Choosing the Optimum Modifier to Increase the Durability of Parts

Made of 110g13l Steel

Shukhrat Chorshanbiev

a

, Nodir Turakhodjaev

b

, Ibrokhim Nasirkhujaev

c

and Asrorkhan Saidakhmatov

d

Tashkent State Technical University, 100095, University str. 2, Tashkent, Uzbekistan

Keywords: Modifier, Steel, Durability Optimization

Abstract: In this article, the production of high-quality, abrasion-resistant, high-strength grinding cones and other

similar details and heavy industrial products for machine-building production enterprises that meet world

standards sets an important task for experts and scientists in this field to improve the existing equipment and

technology. It is important to improve the existing technology and technologies in this field. In turn, the

increase in the level of improvement of equipment in machine-building production enterprises also requires

paying great attention to the quality of metals. It is shown that steel plants, as a rule, do not have special

equipment for processing steel. Under these conditions, the only and very effective way to practically improve

the quality of steel is to process the liquid metal in the steel casting department with special complex modifier

alloys. Modification of metals and alloys (its variety) is a deep process of their presence, which actively affects

the state of metal solutions during crystallization by introducing small additions of substances (modifiers) that

lead to changes in the morphology of mirror inclusions.

1 INTRODUCTION

In production enterprises of the Republic of

Uzbekistan, measures are being taken to obtain high-

quality cast products during the period of liquefaction

of steels with the help of electric arc and induction

furnaces. In production enterprises of the Republic of

Uzbekistan, measures are being taken to obtain high-

quality cast products during the period of liquefaction

of steels with the help of electric arc and induction

furnaces. In this regard, it is important to increase the

priority of research on the improvement of

technologies that provide resource and energy

efficiency in the liquefaction of steels widely used in

industry.

Mechanical engineering consists of a number of

technological processes in production enterprises that

form a unique technological chain. This chain is

closely related to the work unit of each unit and the

work quality of the preceding machines. Considering

this issue, it can be concluded that the influence of

a

https://orcid.org/0009-0007-7690-7089

b

https://orcid.org/0009-0009-4970-5785

c

https://orcid.org/0000-0001-6126-4028

d

https://orcid.org/0009-0002-2864-9699

technological chain equipment on the quality

indicators of machine-building enterprises and heavy

industrial products is great. Therefore, the more

efficient operation of machine-building enterprises

and heavy industry technological equipment without

damage depends to a large extent on the strength of

their details. This mainly requires studying the

working process of the parts that rub against each

other (Dubinin, 1961, Nasser, 2002).

Many scientific practitioners and experts know

that metals used in technology are mainly divided into

two groups - ferrous and non-ferrous metals. Ferrous

metals include iron and its compounds (cast iron,

steel, ferrocolates). The rest of the metals and their

alloys make up the group of non-ferrous metals.

Until now, iron and its alloys, considered the main

material of machine building, are of special

importance among metals. 90% of metals produced

worldwide are iron and its alloys. This is explained

by the fact that ferrous metals have important

physical and mechanical properties, as well as the fact

264

Chorshanbiev, S., Turakhodjaev, N., Nasirkhujaev, I. and Saidakhmatov, A.

Choosing the Optimum Modifier to Increase the Durability of Parts Made of 110g13l Steel.

DOI: 10.5220/0014261200004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 264-268

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

that iron ores are widely distributed in nature, and the

production of cast iron and steel is cheap and

uncomplicated.

The fact that metals have the ability to dissolve

various elements allows the atoms of the substance

surrounding the metal to diffuse into the metal at high

temperature, as a result of which the chemical

composition of the metal surface layer changes.

Diffusion of atoms into a metal is a chemical process,

but temperature plays a major role during this

process, so the diffusion process cannot be considered

a pure chemical process. Such treatment, which

changes the chemical composition of the surface layer

of the alloy, is called chemical-thermal treatment.

When we study the literature of our country and

foreign scientists, the types of chemical-thermal work

are described in detail. In recent years, the method of

changing the structure of alloys simultaneously with

working under pressure is being used more and more

widely. Such processing of alloys is called

thermomechanical processing. When the alloy is

deformed, not only its appearance changes, but also a

coating is formed in it, this coated alloy is heat

treated. Therefore, thermomechanical indicators

should also be included in the literature review

process, which is characteristic of our

various

scientific researches on thermal indicators

(Mirboboev et al., 2004).

2 METHODS

It is important to improve the modern machine-

building industry in the world, to create new

improved technologies, machines and mechanisms

that meet global requirements for various branches of

production, to replace competitive and imported

industries, to conduct deep fundamental research, and

to solve current scientific and technical issues. Also,

the production of high-quality, high-strength and

high-capacity heavy industrial products that meet

world standards has set an important task for experts

and scientists in this field.

In this regard, special attention is paid to the

development of scientific centers of developed

countries, including Russia, Germany, USA,

England, Japan, China and other countries, in order to

create competitive techniques and technologies in

production. In particular, with the help of modifiers

of various composition, they carry out a number of

scientific and research works on obtaining high-

quality castings from parts with high strength

properties of steel and increasing the service life of

mechanical engineering parts made from them.

Scientists from all over the world have conducted

extensive research on the possibilities of heating and

cooling the alloy, making changes to its internal

structure, chemical, physical and mechanical

properties, changing the structure of steel by heating

and cooling, and achieved results.

Modern engineering is the main consumer of

metals produced in our country. A large number of

machine parts and accessories are made of metals in

the machine tool industry, in the automotive and

aviation industries, in electronics and radio

engineering.

Metals used in technology are mainly divided into

two groups - ferrous and non-ferrous metals. Ferrous

metals include iron and its compounds (cast iron,

steel, ferrocolates). The rest of the metals and their

alloys make up the group of non-ferrous metals.

Until now, iron and its alloys, considered the main

material of machine building, are of special

importance among metals. 90% of metals produced

worldwide are iron and its alloys. This is explained

by the fact that ferrous metals have important

physical and mechanical properties, as well as the fact

that iron ores are widely distributed in nature, and the

production of cast iron and steel is cheap and

uncomplicated (Nurmurodov et al., 2016,

Torakho'jaev et al., 2018).

To stay competitive in the steel industry,

steelmakers use a variety of production methods to

reduce production costs without compromising

product quality. In steel production, the production

process plays an important role in its purity. Recently,

the increase in the requirements for the level of purity

requires the optimization of the production process to

meet this demand. Often, the types and distribution of

non-metallic inclusions in steel determine the purity

of the steel. For optimization, it is necessary to fully

evaluate the production process, non-metallic

inclusions in steel, and extensive work is being

carried out by world researchers to implement many

measures to control and clean up non-metallic

inclusions in steel.

Grinding cones are widely used in metallurgical

enterprises of the Republic of Uzbekistan, including

ore crushing units at the enterprise "Almaliq KMK".

As a result of the rapid consumption of used grinding

cones and many similar parts, their service life is not

up to the required level. The average service life of

one grinding cone is 3 months. Therefore, in the

process of their preparation, a number of measures are

being taken to increase the strength of surfaces prone

to cracking, and new developed technologies are

being put into practice. One of such technologies

consists in selecting and adding optimal modifiers

Choosing the Optimum Modifier to Increase the Durability of Parts Made of 110g13l Steel

265

during the melting process to increase the mechanical

properties of the obtained cast products, as well as

increasing its dispersion, durability and hardness as a

result of thermal treatment.

110G13L steels are melted in electric arc furnaces

DS-5MT, DSP-3 in the foundry of TsRMZ JSC

"Almalik KMK" (Ikramov, 2003; Pakhadnya

&Turkevich, 2013).

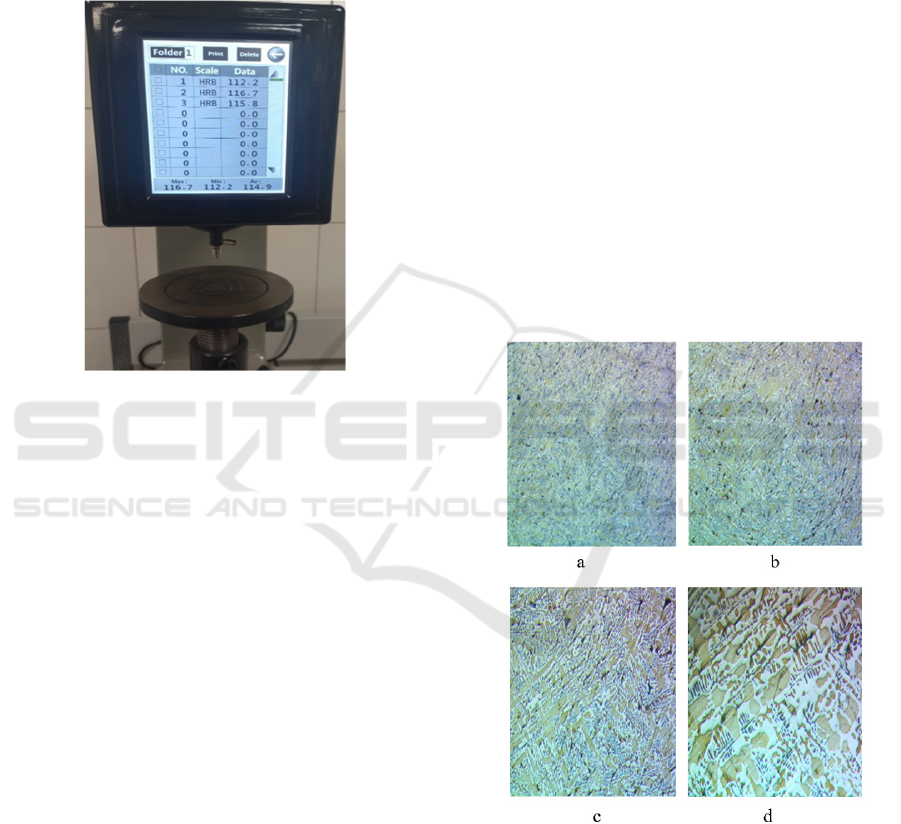

Figure 1: “ТР-5018 PAC Tochline” hardness measurement

machine.

In accordance with the requi- rements of GOST

977-88, in the casting workshop of the Central Repair

Mechanics Plant, a mixture of various chemical

elements was melted into 110G13L steel in an electric

arc furnace DS-5MT, and we took ingot samples

taken as samples. In order to test the hardness of this

solution and in the induction melting furnace

(Induction Melting Machine), several researches

were carried out. We took ferrochrome as an

example, which gave the best results from these

studies. We added 0.5% to 3% of ferrochrome to the

melting solution as a modifier. When added to steel,

ferrochromium provides several of the following

advantages, i.e. increases hardness and strength

improves anti-corrosion properties, increases fluidity,

and increases oxidation resistance at high

temperatures.

On January 26, 2024, cutting and turning of

castings 60x40x20 mm in the laboratory of Tashkent

State Technical University, Department of "Casting

Technologies" was carried out for 2 hours and 45

minutes in the mechanical shop of the Central Repair

Mechanical Plant of "Almaliq KMK" JSC on the

S11MV universal lathe. increased and prepared in

order to determine the hardness, chemical properties

and structures of these metals.

The hardness of cast layers prepared by the most

modern metal-102 stationary Rockwell hardness

tester was checked at the branch of the federal state

autonomous higher educational institution "Misis

National Technological Research University" in

Olmaliq, Republic of Uzbekistan. According to Gost,

designated as NV-186-229.

In this device, the hardness of the metal made of

three parts was measured, it was found to be 116.7

when measured from the middle, and 112.2 and 115.8

when measured from the two ends. When we take the

average of all sizes, 114.9 HRB and NV-321.

(Tursunbaev et al., 2023, Tursunbaev et al., 2024).

3 RESULTS AND DISCUSSION

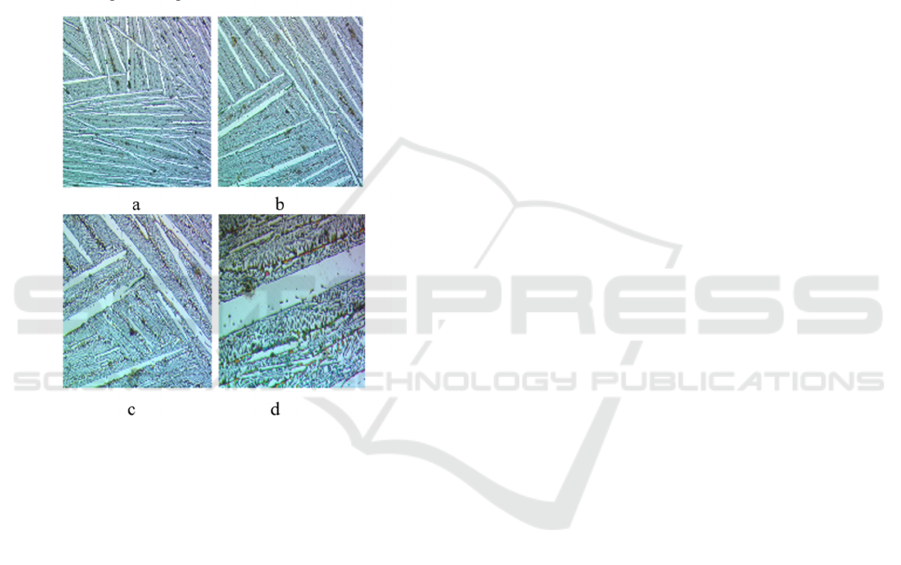

Together with the professor scientists of Tashkent

State Technical University, steel constructions of

brand 110G13L and elements added to this steel as a

ferrochrome modifier were examined under a special

microscope and the desired results were obtained.

Figure 2: The appearance of the modified 110G13L brand

steel structure in different sizes. a- 110G13L-view of the

branded steel structure with a size of 5 µm

;

b- 110G13L-

the appearance of the branded steel structure with a size of

10 µm; c- 110G13L-the appearance of the branded steel

structure with a size of 20 µm; d- 110G13L-view of the

branded steel structure with a size of 50 µm.

As the amount of manganese in carbon steels

increases, austenite in the structure begins to stabilize

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

266

gradually, as a result of which the as-cast state or the

structure after normalization of the alloy changes

from pearlite to sorbite, trostite, martensite, and

finally to austenite (Rasulov and Grachev, 2004,

Kozlov et al., 2003).

Manganese austenite is characterized by its

durability and is prone to scurvy. This type of steel is

mainly used to increase the corrosion resistance under

shock load conditions, where shock occurs on the

surface layer of the metal, and the surface layer of the

material made of such steel is not contaminated under

abrasive cutting conditions, so the use of 110G13L

steel in such conditions does not have an advantage

over other engineering steels.

Figure 3: The appearance of structures detected when 1%

ferrochrome is added to steel of the 110g13l brand. a- The

appearance of the 110g3l brand steel with the addition of

1% ferrochrome as a modifier is 5 µm in size; b- The

appearance of 110g3l branded steel 10 µm in size with the

addition of 1% ferrochrome as a modifier; c- The

appearance of 110g3l branded Steel 20 µm in size with the

addition of 1% ferrochrome as a modifier; d- The

appearance of 110g3l branded Steel 50 µm in size with the

addition of 1% ferrochrome as a modifier.

It is known that the amount of carbon in steel has

a strong influence on its corrosion resistance, so in

some cases, increasing the amount of carbon in steel

to 1.5% leads to a number of complications.

The chemical properties of the "Almalik KMK"

JSC MTM(SRMZ) plant were studied in laboratory

conditions and the following results were obtained

(Novikov, 1996; Tursunbayev et al., 2023).

Manganese increases the stability of austenite and

is usually in the range of Mn:C˃10 for most

standards. If we take into account that the amount of

manganese in steel is 9.5 - 10%, then this has little

effect on the resistance to bending of steel in abrasive

conditions. Therefore, the amount of manganese in it

can be reduced to 9%.

Silicon if its content in steel is 0.8-1%, it almost

does not affect the strength and plasticity of steel, but

it allows to increase the bending resistance of silicon

steel only in abrasive bending conditions without

forging.

Sulfur if it is present in small amounts in

manganese steel, it forms manganese sulfide and does

not significantly affect the properties of the

(Mukushev et al., 2010; Torakho'jaev et al., 2018;

Torakho'jaev et al., 2020).

Phosphorus it begins to have a negative effect on

strength properties when its amount increases from

0.06 to 0.08% in 110G13L steels.

Chrome it is used in alloying manganese steels,

especially 110G13L steels, in such cases the pre-

deformation of the steel is reduced. As a result of

alloying steel with chromium in the amount of 5-20%,

the plasticity and impact viscosity of the material is

significantly reduced, but the hardness of steel

increases, for example, as a result of alloying steel

with 3% chromium, its hardness increases to NV 255.

The advantages of adding ferrochrome to steel are;

reduces graininess, increases hardness and strength,

and increases oxidation resistance at high

temperatures.

Nickel practically does not affect the strength

properties of manganese steels. 0.1 - 0.15% of

titanium included in the composition of steel allows

to increase its resistance to bending, similarly, 0.1 -

0.2% of zirconium affects the strength properties of

manganese steels. Chromium microalloying has a

good effect on the mechanical properties and bending

resistance of steels (Chorshanbiev, 2020, Yu and

Schulte, 1983, Parasyuk, 2014).

A large number of various (different types of

crushers, parts, teeth of excavator pits, etc.) parts

made of 110G13L steel are used in the enterprise of

"Almalik KMK" OJSC. The surfaces of such details

are made without cracks as a result of exposure to

abrasive or abrasive wear under various operating

conditions. As a result, a large amount of manganese

steel scrap is collected. It is recommended that such

steels be microalloyed and modified during remelting

to obtain a structure that allows for increased

corrosion resistance.

When we measured the hardness of selected

modifiers, it was reflected that the hardness of

ferrochrome and molybdenum is high.

Choosing the Optimum Modifier to Increase the Durability of Parts Made of 110g13l Steel

267

In addition, copper and ferrosilium were also

found to have superior performance compared to

other modifiers.

Based on the process of studying the structure of

the above-mentioned modifiers, the following

conclusions were drawn (Korshunov, 1973; Tsurkan,

2012a; Tsurkan et al., 2012b).

4 CONCLUSIONS

1. The following recommendations were developed

as a result of theoretical and practical research on

the topic of choosing the optimal modifier to

increase the durability of steel parts.

2. Optimum modifiers were selected to increase the

strength of steel parts.

3. Properties and structures of several types of

modifiers were studied to increase the durability

of steels.

REFERENCES

Chorshanbiev, Sh., 2020. Collection of scientific works

"Talented youth of New Uzbekistan", first book.

"Development of the technology to increase the

flexibility of shaft-gear teeth". Educational Publishing

House, Tashkent. Bit 8, 212-220.

Dubinin, N.P., 1961. Casting steel, manual, edited by.

Moscow, 887.

Ikramov, U. 2003. Tribanika. Tashkent, Uzbekistan. 77, 84,

126.

Korshunov, V.V., 1973. Issledovanie vliyaniya

modifitsirovaniya na kinetiku protsessa usadki i

deformatsionnuyu sposobnost’ stali 110G13L [veya

110G1ZL] (Avtoreferat dissertatsii kandidata

tekhnicheskikh nauk). Chelyabinsk.

Kozlov, L., Kolokoltsev, V.M., Vdovin, K.N., Ten, E.B.,

Dolgopolova, L.B., Filippenkov, A.A., 2003.

Production of steel ingots, textbook L. Yes. Kozlov.,

Moscow, Mrs. 357.

Mirboboev, V.A., 2004. Structural Materials Technology.

Tashkent, Uzbekistan. 148, 157, 162

Mukushev, D.A., Tsurkan, A.N., Samsonov, Yu.P.,

Makushev, V., Kanya, A., 2010. Increasing the wear

resistance of the lower parts of bulldozers. Bulletin of

the Siberian Branch of the Academy of Military

Sciences, A. Appendix to VN Bulletin.

Nasser, I., 2002. Materials Science. Tashkent "Uzbekistan"

173-179.

Novikov, I.I., 1996. Theory of Heat Treatment of Metals. -

M: Metallurgy, 123-178.

Nurmurodov, S., Rasulov, A., Torakho'jaev, N.,

Bakhodirov, K., Yakubov, L., Abdurakhmanov, Kh.,

Tursunov, T., 2016. Development of new structural

materials with improved mechanical properties and

high quality of structures using new methods. Journal

of Materials Science Research, Canada. Canadian

Center for Science and Education, 5(3), 52-58.

Pakhadnya, V., Turkevich, Z., 2013. Fizika-technicheskie

problem sovremennogo materialovedeniya. Kyiv-

Akademperiodika 39, 55, 77.

Parasyuk, P.F., 2014. The main component is steel

110G13L, and the mode of heat treatment and

durability is sought. Technology, organization and

mechanization of liteynogo proizvodstva, Jorn.

SNIITEITEJMASh 9,18,79.

Rasulov, S.A., Grachev, V.A., 2004. Anthrax metallurgy.

Tashkent "Teacher", 87, 89, 95, 142.

Torakho'jaev N., Chorshanbiev Sh., Sadikova N.,

Chorshanbiev Q., 2020. Journal of Critical Appraisal.

"Methods for increasing the strength of shaftgear teeth

operating in highly abrasive grinding environments".

Journal of Critical Review, 103(4), Roosevelt Rd, Da'an

District, Taipei City, Taiwan.

Torakho'jaev, N.D., Yakubov, L.E., Tursunov, 2018.

Mathematical Model of Heat Treatment to Improve TX

Mechanical Properties. Composite materials. -

Tashkent, 3, 56-60.

Tsurkan D. A., 2012a. Increasing the structural strength of

110g1zl steel and cast parts used in special machines by

modification by Mo, Ni alloy and Polzunovskaya

vestnik N 1/1.

Tsurkan, D.A., Leontiev, A. N.,. Ishkov, A. V., 2012b.

Improving the durability and operational reliability of

caterpillar engine parts of agricultural machinery and

special machines. Altai State University newsletter.

Tursunbaev, S., Turakhodjaev, N., Mardonakulov, S., &

Toshmatova, S., 2024. Effect of germanium oxide on

the properties of aluminum casting details in

agricultural machinery. BIO Web of Conferences, 85.

https://doi.org/10.1051/bioconf/20248501024.

Tursunbaev, S., Turakhodjaev, N., Odilov, F.,

Mardanokulov, S., & Zokirov, R., 2023. Change in

wear resistance of alloy when alloying aluminium alloy

with germanium oxide. E3S Web of Conferences, 401.

https://doi.org/10.1051/e3sconf/202340105001.

Tursunbayev, S., Turakhodjayev, N., Mardanokulov, S.,

Zokirov, R., & Odilov, F., 2023. The effect of lithium

on the mechanical properties of alloys in the Al-Li

system. E3S Web of Conferences

, 390.

https://doi.org/10.1051/e3sconf/202339005046

Yu, A., Schulte, 1983. Praizvodstva atlivak iz stali., Kiev-

Donetsk. izd Vitsha scale. 183.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

268