustav Tressi and Bianca Venturelli, scientists

from the University of Sao Paulo, Brazil, conducted a

study on "The effect of manganese content on the

corrosion resistance and impact toughness of Gadfield

steel." They modeled the process using Thermo-calc

software to estimate the ranges of temperature phase

changes and determine the casting parameters of the

steel. All five steel variant castings were melted

(1450-1500 °C) in induction furnaces with argon and

several results were obtained (Yang et al., 2023; Nodir

et. al. 2022).

2 METHODS

Induction melting of 110G13L modified steel alloy in

laboratory conditions of Tashkent State Technical

University, Faculty of Mechanics, "Foundry

Technologies" department (INDUCTION MELTING

MACHINE, Model: BF-TB2) was carried out in the

furnace.

In the first stage of the research, 1 kg of

110G13L steel slag was loaded at 20

0

C and liquefied

at a temperature of 1250-1300

0

C. Then

ferromanganese-85 in the amount of 0.2% was loaded

into the liquid metal and the temperature in the

induction furnace was raised to 1410

0

C.

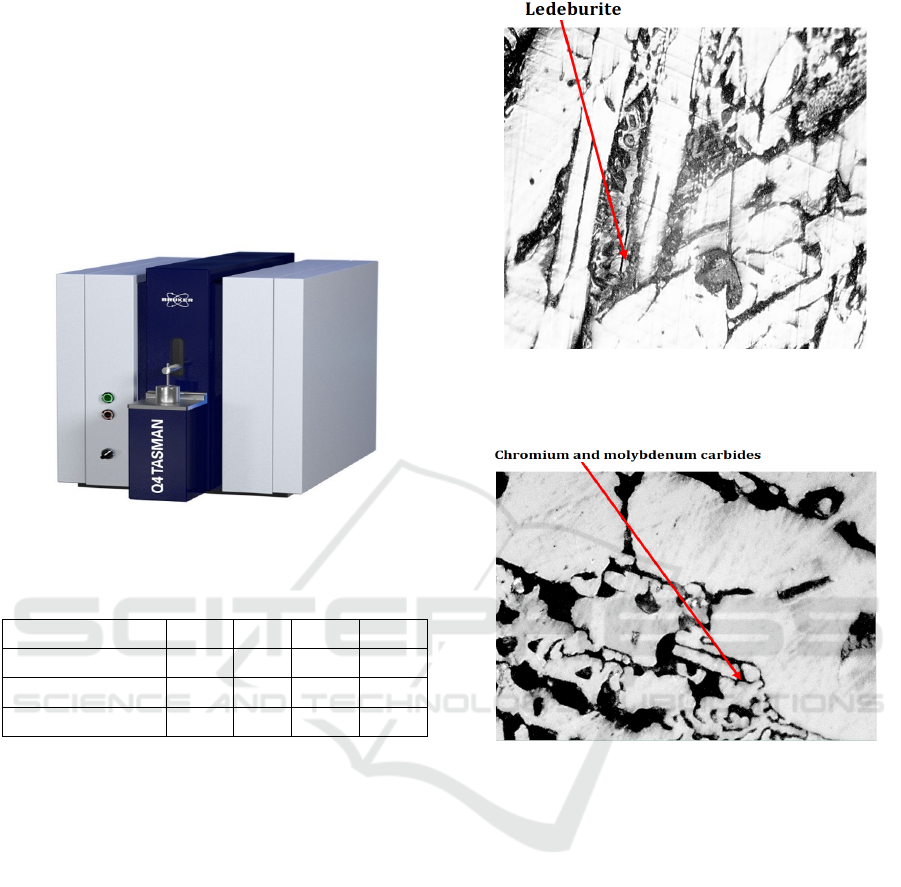

Figure 1: Induction Melting Furnace (Model: BF-TB2).

Figure 2: Induction Melting Furnace (Model: BF-TB2)

To determine the hardness of the obtained sample,

the liquid alloy taken from the furnace was poured

into a sand-clay mold at 1390-1410

0

C. The

temperature of the liquid alloy was measured on a

Kelvin PLTs 3000 device.

Figure 3: Kelvin PLTs 3000 equipment for measuring the

temperature of a liquid alloy (Nodir et al., 2022).

3 RESULTS AND DISCUSSION

As a result of the research carried out in an induction

furnace with the addition of 0.1% ferromanganese-85

as a modifier to 110G13L steel, the following

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

288

indicators were obtained: the hardness of the surface

parts of the sample according to HRB was 95.7 and

97.9, the hardness of the central part was 98.6,

according to HRB average was 97.4, HB-217.8

according to Brinell.

Chemical properties were checked on the "Q4

TASMAN Bruker" device in the center of "INNO"

Innovative Educational and Production Technopark

on the territory of Tashkent State Technical

University.

Figure 4: Kelvin PLTs 3000 equipment for measuring the

temperature of a liquid alloy (Nodir et al., 2022).

Table 1: Chemical composition of steel, weight – %

Name of material C Si Mr P

FeMn - 85 1.15 0.50 11.55 0.056

Name of material S Cr Ni Mo

FeMn - 85 0.018 0.41 0.057 0.35

The hardness of the samples prepared in the

mechanical workshop was determined by the TR-

5018 PAS Tochline lathe, using a metallographic

microscope at the MISIS branch of the Russian State

"National Research and Technology University".

Received of results conclusion from that for

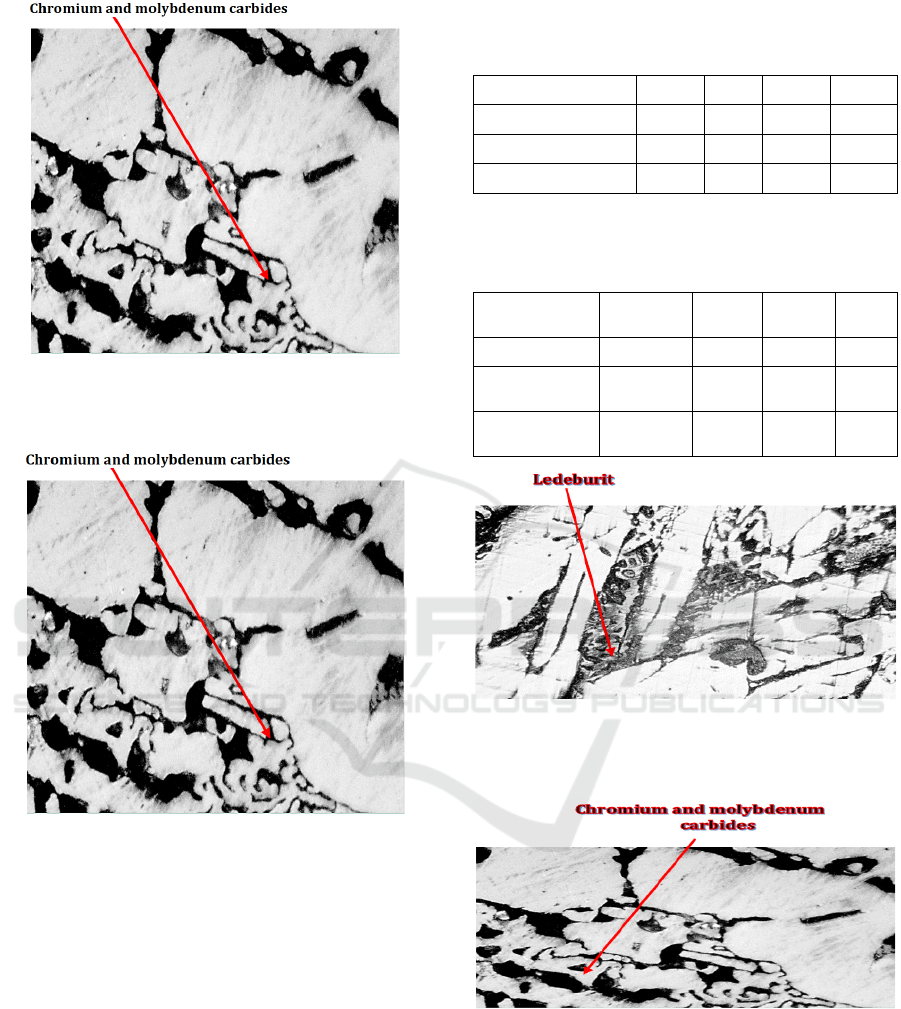

comparison, in unmodified eutectic steel, primary

molybdenum and chromium crystals up to 10 μm

wide and 70 μm long have the dimensions shown in

the above images. The mechanical properties and heat

resistance of the alloy are partially improved.

The second stage of the study was carried out in

an induction furnace with the addition of 0.2%

ferromanganese-85 as a modifier to 110G13L steel.

Figure 5: The results of structures obtained when adding

0.1% ferromanganese as a modifier to 110G13L steel, 1

x100 view.

Figure 6: The results of structures obtained when adding

0.1% ferromanganese as a modifier to 110G13L steel, 2

x400 view.

The following indicators were obtained: hardness of

the surface parts of the sample according to HRB was

96 and 97.7, hardness in the central part was 100.9,

HRB The average was 98.2, according to Brinell HB-

228.

When studying its structure and chemical

properties, the following results were obtained.

Received of results conclusion from that is that

small dispersion carbides of chromium and

molybdenum can be seen in ledeburite layers. It

reduces the size of molybdenum and chromium grains

to 3-4 microns in width and 40-45 microns in length

(Karimov et al., 2021; Mardonov et al. 2023).

Preparation of High-Strength Details from Modified Steel Alloy 110G13L

289

Figure 7: The results of structures obtained when adding

0.2% ferromanganese as a modifier to 110G13L steel, 1

x100 view.

Figure 8: The results of structures obtained when adding

0.2% ferromanganese as a modifier to 110G13L steel, 2

x400 view.

Based on the results presented above, the

following conclusions can be drawn: when 0.1% -

0.2% ferromanganese was added as a modifier to the

composition of 110G13L steel , the hardness of the

surface and central parts of the alloy was found as

follows, i.e., when 0.1% ferromanganese was added,

the hardness was HB -217.8 and adding 0.2% made

HB-228. This explains the small amount of

ferromanganese added as a modifier and the chemical

reactions formed in the alloy did not take place at the

same rate.

Table 2: Results of chemical properties obtained when

adding 0.2% ferromanganese as a modifier to 110G13L

steel are in %.

Name of material C Si Mr P

FeMn - 85 1.15 0.50 11.55 0.056

Name of material S Cr Ni Mo

FeMn - 85 0.018 0.41 0.057 0.35

Table 3: Results of chemical properties obtained when

adding 0.3% ferromanganese as a modifier to 110G13L

steel are in %.

Name of

material

C Si Mr P

FeMn - 85 1.15 0.50 11.55 0.056

Name of

material

S Cr Ni Mo

FeMn -

85

0.018 0.41 0.057 0.35

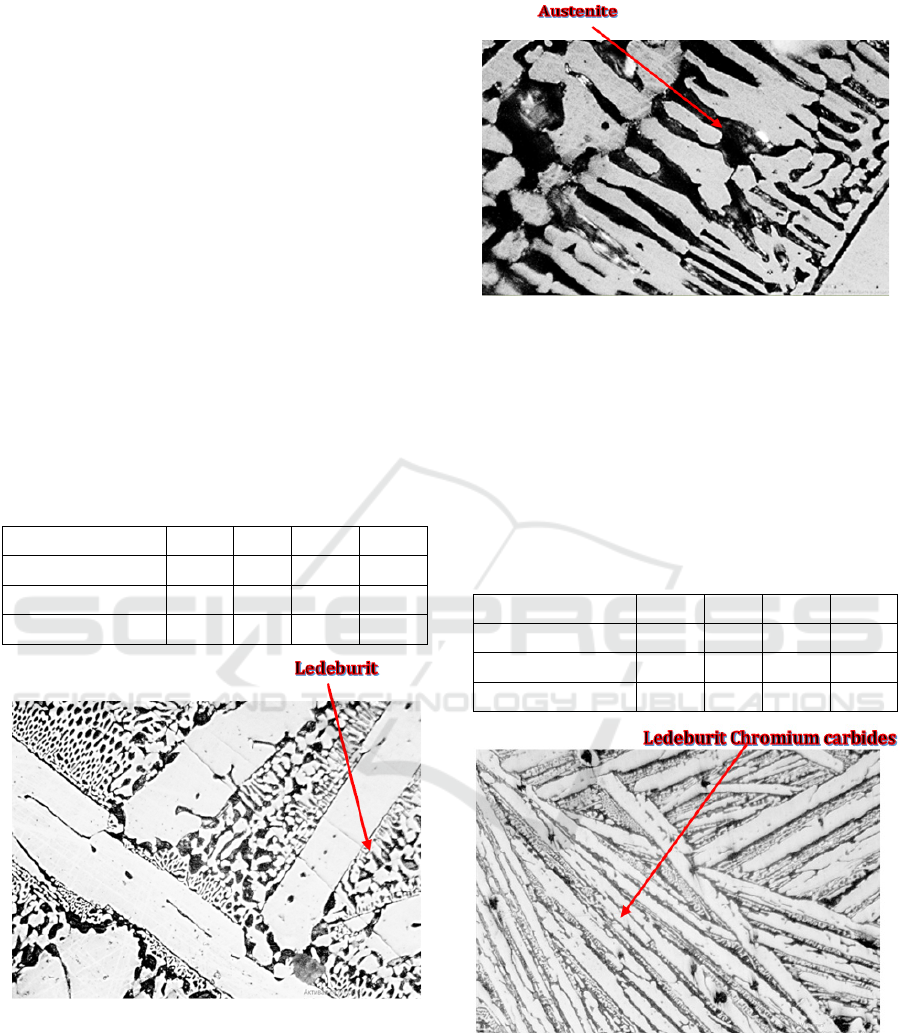

Figure 9: The results of structures obtained when adding

0.3% ferromanganese as a modifier to 110G13L steel, 1

x100 view.

Figure 10: The results of structures obtained when adding

0.3% ferromanganese as a modifier to 110G13L steel, 2

x400 view.

The third stage of the study was carried out in an

induction furnace with the addition of 0.3% of

ferromanganese-85 as a modifier to 110G13L steel.

The following indicators were obtained: the surface

hardness of the sample was 103.9 and 104.1, and the

hardness in the central part was 105.3 , averaged

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

290

104.4 on HRB , HB-269 on Brinell.When studying its

chemical properties and structure, the following

results were obtained.

The microstructure of the sample shows that the

columnar crystals are located on the upper ledeburite

base, and the rounded crystals are chromium and

molybdenum carbides among the ledeburite crystals.

The effect of molybdenum (Fig. 7) was not

noticeable, the heat resistance of the alloy may have

increased.

The fourth stage of the research was carried out in

an induction furnace with the addition of 0.4%

ferromanganese-85 as a modifier to 110G13L steel.

The following indicators were obtained: the surface

hardness of the sample was 108.8 and 109.7, and the

hardness in the central part was 113.4, averaged 110.6

on HRB, HB-311 on Brinell.

When studying its chemical properties and

structure, the following results were obtained.

Table 4: Results of chemical properties obtained when

adding 0.4% ferromanganese as a modifier to 110G13L

steel are in %.

Name of material C Si Mr P

FeMn - 85 1.15 0.50 11.55 0.056

Name of material S Cr Ni Mo

FeMn - 85 0.018 0.41 0.057 0.35

Figure 11: The results of structures obtained when adding

0.4% ferromanganese as a modifier to 110G13L steel, 1

x100 view.

Figure 12: The results of structures obtained when adding

0.4% ferromanganese as a modifier to 110G13L steel, 2

x400 view.

Don't look at it microstructure high in ledeburit

main of austenite big columnar are crystals . The size

of the crystals is 37 micrometers wide and 30

micrometers long. Figure 8 shows the quasi-dendritic

structure of ledeburite grains (Valuev et al., 2012).

Table 5: Results of chemical properties obtained when

adding 0.5% ferromanganese as a modifier to 110G13L

steel.

Name of material C Si Mr P

FeMn - 85 1.15 0.50 11.55 0.056

Name of material S Cr Ni Mo

FeMn - 85 0.018 0.41 0.057 0.35

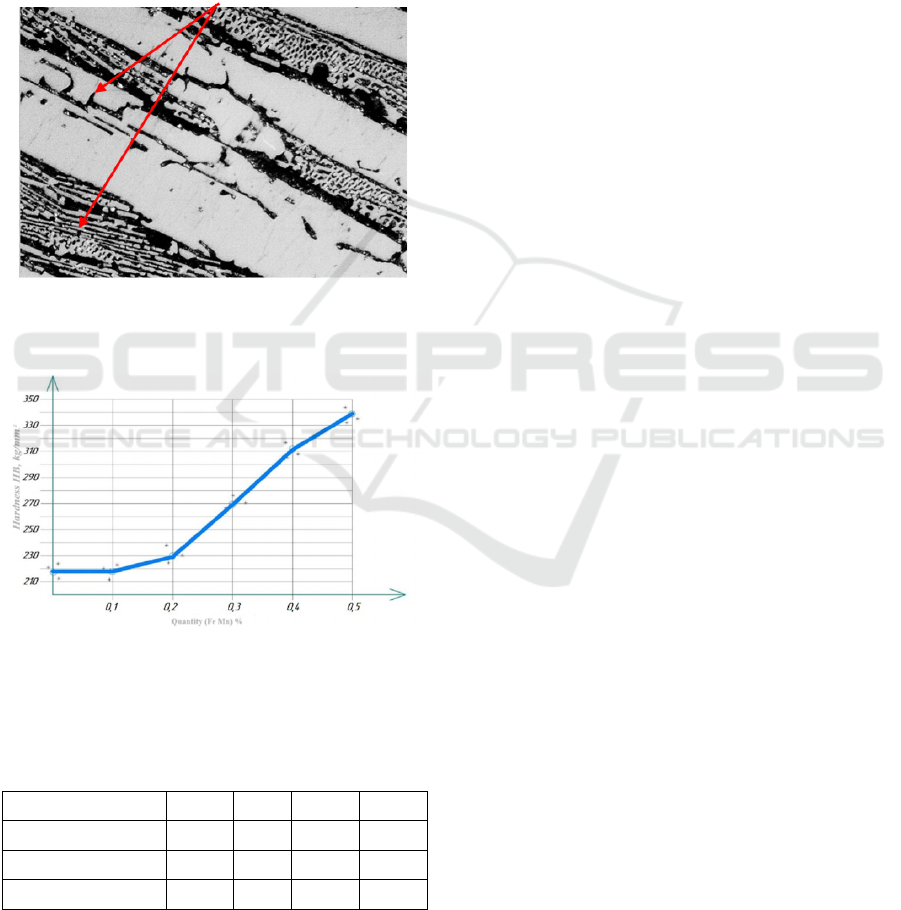

Figure 13: The results of structures obtained when adding

0.5% ferromanganese as a modifier to 110G13L steel, 1

x100 view.

The fifth stage of the research was carried out in

an induction furnace with the addition of 0.5%

ferromanganese-85 as a modifier to 110G13L steel.

The following indicators were obtained: the surface

hardness of the sample was 111.1 and 112.5, and the

Preparation of High-Strength Details from Modified Steel Alloy 110G13L

291

hardness in the central part was 113.8 , averaged

112.4 on HRB , HB-339 on Brinell.

When studying its chemical properties and

structure, the following results were obtained.

The microstructure of the sample - in the form of

primary crystals of high ledeburite. Crystals are 2-3

micrometers wide and 35-40 micrometers long.

The effect of chromium was manifested in

changing the sizes of ledeburite grains, they became

thinner and longer. A small amount of chromium

carbides is present in the ledeburite mass.

Figure 14: The results of structures obtained when adding

0.5% ferromanganese as a modifier to 110G13L steel 2

x400 view.

Figure 15: The highest hardness of 110G13L steel

according to GOST is HB-217-229. 217.8 HB when 0.1%

ferromanganese is added to the composition; 228 HB at

0.2%; 269 HB at 0.3% ; 311 HB at 0.4%; 339 HB at 0.5%.

Table 6: Hardness results.

Name of material C Si Mr P

FeMn - 85 1.15 0.50 11.55 0.056

Name of material S Cr Ni Mo

FeMn - 85 0.018 0.41 0.057 0.35

4 CONCLUSIONS

As a result of theoretical and practical research on the

development of high-strength parts from modified

110G13L steel alloy, the following recommendations

were developed:

1. Load ori musta h shortage to the composition

have the details get for It is recommended to add

ferromanganese in the amount of 0.4-0.5% as a

modifier to 110G13L steel .

2. ferromanganese was added as a modifier to

110G13L steel in the amount of 0.4%, HRB-

110.6 and NV-311 were measured according to

Brinell .

3. ferromanganese was added as a modifier to

110G13L steel in the amount of 0.5%, HRB-

112.4 and NV-339 were measured according to

Brinell .

4. ferromanganese was added as a modifier to

110G13L steel in the amount of 0.4%, it was

increased by 26.4%.

5. When 0.5% ferromanganese was added as a

modifier to 110G13L steel, it was increased by

32.4 %.

REFERENCES

Enloe C M, Fındley K O, Speer A J G. (2015). Austenite

grain growth and precipitate evolution in a carburizing

steel with combined niobium and molybdenum

additions. Metall. Mater. Trans. A, 2015, 46(A): 5308–

5328.

Karimov, K., Turakhodjaev, N., Akhmedov, A., &

Chorshanbiev, S. (2021). Mathematical model for

producing machine parts. E3S Web of Conferences,

264, 04078.

https://doi.org/10.1051/e3sconf/202126404078

Mardonov, U., Meliboyev, Y., & Shaozimova, U. S. (2023).

Effect of Static Magnetic and Pulsated Electromagnetic

Fields On the Dynamic and Kinematic Viscosity of

Metal Cutting Fluids. International Journal of

Integrated Engineering, 15(1), pp: 203-212. doi:

https://doi.org/10.30880/ijie.2023.15.01.018

Mirbabaev. V.A (2004). Technology of structural materials.

Tashkent ." Uzbekistan ". 148, 157, 162.

Najafabadi, V.N.; Amini, K.; Alamdarlo, M.B. (2014).

Investigating the Effect of Titanium Addition on the

Wear Resistance of HadfieldSteel. Metall. Res.

Technol. 2014, 111, 375–382

Nodir, T., Sarvar, T., Kamaldjan, K., Shirinkhon, T.,

Shavkat, A., & Mukhammadali, A. (2022). The effect

of lithium content on the mass of the part when alloyed

with lithium aluminum. International Journal of

Mechatronics and Applied Mechanics, 52–56.

https://doi.org/10.17683/ijomam/issue11.7

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

292

Turakhodjayev N., Chorshanbiyev S.H., Sadikova N.,

Chorshanbiyev K. (2020)a. Journal of critical reviews.

“Ways to increase the strength of shaftgear teeth

working in a highly abrasive grinding environment”.

Journal of Critical Review, No. 103, Section 4,

Roosevelt Rd, Da'an District, Taipei City, Taiwan.

Turakhodjaev N., Chorshanbiev S.H., Kamalov

J.,Yuldashev., Egamshukurov J. (2020)b. Journal of

critical reviews. “Ways to increase the strength of the

surface of the parts”. Journal of Critical Review, No.

103, Section 4, Roosevelt Rd, Da'an District, Taipei

City, Taiwan.

Turakhodjaev, N., Chorshanbiev, S.H., Tadjiev. N. (2023).

Development of Machined Durable Parts of Modified

110G13L Brand Steel. Journal of Educational

Discoveries and Lifelong Learning.Eurasian Scientific

Herald. Eurasian Scientific Bulletin. Pp: 21 - 25.

Umidjon, M., Jeltukhin, A., Meliboyev, Y., & Azamat, B.

(2023). Effect of Magnetized Cutting Fluids on Metal

Cutting Process. In Lecture Notes in Networks and

Systems: Vol. 534 LNNS. https://doi.org/10.1007/978-

3-031-15944-2_9

Wang, XJ., Sun, XJ., Song, C. Chen H., Tong, S.,Han W.,

Pan F., (2019). Grain Size-Dependent Mechanical

Properties of a High-Manganese Austenitic Steel. Acta

Metall. Sin. (Engl. Lett.) 32, 746–754 (2019).

https://doi.org/10.1007/s40195-018-0828-z

Valuev, D.V., Danilov, V.I. (2012). Reasons for negative

formation of structures in carbon steelprocessing of

pressure, J. 7th International Forum on Strategic

Technology (IFOST – 2012): Proceedings: in 2 vol.,

Tomsk, TPU Press. 2 (2012) 151–154.

Yang, Z., Ji, P., Wu, R., Wang, Y., Turakhodjaev, N., &

Kudratkhon, B. (2023). Microstructure, mechanical

properties and corrosion resistance of friction stir

welded joint of Al-Mg-Mn-Zr-Er alloy. International

Journal of Materials Research, 114(1), 65–76.

https://doi.org/10.1515/ijmr-2021-8485

Ya Kozlov, L.V.M. Kolokolchev, K.N.Vdovik, E.B.Ten,

L.B.Dolgopolova, A.A.Filippenkov (2003). Production

of steel castings, textbook edited by L. Ya. Kozlov.,

Moscow, Misis, 357 p.

Preparation of High-Strength Details from Modified Steel Alloy 110G13L

293