Characteristics of Titanium Nitride (Tin) in Increasing the Wear

Resistance of High-Carbon Steel Alloys

Abdujalol Bektemirov

1a

, Nodir Turakhodjaev

2b

, Khusanboy Makhammadjanov

1c

,

Sherzod Tashbulatov

2d

, Anvarjon Akhunjonov

1e

, Abdulkhamid Erkinjonov

1f

and Farrukhjon Abdullaev

2g

1

Andijan Machine Building Institute, Technology of Machine Building, 170100 Andijan, Uzbekistan

2

Tashkent State Technical University, Foundry Technologies Department, 100095 Tashkent, Uzbekistan

Keywords: Titanium Nitride, Wear Resistance, Steel Alloys.

Abstract: In this article, the effect of titanium nitride (TiN) compound on the wear resistance of high carbon steel alloys

is studied. In this case, TiN is added into the alloy as a microparticle modifier, based on improved technology,

for improving the wear resistance of the high-carbon steel alloys. During the research, periodic heat treatment

was also carried out to further improve the mechanical properties of wear resistance alloys obtained by casting.

The device IS.1053-PLMi metallographic microscope was used to analyze the images of the microstructures

in the selected alloy. In the technological process of melting the alloy, the resulting wear resistance and

hardness tests of samples with 0, 0.1, 0.2, 0.3, 0.4, 0.5 and 0.6% of TiN added to the alloy and subjected to

periodic heat treatment were conducted. In particular, samples containing 0.3% and 0.5% TiN, which showed

austenite-trostite at the beginning of the experiment and pearlite-ferrite, pearlite-martensite and a small

amount of bainite at the end of the experiment, achieved high wear resistance and hardness. Mechanical wear

resistance tests were performed on a tribometer. The main goal of the research process is to introduce the

technology of obtaining wear resistant wheel details in a casting method, which improves the internal and

external transportation capabilities of large production enterprises, and as a result, the annual economic value

of the enterprise is increased by increasing the stagnation period of the wheel detail operating under friction

conditions in the enterprise. The stagnation period of the detail has been increased by 2.59 times.

1 INTRODUCTION

Among the FeC alloys, one of the most widely used

alloys is the high carbon steel alloy, which is

generally valued for its mechanical properties such as

long-term wear-resistance and hardness. Such steel

alloys contain on average C 0.60 - 1.4%, and in

extremely high (extreme) cases C is 1.4 - 1.8% and

0.90 - 1.20 % Mn will be available up to. Such an

alloy is thermally and thermomechanically processed

to form microstructures consisting of uniformly

a

https://orcid.org/0009-0002-2583-0900

b

https://orcid.org/0009-0009-4970-5785

c

https://orcid.org/0000-0002-3462-858X

d

https://orcid.org/0000-0001-6559-8881

e

https://orcid.org/0009-0008-1949-2216

f

https://orcid.org/0009-0002-1991-7671

g

https://orcid.org/0000-0001-6126-4028

dispersed grains of spherical ferrite, continuous

proeutectoid solid carbides evenly distributed

throughout the volume. Such microstructures form a

superplastic, but also provide high wear resistance,

hardness and low ductility. Chromium, manganese

and titanium elements and their ferroalloys are used

in many ways to improve the mechanical properties

of high-carbon steel (Cr, Mn and Ti). These, in turn,

positively affect the alloy's mechanical properties,

such as hardness, wear resistance, and corrosion

resistance (Chidi et al., 2022). Although high-carbon

260

Bektemirov, A., Turakhodjaev, N., Makhammadjanov, K., Tashbulatov, S., Akhunjonov, A., Erkinjonov, A. and Abdullaev, F.

Characteristics of Titanium Nitride (Tin) in Increasing the Wear Resistance of High-Carbon Steel Alloys.

DOI: 10.5220/0014261100004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 260-263

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

steels have good wear resistance, the demand for this

property has increased. This led to the advancement

of research aimed at improving the wear resistance of

steel alloys around the world to a new stage, and

scientists of all leading countries of the world

conducted research for the same purpose. In

particular, the well-known British metallurgical

scientist R.W. Bebbington studied the effect of some

ferroalloys, especially ferroboron and ferrotitanium

on steels and the methods of adding them, and made

the following suggestions for improving wear

resistance. In the production of wear-resistant steel

castings, titanium is highly reactive with elements

such as carbon (C), oxygen (O), nitrogen (N) and

sulfur (S) when introduced independently, and no any

difficulty in enriching the alloy composition when

introduced as a ferroalloy (FeTi). Initially,

ferrotitanium was converted into a eutectic alloy

consisting of FeTi40 (40% titanium) and FeTi70

(70% titanium) obtained in aluminothermic

processes, and the influence of the amount of titanium

in FeTi on the casting was studied. It was found that

ferroalloy has the lowest melting point of all alloys

when titanium is exactly 70% (Bebbington, 1992,

Ernest, 1995). According to kazakh metallurgical

scientists V.A. Golubtsov, L.G. Shubya, R.G., during

out-of-furnace processing of the alloy, after

segregation of the alloy, S was in the range of 0.001-

0.003%. At the lowest cost of machining, it was

achieved when S in the alloy was 0.009-0.012%, and

the damage of S, P was neutralized by modifying the

alloy with hard compounds in the form of carbides

and nitrides. In this process, the sulfur content was

reduced, thereby shortening the alloy's machining

time. By treating with inert gas in the furnace, by

accelerating the diffusion of the alloy, sulfur in the

alloy decreased the solubility of hydrogen and

prevented the appearance of cracks in the casting. A

quality structure was formed in the alloy by

modifying the alloy in the cavity. In this case, the

influence of modifiers (WC, TiC, TiN, CrC,) main

element on steel casting was studied in advance

(Golubtsov et al., 2006; Bykov et al., 2006).

2 MATERIALS AND METHODS

The Scientific and practical research work was

carried out on high-carbon steel 65Г (ГОСТ 14959-

2016) alloy. This steel alloy is analogous in

composition to steel 1066, 1566, G15660 alloys

according to international ASME and AISI standards,

and to 65Mn alloy according to JUDE, and such

alloys are usually used for various wheels, springs,

gears, thrust devices, brakes parts that require wear

resistance and rigidity, such as friction discs, bearing

housings, are manufactured using casting and

pressure treatment methods (Kholmirzaev et al.,

2024). In this case, TiN was introduced in the form of

microparticles in the form of microparticles at

intervals of 0.1-0.5% to the alloy with the usual

composition by means of modification outside the

furnace (Rao et al., 2022).

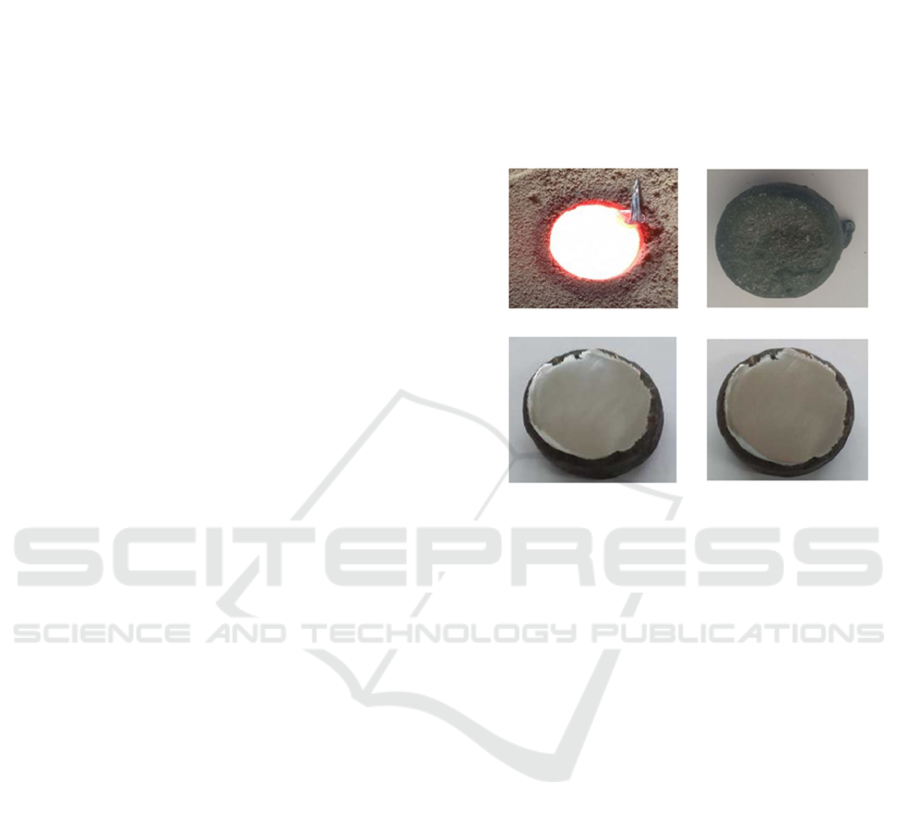

Figure 1: Modified and recast samples.

Titanium nitride is a hard and wear-resistant

material with strong crystallinity and is commonly

used as a modifier in various mechanical alloys, steel,

cast iron and aluminum components to improve the

alloy's volume and surface strength properties.

Titanium nitride is yellow-brown in appearance, but

when compressed under pressure or mechanically

treated, it turns golden.

The density is 5.44 kg/cm3, and the hardness

index of individual parts of the microstructure of the

material is 2050 kgj/mm2, and the melting

temperature of the material is 2930 ˚C. In the study,

steel 65Г alloy was melted in an induction furnace.

CaCo was used as flux during melting. In the last 15

minutes of liquefaction, Mn 1.2 % was added, taking

into account the burning indicators. Out of the

furnace, 5 different amounts (0.1-0.2; 0.2-0.3; 0.3-

0.4; 0.4-0.5; 0.5-0.6 ) modified with microparticles of

TiN. Modified and conventional samples were cast in

the same sand-clay molds for comparison. The

overall obtained chemical composition is shown in

Figure 2. The chemical composition was determined

on the Explorer 5000 device. Grinded and polished

samples are shown in Figure 1.

Characteristics of Titanium Nitride (Tin) in Increasing the Wear Resistance of High-Carbon Steel Alloys

261

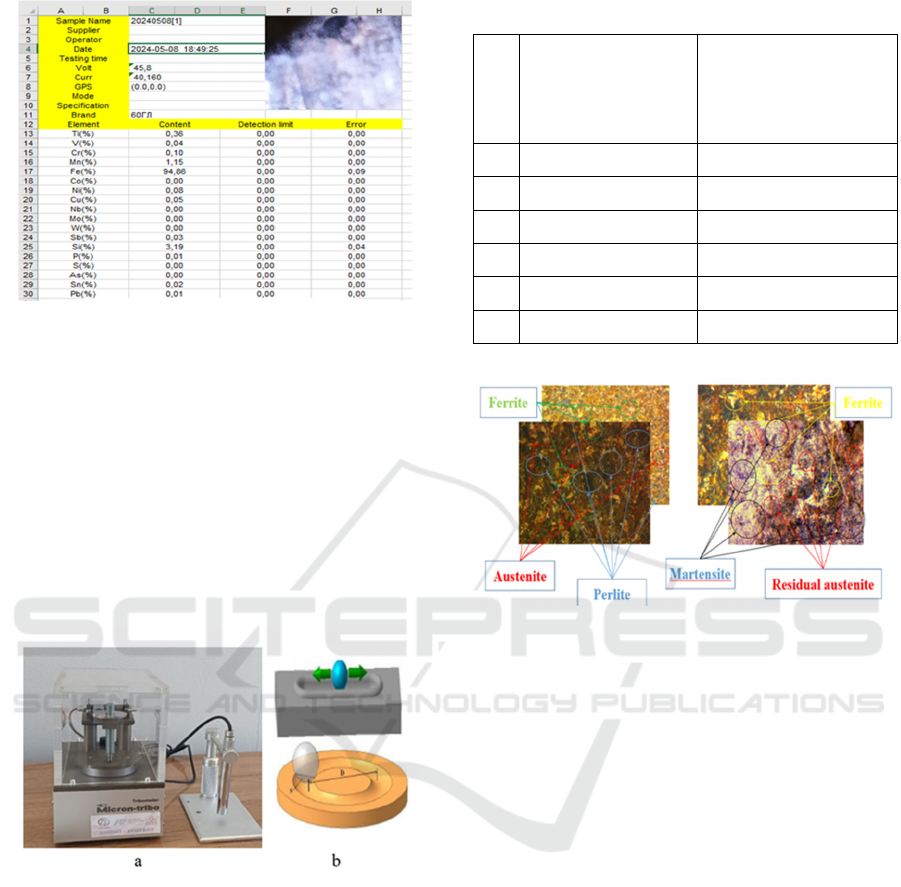

Figure 2: Chemical composition determined in the Explorer

5000 device.

3 RESULTS AND DISCUSSION

The wear resistance tests were carried out on the

samples obtained by the casting method (Tursunbaev

et al., 2023a; Tursunbaev et al., 2023b). Wear

resistance was determined based on the weight of the

sample and the formation of geometric dimensions

within the unit of time. A Micron-tribo wear testing

device was used for wear testing (Fig. 3a.).

Figure 3: a) Micron-tribo; b) Scheme of testing on the

Micron-tribo device.

Wear-resistance of the samples was determined in

two different procedures. In forward and back and

circular motions (Fig. 3b.). The results of the test for

resistance to wear are shown in Table 1.

After the wear test, the samples were polished

using a grinding and polishing machine to prepare

polished section. Microstructural analysis of the

polished samples was carried out by observation

using an optical metallographic microscope. Optical

images and analysis of the microstructures are

presented in Figure 4.

Table 1: The results of the test on resistance to wear.

№

Sample alloys

The total amount of

wear of samples

(g/100 hour)

0 Steel 65Г

5,55

1 Sample 1, TiN 0,1 %

3,70

2

Sample 2, TiN 0,2 % 3,01

3

Sample 3, TiN 0,3 % 2,20

4

Sample 4, TiN 0,4 % 2,16

5

Sample 5, TiN 0,5 % 2,14

Figure 4: Alloy microstructures.

4 CONCLUSIONS

Analyzing the results of practical studies, the

following final conclusion can be drawn: TiN, like all

carbon steels, has a positive effect on the mechanical

properties of high-carbon steel alloys, especially wear

resistance and hardness indicators. In this case, the

nitrogen contained in TiN introduced in the form of

micro-powder at a high temperature in the furnace

formed a three-phase solid layer with Fe, Cr, Mn, and

a small amount of Al, which are the main components

of the alloy. Titanium nitride created new centers of

crystallization in the alloy by itself, and ensured that

the alloy had finer grains. In this case, TiN improved

the connection of crystal lattices with neighboring

crystals. That is, the crystal branches spreading from

the newly formed core serve as the core for the

neighboring crystal. As mentioned above, the

addition of Ti promoted the crystallization of titanium

nitride (TiN) during the crystallization of steel. The

TiN particles formed in the liquid phase have a cubic

shape and relatively large (1-20 mkm) dimensions

compared to those formed in the solid state at the next

process stages. Although it has specific metallurgical

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

262

functions in controlling the growth of subsequent

crystals, the strength of the material is improved by

promoting the dispersion of initial crystallization

centers. When microstructures of samples modified

with TiN were observed after polishing, the hardness

and wear resistance of the samples modified with TiN

showed a relatively positive difference from the

previous indicators due to the formation of new

crystallization centers and the increase in the number

of crystals and the strengthening of each monocrystal.

REFERENCES

Agusiegbe, C.N., Morton, D., & Moore, E., 2022 High-

Carbon Steel in Additive Manufacturing. ME

4133/6133 Mechanical Metallurgy.

https://scholarsjunction.msstate.edu/metallurgy/40.

Bebbington, R.W., 1992. “The role of ferroboron and

ferrotitanium in steels” Production methods, quality

aspects, and addition techniques, INFACON 6. Town.

Volume 2 Johannesburg. SAIMM, pp. 263-267

Bykov, P.O., 2006. Extra-furnace treatment of melts.

Methodological guidelines for the study of the

discipline/comp. Pavlodar: S. Toraigyrov Moscow

State University, p. 41. .http://atl-met.ru/

Chidi, B. S., Okudoh, V. I., Hutchinson, U. F., Ngongang,

M. M., Maphanga, T., Madonsela, B. S., Shale, K., Lim,

J. W., & Ntwampe, S. K. O., 2022. A Perspective on

Emerging Inter-Disciplinary Solutions for the

Sustainable Management of Food Waste. Applied

Sciences, 12(22), 11399.

https://doi.org/10.3390/app122211399.

Ernets, G.J., 1995. The Wear of Bainitic and Pearlitic

Steels. University of Leicester. Thesis.

https://hdl.handle.net/2381/9148.

Golubtsov, V. A., Shuba, L.G., Usmanov. P.G., 2006. Out-

of-furnace processing and modification of steel" (NPP

“Technology”), JSC Chermetinformatsiya. Bulletin of

Ferrous Metallurgy, 11, 47-51

Kholmirzaev, N., Turakhodjaev, N., Saidmakhamadov, N.,

Khasanov, J., Bektemirov, A., & Sadikova, N., 2024.

Effects of titanium (Ti) contents on the wear resistance

of low-alloy steel alloys. E3S Web of Conferences, 525,

03003. EDP Sciences.

Rao, P & Kumar, D Satish & Sambandam, Manjini & Gna,

Balu, 2022. Precipitation of titanium nitride inclusions

during continuous casting of high carbon wire rod grade

steel SWRH 72A. Sādhanā. 47. 10.1007/s12046-021-

01793-z.

Tursunbaev, S., Turakhodjaev, N., Odilov, F.,

Mardanokulov, S., & Zokirov, R., 2023a. Change in

wear resistance of alloy when alloying aluminium alloy

with germanium oxide. E3S Web of Conferences, 401.

https://doi.org/10.1051/e3sconf/202340105001

Tursunbaev, S., Ashirbaev, A., Valiev, A., Xalimov, M., &

Tashimov, N., 2023b. The effect of the amount of

lithium in aluminum lithium alloys on the property of

fluidity. E3S Web of Conferences, 414.

https://doi.org/10.1051/e3sconf/202341704010.

Characteristics of Titanium Nitride (Tin) in Increasing the Wear Resistance of High-Carbon Steel Alloys

263