Pneumatic Feed Mechanism for Precise Seeding of Peanut Seeds

Feruza Alimova

1a

, Boikov Vladimir Petrovich

2b

, Jdanovich Cheslav Iosifovich

2c

1

Tashkent State Technical University, Mechanical Engineering Department, 100057 Tashkent, Uzbekistan

2

Belarusian National Technical University, Minsk, Republic of Belarus

Keywords: Pneumatic Mechanism, Peanut Seeding, Precision Sowing.

Abstract: The article presents the results of research work on the development of sowing machines that ensure high-

quality implementation of the technological operation of sowing peanut seeds. The results of research on the

development of a pneumatic feed mechanism with optimal parameters for precise sowing of peanut seeds in

a dotted method, taking into account the peculiarities of the soil and climatic conditions of Uzbekistan, are

presented. An improved design of a feed mechanism, including a sowing disc that combines the functions of

turning the mass of seeds in the seed chamber, clearly capturing seeds by dosing elements, removing seeds

from the seed chamber and transporting them to the unloading zone has been proposed. This design solution

helps to minimize the process of seed damage, improve the process of capturing and holding seeds in the cells

of the sowing disk, which improves the accuracy of their dotted sowing into the cluster and sustainable

accurate sowing of peanut seeds according to the given seed consumption. The rational parameters of the

sowing disk of a pneumatic feed mechanism, ensuring sowing of peanuts with uniform distribution of seeds-

18% and seed consumption - 60 kg/ha are presented.

1 INTRODUCTION

At the present stage of development of agricultural

production, one of the main tasks of the agricultural

policy of the Republic of Uzbekistan is the need to

produce various oilseeds, including peanuts, which

are valuable raw materials for the confectionery,

medical and technical industries. In Uzbekistan,

peanut crops occupy about 7 thousand hectares. The

soil and climatic conditions of Uzbekistan make it

possible to grow peanuts in almost all areas with a

yield of 27...30 c/ha (Program for researching

scientific priorities of agriculture, global, regional

and territorial

scheduled for 2022-2026, 2021).

The sowing scheme should provide a nutritional

area in rainfed conditions - 70x(25-30), in irrigated

conditions - 70x(10-15) cm. In continuous plantings,

the distance between bunch-type plants can be 30 x

60 cm or 15 x 75 cm; for shoot types, more space is

allowed (Yang et al., 2022), (Feruza et al., 2024).

Peanuts are often sown together with other species.

a

https://orcid.org/0000-0003-1463-6969

b

https://orcid.org/0000-0003-2561-0270

c

https://orcid.org/0000-0002-3165-7625

The most common sowing method is wide-row

with row spacing of 70 cm. For this, corn or cotton

seeders are used. Peanuts can be cultivated using the

checkrowing method according to a 70x70 cm pattern

with 6-8 plants in one hill. This method has the

advantage of increasing productivity and reducing

labor costs for caring for crops by 1.5-2.0 times.

One of the most important conditions for

obtaining high peanut yields is high-quality sowing of

seeds and the technology for its implementation,

carried out in a short agrotechnical time frame.

Currently, in world practice, the creation of seeding

aggregates with high productivity and adapted to

specific soil and climatic conditions is carried out in

the main directions: increasing the level of versatility

of seeders and the use of improved pneumatic

precision seeding devices (Alimova et al., 2023),

(Maojian et al., 2022). So, for example, in seeders that

operate at high speeds, a pneumatic seed dispenser is

widely used, which provides dotted single-grain

seeding of uncalibrated seeds and is highly resistant

to vibrations (Wan et al., 2020), (Xiao et al., 2014).

To improve the movement of seeds, activate the

Alimova, F., Petrovich, B. V. and Iosifovich, J. C.

Pneumatic Feed Mechanism for Precise Seeding of Peanut Seeds.

DOI: 10.5220/0014262400004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 281-286

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

281

supply of seeds to the collection zones and transport

them to the dumping site, use a brush-type seed

supply device, flexible belt type seed feeder,

compartment type section feeder (Yudao et al., 2020),

(Yang 2016). When filling the intake chamber of the

device with seeds, to speed up the suction process and

prevent clogging of the sampling holes, the “suck

before and blow after” model is used, which mainly

consists of a combination seed dispenser with air

suction, three-position switch, seed waste collection

device, vacuum fan, and so on (Liao et al., 2004). The

inexpediency of widespread use of expensive foreign-

made seeders is associated with the specifics of the

republic's fields for peanut crops, which have small

areas. The use of wide-cut sowing aggregates in such

conditions is impossible.

However, the existing models of domestic seeders

today do not fully meet the agrotechnical

requirements for uniform sowing of seeds and at the

same time lead to high costs. In this regard, it is very

important to develop a sowing apparatus that is highly

accurately adapted to the specific soil and climatic

conditions of Uzbekistan. Due to the fact that in the

republic the seed material is a mixture of seeds of

different varieties and calibers, the possibility of

precise sowing with mechanical devices is practically

excluded. In pneumatic devices, when installing disks

with medium-sized holes and the presence of large

seeds, sowing stops, when installing disks with large

holes for large seeds, the holes are quickly clogged

with medium seeds, and small ones pass through the

holes and are thrown out by the exhauster onto the

field surface.

Analysis of the results of preliminary studies of

the operation of these seeders for sowing peanut seeds

showed increased crushing and damage to seeds,

clogging of sowing elements with seed material,

uneven sowing, which leads to additional labor costs:

replanting, thinning and excessive consumption of

seed material.

The analysis showed that in most cases, the

physical and mechanical properties of seeds of

complex shapes (peanuts, sunflower) significantly

limit the range of types of sowing devices capable of

ensuring the stability of the process of dosing and

distribution of seed material, which indicates the need

to create new types of working bodies to ensure high-

quality single selection and seed distribution. Based

on the analysis, the design of a universal sowing

apparatus has been developed, intended for single

selection of peanut seeds having a complex shape (Yu

et al., 2014). Purpose of the study - increasing the

uniformity and stability of seed distribution in a row

based on improving the technological process of

dotted sowing of peanut seeds with minimal crushing

through the development and improvement of the

design of the sowing apparatus, as well as the

justification of its parameters and operating modes

(Liu et al., 2016).

2 MATERIALS AND METHODS

Based on an analysis of the results of research and

development work on the mechanization of sowing

various seeds of agricultural crops, the type and

design of the apparatus for sowing peanut seeds was

selected, and the direction of theoretical and

experimental research was determined. The general

methodology included conducting exploratory

experiments, developing theoretical premises,

experimental studies in laboratory and field

conditions, and economic evaluation of research

results. The studies were carried out in the Central

Asian region under the conditions of the sharply

continental climate of the Republic of Uzbekistan on

typical gray soils. The sowing rate of husked seeds is

50-80 kg/ha. The optimal plant density is 100-120

thousand/ha. The sowing depth is 6-8 cm and depends

on the moisture content and granulometric

composition of the soil.

In accordance with the purpose of the work, the

task of the research was to study the physical and

mechanical properties of peanut seeds of zoned

varieties. The Uzbek Crop Research Institute

(UzNIIR) is studying peanut samples from the

International Crop Research Institute for the Semi-

Arid Tropics (ICRISAT). As a result of the study, two

varieties of peanuts were zoned: “Salomat” and

“Mumtoz”. The Mumtoz variety is zoned for main

sowing, and the Salomat variety is zoned for both

main and re-sowing in the south of Uzbekistan

(Kashkadarya and Surkhandarya regions). In

addition, the Tashkent-112 variety, belonging to the

Valencia group and the Kibray-4 peanut variety,

belonging to the Virginia group, are currently

cultivated in Uzbekistan.

When determining the physical and mechanical

characteristics of peanut seeds, a developed

methodology was used to determine the

damageability and shear stress of seeds, and

instruments were also used to measure pressure and

air flow speed. In the process of experimental

research, a universal laboratory bench, experimental

samples of the apparatus, and a field installation were

used.

In the process of research, the basic laws of higher

mathematics, theoretical mechanics, laws and rules of

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

282

mathematical statistics, methods of mathematical

planning of experiments and strain gauges, as well as

methods given in existing regulatory documents

(GOST 20915-11, GOST 31345-2017, UzDst

319:2017, RD Uz 63.03-98, GOST R 53056-2008).

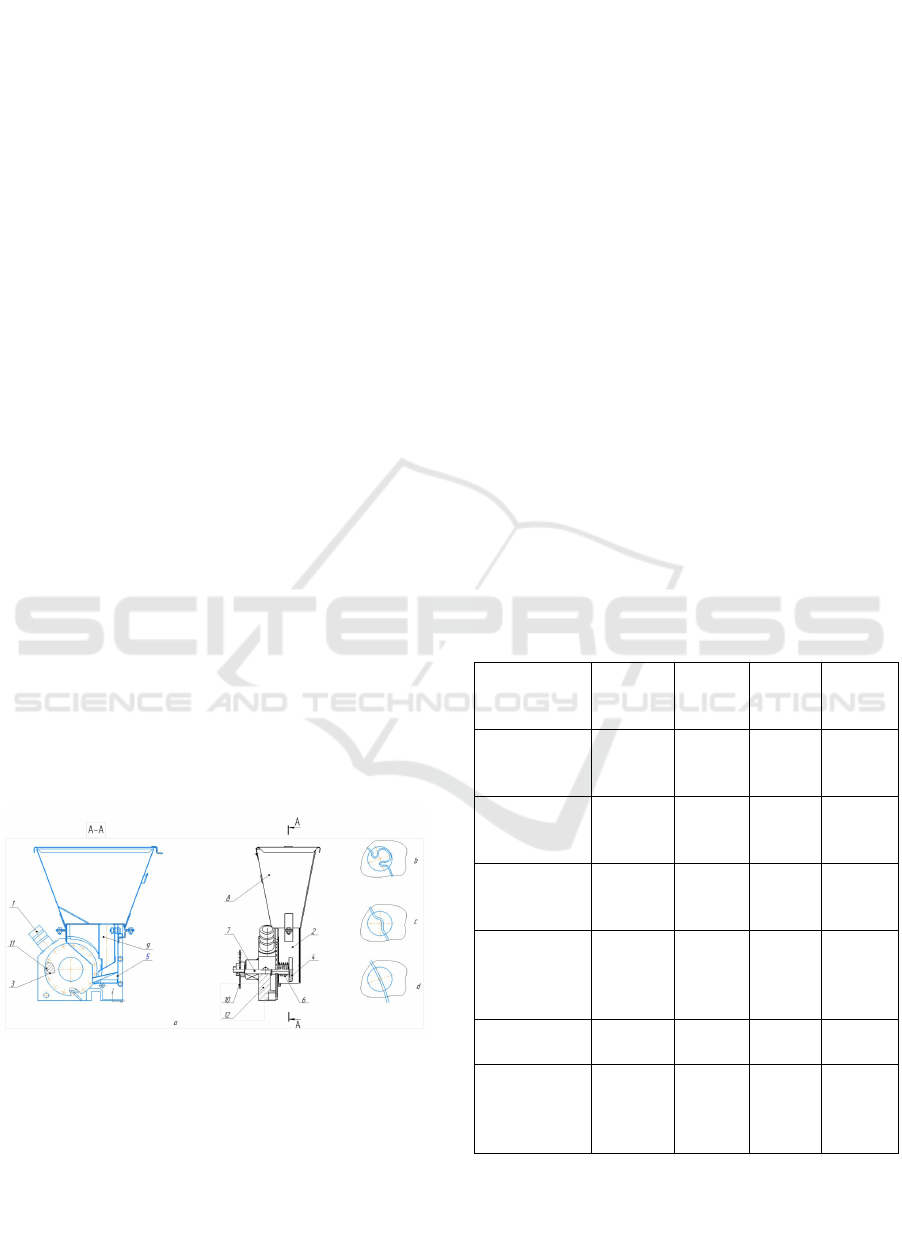

Structure and Working Principle of Pneumatic

Feed Mechanism. The pneumatic sowing apparatus

has a housing combined with the shell of the vacuum

chamber and a sowing disk tightly adjacent to it, a

seed hopper located above the intake chamber as

shown in Figure 1. A cutter for excess seeds is

installed in the upper part of the intake chamber.

Inside the intake chamber there is a dispenser with a

dosing window. The intake chamber fits tightly to the

housing of the sowing device, combined with the

shell of the vacuum chamber and the sowing disk.

The sowing disc is secured to the shaft using a

clamping washer and a bolt. In order to create the

minimum required column of seeds in the seed

capture zone, a groove is made on the dispenser,

which allows the dispenser to be installed at a

different angle to the sowing disk using a lock. A tight

fit of the sowing disk to the housing of the apparatus,

combined with the shell of the vacuum chamber, is

achieved using a spring, thereby ensuring tight

contact between the sowing disk and the shell of the

vacuum chamber. According to the design, in order to

minimize the contact of easily damaged seeds with

the sharp edges of the rotating disk, in the proposed

sowing device, between the housing of the device,

combined with the shell of the vacuum chamber and

the intake chamber, a locking plate is installed, equal

in thickness to the sowing disk.

Figure 1: a-General view of pneumatic feed mechanism:

1-suker; 2-intake chamber; 3-sowing disk; 4-washer; 5-

locking plate; 6-spring; 7- shaft; 8- seed hopper; 9-

dispenser; 10-sprokit; 11- hole; b- hole with Ω-shaped

jumper, c- hole with S-shaped jumper, d- hole with straight-

shaped jumper.

Due to the fact that peanut seeds have a complex

shape and vary in weight and size, the disk cells must

ensure precise suction with a minimum of damage,

excluding slaughter in the cells and gaps during

sowing. For this purpose, the disk cells are made in

the form of holes of increased diameter with jumpers.

3 RESULTS AND DISCUSSION

An analysis of existing technologies and the technical

means used in their implementation is made. Data are

presented on the possibility of sowing peanut seeds in

a dotted manner using existing pneumatic sowing

devices. The technical characteristics of dotted

pneumatic seeders used today in the fields of our

Republic are considered. To find the type of sowing

device for sowing peanut seeds, tests were carried out

on the pneumatic devices of the SPP-8FS (Russia),

SMH-4-04-01 (Uzbekistan), TC-M 4150 (Russia),

SUPN-6(8)M (Russia) seeders. The tests were carried

out on a laboratory bench, the specified operating

mode corresponded to a seeder speed of 6 km/h.

Disks for sowing corn with cells with a diameter of

5.0 mm were used. The results are shown in Table 1.

Table 1: Results of laboratory tests of pneumatic sowing

devices for sowing peanut seeds of the Tashkent-112

Indicators SUPN-

6(8)M

SPP-

8FS

SMH

-4-04-

01

TC-M

4150

Weigh

t

of

sown

seeds,

g

412.3 407.8 203.9 404.7

Weigh

t

of

whole

seeds, g/%

390.0/

94.6

377.1/

92.5

186.2/

91.3

389,3/

96.2

Mass of

crushed

seeds,

g

/%

10.3/

2.5

12.35

/3.0

6.93/

3.4

7.7/1.9

Mass of

seeds with

damaged

shell, g/%

12.0/

2.9

18.3/

4.5

10.81/

5.3

7.7/1.9

Total

damage, %

5.4 7.5 8.7 3.8

Seed

sowing

rate, M

ср

,

p

cs/

m

6.7 8.7 6.6 7.3

Based on the test results, it can be concluded that

the operation of the above devices does not meet the

initial requirements for sowing peanuts: seeding rate

Pneumatic Feed Mechanism for Precise Seeding of Peanut Seeds

283

- 9...12 pieces / m (140...170 thousand pieces / ha),

crushing - no more than 2%.

Key-Parameter Selection and Seeding Process

Analysis. Selection of key parameters and

determination of the optimal diameter of the sampling

holes on the seeding disc

The required vacuum ΔР in the chamber is

determined by the formula

ΔР ≥

р

×

×

× × ×

,

where 𝑑

is the diameter of the hole; 𝑄

- seed

weight; φ - coefficient of friction of the seed in the

cell; 𝑚

р

- average seed weight; 𝑘

- rarefaction

coefficient.

Suction force F

pr

acting on the seed taking into

account Newton’s classical formula:

F

pr

= 𝑘

а

× f × ɣ ×

(

)

,

where 𝑘

а

is the aerodynamic coefficient; ɣ - specific

gravity of air; f is the cross-sectional area of the seed;

𝑉

,𝑉

- air and seed movement speeds; g is the

acceleration of free fall.

𝑘

а

=

𝐹

ΔР × 𝑆

The suction force is expressed through the area of the

hole S and the vacuum ΔP.

P = k × 𝛥Р×𝑆,

where k is a proportionality coefficient that takes into

account the total effects of various factors.

Analysis of the above formulas shows that the suction

force depends on the speed of movement of the seeds,

the magnitude of the vacuum, the size of the seeds and

the cross-sectional area of the hole. The excess of this

force over the force of weight and centrifugal force

contributes to the reliable capture of seeds by the

holes on the disk, holding them in the hole until the

hole with the seed arrives in the position of dropping

into the groove formed by the opener. Focusing on

sowing large peanut seeds as a first approximation,

the diameter of the hole on the disk should be at least

7.5 mm.

Force Analysis of Seed Fixation on the Disk Hole.

To ensure accurate sowing of peanut seeds that vary

in size and weight, a jumper must be installed in the

disc holes, which at the same time increases

resistance and reduces air flow speed. The seed, fixed

to the hole of the disk in the seed chamber, must be

accurately transported to the discharge point

(between the cheeks of the opener) and must not leave

it during movement. One of the decisive factors when

choosing speed modes of operation of the device is

the permissible angular speed of the disk at which the

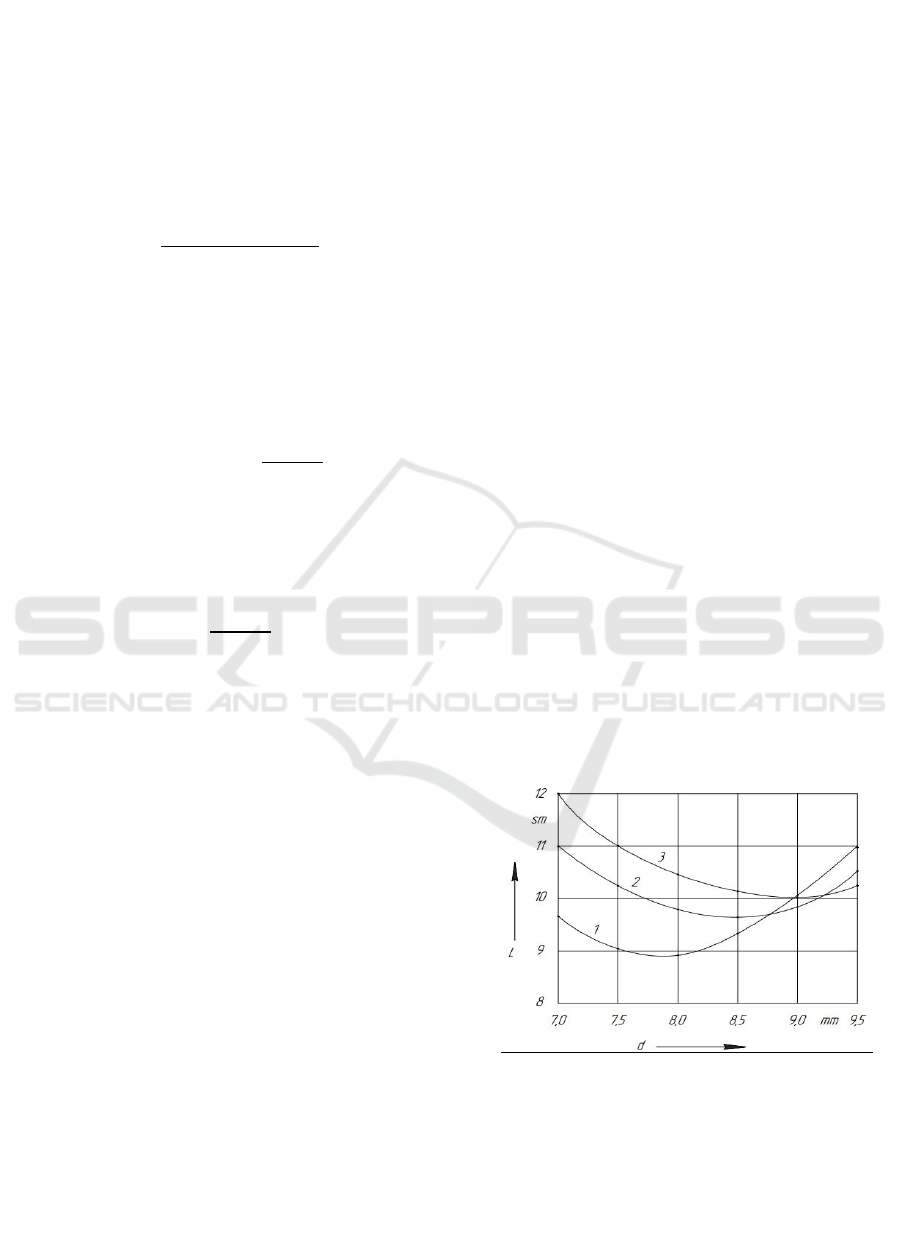

seed does not leave the hole. The theoretical analysis

carried out made it possible to select the range of

permissible angular velocities of the disk when

working with seeds with the highest and lowest

weight force, depending on the vacuum force in the

hole R

v

as shown in Figure 2. The dependence is

parabolic in nature and for a vacuum force P

v

= 0.055

N, the permissible angular velocity should not exceed

24 rad/s

Selection of the Cell of the Seeding Disk. To

reliably capture very large and heavy peanut seeds by

the cell of the sowing disk, it is necessary to have a

large diameter, into which, however, small seeds will

freely pass and medium-sized seeds will jam.

Therefore, in the experimental apparatus, the sowing

disk cells are made in the form of holes of increased

diameter with jumpers. For experimental testing and

selection of the jumper shape, disks were made with

holes of different diameters and different jumper

shapes (straight, S-shaped and Ω-shaped). According

to the research results as shown in Figure 3, the most

stable interval between seeds was obtained with holes

with diameters of 7.5...9.5 mm with an Ω-shaped

jumper. The analysis of the study of the influence of

jumpers on the crushing of peanut seeds when

working with experimental disks is no more than

0.6%, which satisfies the initial requirements.

Figure 2: Permissible angular speed of the disk ω depending

on the force of pressing the seed to the cell: 1 - for seeds

weighing 0.0037 N; 2 - for seeds weighing 0.0058 N

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

284

Figure 3: Changing the interval between seeds in a row (L)

depending on the diameter of the hole (d): 1- with Ω-shaped

jumper; 2-with S-shaped jumper; 3-with a straight jumper

The influence of the rotation frequency of a disk

with different cells on the interval between seeds in a

row during operation of the apparatus under study

was studied. According to the experimental results as

shown in Figure 4, as the disk rotation speed

increases, the seeding uniformity decreases. Thus,

cells were accepted for further work - holes with a

diameter of 7.5...9.5 mm with Ω-shaped and S-shaped

jumpers.

Figure 4: Change in the coefficient of variation of the

interval between seeds in a row (V

L

) depending on the

rotation speed of the sowing disk (ω) with cells: 1 - with an

Ω-shaped jumper; 2-with S-shaped jumper; 3 -with straight

shaped jumper

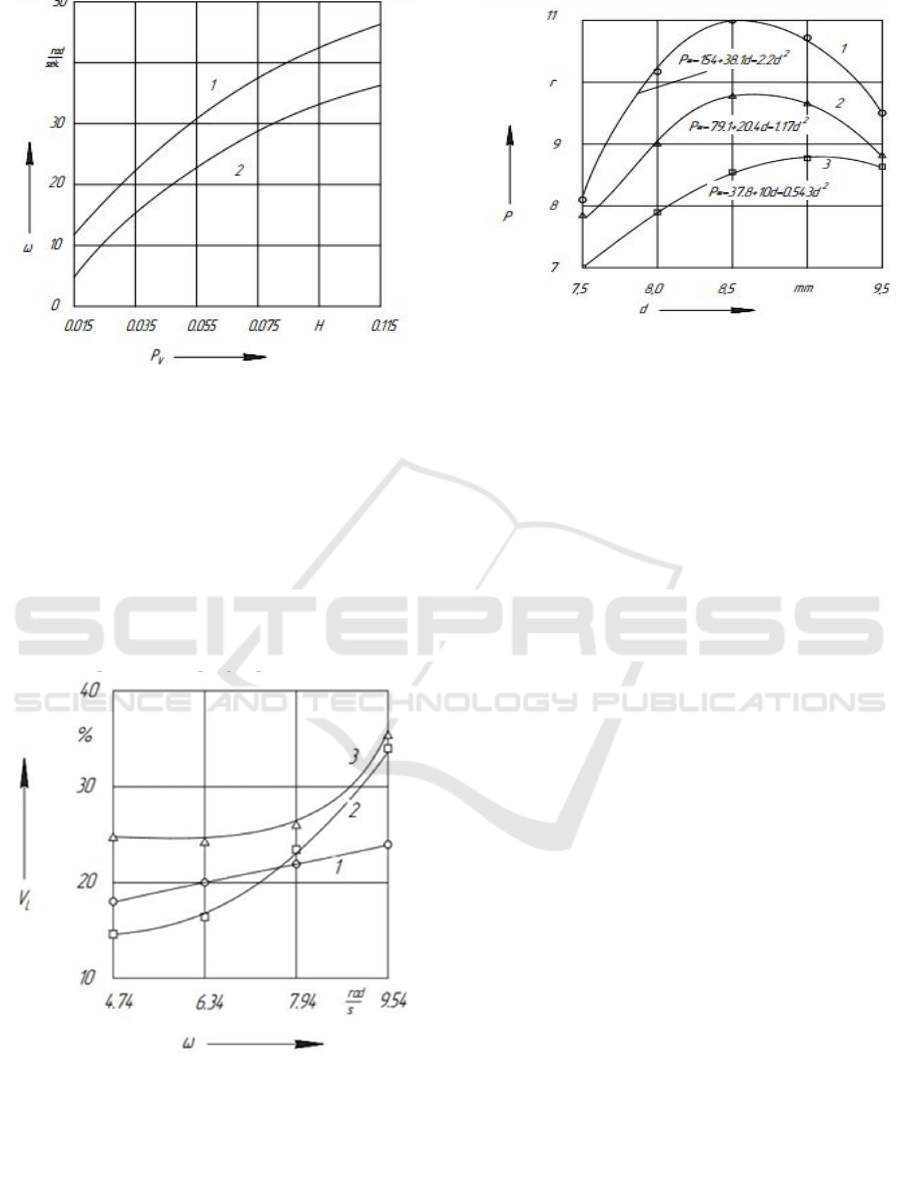

Figure 5: Change in the force of pressing a peanut seed P to

flat disk cells of various diameters when the seed is

positioned: 1 - with a spheroidal end; 2 - sharp end; 3 - flat

4 CONCLUSIONS

1. A promising direction has been identified for

increasing the efficiency of the process of precise

sowing of seeds of complex shapes. In accordance

with the chosen direction, the technological and

design parameters of the dotted seeding apparatus

have been developed and justified. Patterns of

changes in the quality indicators of the precision

seeding process were obtained depending on the

parameters of the sowing disk cells and the

kinematic operating modes of the apparatus.

2. Based on the research, a sowing apparatus has

been developed that provides dotted sowing of

peanut seeds. The obtained analytical

dependencies and theoretical conclusions can be

used by design organizations and research

institutions when creating new designs of seeding

devices for precision seeders.

3 The most suitable for precise sowing of peanut

seeds is a vacuum pneumatic device with a sowing

disk having cells in the form of holes with a

transverse Ω-shaped jumper, which ensures

trouble-free operation of the device with

uniformity of seed distribution V = 18% and seed

consumption of 60 kg/ha. Seeding disk

parameters: angular speed - 4.8….5.2 rad/s;

thickness - 4 mm; number of cells - 16 pcs; cell

diameter - 8.5 mm.

Pneumatic Feed Mechanism for Precise Seeding of Peanut Seeds

285

REFERENCES

BIO Web of Conferences , 01026 (2024) I-CRAFT-2023

85 https://doi.org/10.1051/bioconf/202485 01026

F A Alimova, M T Saidova and B Sh Primkulov (2023)

Pneumatic feed mechanism for accurate sowing of bare

cotton seeds AEGIS-III-2023 IOP Conf. Series: Earth

and Environmental Science 1231 (2023) 012012 IOP

Publishing doi:10.1088/1755-1315/1231/1/012012

https://scholar.google.com/scholar?oi=bibs&hl=ru&cit

es=4322034996561925007&as_sdt=5

Feruza Alimova, Mukhayyokhon Saidova, Bekzod

Primqulov, and Tunahan Erdem (2024) Optimization of

the parameters of the pneumatic feed mechanism for

precise clustered sowing

https://scholar.google.com/scholar?oi=bibs&cluster=1316

6930500057174961&btnI=1&hl=ru

Liao, Q.; Deng, Z.; Huang, H.(2004) Application of the

high speed photography checking the precision

metering performances. Trans. J. Huazhong Agric.

Univ. 2004, 22, 570–573.

Liu, H.; Xu, X.; Liu, J.; Wang, C. Working characteristics

of vertical shallow-basin type seed-metering device

based on high-speed photography and virtual

simulation. Trans. CSAE 2016, 32, 13–19.

Maojian Wei, Peisong Diao, Wenjun Wang (2022) Design

and experiment of the seed delivery device with a

rotating brush wheel for precision seeder. Scientific

Paper • Eng. agríc. 42 https://doi.org/10.1590/1809-

4430-Eng.Agric.v42n6e20220089/2022

https://www.researchgate.net/publication/365809234

“Program for researching scientific priorities of agriculture,

global, regional and territorial scheduled for 2022-

2026” approved by the Cabinet of Ministers on April

24. 2021 -1 in conditions of typical irrigated gray soils

of the Tashkent region pp 16

Wan, S.; Zhang, J.; Zhang, Z.(2020) A major change in

peanut planting technology: Single seed precision

sowing. Trans. Chin. J. Oil Crops 2020, 42, 927–933.

Xiao Lian Lü, Zhi Chao Hu, Hui Juan Zhang, Wei Wang

(2014) https://doi.org/10.4028/www.scien

tific.net/AMR.945-949.330 Design and Research of the

Air-Suction Peanut Precision Dibbler, Advances in

Manufacturing Science and Engineering V. Advanced

Materials Research (Volumes 945-949). June 2014

330-334p

Yang Xiang, Jianming Kang, Chunyan Zhang, Qiangji

Peng, Ningning Zhang and Xiaoyu Wang (2022)

Analysis and Optimization Test of the Peanut Seeding

Process with an Air-Suction Roller Dibbler. Agriculture

2022, 12(11), 1942; https://doi

.org/10.3390/agriculture12111942 Submission

received: 25 October 2022 / Revised: 15 November

2022 / Accepted: 16 November 2022 / Published: 17

November 2022

Yang, L.; Yan, B.; Zhang, D.; Zhang, T.; Wang, Y.; Cui,

T.(2016) Research Progress on Precision Planting

Technology of Maize. Trans. Chin. Soc. Agric. Mach.

2016, 47, 38–48.

Yu, J.; Ding, Y.; Liao, Y.; Cong, J.; Liao, Q.(2014) High-

speed photography analysis of dropping trajectory on

pneumatic metering device for rapeseed. Trans. J.

Huazhong Agric. Univ. 2014, 33, 103–108.

Yudao Li, Zhanhua Song, Fade Li, Yinfa Yan and others.

Design and Test of Combined Air Suction Cotton Breed

Seeder.Journal of Engineering. 2020(29):1-

11DOI:10.1155/2020/7598164

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

286