Optimization of Foliar Chitosan Doses as a Biofertilizer for Enhanced

Pepper Cultivation

Boran İkız

*a

, H. Yıldız Daşgan

b

, Cumali Yeniay and Muhammet Taş

Çukurova University, Department of Horticulture, 01330 Balcalı, Adana, Turkey

Keywords: Capsicum annuum L., Glucosamine, Sustanaible Agriculture, Biostimulant, Yield Optimization, Fruit

Quality.

Abstract: Chitosan is a water-soluble aminopolysaccharide obtained by the deacetylation of chitin, which is the second

most abundant biopolymer after cellulose. Chitin is primarily found in the exoskeletons of shellfish, and

chitosan is produced by converting the acetyl groups in the chemical structure of this natural polymer into

amine groups. The study aimed to evaluate the effects of different chitosan doses on plant growth, yield and

fruit properties of pepper. The experiment included a control group with no chitosan application, as well as

treatments with 150 ppm, 300 ppm, and 450 ppm of chitosan. The applications were made foliar once a week

The 150 ppm chtosan treatment ncreased yeld by 67.4%, and the 300 ppm treatment by 44.9%, compared

to the control. Chitosan treatments also significantly and positively influenced plant growth parameters, such

as plant height, plant width, and leaf number. Additionally, the chitosan applications increased, vitamin C,

total phenols and total flavonoids, EC (electrical conductivity) in the fruit juice.

This study’s objectives are

to ascertain the proper chitosan dosage for application and to track the beneficial benefits of employing

chitosan as a biostimulant.

1 INTRODUCTION

Chtosan s a naturally occurrng bopolymer wth a

wde range of possble uses n agrculture. In

partcular, chtosan s employed as a rhzosphere

modulator, plant growth regulator, and bopestcde.

When used as a bopestcde, chtosan effectvely

combats bactera, fungus, and vruses (Badawy et al.,

2011). It strengthens the structure of the sol, makes t

more capable of retanng water, and encourages

mcrobal actvty n the rhzosphere. It prevents harm

from heavy metals, whch enhances sol health

(Naeem ve et al., 2018). Because t encourages cell

dvson and plant growth, chtosan plays a sgnfcant

role n boostng frut and vegetable output yelds

(Khan et al., 2009). It s well known that the food and

agrcultural ndustres also employ chtosan as a flm

coatng. Bodegradable and antbacteral, chtosan-

based flms are also knd to the envronment.

Accordng to Rhm et al. (2020), ths s an addtonal

alternatve for food preservaton and plant protecton.

a

https://orcd.org/0000-0003-3012-4533

b

https://orcd.org/0000-0002-0403-1627

*

Correspondence Author

It can also have an effect on agrculture’s sustanablty

by beng economcal and envronmentally bengn

(Malerba et al., 2021). Pepper (Capscum annuum L.)

s an economcally mportant crop grown for ts

nutrtonal value, boactve compounds, antoxdant

propertes, and natural colors (Santosh, 2013).

Pepper

s wdely consumed worldwde both as a fresh

vegetable and as a processed product. Varetes of

peppers nclude sweet peppers (e.g., bell peppers) and

hot peppers (e.g., chl peppers). Wth ts hgh content

of vtamn C, vtamn A, and antoxdants, pepper s

consdered a hghly nutrtous vegetable and s

therefore regarded as an mportant source for a healthy

det (Sdhu et al., 2019).

Accordng to 2022 FAO data,

pepper s one of the most mportant vegetables,

cultvated on 2,020,816 hectares wth a producton of

36,972,494 tons (FAO, 2018).

Pepper s also used as a model plant for

botechnologcal and bostmulant applcatons that

enhance resstance to varous botc (pathogens,

nsects) and abotc (drought, salnty) stress factors

˙

Ikız, B., Da¸sgan, H. Y., Yeniay, C. and Ta¸s, M.

Optimization of Foliar Chitosan Doses as a Biofertilizer for Enhanced Pepper Cultivation.

DOI: 10.5220/0014261000004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 253-259

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

253

(Trverd et al., 2020). Pepper s a plant that performs

best under warm clmate condtons. Factors such as

water stress and hgh temperatures have sgnfcant

mpacts on the productvty of pepper cultvaton. To

enhance the plant’s reslence to these envronmental

stresses, varous bostmulants and water management

strateges are employed.

There are over 200 common names used 2nda re

Capscum annuum speces. Among the most common

are chl pepper, red pepper (sweet varetes), bell

pepper, red pepper, jalapeños, and chltepn (hot

varetes), as well as Chrstmas peppers (ornamental)

(Latham et al., 2009; Zhang et al., 2002). In the past,

some knda forms of ths speces were referred to as

C. Frutescens, but the characterstcs used to

dstngush these 2nda re2e observed n many

populatons of C. Annuum, and there s no consstently

recognzable C. Frutescens speces (Zhang et al.,

2002). It can be dffcult to dfferentate Capscum

annuum from cultvated C. Chnense (the hottest

peppers) and C. Frutescens (tabasco peppers), as ther

morphologcal trats may overlap. These three speces

share the same ancestral gene pool 2nda re sometmes

referred to as the “annuum-chnense-frutescens

complex (Aracel et al., 2009).

Caps৻cum annuumL. Contans capsacnods

(capsacn, dhydrocapsacn), carotenods (luten,

zeaxanthn, capsorubn, β-carotene), flavonods

(quercetn, kaempferol, catechn, epcatechn, rutn,

luteoln), and sterodal saponns (capscosde E, F, G,

and capscdn). The man components of C. Annuum

essental ol, dentfed usng GC/MS, are capsamde

and acetc acd. C. Annuum has been reported to

possess varous bologcal actvtes, ncludng

antoxdant, antbacteral, antvral, antprolferatve,

ant-adpogenc, antmutagenc, enzyme nhbtory,

ant-nflammatory, hepatoprotectve, antdabetc,

renoprotectve, hypocholesterolemc, anttumor, ant-

obesty, analgesc, appette suppressant, and ant-

reflux propertes (Yuca, 2002).

2 MATERIALS AND METHODS

The research took place durng the summer growng

season of 2024 at the Unversty of Cukurova, Adana,

Turkye (36°59′N, 35°18′E, 20 m above sea level).

The temperature values n the regon fluctuated

throughout the days, wth daytme temperatures

rangng between 35-40°C. The row spacng was set to

50 cm, and the spacng wthn the rows was 90 cm.

Chtosan (Adaga-NanoWet) was appled to the plants

at doses of 150 ppm, 300 ppm, and 450 ppm per week

to determne the optmal dose after 15 days frst

plantng and per one week.

The pepper seeds used n

ths study were of the Semerkant F1 varety, developed

by the Nunhemscompany. After beng grown nto

seedlngs, they were transplanted nto the sol.).

Harvestng of the plants began 45 days after plantng

and was carred out fve tmes.

Plant heght, plant wdth, and plant canopy

measurements were taken usng a meter, whle frut

length, frut dameter, and frut wdth were measured

usng calpers.

Color measurements were performed

usng the FRU Precse color reader WR-18 color space

system. pH and EC measured by portable WTW

phmeter.

Chlorophyll content was measured usng a

handheld SPAD meter from the Mnolta brand.

Vtamn C content was carred out usng the adapted

approach outlned n Elgalan et al. (2017)’s study.

A randomzed block experment was conducted

usng a four-replcate desgn, wth 15 plants each

replcate. In the context of frut analyss,

measurements were performed on 10 fruts per repeat.

Furthermore, at the tme of harvest, 10 plants were

measured n each replcaton. Statstcal analyses were

performed wth the JMP software.

The am of ths

study s to observe the ameloratve effects of usng

chtosan as a bostmulant and to determne the

approprate chtosan dosage for applcaton.

3 RESULTS AND DISCUSSION

3.1 Plant Heght, Plant Dameter and

Stem Dameter

When examnng the plant heght n pepper plants, t

was observed that the use of chtosan as a bostmulant

ncreased plant heght. Plant heght ncreased n all

three doses compared to the control plants; however,

there was no statstcally sgnfcant dfference

between the treatments. In the control plants, the plant

heght was 48.08 cm, whle the plants treated wth 300

ppm chtosan as a bostmulant ncreased to 55.25 cm.

Smlarly, plants treated wth chtosan exhbted a

greater stem dameter compared to the control plants.

Although the dfference was not statstcally

sgnfcant, the plant dameter was found to be hghest

n the 300 ppm chtosan treatment, consstent wth

other parameters. Salachna and Zawadznska (2014)

demonstrated that chtosan, wth varyng molecular

weghts, can be used as a bostmulant n the

cultvaton of Freesa plants n pots. They observed

that, regardless of the compound’s molecular weght,

plants treated wth chtosan had more leaves and

shoots, flowered earler, and produced more flowers

and bulbs. Addtonally, Kumaraswamy et al. (2021)

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

254

reported that the applcaton of chtosan-slcon nano-

fertlzer on corn plants enhanced growth and yeld.

They observed that these bostmulants ncreased leaf

area as well as stem and root length. Perez et al. (2024)

conducted folar applcatons of chtosan,

brassnosterods, and thdazuron on strawberres,

demonstratng that chtosan treatment ncreased plant

heght, leaf count, leaf area, and frut frmness.

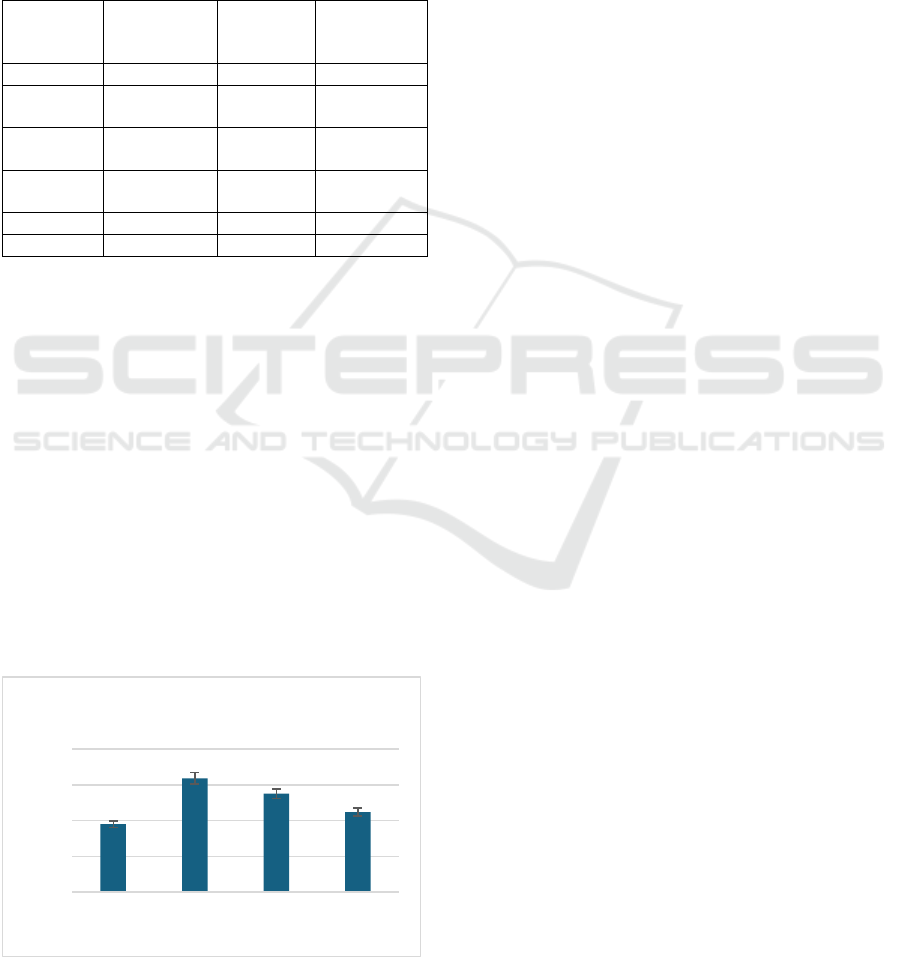

Table 1: Effects of chtosan doses on plant growth

measurements n pepper.

Apps.

Plant-

Dameter

(

cm

)

Plant

Heght

(

cm

)

Stem

dameter

(

mm

)

Control 45.54 48.08 b 12.83 b

150 ppm

Chtosan

53.46 55.00 a 17.42 a

300 ppm

Chtosan

55.08 55.25 a 19.70 a

450 ppm

Chtosan

52.00 54.50 a 17.76 a

P0.05 N.S 0.02 0.002

LSD N.S 6.14 2.80

There s no sgnfcant dfference between means wth the

same letter n the same column, LSD the least sgnfcant

dfference, NS: Non sgnfcant, Apps: Applcatons.

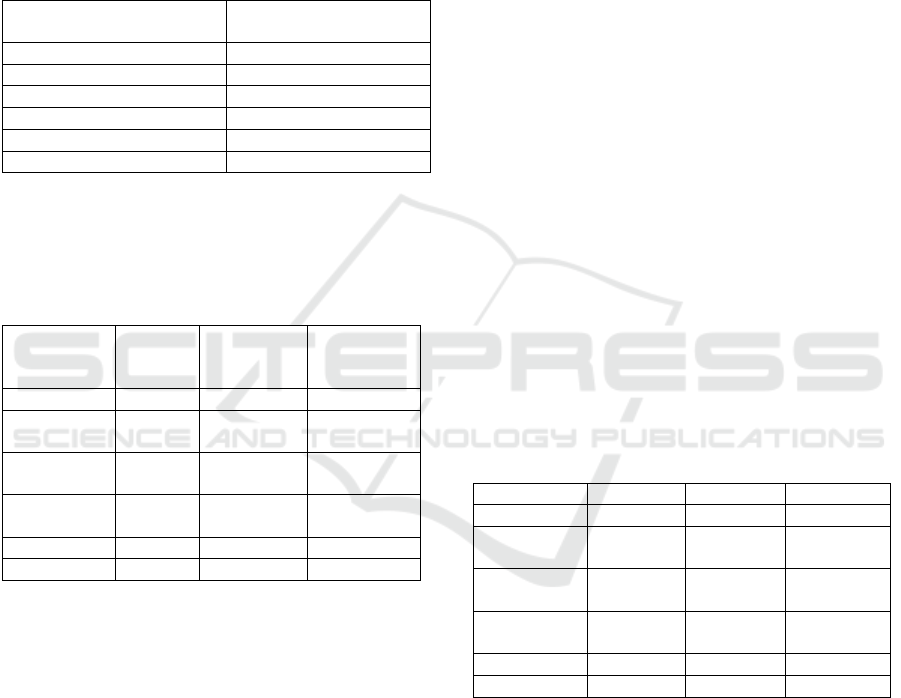

3.2 Yeld

The 150 ppm chtosan treatment ncreased yeld by

67.4%, the 300 ppm treatment by 44.8%, and the 450

ppm treatment by 17.7%, compared to the control

(Fgure 1). Abdel-Mawgoud et al. (2010) appled

chtosan to strawberry plants and observed an ncrease

n the number of fruts per plant as well as

mprovements n yeld parameters per plant. Plant

growth parameters, chlorophyll content, and

consequently photosynthetc capacty, as well as

Vtamn C content an mportant factor n pepper plants

showed better results n all chtosan treatments

compared to the control.

Fgure 1: Effects of chtosan doses on yeld n pepper.

However, t was observed that hgher chtosan

doses led to a reducton n yeld. Usng the lowest

dose of chtosan s also economcally advantageous.

When examnng other parameters, no sgnfcant

dfferences were observed among the dfferent

chtosan treatments.

3.3 Chlorophyll Content

In terms of chlorophyll content, the use of chtosan,

bo-fertlzer yelded hgher results compared to the

control plants. Snce an ncrease n chlorophyll

content s assocated wth photosynthess, t was

observed that chtosan enhances photosynthess,

whch n turn nfluences the ncrease n growth

parameters such as plant heght and stem dameter.

İnam et al. (2024) nvestgated the effects of chtosan

and znc oxde fertlzers on allevatng the severe

mpacts of drought on corn plants. They observed that

the applcaton of 1000 µg/L chtosan produced better

results than both the control and znc oxde

treatments.

Smlarly, n ther study on strawberres,

Perez et al. (2024) suggested that the combned

applcaton of chtosan and brassnosterods

sgnfcantly promoted crown dameter,

photosynthetc pgments, carotenods, and the fresh

and dry weghts of both roots and above-ground parts,

as well as maturaton.

In ther study, Tamer Khalfa et

al. (2024) nvestgated the nteractve effects of sol

mulchng materals (non-mulched, whte plastc, rce

straw, and sawdust) and chtosan folar spray

applcatons (control, 250 mg L⁻¹ regular chtosan,

125 mg L⁻¹ nano-chtosan, and 62.5 mg L⁻¹ nano-

chtosan) on the bochemcal sol propertes and

productvty of common beans grown n clay-salne

sol. Ther research emphaszed the adopton of eco-

frendly strateges to enhance the sustanablty of

agrcultural ecosystems. The hgher chlorophyll

content ndcates enhanced photosynthess, whch n

turn promotes ncreased plant growth and

development. Ths also explans the hgher yeld

observed n chtosan applcatons compared to the

control.

3.4 Frut Propertes

When examnng frut wdth, t s observed that the

use of chtosan shows an ncrease compared to the

control. The use of 150 ppm chtosan ncreased by

8.12% compared to the control, 300 ppm by 26.78%,

and 450 ppm by 11.22%. The use of chtosan has

generally ncreased the frut wdth. Frut sze has also

shown a sgnfcant ncrease n chtosan usage, just

lke frut wdth. The frut sze ncreased by 9.39% n

3801 c

6364 a

5506 ab

4473 b

0

2000

4000

6000

8000

Control 150 ppm

Chitosan

300 ppm

Chitosan

450 ppm

Chitosan

Yield(kg/m2)

Optimization of Foliar Chitosan Doses as a Biofertilizer for Enhanced Pepper Cultivation

255

the 150 ppm chtosan applcaton compared to the

control, 21.74% n the 300 ppm applcaton, and

7.65% n the 450 ppm applcaton.

No correlaton has

been establshed between chtosan applcaton and

dry matter producton percentage (Table 3)

. Wth the

use of chtosan as a bostmulant, not only qualty

parameters but also physcal measurements of the

frut show mprovement (Rahman et al., 2018).

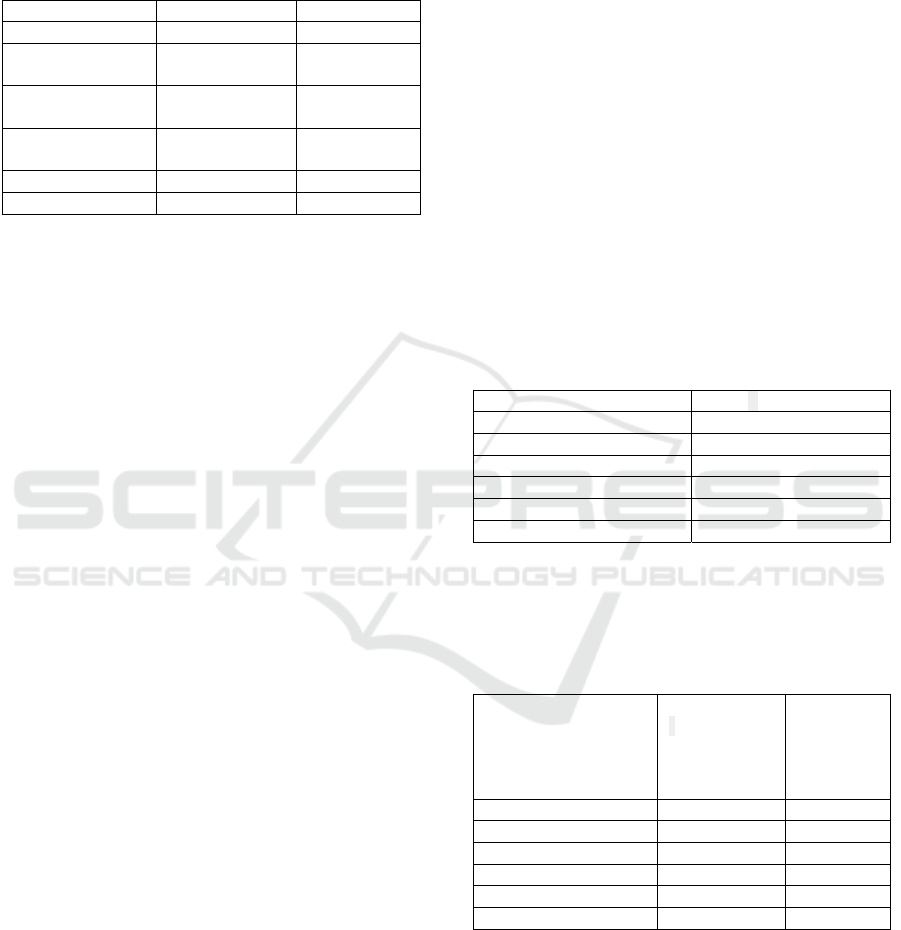

Table 2: Effects of chtosan doses on chlorophyll content n

pepper.

Apps.

Chlorophyll

Content(SPAD)

Control 49.14 b

150

pp

m Chitosan 54.49 a

300

pp

m Chitosan 50.97 a

450

pp

m Chitosan 55.55 a

P

0.05

0.01

LSD 5.001

There s no sgnfcant dfference between means wth the

same letter n the same column, LSD the least sgnfcant

dfference

Table 3: Effects of chtosan doses on frut propertes n

pepper.

Apps. Frut

Wdth

(

mm

)

Frut

Heght

(

cm

)

Dry Matter

(%)

Control 25.5 b 11.50 b 5.31

150 ppm

Chtosan

27.57 b 12.58 ab 5.24

300 ppm

Chtosan

32.33 a 14.00 a 5.36

450 ppm

Chtosan

28.36 ab 12.38 ab 5.44

P

0.05

0.03 0.02 N.S

LSD 4.43 1.47 N.S

There s no sgnfcant dfference between means wth the

same letter n the same column, LSD the least sgnfcant

dfference

3.5 Frut Colour

The LAB color model ncludes L (lghtness), A (green

to red scale), and B (blue to yellow scale). Across all

treatments, the lghtness (L) values are smlar, wth a

slght ncrease observed wth chtosan applcatons.

The hghest lghtness occurs at 300 ppm (46.81),

whle the control group has the lowest value (45.19).

Although the dfferences n lghtness between the

control and chtosan-treated groups are 4ort, they

suggest a modest mprovement n brghtness wth

chtosan (Table 4).

The A parameter, representng the green-red scale,

shows a gradual ncrease wth hgher chtosan

concentratons. The control group has an A value of -

5.18, whle the maxmum shft toward red occurs at

300 ppm (-6.92). Ths ndcates that the 300 ppm

chtosan applcaton slghtly enhances red

pgmentaton compared to other treatments and the

control (Table 4).

4ort he B parameter (blue-yellow scale), the

hghest value s recorded at 300 ppm (18.20 a), wth

both 300 ppm and 450 ppm treatments yeldng

statstcally sgnfcant ncreases n yellow

pgmentaton compared to the control (16.34 b). Ths

suggests that chtosan, partcularly at 300 ppm,

enhances the yellow coloraton of the frut,

potentally contrbutng to a more vsually appealng

appearance (Table 4).

The applcaton of 300 ppm chtosan s the most

effcacous n affectng frut coloraton, resultng n

substantal ncreases n the yellow (B) and red (A)

scales, thereby mprovng overall color

characterstcs. Ths concentraton has the greatest

lghtness, renderng the frut more lumnous.

Chtosan treatments, partcularly around 300 ppm,

sgnfcantly mprove the aesthetc qualty of the

fruts. Dulta et al. (2022) examned the mpact of ZnO

nanopartcle-nfused chtosan coatng on the post-

harvest qualty of eggplants. Improvements n both

the texture and color of the fruts were noted n

comparson to the control.

Table 4: Effects of chtosan doses on frut colour n pepper.

Apps. L(Frut) A(Frut) B(Frut)

Control 45.19 -5.18 16.34 b

150 ppm

Chtosan

46.61 -5.35 18.57 a

300 ppm

Chtosan

46.81 -6.92 18.20 a

450 ppm

Chtosan

46.16 -6.69 17.15 a

P

0.05

N.S N.S 0.01

LSD N.S N.S 1.98

There s no sgnfcant dfference between means wth the

same letter n the same column, LSD the least sgnfcant

dfference, NS: Non sgnfcant.

3.6 Qualty Paramaters

3.6.1 pH and EC n Frut Juce

Although there s a notceable ncrease n pH value,

no statstcally sgnfcant ncrease has been observed.

However, the EC value decreased as the chtosan dose

ncreased, specfcally showng a reducton at the 450

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

256

ppm applcaton (Table 5). In ther study publshed,

Daşgan et al. (2022) found the effects of bostmulant

applcaton on EC and pH wthn the same group.

Table 5: Effects of chtosan doses on pH and EC n pepper.

A

pp

s.

p

H EC

(

dSm

-1

)

Control 5.54 4.99 a

150 ppm

Chtosan

5.86 5.06 a

300 ppm

Chtosan

5.87 5.11 a

450 ppm

Chtosan

5.76 4.47 b

P

0.05

N.S. 0.01

LSD N.S. 0.51

(There s no sgnfcant dfference between means wth the

same letter n the same column, LSD the least sgnfcant

dfference, NS: Non sgnfcant).

3.6.2 Vtamn C

The control group exhbts the lowest Vtamn C

content at 69.6 (b), sgnfyng that n the absence of

chtosan treatment, Vtamn C levels are nferor to

those n treated groups. The 150 ppm chtosan

treatment demonstrates a consderable elevaton n

Vtamn C content to 76.1 (a), whch s statstcally

superor to the control, underscorng the benefcal

mpact of chtosan at ths dose. At 300 ppm, the

Vtamn C concentraton attans 73.0 (ab), surpassng

the control but not exhbtng a statstcally sgnfcant

dfference from the 150 ppm treatment. The 450 ppm

chtosan concentraton yelds the greatest Vtamn C

content at 78.2 (a), exhbtng a statstcally

sgnfcant dfference from the control, ndcatng that

elevated chtosan concentratons may further enhance

Vtamn C levels.

The Vtamn C value showed an

ncrease of 9.34% at 150 ppm, 4.47% at 300 ppm, and

12.36% at 450 ppm compared to the control (Table 6).

The study demonstrates that chtosan treatments

markedly ncrease Vtamn C content. Whle 450 ppm

produces the maxmum concentratons, 150 ppm

provdes a sgnfcant enhancement wth only one-

thrd the quantty of chtosan relatve to 450 ppm. In

lght of the absence of a statstcally sgnfcant

dfference, 150 ppm may be regarded as the more

effectve opton. Plants subjected to chtosan exhbt

enhanced synthess of secondary metaboltes,

ncludng polyphenolcs, lgnn, flavonods, and

phytoalexns, alongsde Vtamn C, resultng n

mproved product qualty. Chtosan nanopartcles of

varyng szes have been employed to encapsulate

Vtamn C, prolong ts shelf lfe, and nvestgate ts

dstrbuton.

3.6.3 Total Phenols and Total Flavanods

Compounds

Total phenol and flavonoid contents in the fruit are

directly associated with quality, and it has been

observed that the use of chitosan in pepper fruit

increases these substances (Gholamipour et al.,

2009). In our study, when examining the effect of

chitosan use on the total phenolic content in pepper

plants, an increase of 15.69% was observed at a 150

ppm dose, 14.81% at a 300 ppm dose, and 12.39% at

a 450 ppm dose. Even though there is no statistical

difference, there is a decrease in the total phenol

content as the dose increases. When the total

flavonoid content was examined, compared to the

control, 150 ppm chitosan showed an increase of

22.21%, 300 ppm an increase of 11.31%, while the

application at the 450 ppm dose showed a decrease of

0.44%. A high dose of chitosan has caused a decrease

in the total flavonoid content (Table 7).

Table 6. Effects of chtosan doses on Vtamn C n pepper.

A

pp

s. Vt C

(

m

g

100

g

FW

−1)

Control 69.6 b

150 ppm Chtosan 76.1 a

300 ppm Chtosan 72.9 ab

450

pp

m Chtosan 78.2 a

P

0.05

0.01

LSD 4.41

There s no sgnfcant dfference between means wth the

same letter n the same column, LSD the least sgnfcant

dfference.

Table 7. Effects of chtosan doses on total phenols and

flavanods n pepper.

Apps. Total phenol

(mg GA/100 g

FW)

Total

flavonods

(mg

RU/100 g

FW)

Control 74.39 b 126.22 b

150

pp

m Chtosan 86.06 a 154.27 a

300

pp

m Chtosan 85.41 a 140.50 ab

450 ppm Chtosan 83.61 a 125.66 b

P

0.05

0.008 0.001

LSD 4.31 14.64

There s no sgnfcant dfference between means wth the

same letter n the same column, LSD the least sgnfcant

dfference.

Optimization of Foliar Chitosan Doses as a Biofertilizer for Enhanced Pepper Cultivation

257

4 CONCLUSIONS

Ths study conclusvely reveals that the applcaton of

chtosan greatly nfluences the growth, physcal

characterstcs, and yeld of pepper plants. The use of

150 ppm chtosan produced the maxmum yeld,

suggestng that lower concentratons are more

effcacous n mprovng yeld results n pepper

growng. Although 300 ppm chtosan was deal for

enhancng frut characterstcs ncludng breadth,

heght, and color pgmentaton, t dd not exceed 150

ppm n overall productvty. Moreover, elevated doses

such as 450 ppm shown no substantal advantages and

could even detrmentally affect yeld. The results

ndcate that chtosan s an excellent bostmulant for

pepper growth, wth 150 ppm dentfed as the

optmal concentraton for enhancng yeld and crop

qualty. Ths research underscores the promse of

chtosan as an economcal and envronmentally

sustanable bostmulant for mprovng pepper yeld.

Future nvestgatons should examne the mpact of

chtosan across dverse envronmental condtons and

varous pepper cultvars to enhance applcaton

methodologes.

REFERENCES

Abdel-Mawgoud, A.M.R., Tantawy, A.S., El-Nemr, M.A.,

& Sassne, Y.N., 2010. Growth and yeld responses of

strawberry plants to chtosan applcaton. European

Journal of Sc৻ent৻f৻c Research, 39(1), 170-177.

Aracel, A.M., Morrell, P.L., Roose, M.L., & Km, S.C.,

2009. Genetc dversty and structure n semwld and

domestcated chles (Caps৻cum annuum; Solanaceae)

from Mexco. Amer৻can Journal of Botany, 96(6),

1190–1202, https://do.org/10.3732/ajb.0800155.

Badawy, M. E. I., & Rabea, E. I., 2011. A bopolymer

chtosan and ts dervatves as promsng antmcrobal

agents aganst plant pathogens and ther applcatons n

agrculture. Journal of Pest Sc৻ence, 84(3), 229-245.

Dasgan, H.Y., Aldyab, A., Elgudayem, F., Ikz, B., &

Gruda, N.S., 2022. Effect of bofertlzers on leaf yeld,

ntrate amount, mneral content and antoxdants of

basl (Oc৻mum bas৻l৻cum L.) n a floatng culture.

Sc৻ent৻f৻c Reports, 12(1), 20917.

Dulta, K., Koşarsoy Ağçel, G., Thakur, A., Sngh, S.,

Chauhan, P., & Chauhan, P.K., 2022. Development of

algnate-chtosan based coatng enrched wth ZnO

nanopartcles for ncreasng the shelf lfe of orange

fruts (C৻trus s৻nens৻s L.). Journal of Polymers and the

Env৻ronment, 30(8), 3293-3306.

Elgalan, I.E.H., Elkareem, M.A.M.G., Noh, E.A.A.,

Adam, O.E.A., & Alghamd, A.M.A., 2017.

Comparson of two methods for the determnaton of

vtamn C (Ascorbc Acd) n some fruts. Am. J. Chem.,

2, 1–7.

Gholampour Fard, K., Kamar, S., Ghasemnezhad, M., &

Ghazvn, R.F., 2009. Effect of chtosan coatng on

weght loss and postharvest qualty of green pepper

(Caps৻cum annum L.) fruts. VI Internat৻onal

Postharvest Sympos৻um, 877, 821-826.

İnam, N.D., & Özdamar Ünlü, H., 2024. Use of oxalc acd

and chtosan to mprove pepper yeld and qualty.

Cogent Food & Agr৻culture, 10(1), 2366381.

Khalfa, T., Abdel-Kader, N.I., Elbagory, M., Ahmed, M. E.,

Saber, E. A., Omara, A. E. D., & Mahdy, R.M., 2024.

Investgatng the nfluence of eco-frendly approaches

on salne sol trats and growth of common bean plants

(Phaseolus vulgar৻s L.). PeerJ, 12, e17828.

Khan, W., Rayrath, U. P., Subramanan, S., Jthesh, M. N.,

Rayorath, P., Hodges, D. M., ... & Prthvraj, B., 2009.

Seaweed extracts as bostmulants of plant growth and

development. Journal of Plant Growth Regulat৻on,

28(4), 386-399.

Kumaraswamy, R.V., Saharan, V., Kumar, S., Choudhary,

R.C., Pal, A., Sharma, S.S., ... & Bswas, P., 2021.

Chtosan-slcon nanofertlzer to enhance plant growth

and yeld n maze (Zea mays L.). Plant Phys৻ology and

B৻ochem৻stry, 159, 53-66.

Latham E., 2009. The colourful world of chlles.

Stuff.co.nz, http://www.stuff.co.nz/lfe-style/food-

wne/1756288.

Malerba, M., & Cerana, R., 2021. Chtosan as a sustanable

tool n agrculture: recent advances and future

perspectves. Internat৻onal Journal of Molecular

Sc৻ences, 22(6), 2938

Martínez-Pérez, M.E., Ruíz-Anchondo, T.D.J., Jacobo-

Cuéllar, J.L., & Calderón-Zavala, G., 2024. Responses

to folar sprays of strawberry varety ‘Portola’to

bostmulants on growth, yeld, qualty, and boactve

compounds. Notulae Botan৻cae Hort৻ Agrobotan৻c৻

Cluj-Napoca, 52(3), 13513-13513.

Naeem, M., Za-ur-Rehman, M., & Akhtar, K., 2018.

Chtosan as a sol amendment for agrcultural

sustanablty. Journal of Plant Nutr৻t৻on, 41(7), 937-

954.

Rahman, M., Mukta, J.A., Sabr, A.A., Gupta, D.R., Moh-

Ud-Dn, M., Hasanuzzaman, M., ... & Islam, M.T.,

2018. Chtosan bopolymer promotes yeld and

stmulates accumulaton of antoxdants n strawberry

frut. PloS one, 13(9), e0203769.

Rhm, J.W., Park, H.M., & Ha, C.S., 2020. Recent

developments n chtosan-based flms for food and

agrcultural applcatons. Carbohydrate Polymers,

115428. DOI: 10.1016/j.carbpol.2020.115428.

Salachna, P., & Zawadzńska, A., 2014. Effect of chtosan

on plant growth, flowerng and corms yeld of potted

freesa. Journal of Ecolog৻cal Eng৻neer৻ng, 15(3).

Santosh, K., 2013. Bberde (Caps৻cum annuum L.) genetk

çeştllk çalışmaları. As৻an J Hort., 8, 280–284.

Sdhu, J.S., Kabr, Y., & Huffman, F.G., 2019. Functonal

foods from Capscum speces: A revew. Journal of

Food Sc৻ence and Technology, 56(10), 4211-4223.

DOI: 10.1007/s13197-019-03915-x.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

258

Trved, P., Duan, Y., & Wang, N., 2020. Integrated

management of bacteral spot and other dseases n

Capscum speces. Phytopathology, 110(7), 1160-1167.

DOI: 10.1094/PHYTO-01-20-0012-RVW.

Yuca, H., 2022. Caps৻cum annuum L. In Novel drug targets

wth tradtonal herbal medcnes: Scentfc and

clncal evdence. 95-108. Cham: Sprnger Internatonal

Publshng.

Zhang Z., Lu, A., & D′arcy, W.G., 2002. Caps৻cum annuum

Lnnaeus, Specal Plant 1:188.1753, Flora of Ch৻na, 17,

313–313.

Optimization of Foliar Chitosan Doses as a Biofertilizer for Enhanced Pepper Cultivation

259